THOUGHT LEADERSHIP

Finding the right value in dynamic modelling of renewables

What value can you derive for renewable energy projects through developing accurate models? When is the effort and expense involved justified by potential benefits?

Renewable energy project developers are often confronted with seemingly large costs to develop accurate dynamic models of their projects. This can be due to regulation, or it may be because that level of accuracy, potentially in excess of the regulatory requirements, adds value to the project. It may be that the modelling actually allows the project to remain viable in the face of connection issues.

On some levels it’s easy to say the regulations require accurate modelling. However, for any renewable energy project there is a level of modelling that will be the right fit , and the regulations shouldn’t ask for more than that without good reason. So let’s look at the relative value of accurate modelling in various contexts, and then later we can see if there’s a mismatch between that value and regulatory regimes.

The requirements for power system modelling of generating units vary from place to place, but as ‘traditional’ generation levels recede and power electronics and intermittency gain more than a foothold in the power system, accurate modelling will increase in importance and value.

The aims of these models cover three levels:

- Level 1: Does my plant work?

- Level 2: Does my plant interact appropriately with the nearby network?

- Level 3: Does my plant interact appropriately with the power system as a whole?

Accurate modelling can add value at any of these levels, but the degree of effort required to release that value depends on the type of project, the type of network and the location in the network.

The issue impacts all renewable energy projects but let’s take a wind farm as an example and move it around the network to explore this.

Small wind farm in the distribution network

Let’s build a 10 MW wind farm and connect it close to a distribution substation on a 33 kV feeder. At this size, most of the ‘does my plant work?’ question is answered by the off-the-shelf inverter controls, so little value is to be gained at that level.

However, the interaction of the plant with the network and nearby customers is critical. The connection point is close to other customers and so the variability of the wind farm can impact the quality of the neighbours’ supply.

Accurate modelling here gives certainty that there’ll be no surprises at commissioning. Imagine convincing a network service provider that your flicker indices are OK, only to have the neighbouring plant force you to redesign or curtail your operations after commissioning. That has real project impact and possibly brand impact too.

Larger wind farm in the sub-transmission network

What if we move our wind farm to the remote end of a 132 kV line and build it ten times bigger? Now we don’t have any neighbours, although we could have some in the future. We have a stability problem because of the long line, so we now need auxiliary plant (e.g. a capacitor bank) to help control voltage and hence maintain production.

We’ve got a plant that has to cater for an external requirement (level 2) but that then implies an internal control or coordination requirement (level 1).

In this scenario, our models’ accuracy helps with internal design and, as a results, saves commissioning time. It also helps optimise production by clearly communicating the control actions of our plant to the wider system model. This allows the degree of stability improvement to be accurately characterised and so constraints are not arbitrarily applied. The business-case levels of production are preserved.

Large wind farm in the transmission network

If we move this large plant to a 500 kV connection point and triple its size, it’s almost akin to the scale of our 10 MW plant back on the 33 kV. Now we’re less interested in voltage controls due to the high fault levels at the connection point. It’s very difficult to see the influence of the wind farm’s controls on the surrounding network. The only possible value now is related to system strength and fault-ride-through phenomena (level 3).

This now requires accurate modelling of a smaller subset of controls, but it’s interacting with the whole system. In a strong system these issues are generally negligible. In a weak network, they’re critical. So, for this example, the value is derived from integrated design of the controls to ensure system compatibility (i.e. no constraints). The value stems from efficiency and effectiveness at levels 1 and 3. The value is in gaining connection, preserving energy production and streamlining commissioning.

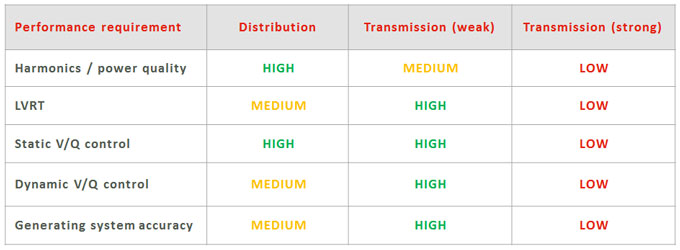

The following tables summarises these three examples. It shows my opinion on the value of dynamic model accuracy to projects connected at various levels of the electricity grid. Note there is never a complete lack of value in having accurate models . Also note that this is relative value.

The cost of accurate modelling may not vary much across these three connection levels but the value it brings to a project does. The table shows an estimation of the value that model accuracy brings relative to the connection point strength and what aspects of the project it helps support.

So if you’re considering a wind farm, or any generation project, don’t forget the value that accurate modelling may bring to that project, but be mindful that this value may be limited due to the nature of the system and locale that you’re connecting into.

The art is to find the ‘Goldilocks Zone’ between the regulatory requirements for model accuracy, production loss through avoidable constraints and modelling effort. Too much or too little attention to these issues leads to unrealised project value. If we find the right balance, it’ll be just right.

If you would like to find out more about how Entura can help you adapt successfully to the rapidly changing market for electricity generation and energy services, contact Donald Vaughan on +61 3 6245 4279 or Silke Schwartz on +61 407 886 872.

This author originally presented on this topic at the Clean Energy Council Wind Industry Forum in March 2016.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

28 April, 2016