Dam safety: protecting lives and driving efficiencies

Humans have been damming rivers since 3000 BC for water retention and supply.

People can fish in the lakes formed by dams, sail on them, swim in them. They are important to life, providing water supply, irrigation for crops and power generation. But if a dam fails, causing devastating flooding downstream, the results can be catastrophic.

The worst dam failure in history occurred in China in 1975 when the Banqiao Reservoir Dam and other dams in Henan province failed, killing an estimated 171 000 people, with 11 million people losing their homes.

Safety is the key

Dam safety is a crucial aspect of modern dam building. Ensuring the safety of existing dams is a key concern of any dam owner, whether the dam is for generating power, protecting a nearby population from potential flooding or for the age-old reason of water supply.

Specialist power and water consulting firm Entura provides dam safety programs for Gordon Dam, the largest concrete arch dam in Australia, and other assets owned by Entura’s parent company, Hydro Tasmania, and for government and corporate clients around Australia, south-east Asia and southern Africa.

Hydro Tasmania is Australia’s largest water manager, so it needs to ensure that the risk of a failure across the portfolio is very, very small. With 55 large dams and many smaller ones, Hydro Tasmania needs to be able to identify the highest risk dams, so it is able to prioritise work on maintenance and refurbishment. This is achieved using a process undertaken by Entura called a portfolio risk assessment (PRA).

Hydro Tasmania is committed to the safety of its assets for the people of Tasmania and its PRA enables the business to prioritise where it focus its financial resources, management and dam safety efforts.

What’s the level of risk?

Energy and water asset owners are increasingly choosing to implement a dam safety program to quantify and manage operational risks, evaluate high risks and find solutions for identified risks or deficiencies. Entura believes that a risk-based framework like a PRA is the best way to achieve an efficient and effective dam safety program.

Older dams or dams located upstream from populated areas are often high risk. The inspection regime for high-risk dams is understandably more robust and rigid than for low risk dams. However, it’s not just ageing that creates risks for dams. In Australia, the methods used to predict and anticipate floods are equally important, as is the increased knowledge that we’ve gained of the various causes and mechanisms through which dams can fail.

Entura’s PRA reviews the consequences of failure of a dam by looking at the impact that it may have on downstream populations, and also looks at the chance of failure occurring by considering extreme events such as floods and earthquakes, taking into account the specific site conditions. It is the combination of the chance of failure with the resulting consequence that determines the level of risk.

A world-wide issue

A number of dam owners across the Asia-Pacific region are now looking at Entura’s PRA program, especially when they have a significant dam portfolio already developed. Our clients in the region are exploring how they can best use their resources and how to prioritise expenditure on their assets.

Having undertaken safety reviews and dam safety work in the Philippines, China, Indonesia, Malaysia, New Zealand, Papua New Guinea, Fiji and India, Entura understands the typical safety needs and drivers of dam owners across the world.

Australia has well-developed dam safety legislation in which Malaysia, for example, with its increasing number of dams, is very interested. Malaysia has experienced the tragic results of a dam safety incident, with the death of a number of people due to water releases through the spillway gates of Sultan Abu Bakar Dam.

On behalf of the Ministry of Public Utilities, Sarawak, Malaysia, Entura used its dam risk framework, similar to that used in a PRA, to assess whether the Bakun and Murum dams were ready to be impounded as construction reached conclusion. This dam risk framework looked at the potential scenarios that could lead to the sudden release of reservoir water, the likelihood of these scenarios occurring, and the corresponding consequences. Through this process the key dam safety risks were identified, and actions were determined to either eliminate or reduce the risks to an acceptable level. These actions needed to be addressed prior to impoundment.

Dam safety is an ongoing concern

The safety and risk-level of a dam can change with time. As dams or assets age, the way they are managed needs to change and they often need upgrading to ensure continued safe operation and desired life expectancy. But undertaking upgrades can potentially increase the risk of the dam during the construction phase – due to the removal of shoulder material from an embankment, or restricting the discharge capacity in a spillway chute. To contain the risks during the construction phase, operational practices might need modification, for example, operating a dam at a lower lake level during the period of construction to ensure the overall risk is not significantly increased. This is why it is so important to have a plan to manage the safety of the dam during its entire lifecycle.

Five steps to assess dam safety risks

Risks can be reduced in a range of ways and, in many cases, a number of risk treatment options are used together:

- reducing the likelihood of the risk occurring (e.g. strengthen a dam)

- reducing the consequences if the risk does occur (e.g. upgrade emergency planning)

- staging risk treatments (e.g. address most cost-effective risk mitigation works first)

- balancing the resources required to treat a risk with the benefits of reducing the risk (e.g. examine various levels of investment and their respective risk reductions).

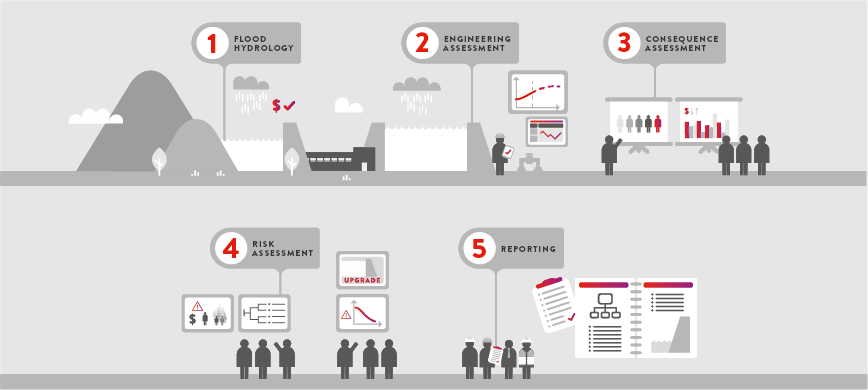

Entura’s portfolio risk assessment approach has five key steps:

| 1 – Flood hydrology | Flood hydrology is a key input as it is used in both the engineering and consequence assessments. Generally the hydrology is based on current best practice. For some low-hazard dams, an innovative regional flood hydrology approach has been developed that provides sufficiently robust answers at minimal cost. |

| 2 – Engineering assessment | The engineering assessment is a critical part of the process as it requires all potential failure modes to be identified and then the probability of failure to be estimated for each mode. The engineering assessment gathers all the information about the dam including design, construction, geology and operations that may assist in defining the potential failure modes. This is presented as response curves (i.e. conditional probability of failure). The level of detail varies with the hazard category of the dam (i.e. a high-hazard-category dam receives more intense scrutiny than a low-hazard dam). The engineering assessment also ensures an assessment of compliance with current engineering standards. |

| 3 – Consequence assessment | Key steps in the consequence assessment method include developing a dam break model; mapping the inundation zones; assessing the population at risk and probable loss of life; assessing the financial and economic losses; and qualitatively assessing the environmental, social and intangible consequences. |

| 4 – Risk assessment | The risk assessment uses event trees that evaluate societal and individual life risk and financial risks. Risks can be aggregated across a range of load conditions and failure modes to give a total risk position, retaining visibility of the scenarios that contribute to the total risk. Where the risks are unacceptable, upgrade concepts are developed and their impact on reducing risk is plotted. |

| 5 – Reporting | The results of the risk assessment are reported, summarising the potential failure modes, consequences and risk profile for each individual dam. Summary data across the portfolio is also presented, including information on the failure modes, and risk of all the dams against societal life risk and financial risk criteria in a simple but meaningful format. |

Resource levelling

All businesses need to share resources across many activities besides risk mitigation works. For a hydropower company, a significant reinvestment in generating plant is required to both manage risk and maintain asset capability. Resources are also needed for investment for growth and diversification.

Within the dam portfolio, it is important to ensure that resources, both human and financial, are not applied to risk mitigation projects at the expense of the fundamentally important surveillance and monitoring activities. A balance is needed between reducing risk and maintaining and enhancing surveillance and monitoring instrumentation.

An ongoing effort

Finally, it is important to realise that the capital works program for dam safety risk reduction is not a static program, locked in and then implemented without change. Rather, it is an active program that is reviewed regularly, actively managed and needs to remain responsive to new or changed risks, developing understanding of dams engineering, shifts in business priorities, delays to projects, and new developments in risk management processes.

The same process can be applied to other assets

The PRA process can also be used for other assets that have a low chance of failure but high consequences if failure were to occur. At Entura, we have successfully applied our PRA process to penstocks and pipelines, and to canal systems, identifying key risks and prioritising the actions needed in a way that most effectively manages resources.

If you would like to discuss how we can assist you with assessing your dam risks or developing a resource-effective and comprehensive dam safety program, or apply the same PRA process to other key assets, please contact Richard Herweynen on +61 3 6245 4130.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

A bright future for RAPS: reliable, cheaper power for remote areas

Remote area power systems that integrate renewable energy sources such as solar and wind with storage or diesel backup are increasingly allowing remote communities to become more self-sufficient and sustainable by providing dependable, secure power that is cheaper than relying on diesel-generated power alone.

Saving money and the environment

Using renewable energy technologies to create power in a range of remote areas such as small to medium towns, mines or even islands makes perfect sense. The fuel usually used in these locations is diesel, which is expensive, vulnerable to broader pressures on price and supply, and can also be slow, complicated and costly to transport to remote areas.

Falling costs of renewable technologies, free fuel from the sun and wind and large savings on displaced diesel add up to significant commercial motivation to move towards renewable or hybrid systems. But there’s also a compelling environmental argument for developing RAPS – it reduces consumption of fossil fuel, lowers carbon emissions and helps reach sustainability goals.

This environmental argument carries extra urgency for low-lying island communities on the front line of climate change, as rising sea levels threaten their very existence.

Why Yap needs RAPS

To the north of Papua New Guinea, in the Western Pacific Ocean, lies one of these vulnerable islands: the postcard-perfect paradise of Yap. While Yap has already started to recognise the early impacts of climate change and increasingly severe weather events on its farms, coral reefs and palm-lined beaches, it has also witnessed at close range the high consequences of vulnerability to oil prices, as the world oil price shock in 2008 threw the neighbouring Marshall Islands into a state of fiscal crisis with the government having to bail out its own state-owned power utility.

As an early step towards reducing Yap’s heavy reliance on imported diesel for power generation, and to enable the island to rely as much as possible on indigenous, renewable resources, the Yap State Public Service Corporation (YSPSC) commissioned specialist power and water consulting firm Entura to design and supervise the delivery of a US$11 million integrated high-penetration renewable energy RAPS.

The RAPS project will also help Yap play its part in helping achieve the Federated States of Micronesia’s ambitious targets of 30 per cent renewable energy by 2020 and 70–100 per cent by 2050. The project will reduce fossil fuel consumption in Yap through developing renewable energy and improving the supply-side energy efficiency of the current grid. Once completed, the project aims to provide 17 per cent of Yap’s annual energy production and enable Yap to experience up to 70 per cent renewable penetration when conditions allow. The system is forecast to deliver an annual fuel saving of up to US$500 000.

Integrating renewables no longer a challenge

Until recently, integration issues have made it difficult to introduce large amounts of renewable energy into remote diesel-based electricity systems. High intermittency of renewable sources presented challenges for reliability and quality of supply in remote power systems. But new technological developments such as intelligent control systems, improved storage technologies and demand-side management assist with overcoming these concerns and increase the reliability of off-grid renewable systems.

As each RAPS is different, the challenge that remains is choosing the right solution and integrating it in the right way.

Yap’s power system is designed to meet the 2.2 MW load for the 7000 people living on the main island, delivering up to 1 MW of wind energy from small but robust turbines and 300 kw of remotely controlled grid-connected solar energy from the rooftops of seven government buildings. Two high-speed diesel generators have been included in the system, and have been selected for their responsiveness and ability to support higher renewable energy penetration and even out any energy fluctuations.

The clever trick to keep all these different electricity-generating assets working together smoothly to provide a continuous and reliable electricity supply is an innovative integration and control system. The overall design of Yap’s integrated high-penetration renewable energy system, combined with the automated integration and control system, balances and maintains the quality of the energy supply to maximise the amount of renewable energy used on the island.

Building capacity for the long term

The YSPSC is a sophisticated utility that fully embraces its commitment to provide clean and affordable power that is sustainable not only for the environment and the economy but also for Yap’s community in the long term.

The power system has been carefully designed to be able to realise future goals of operating at zero diesel, as well as to be able to be operated and maintained within the community rather than by external specialists.

YSPSC and Entura are working together to deliver the principles of ‘design and build, operate and maintain’, as opposed to a ‘build-neglect-rebuild’ paradigm, by working to develop capacity within the Yap community, so that the local people will not only be the owners of a new state-of-the-art energy system, but will also have the opportunity to develop the skills to operate and maintain it into the future.

Construction of the Yap RAPS is due to start in mid-2015 and finish in early 2016.

RAPS around the world

Entura and its parent company, Hydro Tasmania, have previously been involved with the delivery of hybrid off-grid systems and RAPS in the Solomon Islands, Vanuatu, King and Cape Barren Islands, and are currently assisting our clients in delivering a suite of projects in Australia, as well as in the Cook Islands.

Hydro Tasmania’s hybrid off-grid solution on King Island is now recognised as a world-first, achieving the ability to operate a megawatt-class power system solely on renewable energy sources for extended periods of time, when conditions allow. The King Island Renewable Energy Integration Project has also demonstrated that hybrid systems with the right mix of enabling and generation technologies are not only lower cost alternatives, but can also be more reliable and robust than traditional diesel generation in off-grid systems.

If you would like to discuss if a RAPS is the best solution to power your remote operations or community in a sustainable and cost-effective manner, please contact Silke Schwartz on +61 407 886 872 or Shekhar Prince on +61 412 402 110.

MORE THOUGHT LEADERSHIP ARTICLES

Reliable, renewable energy now powering South Africa

In many developing nations, governments and utilities are scrambling to bring much-needed power to their people and industries to improve quality of life and drive economic growth.

Small hydro (around 40 MW or under) from run-of-river schemes is an ideal solution to contribute to growing and greening the energy mix in developing countries, providing clean and reliable power from a country’s rivers without the significant environmental or social impacts of large dams or the economic and environmental costs of fossil fuels.

The Neusberg hydropower project – a run-of-river small hydropower project near Kakamas in the Northern Cape of South Africa – is one small but effective step towards South Africa’s ambitious goals of raising the living standards of its growing population and supporting vital economic activity through encouraging the development of renewable energy by independent power producers.

What is the Neusberg hydropower project?

Using the power of the mighty Orange River, the Neusberg hydropower project creates electricity by diverting some water for a short distance as it runs downstream from the existing Neusberg Weir, returning the water back to the river after it runs through the hydroelectric plant’s three 4010 kW turbines.

The Neusberg project is highly efficient, producing 10 MW of reliable and sustainable baseload power for the equivalent of up to 5000 homes with no adverse impacts on irrigation, fish or environmental flows.

Success through collaboration, innovation and expertise

The Neusberg project needed a particularly innovative design solution and effective planning and collaboration for it to meet the needs of the region, satisfy the requirements of all major authorities and stakeholders, and still achieve the objectives of the developer.

And that’s where specialist power and water consulting firm Entura drew on its extensive experience in hydropower development to find the right answers to move the project towards successful completion.

For example, developing all the necessary tender and contractual documentation and negotiating and achieving regulatory approvals are critical administrative steps but can prove challenging. Entura’s owner’s engineer services helped the Neusberg project overcome these development-stage hurdles – such as helping to achieve the vital water use licence by proposing suitable designs for the project and then working through a collaborative process to modify the designs to meet the authority’s requirements while still achieving the developer’s objectives.

Tailored solutions for tricky challenges

A major challenge for the Neusberg project was to produce economical and reliable power to relieve pressure on the electricity network at the same time as ensuring adequate water supply for irrigation by local fruit-growers throughout the construction and operation of the project. Other specific local requirements also needed to be met, such as maintaining the ability of the Neusberg Weir to meaningfully measure river flow, maintaining the aquatic environment and minimising the impacts from construction activities.

- To guarantee an uninterrupted supply of water to the local irrigation scheme, construction of the hydro project called for clever planning. Since an existing irrigation canal ran through the powerhouse site and needed to remain in operation, a temporary diversion canal was created to allow the powerhouse and forebay to be constructed in two stages without interrupting irrigation supply.

- To ensure that the flows into both the hydroelectric project and the irrigation canals are sufficient, a weir was placed at the offtake for the hydro project providing passive protection against the water level in the reservoir being drawn down. The level of the top of the weir was carefully designed so that the length of the weir was reduced – lowering construction costs while providing the protection required for the irrigation canal and allowing sufficient flow into the headrace canal.

- The Neusberg Weir is a very important flow measuring structure as it provides accurate information on the flow in the Orange River to both South Africa and Namibia. The hydro project takes water away from the weir, so to restore the ability to measure flows, two devices were installed – an instrument in the canal upstream of the powerhouse, and the weir in the tailrace. The measuring weir in the tailrace provided an extra benefit for the aquatic environment, by acting as a barrier to fish movement and enabling fish to find their way to the existing fish ladder to travel upstream.

- To minimise costs and impacts of construction, the design of the Neusberg project dispensed with the typical aboveground powerhouse structure. Instead, the concrete roof of the powerhouse has a removable hatch allowing equipment to be lowered through the roof by crane into the turbine chamber.

Community benefits both now and into the future

The Neusberg project has brought an ongoing social and economic boost to the local community that goes well beyond providing an important source of electricity. During the construction phase, it created much-needed local employment in a region in which opportunities are scarce, and supported local and national businesses through spending on goods and services.

But the benefits keep flowing long after construction is finished, as the local community has a

15 per cent ownership stake in the hydropower scheme and an 8 per cent stake in operation and maintenance contractors, ensuring that the community trust will share in the project’s success for many years to come.

Entura’s role in the Neusberg project

Entura has played a vital role in the successful civil design and was also responsible for the electrical and mechanical construction of the Neusberg project by drawing on our day-to-day experience of owning, operating and maintaining hydropower assets for more than 100 years as part of Hydro Tasmania, Australia’s largest renewable energy producer and water manager, and an equity stakeholder in the Neusberg project.

If you would like to discuss how Entura can help you develop a hydropower scheme that can meet your power needs in a cost-effective and sustainable way, please contact Christoff LeGrange on +27 21 202 2231 or Shekhar Prince on +61 412 402 110.