Becoming the Battery of the Nation

This article appeared first on the International Hydropower Association blog.

How can a small island become a giant battery for a nation? We’re finding the answers in increasing interconnection, developing new pumped hydro and repurposing our existing hydropower assets.

Tasmania is a small island state, with excellent water and wind resources. We’re powered mostly by an extensive hydropower system developed over the last hundred years – supplemented with newer wind developments. We’re connected to Australia’s National Electricity Market by an interconnector running across Bass Strait to the mainland. This has allowed us to trade in the national market for some time now, but as thermal generation progressively retires and Australia embraces greater proportions of variable renewables, the future national market will be vastly different. It will be characterised by low-cost variable renewable energy sources firmed by dispatchable storage and generation.

With Tasmania’s fantastic natural resources, established hydropower system and expertise, we want to be the ‘Battery of the Nation’, offering the generation and the storage and system support needed to help Australia achieve a clean, reliable, affordable energy future. Our Battery of the Nation vision is shaping up to be one of the most credible, competitive and coordinated solutions, able to be built in stages, aligned to market drivers.

In a nutshell, the Battery of the Nation means generating more renewable energy from our hydropower and wind assets, developing more storage solutions in the form of pumped hydro and building more interconnection to the mainland so that we can get our product to the national market to quickly and reliably support variable generation.

With the support of funding from the Australian Renewable Energy Agency (ARENA), we’ve been making progress towards this vision on a number of fronts.

Connecting the battery

Batteries aren’t much use if they’re not connected, so we need more interconnection to mainland Australia to get the power to where it’s needed. The initial business case for a new, second interconnector between Tasmania and mainland Australia shows it stacks up, and federal funding has recently been secured to fast track this 1200 MW interconnection project, known as Marinus Link.

Priming the pump

Around the world, significant investment is being made in new technologies such as grid-scale batteries and solar thermal projects, yet pumped hydro remains the most viable technology for longer term storage (greater than eight hours). Our state has significant pumped hydro potential and our existing hydropower assets offer excellent potential to repurpose and create cost-effective pumped hydro. We’re filtering down the possible pumped hydro options to identify around 2500 MW of future potential. The three most promising sites offer between 12 and 31 hours of storage and would cost around AUD 1.5 million / MW to develop. Further feasibility investigations will identify which one of these three will be the preferred option that can be ready to take advantage of more interconnection.

Redeveloping existing assets

We are also focusing on how to get the most out of our existing hydropower assets by repurposing and futureproofing them for a transitioning electricity market. The Tarraleah scheme in Tasmania’s central highlands was commissioned in the 1930s and our studies have been considering whether the scheme should be progressively refurbished or redeveloped. Redevelopment would more than double the scheme’s capacity from 104 MW to up to 220 MW – contributing to Battery of the Nation targets. By converting the station to flexible and fully dispatchable operation, instead of just baseload, it could flexibly boost output at times of high market demand and provide the ancillary services likely to be increasingly valued in the market. It is also expected to have flow-on benefits for the entire cascade of power stations below it.

We are also continuing major refurbishment and upgrades of other existing hydropower assets so that we can get more generation, efficiency and longevity from these assets to support our plan to become the Battery of the Nation.

Benefits for our island and the nation

The Battery of the Nation vision offers economies of scale and diversity by combining flexible, reliable renewable energy resources with cost-competitive, large-scale storage that can be built in stages, aligned to market drivers.

Battery of the Nation is designed to serve and support our local and national communities. Across the nation it will contribute to achieving lower power prices, reliable and secure energy supply, and meeting sustainability targets. It will also offer specific benefits to Tasmania through energy security and economic stimulus.

Battery of the Nation is a bold and bright vision to unlock our potential to contribute to the nation. It’s an example of how to reimagine hydropower and storage for the new market paradigms of a shifting energy future.

Can the power grid weather the weather?

Even a single day of load shedding makes people doubt the national grid’s robustness. How will the grid cope if we experience extreme weather conditions more often?

Things get hot in Australia. They can get smoky, or wet, or cold. Australia’s beauty is in its ruggedness, its unpredictability and its diversity of natural environments. It’s what Dorothea Mackellar captured so well in the famous Australian poem ‘My Country’ – a ‘sunburnt’ land of ‘flood and fire and famine’, with ‘droughts and flooding rains’.

As dramatic weather patterns become more intense and more frequent, the electricity grid must be robust, or at least be managed to adapt to short-term challenges.

If we get the design standards right and if conditions fall within the expected extremes contemplated by the framers of the standard, then everything works. However, what happens when conditions are abnormal? In heatwaves, we see people hosing the rail network to stop expansion. We’ve seen hosing to cool distribution power transformers at peak times too. But there’s only so much water and so many hoses that we can deploy when the heat is on. It’s not a sustainable solution.

Can we manage?

Yes … but we must manage actively. Business as usual will not be enough. Consumers will not tolerate lower levels of reliability based on the weather. So something has to change.

There are a few mutually supporting paths we could take, including (1) considering extreme temperature ratings and improving the reach and spread of weather monitoring and weather-dependent grid management; (2) adjusting standards to contemplate higher temperatures; and (3) reducing our reliance on high flows to deliver peak demand.

1. Consider extreme temperature ratings

Incentives already exist for our network service providers (NSPs) to release hidden capacity in networks. The incentives remain a small percentage of the overall regulated income they receive. The contemplation and control of realistic ratings under unusual weather conditions could be made more attractive to our NSPs. The NSPs would then be more likely to make these opportunities for capacity benefits transparent to the regulator and the public.

Generators are now being required to stipulate capacity at higher temperatures, but this is not being applied universally across existing plant. As we saw in Victoria this summer, the market is very reactive to the unplanned withdrawal of power from large thermal units – as much, if not more, than it is to variations in wind and solar power. Thermal machines have shown themselves to be sensitive and not always robust in prolonged hot spells.

2. Change the standards

If maximum temperatures continue to climb, our standards or ratings may need to be adjusted to suit. In a global market, we have to be careful about being too ‘special’ or we’ll end up paying for specifications that cost more than the benefits they deliver. A half-way position may be for generators to estimate their capacity in relation to temperature conditions and require tuning of these estimates over time. This would at least give us an idea of the temperature effects on production across the fleet. The results of this might then inform the need for changes to standards or at least build quality to relieve unmanageable reductions.

3. Reduce reliance on high flows

We’ve seen the effect that emergency events such as storms and fire have on the grid. Storms are managed through localised declarations of special constraint sets. They’re also generally short-lived. As we saw with the Tasmanian bushfires this summer, smoke and fire can affect a transmission corridor for weeks at a time. Because intense storms and fires tend to be rare, the market can take some time to adapt. Some planning or scenario work by AEMO might help prepare the market and reduce the impact on supply.

Reducing our reliance on high flows to regulate price or maintain supply may also be valuable. This suggests a need for storage/s at opposite ends of tie lines and interconnectors so that short periods of constrained flow can be compensated partially or fully by the far-end storage.

We may also need some flow-path diversity on critical corridors or on corridors that link dispatchable generation sources with loads.

There’s little doubt that Australia will experience more frequent and intense floods, fires and heatwaves. In our ‘sunburnt country’ we need to keep our eyes firmly on the future of our climate, and we must build resilience into our generators, grid and market systems.

If you would like to find out more about how Entura can help you navigate your challenges in the electricity market, please contact Donald Vaughan on +61 3 6245 4279.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Powering up the Pacific with hybrid renewables

Beyond the typical images of blue water, white sand and sunny days, many Pacific islands are becoming visions of renewable energy innovation.

For remote off-grid communities with abundant sun and wind, such as Pacific islands, hybrid renewable energy systems offer exciting potential for achieving sustainable, secure and affordable power supply. Governments and utilities across the Pacific are embracing opportunities to harness the power of nature and lessen reliance on expensive and emissions-intensive diesel fuel.

At first glance, this picture looks perfect. But it isn’t simple. Off the grid, the impact of the intermittent nature of renewable energy is magnified. As the proportion of renewable energy in the power system increases, so does the need for enabling and supportive technologies to stabilise the power system while maximising the use of the sun and wind. This calls for innovation and integration.

A leading example of an advanced hybrid renewable power system has been completed on Yap, in the Federated States of Micronesia. It’s an inspiring example of innovative deployment of hybrid renewables to increase the energy security and sustainability of an off-grid island.

Yap, like many remote and small island states, will benefit from a clean energy power system for three main reasons: to reduce heavy reliance on imported fossil fuels, to stimulate economic growth and social development, and to improve resilience during increasingly frequent and severe storm events.

After decades of operating on diesel fuel only, Yap’s advanced hybrid renewable energy system is now enabling Yap to experience up to 70% instantaneous renewable penetration when conditions allow, with an average renewable contribution of 17%. It is delivering an annual fuel saving of up to US$500 000, and is designed to accommodate even more renewable energy generation into the future.

The journey towards a hybrid renewable energy system

Back in 2014, with funding from the Asian Development Bank and the World Bank, Entura helped the Yap State Public Service Corporation take early steps on a renewable energy journey. Like many small island nations on the frontline of climate change, and facing the damage of shrinking coastlines and the ravages of tropical storms, Yap recognised the value of renewables in reducing diesel consumption, increasing resilience and economic viability, and offering lasting benefits to its community and environment.

The first stage of the process was determining the most appropriate hybrid diesel/renewable power system that would displace the greatest amount of diesel fuel within the project’s budget and transform the manually operated 100% diesel power station into a flexible, integrated and automated power system incorporating wind, solar and diesel generation.

The power system was designed to meet the 2.2 MW load for the approximately 7000 people living on the main island, delivering up to 825kW of wind energy from small but robust wind turbines and 300 kW of remotely controlled grid-connected solar energy from the rooftops of seven government buildings.

Entura provided owner’s engineer services on site during construction and commissioning. In this stage, a new breed of high-renewable-supporting diesel generators were installed, and major works were carried out to install three 275 kW cyclone-proof wind turbines. As well, an island-wide communications network was installed, providing vital interconnection for the distributed solar PV and the wind turbines. This stage of the project also brought in the ‘brains’ of the system: a centralised control system.

The overall architecture of Yap’s integrated renewable energy system, combined with the innovative automated integration and control system, balances and maintains the security of the energy supply, and also maximises the amount of renewable energy used on the island.

A future focus

With a strong focus on the future, the communications network and control system are designed to accommodate further integration of more renewable energy generation as required or desired. Entura is investigating the feasibility of including even more diversified, distributed, variable renewable energy generation to be incorporated into this system, including up to an extra 1.6 MW of ground-mounted solar, 1 MW of floating solar, 300 kW of roof-mounted solar, a 1.5 MW battery energy system, as well as the potential for another 825 kW of wind power (depending on land-owner negotiations).

As well as being designed to be able to realise future goals of operating at zero diesel, Yap’s power system is also intended to be able to be operated and maintained within the community rather than by external specialists. The Yap State Public Service Corporation and Entura are working together to develop capacity within the Yap community, so that the local people will not only own the new state-of-the-art energy system, but will also have the opportunity to develop the skills needed to operate and maintain it into the future. Local power authority crews are now fully competent in solar system installation and maintenance, and have installed all the solar components of the scheme.

For Yap, access to reliable, affordable and sustainable modern energy is an important step towards lasting social and economic benefits for the local community, as well as better protection of the beautiful but fragile natural environment.

This example of effectively integrating existing and new technologies to create a secure clean energy system is at the forefront of world’s best practice. The success of the project has obvious application for remote, off-grid or island communities worldwide – but the strength of the technologies and their integration and control are equally applicable to the creation of ‘dispatchable’ renewables at any scale.

If you would like to discuss how Entura can support your journey towards hybrid or dispatchable renewables, please contact Patrick Pease or Shekhar Prince on +61 412 402 110.

MORE THOUGHT LEADERSHIP ARTICLES

Safer dams are a matter of priority

Examples from around the world demonstrate the devastating consequences of dam failures. Safety must be every dam owner’s key concern, but how should action be prioritised across a large portfolio of dams?

To prioritise effort and resources to achieve the best safety result across a whole portfolio of dams, you need a portfolio risk assessment (PRA). A PRA determines the risk position of the dams based on known information, identifies any information gaps, develops a strategy to close these gaps, and then determines the most effective actions to decrease any risks.

APPLYING PRA TO A LARGE AND COMPLEX PORTFOLIO

Entura has supported dam owners and water managers across the Indo-Pacific region with PRAs, but our most extensive application of the PRA process has involved the 54 large dams of our parent company, Hydro Tasmania.

Hydro Tasmania is Australia’s largest water manager and is committed to ensuring that the risk of a dam failure is very, very low across the entire portfolio. Across so many dams, clear priorities are needed to focus dam safety efforts and human and financial resources.

It has now been 20 years since Hydro Tasmania’s PRA journey began in 1999, so it’s timely to reflect on its outcomes.

With so many dams of greatly varying types, ages and heights, the PRA across Hydro Tasmania’s dams was always going to be complex, and needed to be staged. The first step was a small pilot study on five selected dams that represented the range of potential risks within the broader portfolio.

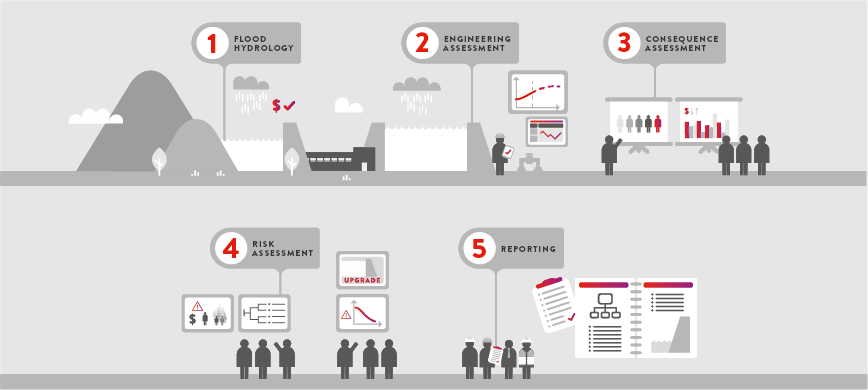

During the pilot study, the five steps of Entura’s PRA process were defined:

This methodology was applied across Hydro Tasmania’s dams portfolio, and an average of eight dams were added to the review each year.

By 2005, the initial ‘baseline’ assessment of the full portfolio was complete. The focus of the dam safety program has now moved to investigation and implementation of upgrades, and the communication of outcomes to senior management.

The PRA process has increased the focus on potential failure modes and risk as drivers of the dam safety program and as the basis for deciding priorities for allocating operational and capital resources.

DETERMINING PRIORITIES THROUGH A RISK FRAMEWORK

Entura’s PRA process reviews the consequences of failure of a dam by looking at the impact that it may have on downstream populations and infrastructure. The engineering assessment considers the effects on dams of extreme events such as floods and earthquakes, taking into account the specific site conditions. Combining the chance of failure and the resulting consequence determines the level of risk.

Hydro Tasmania assesses, prioritises and mitigates risks across the business using an integrated business risk management program, and the dam PRA feeds into this overall risk management approach. A dam’s assessed risk rating across common tolerance criteria drives the risk management response. The assessed dam risks are plotted together on a chart to provide a risk profile for the whole portfolio. This allows dam safety risks to be compared, understood and communicated readily throughout the business in a similar way to all other business risks.

The initial objective of the dam safety program is to reduce all the risks categorised as ‘high’ or ‘extreme’ as soon as practical , and then to continue with a program of investigations and capital works to diminish risks even further. Actions for dams lying in the higher risk zones did not wait for completion of the PRA, but were initiated as soon as risks were identified.

Some cost-effective and expedient risk-mitigation was achieved by identifying and implementing ‘quick wins’. These early actions reduced the overall portfolio risk while more complex mitigation plans were being developed. In some cases the ‘quick win’ actions have even provided the ultimate solution. In other cases, more major works have been required.

PROGRESSING THE DAM SAFETY JOURNEY

The PRA process has substantially benefited Hydro Tasmania’s dam safety program, by improving understanding of the dam portfolio, underpinning a strong strategic plan for addressing risks, improving surveillance and monitoring, and considerably strengthening dam safety emergency planning and warning.

However, this isn’t the end of the dam safety journey. Knowledge of any dam is never complete, and it is critical for dam owners to remain aware that not every failure mode may necessarily have been identified in a baseline study that relies on existing information. There may still be a level of uncertainty about the ‘unknowns’.

For Hydro Tasmania’s PRA, identifying these uncertainties enabled development of a prioritised list of investigations necessary across the portfolio. These detailed investigations have been critical to the development of the dam safety program, by confirming any potential failure modes identified in the PRA.

The list of potential failure modes of a dam portfolio must be rigorously and regularly reviewed, and investigations to reduce uncertainty about the portfolio should be ongoing. New methods and techniques for analysis are being developed all the time, and it is important to understand how these may change existing risk assessments. As well, the safety and risk-level of a dam can change as dams age, or when there are changes to the way the dam is managed.

It is also important to realise that the capital works program for dam safety risk reduction across a portfolio must remain flexible and be actively managed to respond to new or changed risks, new developments in the field of dam engineering, shifts in business priorities, delays to projects, and new developments in risk management.

The sheer number and variety of types, ages and consequence categories of Hydro Tasmania’s dams made Hydro Tasmania’s PRA a challenging process, but the benefits are substantial. The baseline study completed in 2005 is not the end of this journey, which continues to prioritise actions, reduce risks and enhance safety across the portfolio.

If you would like to discuss how we can assist you with assessing your dam risks, developing a resource-effective and comprehensive dam safety program, or applying the same PRA process to other key assets, please contact Paul Southcott, Richard Herweynen or Phillip Ellerton.

About the author

Paul Southcott is a specialist civil engineer at Entura. He has more than 32 years of professional expertise in civil and dam engineering, as well as expertise in geotechnical, foundation, structural, hydraulic and hydropower engineering. Paul’s dam engineering experience spans geotechnical and hydrological investigation; feasibility and options studies; concept, preliminary and detailed design; engineering assessment, consequence assessment and risk assessment; safety reviews; monitoring and surveillance; and emergency planning. He has extensive experience in dam risk assessment including as project manager for Hydro Tasmania’s, Taswater’s and SAWater’s portfolio risk assessment projects. He was a member of the ANCOLD committee that issued the Guideline on Consequence Categories for Dams in 2012 and is currently a member of the ANCOLD committee drafting the new Guideline on Geotechnical Investigations for Dams.

MORE THOUGHT LEADERSHIP ARTICLES

Should you upgrade or replace your SCADA system – which option is best?

New functionality, increased visibility of plant, greater security … SCADA systems are rapidly advancing. So, should you stick with what you have, upgrade some components, or embrace a complete replacement?

This is an important and complex question for power and water owners, operators and utilities to consider. As SCADA systems become obsolete, outdated or unsupported, a range of risks come into play – so you need to carefully weigh up your options in terms of benefits and costs. Choosing the wrong system could affect your business operations or your future upgrade options.

The first step in your decision making must be to explore and understand the available SCADA options in the context of your business strategy. SCADA systems are too great an investment and too important for ad hoc or hasty decisions. This is the time for a clear-headed view of your business goals over the long term, and how your choice of action will support achieving the outcomes you seek.

In the context of this strategic view, you now need to objectively assess the value and relevance of your existing SCADA system and identify if the entire system needs to be replaced or whether some devices or software can be reused. Let’s look at ten key considerations in the decision:

1 System architecture: When you introduce new equipment or systems, your system architecture is likely to be affected. Changes to system architecture can affect the reliability or operation of your plant. A partial upgrade may or may not significantly affect the system architecture – it really depends on the changes made. The system architecture following a total system replacement may be dictated by the vendor you select, so keep this in mind when selecting vendors. Does this system suit your business or the vendor supplying it? Also make sure that your system architecture is thoroughly and accurately detailed, and keep your SCADA strategy in your back pocket for reference throughout your journey.

2 Reliability: If parts of your existing SCADA system are reused, will this impact the reliability of the new system? Depending on the age and condition, there may be a greater risk of unreliability with the reuse or partial upgrade of components vs a complete replacement. The key here is to ensure the right people can evaluate the system and components with the knowledge of how to overcome these challenges. To minimise the likelihood of equipment failures and achieve the best outcome in terms of reliability, sometimes the best option is to carry out a full replacement.

3 Costs: A complete SCADA replacement is a costly exercise but at some point you can’t keep delaying a major outlay by only fixing the immediate concerns. Just like the increasing costs of servicing and replacing parts on an ageing car, at some point the ongoing incremental costs may no longer be worth it, and you may have to consider a total replacement. Regardless of the option you choose, having the expertise to make this call and carefully planning/estimating the work will reduce the risks of unexpected costs. The key decision-makers in your business will need to explore how to balance the initial outlay against the potential cost savings to be achieved through limiting the duration of system outages and attaining a longer whole-of-system life.

4 Functionality: The range of SCADA devices is extensive. A simple device may be cheap but it may not have been designed and built to meet high performance and reliability requirements, and it may not have the management functionality or redundancy capability you need. Your choice of functionality is partly a matter of initial cost, but you also need to carefully consider how much you need the extra functionality, what savings that functionality can offer over the longer term, your tolerance for failure, and the cost of failure to your business.

5 Compatibility and standardisation: When devices and software are upgraded or replaced, compatibility challenges and limitations may arise when interfacing with existing system components. Carefully assess your existing system and verify that the specifications and functionality of the proposed equipment are sufficient. Also consider the benefits of standardisation of system components. Standardising equipment throughout your site or sites can greatly speed up fault diagnosis, reduce design costs, minimise the need for more training, and lower your spares requirements.

6 Human interface: When your SCADA system upgrade includes the Human Machine Interface (HMI), identify which parts of your HMI screens work well and which don’t, and consider the option of designing your screens from the ground up. Avoid cluttered interfaces and consider dashboards for a single, easily interpreted overview of parts of your plant or station. If you’re changing your screen navigation and displays, you will need to allow for additional training to ensure your people are confident and capable of operating and monitoring the new system. Upgrading your HMI with a newer version of the software may be the best way forward depending on your requirements. This may require less financial outlay in terms of licensing, engineering and training costs and may be less intrusive on your system. If your system assessment warrants a complete replacement, you should carefully evaluate alternative HMI solutions to achieve the right functionality, product roadmap and financial outlay.

7 Security: How will upgrading parts of your SCADA system affect overall system security? SCADA security has evolved dramatically in recent years. Managing today’s SCADA systems can be a challenge without the right security precautions in place. Because SCADA system attacks exploit both cyber and physical vulnerabilities, it is critical to align cybersecurity measures accordingly. System security challenges of partial upgrades may not be able to be overcome depending on the age and type of equipment. So implementing a new system with the latest security technology is becoming the best option for limiting your exposure to attack.

8 Future-proofing: Just as you need to plan your pathway to implementation, you also need to keep your eyes on the future. If you’re upgrading old components, factor in the end-of-life date for support. If a device becomes obsolete, you’ll need a changeover plan to limit the impact on the system. Even if your upgrades give you the functionality you need now, what will you need in the future? Transitioning to a new SCADA system will introduce new functionality that is likely to increase the effectiveness of your operations and maintenance, and give you the opportunity to embrace the potential of big data, machine learning and artificial intelligence.

9 Pathway to implementation: Whatever the journey you’re on, you need to think about the path ahead so that you don’t encounter unexpected obstacles such as hidden costs or schedule blow-outs. Identify what upgrading may mean for your existing system and what limitations your system may have. Will your historical data need to be migrated to your new system, and, if so, how will this need to be handled? Upgrading to a new version of your SCADA system may be the easiest solution, but if you decide you need a new system, you’ll need to carefully handle your historical data and massage the data into the correct format for your new system.

10 Testing and commissioning: During the design process, contemplate how your system will be implemented and commissioned. Commissioning new equipment instead of reusing old technology may reduce the risk of incompatibilities and unusual operations. It may also reduce the time required for testing due to thorough system factory acceptance tests. Retesting of old equipment may have considerable impacts on your plant or station operations. The testing process and sequence is another key item that can make or break your system implementation. Assess how your system will behave during the cutover process and how the correct sequence or test process could reduce or eliminate your plant or station downtime.

Deciding whether to upgrade or completely replace your SCADA system is very much a case-by-case situation – but you’ll find the right solution if you consider all the key issues carefully and have your decision assessed by the right people and carried out objectively.

If you would like to discuss your SCADA challenges and opportunities, contact Patrick Pease or Shekhar Prince on +61 412 402 110.

MORE THOUGHT LEADERSHIP ARTICLES

Limber up for a more flexible electricity grid and market

Integrating renewables into grids and markets is a hot topic worldwide, with many challenges and approaches to explore.

In late June 2018, a series of meetings run by the International Energy Agency (IEA) in Yokohama, Japan, brought together a wide range of electricity industry regulators and participants to discuss the IEA’s current work in this arena. There was a lot of ground to cover. I shared the Tasmanian experience of managing frequency using inertia and governor tuning.

For me, three main takeaways from the discussions are that we need to improve Australia’s market arrangements, increase flexibility, and we should try to re-imagine the grid as an interaction.

Improving Australia’s market arrangements

Anyone who’s been watching the Australian electricity sector over the last few years will recognise that there’s room for improvement in our market arrangements.

The National Electricity Objective (NEO) aims to promote the long-term interests of electricity consumers through efficient investment in, and operation of, electricity services. These consumer interests include the price, quality, safety, reliability and security of supply of electricity. It also means ensuring the reliability, safety and security of the national electricity system. However, commercial and environmental drivers are beginning to affect the security of electricity, and in some instances affecting the price as well.

It’s hard to see why we’ve ended up where we are. What’s important is what we do next, and why.

Understanding and pursuing flexibility

All sources of generating plant have flexible and inflexible attributes. We have always worked around the limitations and taken advantage of the benefits. Now, with disruption, prosumers, micro-grids and all the other ‘scary’ status-quo-busters, we have much more freedom to achieve flexibility than we have had in the past. That is, generators, grids and customers can all provide flexibility and add to the overall value of the electricity market.

Designing new plant, retrofitting old plant and improving controls to increase flexibility must all form part of planning and regulation as we continue to decarbonise electricity production.

Imagining the grid as interaction, not assimilation

The philosophy of grid revolution to date has been assimilation. That is, where possible, new generators need to look and feel like traditional generators.

As system security margins decrease, this is becoming even more the case. It sets up a sometimes false dichotomy in terms of market share, political ideology, technical requirements and standards, and assessment of value. And this is unhelpful as we move towards an electricity sector with increasing proportions of renewables. One reason why Australia may have ended up where we are now may be that the NEO is silent on environmental impact.

When we think of the grid and the market as spaces for interaction rather than assimilation, these dichotomies break down and we’re more likely to achieve fruitful outcomes. Interactions are not just technical (electrons and Ohm’s law) or commercial (tariffs and hedges) but also human.

The electricity transformation will be able to occur faster and more successfully when the electricity industry embraces the power of the demand side, interacts in a more beneficial way with human-scale usage patterns and requirements, and thinks about the flexibility that exists or is required in demand, storage and production.

Finding a new approach

This all sounds marvellous, doesn’t it? It is the sort of regulatory utopia that could only come from a group of government officials sitting around a table a long way from home. But for me, it was refreshing. The thought that the market serves a higher ideal can only inspire. Certainly, the developing countries that presented at the meetings are firmly motivated by the immediate benefits and opportunities that reliable access to electricity will provide to their people.

In some ways Australia, too, is a developing country in the electricity sector. In the status quo, the path to future sustainability is blocked by the threats of climate change and, in some respects, by resource scarcity (depending on your view of the horizon). We need to develop a new approach to electricity production and consumption just as developing countries do.

If we think of the market as a facilitator for humans to flourish, then we must be careful to design markets for this purpose. Is the Australian market hampered in this respect by the dominance of a limited number of large players? Is there sufficient direct participation of individuals in the market? Does the regulatory framework accurately and adequately reflect the needs of all market players? Does the market inherently promote and reward flexibility?

Market power, democracy and flexibility

My feeling is that there’s work to do across each of these areas.

A former Australian trade minister once remarked that Australia would always be somewhat of an oligopoly. We will never have large-enough markets that won’t be dominated by a few players. In some sectors we’ve enshrined protections that almost guarantee it. The current market design has led the electricity sector down this path.

This is okay so long as the behaviour of these players remains able to be influenced by their customers through choice of provider and volume, but this isn’t always the case.

Allowing more players to provide greater diversity of energy and grid services will help to erode the power of the oligopoly and will also increase the flexibility of the grid and the market. Various system incidents in South Australia and the Northern Territory have highlighted the need for flexibility. If we understand flexibility properly, we will understand a way to meet the need for it.

Greater flexibility can mean different usage patterns, different contributions from a wider number of players and more give and take between the grid and the various generating technologies. Providing rewards for flexibility will encourage diverse contributions, slow the retirement of existing plant, and bring new players into the mix.

Markets, grids and power plants must be planned and will need to allow for greater flexibility to provide better outcomes for customers. It’s time for the electricity sector, its regulators and its customers to limber up.

If you would like to find out more about how Entura can help you navigate your challenges in the electricity market, please contact Donald Vaughan on +61 3 6245 4279.

This article was first published in RenewEconomy.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.