Safer dams are a matter of priority

Examples from around the world demonstrate the devastating consequences of dam failures. Safety must be every dam owner’s key concern, but how should action be prioritised across a large portfolio of dams?

To prioritise effort and resources to achieve the best safety result across a whole portfolio of dams, you need a portfolio risk assessment (PRA). A PRA determines the risk position of the dams based on known information, identifies any information gaps, develops a strategy to close these gaps, and then determines the most effective actions to decrease any risks.

APPLYING PRA TO A LARGE AND COMPLEX PORTFOLIO

Entura has supported dam owners and water managers across the Indo-Pacific region with PRAs, but our most extensive application of the PRA process has involved the 54 large dams of our parent company, Hydro Tasmania.

Hydro Tasmania is Australia’s largest water manager and is committed to ensuring that the risk of a dam failure is very, very low across the entire portfolio. Across so many dams, clear priorities are needed to focus dam safety efforts and human and financial resources.

It has now been 20 years since Hydro Tasmania’s PRA journey began in 1999, so it’s timely to reflect on its outcomes.

With so many dams of greatly varying types, ages and heights, the PRA across Hydro Tasmania’s dams was always going to be complex, and needed to be staged. The first step was a small pilot study on five selected dams that represented the range of potential risks within the broader portfolio.

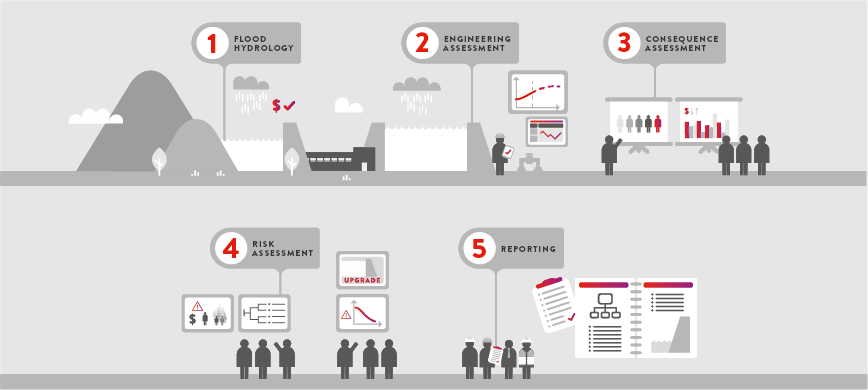

During the pilot study, the five steps of Entura’s PRA process were defined:

This methodology was applied across Hydro Tasmania’s dams portfolio, and an average of eight dams were added to the review each year.

By 2005, the initial ‘baseline’ assessment of the full portfolio was complete. The focus of the dam safety program has now moved to investigation and implementation of upgrades, and the communication of outcomes to senior management.

The PRA process has increased the focus on potential failure modes and risk as drivers of the dam safety program and as the basis for deciding priorities for allocating operational and capital resources.

DETERMINING PRIORITIES THROUGH A RISK FRAMEWORK

Entura’s PRA process reviews the consequences of failure of a dam by looking at the impact that it may have on downstream populations and infrastructure. The engineering assessment considers the effects on dams of extreme events such as floods and earthquakes, taking into account the specific site conditions. Combining the chance of failure and the resulting consequence determines the level of risk.

Hydro Tasmania assesses, prioritises and mitigates risks across the business using an integrated business risk management program, and the dam PRA feeds into this overall risk management approach. A dam’s assessed risk rating across common tolerance criteria drives the risk management response. The assessed dam risks are plotted together on a chart to provide a risk profile for the whole portfolio. This allows dam safety risks to be compared, understood and communicated readily throughout the business in a similar way to all other business risks.

The initial objective of the dam safety program is to reduce all the risks categorised as ‘high’ or ‘extreme’ as soon as practical , and then to continue with a program of investigations and capital works to diminish risks even further. Actions for dams lying in the higher risk zones did not wait for completion of the PRA, but were initiated as soon as risks were identified.

Some cost-effective and expedient risk-mitigation was achieved by identifying and implementing ‘quick wins’. These early actions reduced the overall portfolio risk while more complex mitigation plans were being developed. In some cases the ‘quick win’ actions have even provided the ultimate solution. In other cases, more major works have been required.

PROGRESSING THE DAM SAFETY JOURNEY

The PRA process has substantially benefited Hydro Tasmania’s dam safety program, by improving understanding of the dam portfolio, underpinning a strong strategic plan for addressing risks, improving surveillance and monitoring, and considerably strengthening dam safety emergency planning and warning.

However, this isn’t the end of the dam safety journey. Knowledge of any dam is never complete, and it is critical for dam owners to remain aware that not every failure mode may necessarily have been identified in a baseline study that relies on existing information. There may still be a level of uncertainty about the ‘unknowns’.

For Hydro Tasmania’s PRA, identifying these uncertainties enabled development of a prioritised list of investigations necessary across the portfolio. These detailed investigations have been critical to the development of the dam safety program, by confirming any potential failure modes identified in the PRA.

The list of potential failure modes of a dam portfolio must be rigorously and regularly reviewed, and investigations to reduce uncertainty about the portfolio should be ongoing. New methods and techniques for analysis are being developed all the time, and it is important to understand how these may change existing risk assessments. As well, the safety and risk-level of a dam can change as dams age, or when there are changes to the way the dam is managed.

It is also important to realise that the capital works program for dam safety risk reduction across a portfolio must remain flexible and be actively managed to respond to new or changed risks, new developments in the field of dam engineering, shifts in business priorities, delays to projects, and new developments in risk management.

The sheer number and variety of types, ages and consequence categories of Hydro Tasmania’s dams made Hydro Tasmania’s PRA a challenging process, but the benefits are substantial. The baseline study completed in 2005 is not the end of this journey, which continues to prioritise actions, reduce risks and enhance safety across the portfolio.

If you would like to discuss how we can assist you with assessing your dam risks, developing a resource-effective and comprehensive dam safety program, or applying the same PRA process to other key assets, please contact Paul Southcott, Richard Herweynen or Phillip Ellerton.

About the author

Paul Southcott is a specialist civil engineer at Entura. He has more than 32 years of professional expertise in civil and dam engineering, as well as expertise in geotechnical, foundation, structural, hydraulic and hydropower engineering. Paul’s dam engineering experience spans geotechnical and hydrological investigation; feasibility and options studies; concept, preliminary and detailed design; engineering assessment, consequence assessment and risk assessment; safety reviews; monitoring and surveillance; and emergency planning. He has extensive experience in dam risk assessment including as project manager for Hydro Tasmania’s, Taswater’s and SAWater’s portfolio risk assessment projects. He was a member of the ANCOLD committee that issued the Guideline on Consequence Categories for Dams in 2012 and is currently a member of the ANCOLD committee drafting the new Guideline on Geotechnical Investigations for Dams.

MORE THOUGHT LEADERSHIP ARTICLES

Size isn’t everything when it comes to dam risks: a ten-point plan for safer dams

The failure of a dam in July 2018 in Laos highlights again how crucial it is that dams are designed, constructed and operated safely – regardless of their size.

Dams provide many essential benefits – such as water supply, irrigation, power generation, flood mitigation, drought management and recreation – but we must always ensure that these values are carefully balanced against any level of potential risk the dam may pose to its community and environment. When a dam is designed, constructed and operated according to current best practice, it’s highly likely to be safe.

Dam risk is the combination of the chance of dam failure, however small, and the consequence of that failure. We need to ensure that the level of risk is minimised to what is considered ‘acceptable’ by society. This level of risk can then be compared against other risks that society accepts, such as in the aeronautical, chemical or electrical industries.

If a dam has a high hazard (or consequence) category, its chance of failure must be remotely small, ensuring that the risk to society is acceptable. A dam with a higher hazard category requires higher engineering and operational standards. This is a fundamental concept for dam owners and developers, and is crucial to ensure an acceptable dam safety risk.

The only way that the level of hazard can be properly determined is through adequate consideration of the potential downstream consequences of the dam’s failure. The guidelines of the Australian National Committee on Large Dams (ANCOLD) have renamed the ‘dam hazard category’ to ‘dam consequence category’ – highlighting that the hazard category should be based on potential downstream consequences. Regrettably, the dam hazard category given in international dam safety guidelines are still based only around dam height and reservoir volume.

The failure of the saddle dam at the Xe-Pian Xe-Namnoy hydropower project under construction in Laos illustrates that the height of a dam is not the major determining factor of that dam’s hazard category. The fact that this saddle dam was only 16 m high did not make it less of a hazard than the main 78 m high dam.

In some situations, saddle dams can even pose a higher level of hazard than the higher main dams because of the great volume of water stored in the upper part of the reservoir, the lower level of surveillance and emergency planning at the saddle dam than at the main dam, and the fact that water flow downstream is not usually expected from a saddle dam so the population downstream may be larger as well as less aware of potential risks.

So how can we ensure an acceptable level of safety? Here’s our ten-point plan for safer dams

1 – Assess the downstream consequence through dam break modelling

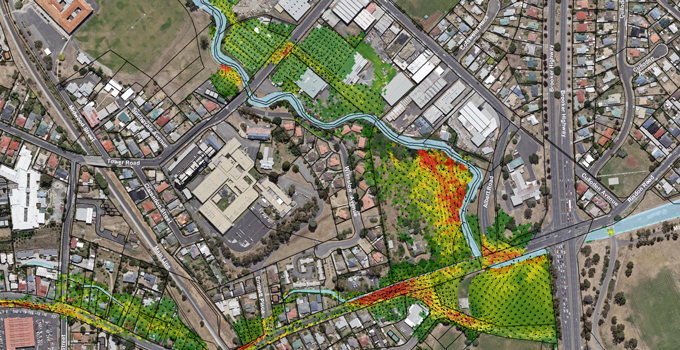

Dynamic hydraulic modelling software can be used to model hypothetical dam failure, quantifying the likely downstream flood wave such an event could generate. Based on this modelling, you can map the flooded area and determine the downstream consequences for life safety, property damage, economic impacts, environmental and heritage damage, and social impacts such as employment, health and wellbeing. Now, the dam’s hazard (or consequence) category can be determined, forming the basis for the design criteria and operational requirements.

2 – Adopt the appropriate design standards for the hazard category

In most international guidelines, the hazard category of the dam determines the design criteria. The greater the downstream consequence, the more stringent the design criteria adopted. However, every dam site is unique, so it is not always possible to design everything according to a general design standard because there simply isn’t a design standard for everything. This requires good engineering judgement. A framework for that judgement is a failure modes analysis for the dam.

3 – Undertake a failure modes analysis

A failure modes analysis identifies the sequence of events that need to occur to lead to dam failure. This process will help to identify the key issues associated with the particular dam site. It will focus the design effort on the elimination of the specific failure modes for the particular dam. It is vital that the dam foundation and reservoir impoundment are considered, and that credible failure mechanisms associated with geological defects are identified and assessed.

4 – Use experienced contractors and ensure quality control

The design engineer must be involved during the construction phase to ensure that the design intent is fully captured and that any changes are carefully considered so that no new failure modes are introduced. Unless the dam is constructed in accordance with the design documentation (the drawings and specifications), there’s no guarantee that the dam will comply with the design criteria and perform as intended.

5 – Implement appropriate dam safety principles during construction

These principles include ensuring adequate flood capacity, dam safety monitoring (especially if water can be stored behind the dam) and dam safety emergency plans. An effective dam safety emergency plan should be active and appropriately updated during all phases of a dam’s life cycle – during construction, first filling, ongoing operation and during major dam upgrades.

6 – Ensure adequate governance through an independent review panel

An independent review panel should be part of any dam engineering project involving a high hazard, to ensure adequate governance and identification of all hazards and potential failure modes. Most large-scale civil projects will encounter the competing demands of time, cost, quality and safety. However, the independent review panel will ensure that no corners are cut in quality or safety in the drive to meet budgets and schedules.

7 – Heighten scrutiny of the dam during unusual events

Unusual events such as the first filling, major floods or major seismic events require increased attention to dam observations and/or measurements. In these circumstances, surveillance needs to be more frequent, via both physical inspections and monitoring with instrumentation. If anything unusual occurs, a response should be initiated through the dam safety procedures in the dam safety management plan. The initial response will be to further understand what is occurring, and determine if it is a dam safety issue or not. It is good practice that dam engineers are involved during unusual events to interpret information and advise the owner.

8 – Maintain an appropriate dam safety program

Long before the dam is filled, the dam safety program should be underway, including operational instrumentation, regular routine inspections, and the personnel and systems in place to make the necessary decisions should any unusual observations occur. Dam engineers can provide ongoing advice to owners when in-house capability is lacking, and can offer an independent set of eyes to ensure currency of the existing systems.

9 – Check your dam safety documentation

Ensure that key dam safety documentation is present, relevant and kept current, including a dam safety management plan, dam surveillance plan, dam operation and maintenance plan, dam safety emergency plan, and evacuation plan.

10 – Consider a dam portfolio risk assessment, regardless of dam size

Even if you think a dam is unlikely to create a high risk, it is worthwhile confirming this, so that you can ensure the appropriate level of dam safety management. If you own a portfolio of dams and you are not sure whether you are exposing society to an unacceptable risk, you should consider a dam portfolio risk assessment to confirm the safety status across your suite of assets. As we’ve indicated, small dams don’t necessarily mean smaller risks .

Running a portfolio risk assessment across numerous small dams may indicate that some have more than a negligible risk, particularly in terms of their criticality to the business or previously unidentified life safety risks. These small dams can then be rolled into your broader dam safety program to ensure that, despite their small size, they are assessed, operated and maintained in alignment with their risk, as for your larger dams.

Whatever the size or purpose of your dam, safety needs to remain your top priority. These ten steps form a best-practice pathway so you can be sure that you’re doing everything possible during dam design, construction and operations to minimise the chance of dam failure and its downstream consequences.

To discuss how Entura can support your dam safety activities, please contact either Richard Herweynen on +61 3 6245 4130 or Shekhar Prince on +61 412 402 110.

About the authors

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

Paul Southcott is a specialist civil engineer at Entura. He has more than 28 years of professional expertise in civil and dam engineering, as well as expertise in geotechnical, foundation, structural, hydraulic and hydropower engineering. Paul’s dam engineering experience spans geotechnical and hydrological investigation; feasibility and options studies; concept, preliminary and detailed design; engineering assessment, consequence assessment and risk assessment; safety reviews; monitoring and surveillance; and emergency planning. He has extensive experience in dam risk assessment including as project manager for Hydro Tasmania’s, Taswater’s and SAWater’s portfolio risk assessment projects. He was a member of the ANCOLD committee that issued the Guideline on Consequence Categories for Dams in 2012.

MORE THOUGHT LEADERSHIP ARTICLES

What can dam owners do to better manage floods and avoid the blame game?

To keep communities and assets safe during flood events, dam operators need to make rapid and difficult decisions. The best protection is having the right systems in place before an emergency arises.

Dam operators are sometimes blamed for causing flood disasters due to the way the dam was operated during intense rains, such as by suddenly releasing water through gates and valves. Yet this criticism is not always warranted, as these actions may have only been one part of the problem associated with the flood. At times, sudden releases may be necessary to maintain the safety of the dam, as the dam’s failure would have even greater consequences than the additional flooding due to the releases.

In 2010 and 2011, Australia experienced some of its biggest flood events, with large areas of Queensland declared disaster zones. At the time of the Queensland floods, there was significant scrutiny of how Wivenhoe Dam was operated, even though it was part of the engineering system designed to mitigate flood risks. Blame and criticism abounded. Individual flood operations engineers were criticised for making poor decisions. The managers of the dam operator were blamed for not drawing down the dam at the beginning of the wet season despite a long drought immediately prior to the floods. The Bureau of Meteorology was criticised for not providing adequate warnings and for inaccurate forecasts. Planners were blamed for allowing development in flood-prone areas. Local authorities and engineering consultants were harshly scrutinised for their modelling and analyses.

Fast forward to 2018, when devastating floods in Kerala, India, resulted in significant loss of life, displacement of people and extensive damage. In this circumstance, blame has been directed at the dam operators, government authorities, planners, flood forecasters, and dam management bodies. Media articles have called it a ‘man-made disaster’, and claims have been made that water should have been discharged earlier from the reservoirs prior to the monsoon, that gates should have been opened gradually, that better warning should have been provided, that power stations should not have been out of action due to maintenance, and that other dam functions such as water supply and power generation should have been secondary to flood mitigation.

Decision-making about dams can be complex, especially given that most dams have more than one purpose: they may supply water for drinking and irrigation, as well as provide flood mitigation benefits for downstream communities. However, the way a dam is operated for both these purposes may be very different and frequently conflicting. For example, a dam for water supply aims to maximise stored water to safeguard supply during droughts; however, a dam for flood mitigation needs as much free space as possible in the reservoir to mitigate the downstream flood risk. Climate change is likely to increase the conflict between water supply and flood mitigation as more severe droughts and floods are anticipated, which will increase the challenges for dam operators – so it is critical that we learn from events such as these examples from Australia and India.

So what can a dam owner do to better manage a major flood event?

The enquiries and reviews that followed the 2010/2011 floods in Australia overwhelmingly indicated the need for improvements in non-structural measures such as development planning, the production and availability of quality flood management information, emergency response management and community participation. The owner and operator of Wivenhoe Dam also discovered the importance of maintaining up-to-date, clear and unambiguous dam flood operating rules, and the need to follow these flood operating rules at all times.

The following seven elements should be in place for every dam owner who wants to better manage major flood events:

1 – Flood forecasting systems

Flood forecasting is critical for protecting public safety and preserving infrastructure. Effective flood forecasting systems provide accurate and timely warning of impending floods. Longer warning times provide greater opportunity to activate emergency management or evacuation plans and to manage water infrastructure. Although the intent of a flood forecasting system is to provide the most accurate forecasts possible, the reality is that there are limitations, especially during major flood events. Reviews undertaken of the 2010/2011 Queensland floods indicated issues with flood data collection and the need for improvements in the coverage of warning networks.

Flood forecasting depends on the timely availability of high-quality data from the right locations in a catchment. Without good real-time telemetered rainfall and streamflow data it will be difficult to develop a dependable flood forecasting system that can be used for real-time decision-making. There needs to be some redundancy in the system because some of the instruments and/or communications systems may fail during a major flood event. This requires an investment both to install and to maintain these instruments. With numerical weather forecasts increasingly available, there is now an opportunity to use this data in flood models to provide even longer lead times for action.

2 – Adequate catchment planning

Catchment-scale management is needed to manage flood risks. Developing flood inundation maps and understanding the consequences of upstream dam failures provide an opportunity for appropriate land use and planning controls downstream, minimising loss of life and property. These tools also provide a basis for developing appropriate structural and non-structural flood mitigation measures and emergency management plans.

3 – Operational model for dam infrastructure

A dam operator needs an operational model that is either linked to the flood forecasting model or embedded in it. If the river system has a cascade of dams, the entire cascade should be modelled as one system, as the operation of each dam affects other linked dams. Understanding these complexities will be critical when managing a major flood event, so that cascade impacts can be assessed and determined prior to implementing an action. Maximum flood mitigation can be achieved by operating linked dams together. Outside of a flood event, these operational models can be used to run potential flood scenarios to help develop clear operational procedures guiding the operation of the dams during a flood event and to train operators so they understand their critical role.

4 – Clear operational procedures for dams during flood events

Given the potential significant impacts on communities downstream, it is imperative that dams are operated during flood events in accordance with clearly defined operational procedures to protect the structural safety of the dams and minimise impacts to life and property. Importantly, all operational decisions during flood events must be documented when they are made, not retrospectively. Pre-releases may be part of these operational procedures, including seasonal targets for reservoir levels to help mitigate flood risks associated with a defined wet season.

Certain triggers (e.g. reservoir level, flood predictions) will shift normal reservoir operation to flood operation. Given infinite possible flood scenarios, it is not always possible or appropriate to provide completely prescriptive flood operating procedures. The manual of operational procedures must be designed to guide decision making based on professional judgements by qualified engineers, ensuring the decisions are robust for all circumstances. When making decisions about releasing water from dams during flood events, consideration should be given to rain falling in catchments not controlled by the dams. Operational decisions must be linked back to the wider flood forecasting system.

5 – Dam safety emergency plans

All high-hazard dams should have a dam safety emergency plan (DSEP, or sometimes called an emergency action plan, EAP), which forms an important part of the overall dam safety management procedures and dam safety documentation. The purpose of a dam safety emergency plan is to provide procedures for the dam owner to manage the dam during an emergency (whether flood, earthquake, or major dam safety incident). The plan needs to clearly outline who does what and when and usually has graded levels of response as the incident develops. A major flood event should trigger the procedures of the dam safety emergency plan, providing a heightened level of awareness of the performance and safety of the dam.

It is important that this plan has clear roles and responsibilities and clear communication channels both internally and externally to emergency services and the media. Clearly documenting the decisions and communications throughout the emergency is critical, and all involved should keep detailed logs of events. This allows effective debriefing after the event to identify improvements to the plan and, in the worst case, will assist in defending any legal action. If at any point the dam is at risk of failure, a dam safety emergency will be declared and emergency services must commence evacuation.

6 – Flood evacuation plans and flood management centre

Flood evacuation is generally the responsibility of the affected state or district’s emergency services. Flood evacuation plans are prepared as part of the planning process for mitigating the risk associated with a major flooding event. Floodplain mapping forms a part of any flood evacuation plan. These maps show the area that will be flooded in various magnitudes of floods.

Evacuation plans will determine when people need to be evacuated and by what routes, before these evacuation routes are flooded. They will clearly nominate where evacuation centres will be set up on non-flood-prone land with necessary food, water and sanitary facilities. Setting up a centralised flood management centre will help to provide a focal point for information, communication and decision-making throughout the flood event, ensuring clear governance, oversight, roles, responsibilities, communication and cooperation.

Severe flooding is likely to disrupt power and communication systems so available back-up need to be planned, including portable generators, radios and satellite phones. Modern communication tools such as mobile phones are increasingly allowing widespread communication of flood warnings, as well as audit trails of warnings so that post-flood reviews can improve emergency management and evacuation procedures over time.

7 – Community education and awareness

Effective flood evacuation is only possible if the downstream community is aware of the risk and the action they need to take following certain warnings. This awareness is best achieved through community information sessions. Working with communities before a disaster strikes will put them in a better position to deal with its impacts. The 2010/2011 Queensland floods showed that helping people to become more self-reliant is of benefit if/when emergency services are overwhelmed. To achieve this, flood risk information and flood predictions should be publicly available, along with education and clear communication.

These seven factors are not the sole responsibility of a dam owner; instead, cooperation is needed among authorities, and dam owners should encourage and facilitate this. Using a framework based on these seven components, dam owners will continually improve flood management, better securing the safety of people and property downstream, as well as minimising the likelihood of significant reputational and legal risks.

To discuss how Entura can partner with you to better manage dam safety and flood-related risks, contact Richard Herweynen on +61 3 6245 4130.

About the authors

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

Maximising the benefits of GIS for better business decisions

‘Location, location, location!’ It’s a familiar catch-phrase in the real estate industry, but it’s just as relevant in the power and water sector. Wherever there’s location-related data, a geographic information system will guide better business decisions.

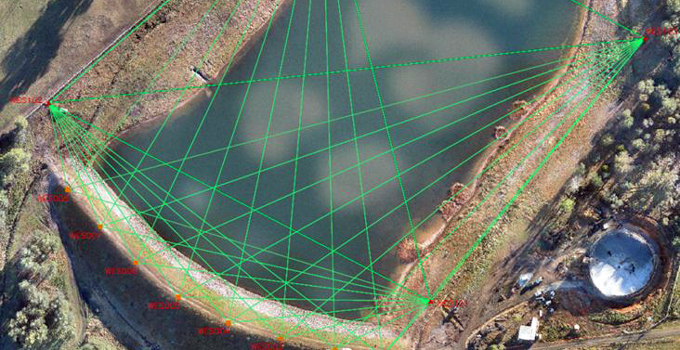

Mobile devices and apps are increasingly using location-based data collected via satellites, drones, LIDAR and other rapidly developing sensing and data capture technologies. With these advances, we are able to find relevant information more quickly and draw on that information to make informed decisions. We’re seeing this proliferate in everyday life through apps that help us navigate, find services and products, and make decisions ranging from the trivial to the profound.

Developers and managers of power and water infrastructure projects who embrace GIS (geographic information systems) stand to gain benefits on an even greater scale. Gathering high-quality spatial information and analysing it to guide business decisions will certainly improve productivity and the bottom line.

Better decisions are the necessary foundation for increased revenue, lower costs, greater efficiency and productivity, and reduced risks. So, if the technology is available and there’s so much to gain, why isn’t GIS being as widely used in the power and water sector as it could be? What may be holding businesses back from fully embracing this powerful and dynamic technology?

Do we really need to use GIS for this project?

All power and water projects involve location – from finding an optimum site for your project, to analysing combinations of spatial data to make the best management decisions or to predict events. Whenever you ask a ‘where?’ question, GIS can help. Where is the asset best located? Where are the constraints or hazards? Where are the reports of previous work done in this area? Where are the customers or opportunities?

In other words, rather than asking whether GIS is needed on a project, consider making GIS a default for every project. The real question should be “how can we maximise the benefits of using spatial data and GIS on this project?” GIS can offer business benefits far beyond the most commonly understood use: making a map.

Data capture in the field can now be streamlined – gone are the days of capturing field data with pen and paper. Users can now collect data on mobile devices, sync to databases while in the field, share data, and generate their own maps, queries and reports. Embracing these advances will save time and enable faster and better decisions.

As well as providing valuable business insights, spatial analysis and location intelligence can greatly improve communication and knowledge sharing – within project teams, with the broader business, and with the community and stakeholders – via tools such as web maps and apps, visual analysis and 3D modelling.

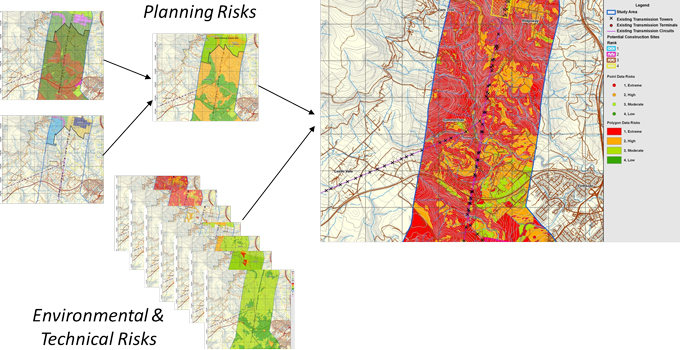

One of the most important applications is the simultaneous analysis of different spatial datasets to provide the best solutions or choices between alternative options, locations, objects and so on. This process is better known as multi-criteria analysis (MCA) and it can be used for many applications.

For example, MCA can be used to find the optimum site for your project taking into account a range of values such as local geology, threatened species, resource availability, land use and terrain, planning restrictions, communities and demographics. Using MCA, you can establish areas of best fit for your project based on thematic overviews of areas of constraint, cost of construction, access and transportation routes.

Risks such as bushfire, weeds, threatened species, pollution sources, landslides and erosion can also be more easily and fully understood, supporting your ongoing site management of such issues.

GIS also links with document management, asset management, business intelligence and enterprise resource planning (ERP) systems. It can act as a portal, creating a central point of easy access, pulling together information and making it available on one of the simplest forms to interpret – a map.

Of course GIS is not the answer to everything, and it is not a standalone platform. However, there’s much it can offer across many different business activities, working together with other business systems.

What about the costs?

The return on investment of using GIS should be positive if it is used appropriately. For site selection of power and water projects, using GIS is a no-brainer. For example, using GIS to find the best site for a wind farm – locating the best winds, minimal constraints, good proximity to existing infrastructure and appropriate land use – will obviously result in vastly greater returns than siting the wind farm in an inferior location.

Some examples may be less immediately apparent, but equally valuable – for example, using GIS to increase efficiencies in everyday workflows. If your workers are taking an extra half hour every time they need to find previous work completed in an area, this time can add up quickly. Or perhaps they can’t find previous information, so work is re-done unnecessarily. These costs will keep adding up. Instead you could use a GIS web map to locate all your previous reports and projects, so that a simple click on a map finds the files and saves hours (if not days) of time.

Do we need specialist software or skillsets?

With most things, you do need specialised skillsets and software to get good results, and of course bad data in equals bad data out. Users of GIS do need to understand and assess the spatial data needs in each application.

You could undertake some GIS work yourself using free or open-source software. However, be aware of the risks of using data or tools that aren’t fit for purpose. Just because you know how to use Microsoft Word, doesn’t mean you could write a detailed report outside your area of expertise!

We have seen cases where coarse-resolution data has been used to infer finer project details and costs, resulting in poor decisions. We have also seen inexperienced operators make invalid assumptions. To get the best results, you need to be sure that you’re using the technology wisely.

If you are engaging a power, water or environmental consultant on a project, they are likely to have access to GIS capability; however, GIS is still often underutilised. When deciding who to engage on your project, ask your consultant how they will maximise the benefits of GIS to produce better outcomes for your project.

To discuss how Entura can help you harness the potential of GIS to improve your power and water project decisions and outcomes, contact Stephen Thomas on +61 3 6245 4511, Patrick Pease or Phillip Ellerton on +61 439 010 172.

About the authors

Stephen Thomas is Team Leader and Senior Technical Officer with Entura, specialising in geographic information systems, 3D visualisation and CAD software. Steve has over twenty-six years of technical experience and specialises in environmental assessments and approvals for engineering surveys and property. He has created 3D models and animations of proposed developments including wind farms, urban landscapes and city frameworks. Steve’s work on the Hobart Waterfront 3D model won an international award in geospatial modelling.

MORE THOUGHT LEADERSHIP ARTICLES

Six sink-or-swim questions for the modern dam engineer

Technology and expectations are constantly evolving for the dam engineer but the ultimate goal remains the same: safe, lasting dams. Are you fully equipped to make that target a reality?

All industries and jobs change over time, but for dam engineers there has been very significant change on many fronts over the last few decades. Improvements and new developments in technology and construction methods are constantly emerging. Expectations of the role continue to broaden beyond technical skills. And, since the 1970s and 1980s, dam engineers have needed to keep abreast of the surge in legislation, regulations and procedures for modern dam safety programs which emerged in the wake of major dam failures.

Of course, generational change is also always occurring. For organisations that have experienced bubbles and dips in the age distribution of their workforce, this is particularly challenging, and gaps may emerge in particular experience brackets. As older engineers move towards retirement, they take with them the knowledge of the generation who designed and constructed older dams that may still retain original technology.

The modern dam engineer therefore faces a dual challenge: not only to stay up to date with the latest technology and requirements, but also to maintain an understanding of older equipment and instruments.

For dam owners and managers, success in your business strategy will depend on ensuring that your dam engineers have the right skills and competencies. Investing in workforce planning and training for your people will help you manage risk, deliver your key functions, and move toward your long-term business goals.

To me, the following key factors are essential for the modern dam engineer to keep on top of our fast-changing profession.

1 – Are you keeping up with changing technology for dam engineering and monitoring?

Dam engineering and monitoring technology keeps improving, and the pace of change gets faster all the time. Defensive measures to ensure the safety of dams have improved greatly over recent decades, such as filters for internal erosion protection, and corrosion protection in ground anchors.

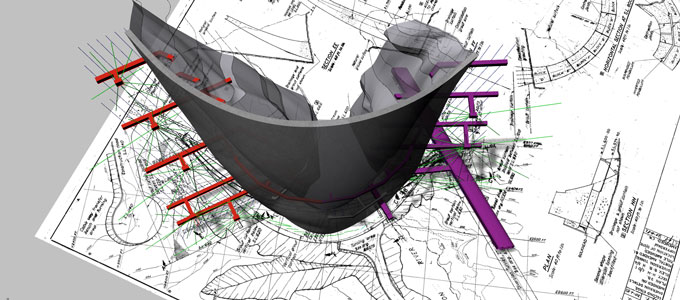

Methods for analysing dams have also become more sophisticated with increased computing power and more advanced analysis software, in particular for extreme floods and non-linear analysis for seismic loading. The modern dam engineer also has access to contemporary geotechnical and structural monitoring instruments, which are useful for interpreting the behaviour of a dam.

It is no longer acceptable for a dam safety engineer to rely only on visual inspection and monitoring data. Modern dam engineers need to understand the underlying design philosophy and keep up with the latest construction practices and their impacts on dam behaviour. We also need to maintain an enhanced understanding of the performance of dam structures and appurtenance structures under various load conditions.

In recent years, advanced instruments and automated data acquisition systems have enabled real-time monitoring of dams and near-continuous time history records for the dam engineer to evaluate.

Dealing with this great volume of data can be very time-consuming and beset by a range of challenges, so it is important that the modern dam engineer embraces the best technological advances to streamline the collection, organisation, interpretation and presentation of the data so that it serves its ultimate function: to quickly identify pertinent issues or anomalies.

2 – Are you guided by risks, with a thorough understanding of failure modes?

The modern dam safety engineer needs a thorough understanding of dam safety risks and assessment practices. Risk assessment now defines the dam surveillance scope and program, and failure modes analysis forms the foundation of a risk-based dam safety and surveillance program.

When assessing failure modes, the dam engineer needs to work alongside geologists and construction engineers to understand the impact of construction and to identify features that are not readily visible through visual inspections but could affect the safety of a dam.

3 – Do you consider and understand the impacts of environmental changes?

For dam engineers, consideration of environmental factors is nothing new. However, the potential for changes in weather patterns, and the consequences of these changes, are increasingly important concerns for the modern dam engineer.

In an era in which the climate is changing, dam engineers now need to, for example, consider changes in the size and frequency of rare flood events when evaluating the required spillway capacity, or investigate the adverse impacts on embankment dams during long periods of low rainfall, which could cause desiccation and cracking of the clay material.

4 – How do you prioritise activities within constrained budgets?

Some large dams are now more than 50 years old and are in disrepair or inadequately monitored. However, the limited budgets of public and private sector dam owners can constrain their ability to fund comprehensive surveillance programs and dam remediation works.

This places increasing pressure on the modern dam safety engineer, who should recommend a prioritised program of risk-reduction work within the context of the owner’s financial constraints, to ensure that risks are adequately managed.

5 – Can you engage effectively with the dam’s community and stakeholders?

Dam engineers are increasingly required to consider the safety of dams in the context of the community’s cultural and heritage interests. Community scrutiny of the safety of a dam, or of planned works to improve safety, continues to increase.

With the advent of social media, public scrutiny is now immediate, constant and global. This is a challenge for modern dam engineers, who are not often trained in community engagement.

6 – How safe are your practices?

Over the past two decades, workplace health and safety requirements have had a significant impact on dam engineering. Although not a new responsibility, the regulatory requirements to ensure safe construction, operation, maintenance and decommissioning have increased, requiring modern dam engineers to be aware of legal requirements and safety standards beyond their core skills.

In a world in which the availability and uses of water are increasingly in demand and under strain, we need safe, reliable, enduring dams. Investing in the skills and competencies of modern, professional dam engineers is a critical step towards achieving that goal.

If you would like to talk further about developing your dam engineers, or filling gaps in your own expertise, contact Richard Herweynen, Phillip Ellerton or Dale Bryce.

MORE THOUGHT LEADERSHIP ARTICLES

Keeping safe around dams

When we hear ‘dam’ and ‘safety’ in the same sentence, it’s natural to think first of catastrophic dam failures and their devastating impacts on downstream communities. However, keeping the public safe around dams also involves considering and mitigating some more common and less documented risks…

Dams, water courses and water bodies typically offer a range of recreational benefits enjoyed by many. But where there’s water, there’s inherent danger, including the risk of drowning.

Asset managers know much more about the numbers of fatalities relating to dam failures than about the fatalities associated with the overall ongoing presence and operation of dams. But we do know that drownings in dams and waterways make up more than a third of total drowning statistics in Australia, and the situation is similar around the world.

Regardless of the specific circumstances of each of these fatalities, it is clear that owners and regulators of dams and water courses need to take action to help protect the public from these largely avoidable deaths.

In 2012 the International Committee on Large Dams established a working committee to start identifying these public safety risks, describe the international state of practice to manage and mitigate the risks, and develop a guidance bulletin on best practice measures and public education about safety around dams. This project is well underway, and here I’ll take a look at some of the key risks and possible mitigations being considered.

WHAT ARE THE RISKS?

The general public tends to underestimate the hazards linked to activities around dams and waterways, particularly the possibility and effects of sudden changes in water level and flow.

Accidents may happen around dams and water bodies during a range of activities – not only those considered more overtly dangerous (such as abseiling or rock climbing), but also during activities such as swimming, kayaking, boating or fishing. Falls from heights and other activities not associated with access to water are also of concern.

However, many drownings are due to the particular risks relating to hydraulic structures and the inherent nature of their operation, and to rapid changes in water levels and conditions.

Hazards around dams are often associated with swift and turbulent currents near intakes and spillways. These currents may be created by the changes in flows and water levels during normal operations of spillways or during flooding. Unexpected rapidly rising water levels can result from weather conditions, but also from sudden changes in output from hydropower stations, and have the potential to cause people to be inundated or swept away.

Around the world, a large proportion of drownings have been associated with a particular subset of hydraulic structures referred to as ‘low-head weirs’. Under certain flow conditions, these can display a particularly dangerous hydraulic phenomenon, earning them a common description as ‘drowning machines’. This type of structure has particularly attracted attention, and has been investigated, in the United States as it constitutes a large proportion of preventable death in a number of states.

WHAT CAN DAM OWNERS DO?

Where people are undertaking recreational activities with a recognised level of risk, there is an implied responsibility to observe regulations and warnings, take common safety precautions, and be capable and in a suitable state to undertake the activity.

However, the absence of such behaviours does not remove the liability of the asset owner or manager. In fact, their responsibility is even higher in inherently hazardous site conditions, conditions posing a hazard that is not readily identifiable, or where changes in operations lead to changes in the hazard level.

So, what actions should a dam owner or manager take to best protect the public? While not all incidents can be avoided, the possible actions below form a comprehensive approach to minimising risk and reducing probability and consequences.

| Develop a public safety policy and plans, ensuring compliance with laws and regulations |

Start by documenting your commitment to public safety in a policy statement identifying your statutory and legal requirements, and establishing your objectives, tolerance criteria and targets. Translate your policy into a public safety management plan indicating how you will manage the public safety risk at each site. This should be based on a risk assessment of the facility, identifying the hazards, assessing the degree to which the public is exposed, identifying appropriate control measures and assigning responsibilities. |

| Conduct a risk assessment, incorporating comprehensive local insight and regular review |

The risk assessment process is an important step in managing public safety risk as well as complying with statutory and common law obligations. It helps focus on the risks that really matter. Most organisations have an accepted method for analysing, assessing and managing risk; this may be tailored to incorporate public safety risks. Consider such factors as seasonal and daily weather effects. For example, during summer, or other periods of low flow, the public may anticipate a lower likelihood of rapidly changing conditions. There may also be a general lack of awareness that spills can result from other factors than adverse weather, such as changes in generation or earlier precipitation upstream. The quality of the risk assessment and the effectiveness of control measures depend on the degree of site-specific knowledge which is best obtained from staff working at the location or engaged in its operation. The risk assessment should be periodically reviewed to ensure the assumptions remain valid. |

| Exclude the public where necessary through fencing, gates, artificial and natural barriers |

The selection of exclusion devices and layout depends on the particular site and requires input from people with a good local understanding. Note that the effectiveness of public exclusions can vary over time as usage of an area changes or as the public becomes complacent or desensitised to the hazards. |

|

Warn the public of dangers and of changed conditions through signage and other audible and visual alarms

|

Signage and alarms warn of changes in operations (e.g. gate opening) and conditions (e.g. water level or flow). Carefully consider their placement, maintenance, language, readability, and use of terms and symbols. In some circumstances, audible and visual alarms may be appropriate. As with physical barriers, over time the effectiveness of warnings may diminish, particularly if there is a real or perceived lack of connection between the activation of the warning and the occurrence of the hazard. |

|

Educate targeted populations and the general public

|

Best practice suggests that education applied well either via mass media or to targeted populations can have a significant impact. |

| Train supervisory personnel, including in intervention and rescue techniques and incident management |

Training supervisory personnel in hazard identification, risk assessment, compliance assessment and enforcement is important. This can include specific training and simulations in intervention and rescue techniques where appropriate. Many dam owners are reducing the site presence needed to meet operational requirements; but determining the appropriate presence required should take account of the need to maintain a public profile and awareness of public interaction. Periodic patrols are also valuable to identify changed patterns of public use. A public safety incident may be managed by local intervention or could escalate into an emergency, crisis or disaster for an operator depending on the nature and scale of the incident. Effective incident management must go beyond the immediate need to contain the incident (e.g. perform a rescue), by also considering the implications for risk assessment, education, and the return to business operations. |

| Decommission the dam where appropriate | In some circumstances, decommissioning may be an appropriate method to reduce risk. Public safety may add weight to a decision based on other business or operational considerations. |

| Monitor, report and review |

Incident reporting relating to public safety around dams is often poorly undertaken and lacking sufficient detail. There are also very few reports of near misses, which can provide important lessons about mitigating risks, and very limited databases or documented case studies available. To improve this situation, the forthcoming guideline from the ICOLD committee will propose an incident reporting process that can be applied by owners and regulators to improve their practices regarding public safety around dams. |

The ICOLD bulletin will form a valuable tool for owners, operators and regulators to manage and mitigate this significant risk area. A good way to start the process is by seeking the assistance of others who have experience in assessing and managing the public interaction with dam and waterway assets.

Every life lost in a dam-related accident is a tragedy. Through these best practice measures, dam owners and managers have a much greater opportunity to help reduce the many hundreds of dam-related fatalities occurring around the world each year.

If you would like to find out more about how Entura can help you improve safety around dams, please contact Phillip Ellerton on +61 439 010 172 or Shekhar Prince on +61 412 402 110.

MORE THOUGHT LEADERSHIP ARTICLES

More water storage needed for a sustainable future

Global declines in water storage are increasingly troubling. With greater hydrological variability due to climate change, more storage will be vital to provide the same level of security of water, food and energy.

Water storage is a fundamental protection from the impacts of a changing climate, safeguarding the supply of water, and the water–food–energy nexus, even during extended drought.

For thousands of years, dams have stored water to irrigate crops, control flooding, supply water for industrial and household use, and generate hydroelectric power – contributing enormously to food security, human development and economic growth.

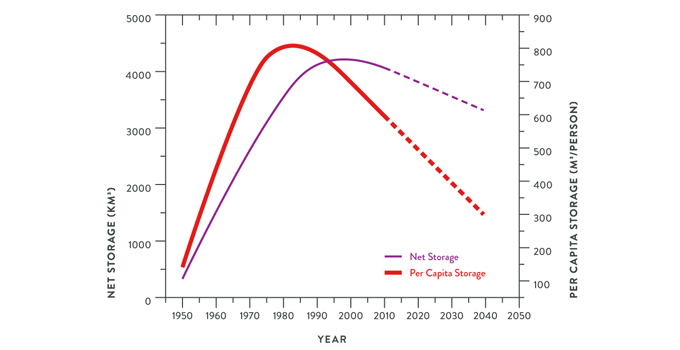

These days, many dams serve more than one function, but remain the primary mechanism for coping with the variability of water supply and demand. During the last century, more than 45 000 dams higher than 15 m have been constructed worldwide, creating a combined storage capacity estimated to be between 6700 and 8000 km3, representing 17 per cent of global annual runoff.

Security of water, food and energy are inextricably linked. For example, approximately 50 per cent of all large dams worldwide are used for irrigation. Without sufficient water storage, irrigated agriculture (the largest user of water at the global level, contributing 40 per cent of the world’s food) is at the mercy of changing patterns of rainfall and runoff.

Understanding water storage issues is essential for successfully managing water resources. At the simplest level, it is a matter of ‘inflow (water supply) less outflow (water demand) equals change in storage’. But it is particularly important to understand whether storage declines relate to reducing supply, increasing demand, or both. The answer is both, and more.

Key factors influencing storage are greater variability of inflows due to climate change, increased demand due to population growth, reduced net storage due to sedimentation, and less dam construction occurring worldwide due to environmental and social impacts.

Climate change

The effects of climate change are predicted to increase and to result in greater magnitude and frequency of hydrological extremes, such as prolonged droughts and significant floods. With prolonged drought, inflows to storages will reduce. If demand remains the same, stress on existing water storages will increase.

Population growth

It is estimated that in 2017 Earth supports around 7.5 billion people, yet 200 years ago the number was less than 1 billion. Population and water demand are strongly linked. With our world population increasing at around 80 million people per year, rising demands for basic services and growing desires for higher living standards will intensify the demand for water and put additional strain on existing storages.

Sedimentation

Many of the larger reservoirs worldwide have had their lifespans reduced significantly due to deposits of sediment within the storages, diminishing net storage in many regions of the world. Globally, the annual rates of loss relative to installed storage capacity are generally estimated to range between 0.5 and 1.0 per cent, equating to a total worldwide loss of storage of around 40 to 80 km3 per year.

Reduced dam construction

Installation of large reservoirs peaked during the 1960s and 1970s, both in number and storage volume. However, some of these larger reservoirs caused significant environmental and social damage, bringing dam construction under great scrutiny and ultimately decreasing dam construction worldwide.

With less dam construction, some decommissioning of older dams and loss of storage due to sedimentation, net storage worldwide is falling, most dramatically in storage per capita. Such reduction in storage is likely to undermine reliability of supply.

Source: GW Annandale, GI Morris & P. Karki, Sediment Management at Reservoirs and Hydropower Plants: New World Bank Technical Note, ICOLD International Symposium, Johannesburg, May 2016.

Few kinds of development projects arouse as much controversy as dams. However, large dams vary considerably in their environmental and social impacts. The severity of environmental impact is largely determined by the dam site. While dams at good sites can be very defensible from an environmental standpoint, those proposed at bad sites will be inherently problematic even if all feasible mitigation measures are properly implemented. The challenge is to find the good dam sites to enable these necessary water storages to be developed.

How can we take action?

The following actions form a useful response to reduced worldwide storage and the pressing need to increase water storage to maintain reliable water supply, irrigation and energy systems in a changing climate:

- Prioritise managing existing storages well, and recognise the importance of storages for maintaining reliable supply. Appropriately manage sedimentation and its impact. Employ near-real-time management of water based on improved information systems to ensure the best economic use of existing reservoirs.

- Explore opportunities to increase the storage capacity of existing reservoirs by raising dams or by improving interconnection. Often, this can be more cost-effective and have lower environmental impacts than a new dam project.

- Identify dam sites, either on-stream or off-stream, which will minimise environmental and social impacts. Good site selection is the most effective environmental mitigation measure.

The net decline in global reservoir storage demands a different mindset for analysing the economics and construction of sustainable dam projects. Rather than debating whether more dams are required, decision-makers must accept that more storage will be needed and should plan accordingly.

If you would like to find out more about how Entura can help you develop a sustainable water storage solution or respond to these worldwide challenges, contact Richard Herweynen on +61 3 6245 4130 or Shekhar Prince on +61 412 402 110.

A version of this article has been previously published in the International Hydropower Association blog.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

Is your dam instrumentation telling you what you need to know?

For dam owners, measuring the right things in the right locations is essential for a successful dam safety program.

Dam owners who value dam safety need useful data from reliable instrumentation to be confident that they’ll be warned if a dam safety incident is developing, which, if undetected, could lead to an emergency.

However, you need to be measuring the right things, providing useful data for interpreting the dam’s performance. It is also important to find the optimum balance as too much data can be time-consuming, requiring significant technical resources to collect, process and analyse properly.

Am I measuring the right things on my dam?

The main purpose of dam instrumentation is to provide useful data on the dam’s performance: whether the dam is performing as expected, or something unusual is happening. Something unusual happening could indicate the beginnings of a dam safety incident. Knowing early can provide time to take action, and prevent a dam safety incident from developing into an emergency. To be able to take action, you need to be measuring the correct things on your particular dam.

A number of dam authorities including the Australian National Committee on Large Dams (ANCOLD) provide guidelines on dam safety management which include some guidance on the type of instrumentation normally adopted for a particular dam type. However, no guideline or standard can prescribe exactly what is required for your unique dam.

Any instrumentation design for a new dam, or review of instrumentation for an existing dam, should be based on the identified failure modes for your asset. As part of any dam design or review process, one of the first steps is to identify the relevant failure modes for the dam, and how these failure modes would initiate. This information is essential for determining what parameters should be measured, and therefore the type and location of instrumentation.

Rather than basing your instrumentation requirements for a new dam on what was selected for your last project, you should consider the unique characteristics of a particular dam site and design. Potential failure modes should be identified, and the instrumentation should be located, selected and specified to provide data that will help identify the initiation of these potential failure modes. This will ensure that you are collecting data for good reason (rather than for the sake of collecting data), and that there is a strong link between the surveillance data and the safety of your dam.

Key failure modes will depend on the type of dam, the characteristics of the dam site and particular details associated with the dam design. For example, following the review of an earth and rockfill embankment dam on a soil foundation, a key failure mode was identified as piping through the dam or foundation. The design therefore included an appropriate set of instrumentation, including piezometers and leakage weirs, to monitor the development of that failure mode.

Do I need to keep measuring and collecting data?

The basis for evaluating whether to keep measuring and collecting data, and whether instrumentation needs to be replaced if it is no longer working, is to determine the potential failure modes for your dam, and to review the instrumentation based on these failure modes.

When reviewing your dam instrumentation, ask the following:

- Does the particular instrument measure a key failure mode?

- Is the monitoring data useful and reliable?

- Would other instruments provide the same or better level of monitoring data on this failure mode?

This review could potentially lead to some rationalisation of existing instrumentation, saving operational expenses and allowing you to focus your dam safety budget on more critical aspects. For example, a particular concrete dam we worked on had an extensive number of thermocouples installed to measure temperatures during construction due to concerns of thermally induced cracking. Once the dam had been operational for a number of years, the temperature data no longer provided information on a relevant failure mode, so the thermocouple monitoring system was decommissioned.

Reviewing your dam instrumentation may also identify new instrumentation requirements, if current instrumentation is not providing the information needed for a particular failure mode. For example, following the review of a concrete arch dam, sliding on a crack within the concrete was identified as a key failure mode. Additional monitoring was specified to monitor the width and extent of the crack.

Reviewing your dam monitoring program

Entura has developed the following checklist to help you review your dam monitoring program and rationalise it to focus on key failure modes. This checklist can also be used to assess data monitoring programs for other important assets, such as underground caverns for power stations.

| Step 1 | Identify the key failure modes for the dam, and how they would initiate. |

| Step 2 | Identify dam safety instrumentation required to monitor the initiation of each key failure mode. |

| Step 3 | Review the current level of dam safety instrumentation. |

| Step 4 | If current instrumentation does not address a key failure mode, determine the additional instrumentation required. |

| Step 5 | If any of the current instrumentation does not provide relevant data about initiation of any of the identified failure modes, decommission it. |

| Step 6 | Undertake capital works to install new instrumentation (if required). |

| Step 7 | Revise dam safety systems to incorporate revised instrumentation. |

| Step 8 | Use surveillance data to report against the identified failure modes. |

Dam surveillance, including both inspections and instrumentation monitoring, is a fundamental activity in any dam safety program. But don’t just collect data for the sake of collecting data. Make sure that the data is telling you everything you need to know about the potential failure modes for your unique dam.

To discuss how you can get your instrumentation right for your particular dam or other critical assets, please contact Phillip Ellerton on +61 439 010 172, Tim Griggs on +61 3 6245 4152 or Richard Herweynen on +61 3 6245 4130.

About the authors

Tim Griggs is a Senior Dams Engineer with Entura. He has over 20 years of experience in civil and dam engineering including the design and construction support of a number of new dams, upgrades to existing dams and dam safety review work. Tim has a particular interest in dam safety instrumentation and has prepared instrumentation specifications for both new and existing dam projects.

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

Portfolio risk assessment takes dam safety programs to the next level

A portfolio risk assessment allows owners of dams and other water assets to see the bigger picture of how to prioritise their efforts and resources to achieve the best safety result across their whole portfolio.

Constraints on budgets and resources remain key challenges for owners of dams and water assets, especially those with a large asset portfolio, as they attempt to reduce the risk to communities to an ‘as-low-as-reasonably-practicable’ level. Without a tool to prioritise safety works, it is impossible to use limited resources most effectively.

Dam owners have often overlooked the importance of prioritising their dam safety activities, resulting in resources being allocated equally to all dams or allocated randomly to selected dams.

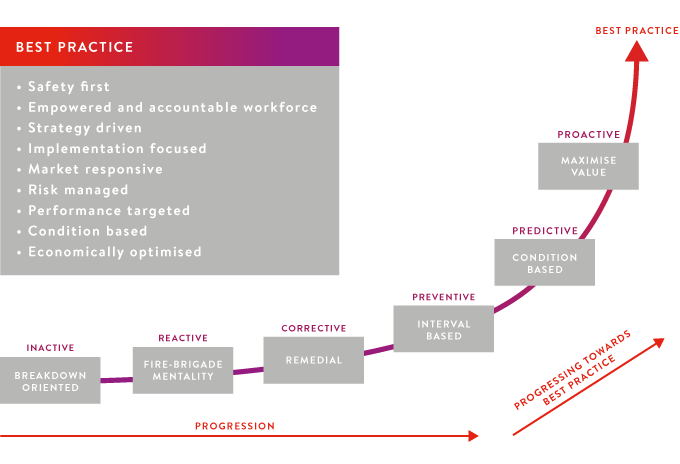

For example, the traditional indexing method, which uses a standards-based deterministic approach to review deficiencies at a dam, does not look at the consequences of those deficiencies, so it fails to inform the dam owner of the associated dam safety risk.

Using a method such as this can often lead to defensive design, cost-ineffectiveness, blind upgrade, or a generic surveillance and monitoring program across all dams, and does not greatly assist the dam owner in managing the dam safety risk. Ultimately, resources may be wasted on low-risk dams, rather than used appropriately on dams with high safety risks.

Current best practice involves a risk-based probabilistic approach and takes into account the risk of failure of each dam to prioritise dam safety works. However, for a large dam portfolio, a full detailed risk assessment for all dams can be very costly and time consuming.

So, how can an owner of a portfolio of dam assets assess safety and prioritise investment without unnecessary effort or expense? The answer is portfolio risk assessment.

How portfolio risk assessment works

A portfolio risk assessment (PRA) is often a starting point for an effective dam safety program. It is not a detailed risk assessment of any particular dam, but an affordable high-level assessment at the portfolio level that presents to the dam owner the relative risk position of all dams. This enables the dam owner to better prioritise ongoing dam safety works and develop investment strategies.

In a PRA, the safety risk posed by each dam in the portfolio is usually assessed based on historically available information as well as information gathered in a workshop-type environment by an expert team of various disciplines. Key failure modes of each dam are identified, and the risks are quantified based on available information.

The key objective as a first step is to determine the first-pass risk position of the dams, followed by identifying any information gaps, strategy and priority to close these gaps. Output from a PRA can be tailored to suit organisational requirements, with risk positions determined in terms of societal, financial and political risks.

Flow-on benefits of the PRA process

PRA has proven to be a cost-effective tool in revolutionising an effective dam safety program for many dam owners in Australia and worldwide. It provides flow-on benefits to dam owners in managing their dam assets. In particular:

- Providing high-level focus and ease of reporting: A PRA provides an overview and high-level visibility and understanding of the current risk profile of the dam assets. This allows the dam owner to better focus on key dam safety issues, and makes reporting to senior management easier.

- Understanding relative risk and prioritising action: Establishing the risk profiles of all dams in a single risk plot not only informs whether the risk position of each dam is tolerable in accordance with industry best practice and guidelines, but also allows an understanding of the risk position of each dam relative to the others. This provides an opportunity for the high safety risk dams to be targeted first for dam safety activities, and allows prioritisation of dam safety recommendations.

- Best use of resources and identifying quick wins: Understanding the relevant dam safety risk profile provides clear direction for appropriately using resources to target mitigation of key risk items rather than attempting to implement all recommended actions at once, which is often not achievable. This also provides the opportunity to identify ‘quick win’ remedial works which may be less expensive yet significantly reduce risk.

- Ensuring key documentation is in place: Understanding the relevant safety risks of the dams also obliges the dam owner to ensure key documentation is in place, particularly for high safety risk dams. This may include dam safety emergency plans, operations and maintenance manuals, dam data books, hydraulic data, dam break inundation maps, and geotechnical reports.

- Reviewing surveillance and monitoring practices: A PRA provides an opportunity to review the existing dam surveillance and monitoring practice, and adopt a cost-effective risk-based approach to target the key failure modes rather than a blanket approach. As an example, a dam with a high risk of piping may require telemetered V-notches, whereas one without a high risk of piping may only require manually read V-notches or visual observations. In addition, the inspection frequency for dams with relatively low risk positions may be reduced, freeing up resources for use on dams with high safety risk.

- Improving dam safety emergency planning: An understanding of a dam’s key failure modes and failure consequences also allows improvement of critical dam safety information (e.g. event triggers, emergency evacuation), resulting in improved emergency planning.

Updating the PRA for continuous improvement

The outcome of a PRA would inform the knowledge gaps for any particular dams, and the necessary future works and investigations required to close those gaps. Following additional investigations, studies, remedial or upgrade works as a result of the initial PRA, it is good practice to update the PRA to review the portfolio risk and adjust the dam safety management strategy to achieve continuous improvement.

This will not only help dam owners to plan and prioritise their resources appropriately, but will also demonstrate to the regulator that an effective dam safety program is being implemented, which meets compliance requirements as well as industry best practices.

If you would like to discuss how Entura can assist you with assessing your dam risks through a portfolio risk assessment program, or apply the same PRA process to other key assets, please contact Shao Ng on +61 3 6245 4141 or Phillip Ellerton on +61 439 010 172.

About the authors

Shao Ng is a Senior Civil Engineer at Entura and has more than 16 years of experience in civil and dam engineering in Australia and overseas. Shao has considerable experience in project management, dam design and construction, geotechnical investigations, inspections and surveillance reviews, emergency planning, and dam operation and maintenance, and is familiar with national and international dam safety standards, guidelines and local regulatory requirements. Shao also has extensive experience in dam PRA.

MORE THOUGHT LEADERSHIP ARTICLES

Managing risks for successful, sustainable projects

All power and water projects involve risks. The key to project success and sustainability is being able to anticipate, monitor and manage the full range of risks throughout the project lifecycle.

For power and water asset developers, sustainability is increasingly recognised as a key marker of project success and corporate reputation. Whether you’re building a hydropower station, a dam, a wind farm or a solar farm, achieving sustainability means ensuring that projects appropriately balance technical, environmental, social and economic considerations to deliver benefits and minimise risks across all these areas.

Power projects, especially in developing countries, hold great potential to contribute to the greater good by increasing prosperity and alleviating poverty, but growth must be balanced against any current and future impacts on communities or the environment. Sustainability is therefore a key concern for responsible developers, and for international financing organisations such as the Asian Development Bank, the International Finance Corporation and the World Bank.

Managing risks carefully, ethically and transparently can improve the financial and technical viability of the project, the ability to secure finance, the ability of key stakeholders to make informed decisions about the project’s future, the likelihood of community acceptance or ‘social licence to operate’, and the overall project outcomes, both now and for long-term success and sustainability.

What are the risks?

Some of the key risks to be considered throughout the design, development and operation of a power or water asset include factors such as the need or market for the project, the future energy or water demand, the best technology or design for the project, and the current and future availability of the resource.