When is the best time to invest in deeper understanding? An example from hydraulic modelling

With projects and operations, like life, knowledge is power – the power to make informed decisions and manage risk. That knowledge can be gained in different ways, at different costs, and at different stages of a project. In an era of ever-more-sophisticated digital tools, how do we decide what’s best for the project?

The understanding of when to invest in more accurate assessments is changing. Traditionally, more accurate assessments were time-consuming and costly, and left to later in a project’s life. Now, however, improved techniques and computing power make greater accuracy both possible and affordable earlier.

Here we look at the issue of when to invest in more accurate assessment tools using the example of where hydraulic modelling is a key part of projects, often in the development of water infrastructure.

As a project evolves or a system is operated, different levels of knowledge will be needed to make informed, defensible decisions. This knowledge comes from experience and from assessments specific to the project. With water modelling, these assessments vary in complexity and data requirements. They also need to be integrated into the design and approval for the development.

Investing too early in a detailed assessment can be wasteful, as there usually isn’t the data to support the approach. Even if the data is available, a high-cost investment too early in the project can be wasteful if the project is stopped or changes direction. However, investing too late in gaining a better understanding of the system and risks can lead to poor decisions and rework later, as the design may have advanced on poor assumptions for critical elements.

There is, therefore, always a balance to be found in the timing and the approach to take. If there are too many options for solutions late in the project life, there’s a danger of analysis paralysis. Knowledge gaps, too, can paralyse a project.

Increasingly sophisticated modelling is becoming more widespread and available

Understanding the behaviour of water as it moves around us, our environment and our structures is based on physics and statistics. Hydraulic modelling of water systems can range from a single line equation that takes only seconds to calculate, to complex numerical models that take months to work through.

In the past, with limited or no computing power, modelling required hand calculations. As techniques improved and computing power increased, it became possible to conduct numerical modelling with a simplified set of physics. For surface and pressurised water systems, these were called one-dimensional models. Over time, it became practical to use two-dimensional models, then limited three-dimensional models, and then full three-dimensional ‘CFD’ models. Computational fluid dynamic (CFD) models are the current state-of-the-art tools for hydraulic modelling.

CFD and physical modelling can provide such competitive advantage that there are now rules to limit the use of these tools in the racing car industry. This is because the tools are costly, so less affluent teams are disadvantaged by not having access to them. To level the playing field, the top teams are required to use less than the bottom teams.

In the world beyond racing cars, there are also limits on using state-of-the-art tools. Limits can be financial, skills, suitable input data and time. But as they become easier to use, CFD tools are finding their way into the early stages of projects.

In hydraulic modelling, not every engineer has access to a hydraulics laboratory in their office, although we all wish we did! So when there are uncertainties about how a system may work, it’s not usual to make a physical scale model and test things to get the insights needed to fill any knowledge gaps. To give engineers early insights into a system’s behaviour – which helps us find the best solution faster – we used to use simple hand calculations or one-dimensional models, but it is now becoming more common to use CFD and other advanced tools earlier in a project’s life.

Advantages of CFD in practice

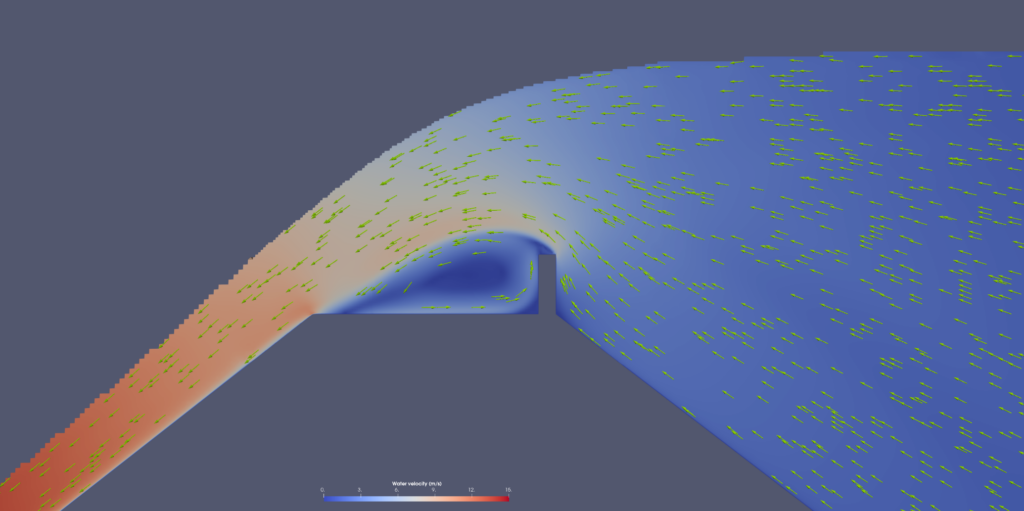

Let’s look at a real-world example: understanding the overtopping of a dam wall with an upstream parapet wall during an extreme flood.

In this project, only hand calculations were to be used to work out the relationship between water flow rate and water depth above the wall. But during the hand calculations, it wasn’t clear if the water, after flowing over the parapet wall and then flowing over the rest of the crest, would build up and affect the upstream water levels by submerging the parapet. If the parapet was submerged, this would change the hand calculation method. There was a knowledge gap.

Initially, some testing was done with a one-dimensional numerical model, but this didn’t provide much insight into the hydraulic behaviour. So a simple CFD model was quickly built based on some hand sketches. The CFD model made it clear that there was no submergence of the parapet, allowing the use of the correct hand calculations. It filled the knowledge gap.

Now that the CFD model had been built, it could also be used to help validate the key inputs to the flow–depth relationship over the dam. The CFD model therefore benefited the qualitative understanding of the system’s physical behaviour as well as providing a second approach to solving the initial problem and improving confidence in the solution.

So what’s the lesson here?

CFD wasn’t initially considered when the overall project was scoped, as CFD was traditionally considered to be too expensive. In the end, though, it was a valuable key to filling a knowledge gap and provided unplanned secondary benefits.

CFD isn’t going to be the answer for every hydraulic modelling project – but the general solution is to use the most accurate method that can be afforded as early in a project or operation as possible. There will always be a balance to be found in when to invest in accurate assessments, but the decision should be based on the contemporary lower effort to use and get results from these approaches, and the power gained by the extra knowledge they can provide.

If you’d like to talk with Entura about your water or dam project, contact Richard Herweynen.

About the author

Dr Colin Terry is a civil engineer at Entura with three decades of experience in Australia and New Zealand. His experience includes modelling, planning, design and construction support. He has worked on multidisciplinary projects across various parts of the water cycle including catchment management, water supply, hydropower, land development, transport, and water quality in natural systems – with a focus on surface and piped water.

MORE THOUGHT LEADERSHIP ARTICLES

Engineering – by humans, for humans

When engineers think about the future, do we get so engrossed in the complex technical problems that we don’t attend enough to the human angle?

Engineers have a reputation, whether rightly or wrongly, for being poor communicators, working obsessively and in isolation, and focusing on the immediate goal rather than its impacts on communities. Often, clichés have a basis in truth. If we are going to shift perceptions, we need to start by thinking about the way we work and the leadership we show to the next generation of engineers.

There’s no way we can predict the major developments, challenges or solutions of the next five or six generations of engineering careers. What we should focus on is what we can do right now to lead change in our profession and our communities – and I think the keys are communication, collaboration and community.

Communication

I recently listened to a podcast in which two energy market experts talked with a power system engineer. They discussed all sorts of technical matters relating to frequency and voltage control. I love those topics, but this conversation was limited and uninspiring because the participants simply didn’t have a common language or understanding.

We need to learn to communicate in ways that a variety of people can understand. That will mean better conversations with the people who can help our work have greater impact, and it will help our communities to appreciate the importance of our work in their lives.

It’s too easy for us as a profession to sit at our desks or stand under our hard hats and luxuriate in how clever we are, and then bemoan how so many people have no idea what we do and don’t value our work.

When things that involve engineers go wrong, a flurry of opinions erupts. Failures such as the blackout in South Australia, or the cladding issues at the Grenfell Towers, or issues with airlines or bridges or dams all lead to our communities questioning and debating engineering practice. Engineers tend to try to stay out of this rough and tumble for fear of being misrepresented. Yet maybe it’s better that we do engage where we can, since being misrepresented on a small issue is better than allowing a groundswell of misguided public opinion due to a lack of understanding of engineering principles.

We need to try to better explain our work and find simple ways to convey the complexities of the decisions that we make.

Collaboration

The world is far more complex now than it was a century ago – but it is impossible to imagine what level and pace of change future generations will experience. If we want to transform our world or help build a better future, we can’t do it by ourselves.

Engineering no longer operates in isolation, if it ever did. We must collaborate across the engineering team and across other professional disciplines to achieve truly effective development for our communities. Sometimes we may need to focus a little less on technical delivery as a primary outcome, and increase our recognition of the value gained by engaging successfully with the communities on whom the project relies for success.

Collaboration makes our work more effective, and exposes us to a wider range of inputs and values that we can incorporate into our designs and processes. Engineering can be a leader but it can also be a facilitator for better outcomes when we draw on, listen to and learn from the other experts involved in other aspects of our projects.

Community

Engineering work almost always benefits more people than merely the one who pays the bill. Much of my work is in connecting wind farms and solar farms to the grid. Mostly my work is paid for by the owner of the farm, and while it delivers direct benefits to the owner through return on investment, it also affects everyone connected to the nearby network. It affects the network service provider and market operator, it pays salaries, and it supplies the clean energy that helps the country reduce emissions and meet its international targets. In other words, my work, which may seem intangible, has tangible effects in the real world.

If we agree that our labours produce real impacts, we need to take better care to fully consider the wider consequences of our work, which often has the potential to cause ‘collateral damage’. We can’t build a road or a wind farm without changing the landscape. When we build a machine, it uses energy and may emit pollutants; and it reduces reliance on manual labour, which may put someone out of a job. There may be a risk to lives, livelihoods or the environment if something goes wrong.

Do we always make decisions about these matters with the community front of mind, or do we place our clients on the higher pedestal? This is a tricky area and I’m not espousing a puritanical approach. However, if we knew in 1919 what we know now about lead poisoning, acid rain, greenhouse gases, scarcity and general sustainability principles, what different choices could have been made?

In a time of automation, we need to think about benefits and risks and how they affect our communities. On one occasion early in my career, I designed a controller to turn on and off a couple of compressors at a power station. I wrote some code to balance the run hours. A few months after the new system was commissioned, I asked one of the operators how the system was going, in terms of the run hours management, and he said ‘you’ve done me out of a job’. I hope he was joking. The task he’d been doing wasn’t particularly important, but there was value in having a person who was in tune with the equipment to take care of it, and there was also value in giving that person dignity through work.

My point is that we must keep our communities foremost in our minds as we go about our work. It’s not just about what we produce. It is the way we work and the people we choose to work with and for. Our influence on the development of the next generation of engineers perhaps has more impact on communities than our actual work outputs.

Through communication, collaboration and community, engineering can be both ‘more human’ and ‘for humans’.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Should you upgrade or replace your SCADA system – which option is best?

New functionality, increased visibility of plant, greater security … SCADA systems are rapidly advancing. So, should you stick with what you have, upgrade some components, or embrace a complete replacement?

This is an important and complex question for power and water owners, operators and utilities to consider. As SCADA systems become obsolete, outdated or unsupported, a range of risks come into play – so you need to carefully weigh up your options in terms of benefits and costs. Choosing the wrong system could affect your business operations or your future upgrade options.

The first step in your decision making must be to explore and understand the available SCADA options in the context of your business strategy. SCADA systems are too great an investment and too important for ad hoc or hasty decisions. This is the time for a clear-headed view of your business goals over the long term, and how your choice of action will support achieving the outcomes you seek.

In the context of this strategic view, you now need to objectively assess the value and relevance of your existing SCADA system and identify if the entire system needs to be replaced or whether some devices or software can be reused. Let’s look at ten key considerations in the decision:

1 System architecture: When you introduce new equipment or systems, your system architecture is likely to be affected. Changes to system architecture can affect the reliability or operation of your plant. A partial upgrade may or may not significantly affect the system architecture – it really depends on the changes made. The system architecture following a total system replacement may be dictated by the vendor you select, so keep this in mind when selecting vendors. Does this system suit your business or the vendor supplying it? Also make sure that your system architecture is thoroughly and accurately detailed, and keep your SCADA strategy in your back pocket for reference throughout your journey.

2 Reliability: If parts of your existing SCADA system are reused, will this impact the reliability of the new system? Depending on the age and condition, there may be a greater risk of unreliability with the reuse or partial upgrade of components vs a complete replacement. The key here is to ensure the right people can evaluate the system and components with the knowledge of how to overcome these challenges. To minimise the likelihood of equipment failures and achieve the best outcome in terms of reliability, sometimes the best option is to carry out a full replacement.

3 Costs: A complete SCADA replacement is a costly exercise but at some point you can’t keep delaying a major outlay by only fixing the immediate concerns. Just like the increasing costs of servicing and replacing parts on an ageing car, at some point the ongoing incremental costs may no longer be worth it, and you may have to consider a total replacement. Regardless of the option you choose, having the expertise to make this call and carefully planning/estimating the work will reduce the risks of unexpected costs. The key decision-makers in your business will need to explore how to balance the initial outlay against the potential cost savings to be achieved through limiting the duration of system outages and attaining a longer whole-of-system life.

4 Functionality: The range of SCADA devices is extensive. A simple device may be cheap but it may not have been designed and built to meet high performance and reliability requirements, and it may not have the management functionality or redundancy capability you need. Your choice of functionality is partly a matter of initial cost, but you also need to carefully consider how much you need the extra functionality, what savings that functionality can offer over the longer term, your tolerance for failure, and the cost of failure to your business.

5 Compatibility and standardisation: When devices and software are upgraded or replaced, compatibility challenges and limitations may arise when interfacing with existing system components. Carefully assess your existing system and verify that the specifications and functionality of the proposed equipment are sufficient. Also consider the benefits of standardisation of system components. Standardising equipment throughout your site or sites can greatly speed up fault diagnosis, reduce design costs, minimise the need for more training, and lower your spares requirements.

6 Human interface: When your SCADA system upgrade includes the Human Machine Interface (HMI), identify which parts of your HMI screens work well and which don’t, and consider the option of designing your screens from the ground up. Avoid cluttered interfaces and consider dashboards for a single, easily interpreted overview of parts of your plant or station. If you’re changing your screen navigation and displays, you will need to allow for additional training to ensure your people are confident and capable of operating and monitoring the new system. Upgrading your HMI with a newer version of the software may be the best way forward depending on your requirements. This may require less financial outlay in terms of licensing, engineering and training costs and may be less intrusive on your system. If your system assessment warrants a complete replacement, you should carefully evaluate alternative HMI solutions to achieve the right functionality, product roadmap and financial outlay.

7 Security: How will upgrading parts of your SCADA system affect overall system security? SCADA security has evolved dramatically in recent years. Managing today’s SCADA systems can be a challenge without the right security precautions in place. Because SCADA system attacks exploit both cyber and physical vulnerabilities, it is critical to align cybersecurity measures accordingly. System security challenges of partial upgrades may not be able to be overcome depending on the age and type of equipment. So implementing a new system with the latest security technology is becoming the best option for limiting your exposure to attack.

8 Future-proofing: Just as you need to plan your pathway to implementation, you also need to keep your eyes on the future. If you’re upgrading old components, factor in the end-of-life date for support. If a device becomes obsolete, you’ll need a changeover plan to limit the impact on the system. Even if your upgrades give you the functionality you need now, what will you need in the future? Transitioning to a new SCADA system will introduce new functionality that is likely to increase the effectiveness of your operations and maintenance, and give you the opportunity to embrace the potential of big data, machine learning and artificial intelligence.

9 Pathway to implementation: Whatever the journey you’re on, you need to think about the path ahead so that you don’t encounter unexpected obstacles such as hidden costs or schedule blow-outs. Identify what upgrading may mean for your existing system and what limitations your system may have. Will your historical data need to be migrated to your new system, and, if so, how will this need to be handled? Upgrading to a new version of your SCADA system may be the easiest solution, but if you decide you need a new system, you’ll need to carefully handle your historical data and massage the data into the correct format for your new system.

10 Testing and commissioning: During the design process, contemplate how your system will be implemented and commissioned. Commissioning new equipment instead of reusing old technology may reduce the risk of incompatibilities and unusual operations. It may also reduce the time required for testing due to thorough system factory acceptance tests. Retesting of old equipment may have considerable impacts on your plant or station operations. The testing process and sequence is another key item that can make or break your system implementation. Assess how your system will behave during the cutover process and how the correct sequence or test process could reduce or eliminate your plant or station downtime.

Deciding whether to upgrade or completely replace your SCADA system is very much a case-by-case situation – but you’ll find the right solution if you consider all the key issues carefully and have your decision assessed by the right people and carried out objectively.

If you would like to discuss your SCADA challenges and opportunities, contact James Devine on +61 417 389 713, Patrick Pease or Shekhar Prince on +61 412 402 110.

About the author

James Devine is Entura’s Specialist SCADA Engineer and has over sixteen years’ experience in SCADA and automation design, implementation, commissioning and project management. James has worked with clients both within Australia and overseas on a diverse range of systems including solar and wind farm SCADA systems, substation SCADA and automation systems, hydro and gas generation SCADA systems, water and wastewater SCADA systems, and wide-area SCADA and telemetry systems. James has considerable experience reviewing many clients’ existing systems and proposed designs, as well as providing specialist technical advice for single-site SCADA and automation systems through to wide-area SCADA systems and master stations.

MORE THOUGHT LEADERSHIP ARTICLES

Maximising the benefits of GIS for better business decisions

‘Location, location, location!’ It’s a familiar catch-phrase in the real estate industry, but it’s just as relevant in the power and water sector. Wherever there’s location-related data, a geographic information system will guide better business decisions.

Mobile devices and apps are increasingly using location-based data collected via satellites, drones, LIDAR and other rapidly developing sensing and data capture technologies. With these advances, we are able to find relevant information more quickly and draw on that information to make informed decisions. We’re seeing this proliferate in everyday life through apps that help us navigate, find services and products, and make decisions ranging from the trivial to the profound.

Developers and managers of power and water infrastructure projects who embrace GIS (geographic information systems) stand to gain benefits on an even greater scale. Gathering high-quality spatial information and analysing it to guide business decisions will certainly improve productivity and the bottom line.

Better decisions are the necessary foundation for increased revenue, lower costs, greater efficiency and productivity, and reduced risks. So, if the technology is available and there’s so much to gain, why isn’t GIS being as widely used in the power and water sector as it could be? What may be holding businesses back from fully embracing this powerful and dynamic technology?

Do we really need to use GIS for this project?

All power and water projects involve location – from finding an optimum site for your project, to analysing combinations of spatial data to make the best management decisions or to predict events. Whenever you ask a ‘where?’ question, GIS can help. Where is the asset best located? Where are the constraints or hazards? Where are the reports of previous work done in this area? Where are the customers or opportunities?

In other words, rather than asking whether GIS is needed on a project, consider making GIS a default for every project. The real question should be “how can we maximise the benefits of using spatial data and GIS on this project?” GIS can offer business benefits far beyond the most commonly understood use: making a map.

Data capture in the field can now be streamlined – gone are the days of capturing field data with pen and paper. Users can now collect data on mobile devices, sync to databases while in the field, share data, and generate their own maps, queries and reports. Embracing these advances will save time and enable faster and better decisions.

As well as providing valuable business insights, spatial analysis and location intelligence can greatly improve communication and knowledge sharing – within project teams, with the broader business, and with the community and stakeholders – via tools such as web maps and apps, visual analysis and 3D modelling.

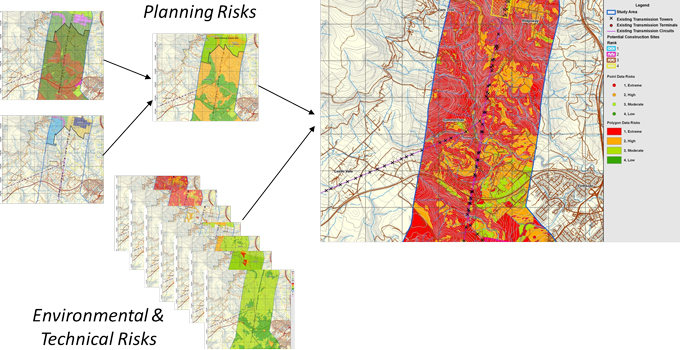

One of the most important applications is the simultaneous analysis of different spatial datasets to provide the best solutions or choices between alternative options, locations, objects and so on. This process is better known as multi-criteria analysis (MCA) and it can be used for many applications.

For example, MCA can be used to find the optimum site for your project taking into account a range of values such as local geology, threatened species, resource availability, land use and terrain, planning restrictions, communities and demographics. Using MCA, you can establish areas of best fit for your project based on thematic overviews of areas of constraint, cost of construction, access and transportation routes.

Risks such as bushfire, weeds, threatened species, pollution sources, landslides and erosion can also be more easily and fully understood, supporting your ongoing site management of such issues.

GIS also links with document management, asset management, business intelligence and enterprise resource planning (ERP) systems. It can act as a portal, creating a central point of easy access, pulling together information and making it available on one of the simplest forms to interpret – a map.

Of course GIS is not the answer to everything, and it is not a standalone platform. However, there’s much it can offer across many different business activities, working together with other business systems.

What about the costs?

The return on investment of using GIS should be positive if it is used appropriately. For site selection of power and water projects, using GIS is a no-brainer. For example, using GIS to find the best site for a wind farm – locating the best winds, minimal constraints, good proximity to existing infrastructure and appropriate land use – will obviously result in vastly greater returns than siting the wind farm in an inferior location.

Some examples may be less immediately apparent, but equally valuable – for example, using GIS to increase efficiencies in everyday workflows. If your workers are taking an extra half hour every time they need to find previous work completed in an area, this time can add up quickly. Or perhaps they can’t find previous information, so work is re-done unnecessarily. These costs will keep adding up. Instead you could use a GIS web map to locate all your previous reports and projects, so that a simple click on a map finds the files and saves hours (if not days) of time.

Do we need specialist software or skillsets?

With most things, you do need specialised skillsets and software to get good results, and of course bad data in equals bad data out. Users of GIS do need to understand and assess the spatial data needs in each application.

You could undertake some GIS work yourself using free or open-source software. However, be aware of the risks of using data or tools that aren’t fit for purpose. Just because you know how to use Microsoft Word, doesn’t mean you could write a detailed report outside your area of expertise!

We have seen cases where coarse-resolution data has been used to infer finer project details and costs, resulting in poor decisions. We have also seen inexperienced operators make invalid assumptions. To get the best results, you need to be sure that you’re using the technology wisely.

If you are engaging a power, water or environmental consultant on a project, they are likely to have access to GIS capability; however, GIS is still often underutilised. When deciding who to engage on your project, ask your consultant how they will maximise the benefits of GIS to produce better outcomes for your project.

To discuss how Entura can help you harness the potential of GIS to improve your power and water project decisions and outcomes, contact Stephen Thomas on +61 3 6245 4511, Patrick Pease or Phillip Ellerton on +61 439 010 172.

About the authors

Stephen Thomas is Team Leader and Senior Technical Officer with Entura, specialising in geographic information systems, 3D visualisation and CAD software. Steve has over twenty-six years of technical experience and specialises in environmental assessments and approvals for engineering surveys and property. He has created 3D models and animations of proposed developments including wind farms, urban landscapes and city frameworks. Steve’s work on the Hobart Waterfront 3D model won an international award in geospatial modelling.

MORE THOUGHT LEADERSHIP ARTICLES

Maximising irrigation certainty and security with the right data

Perhaps the greatest gift to any agricultural region is increased certainty of reliable, available water.

Agricultural communities thrive when they can depend on irrigation. Confidence in a reliable supply of irrigation water is critical for increasing agricultural productivity, diversifying businesses, creating new opportunities for investment, and strengthening rural and regional communities.

To be successful, an irrigation scheme must deliver adequate and secure water to users when required. In an increasingly volatile climate, secure water supplies can only be guaranteed through careful management and through well-informed planning and decision-making.

But how can irrigation managers decrease the risks to their storages and supply systems, and increase the effectiveness of their plans and decisions?

The answer lies in the quality of the data and analysis on which their decision-making depends. Irrigation storages and systems are huge investments, and getting the best out of them should also involve some targeted investment in a state-of-the-art data management and decision-support system.

The key components of a water management system

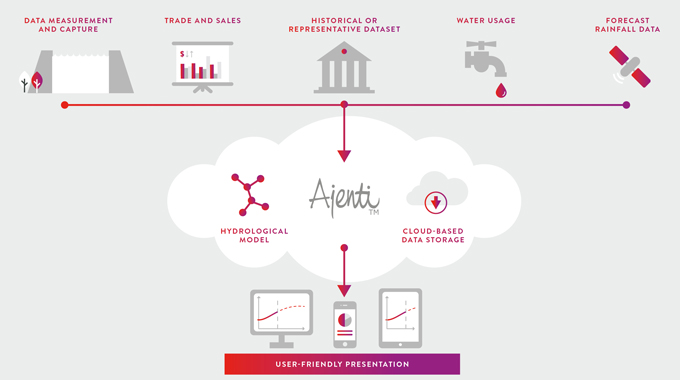

Water managers considering implementing a water management system should look for the following key components and features:

- accurate measurement and data capture from well-maintained field sensors and telemetry

(including automated quality checking to detect major data errors or missing data) - historical data, or a representative dataset, that shows inflow patterns and generates stochastic inflow data

- an optimal hydrological model of the catchment and storage that models inflows and water levels and how the storage varies (models should be reviewed periodically with the most recent data to ensure that the parameters are still optimal and that forecasts are performing as expected)

- forecast rainfall data for the short term, directly incorporated into the system from the relevant meteorological forecasting agency

- user-friendly customisable dashboards or apps that allow rapid oversight and interpretation of the state of the system and short-term forecasts

- cloud-based storage of information in a robust database, providing a reliable, fully hosted and maintained service, continuously operated and improved by experts, without the need to invest in hardware or directly employ specialist technical expertise.

In combination, these features provide the foundations for a successful water management system, and a worthy investment in water security, providing resilience to climate variability and shifts.

An award-winning integrated water management system in operation

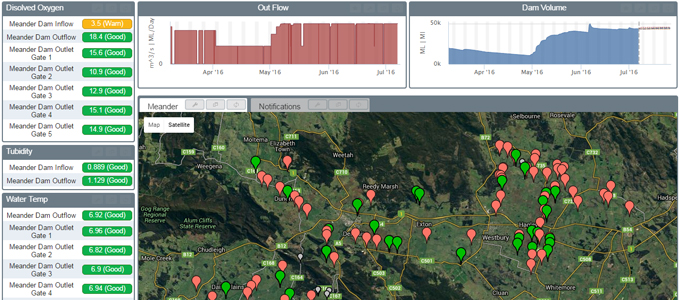

Tasmanian Irrigation engaged Entura to design, develop and deliver an integrated water management system for Meander Dam in northern Tasmania. This dam provides irrigation water to an agricultural area with further development potential, regulates seasonal environmental flows, and also generates hydropower to help offset operational costs.

Entura’s water management system delivers a full picture of the dam’s current status and possible short- and long-term water storage and power output scenarios, providing reliable information to help deliver irrigation certainty while maximising hydropower generation and ensuring dam safety.

The system harnesses real-time rainfall and flow monitoring data captured by a network of catchment telemetry. This information is combined with a hydrological model of the catchment and weather forecasts from the Bureau of Meteorology to produce short-term (7 day) and long-term (up to a year) forecasts and simulations, showing a range of possible scenarios and probabilities for water storage and power output.

These forecasts and simulations offer the necessary insights to understand the immediate and longer term implications of management actions, and to make operational decisions based on different risk profiles.

The dam’s current status and possible future scenarios are presented via a user-friendly dashboard interface. The data can be delivered in whatever format or platform the client desires, and is able to integrate with other applications or have other features added to it.

Real-time information from water meters on pumps within the irrigation area is also brought into the system to give the operator a complete water balance in the area fed by the dam.

Because Entura’s solution is cloud based, it is robust, ensures continuous effective operation and maintenance, and allows very high reliability (99.995% uptime) to be achieved for reasonable cost.

Entura backs-up the system with 24/7 expert support to keep it performing at an optimal level. This is a cost-effective and secure way for an irrigator to access the expertise behind a specialist best-practice system, avoiding the need to purchase and maintain expensive hardware, reducing the requirement for any specialist technical capacity on staff, and eliminating the risk of system error or outage.

Benefits of the water management system

Certainty of water supply

In the region dependent on Meander Dam, Entura’s system contributes to Tasmanian Irrigation’s ability to deliver certainty of water supply, which is crucial for increasing agricultural output and productivity and maintaining resilience. Water security delivers greater confidence for investment in these individual farms and high-value crops, but also increases the confidence and development of the region as a whole, strengthening the community through increased employment and economic activity.

In the 2015–16 irrigation season the region experienced below-average rainfall that resulted in reduced inflows into Meander Dam and increased demand for water supply to irrigators. With the aid of the integrated water management system, Tasmanian Irrigation was able to match demand from predicted storage levels, fulfilling irrigator expectations and retaining sufficient storage capacity to be able to extend water delivery for an additional month. This ensured that irrigators were able to finish final crops and also maintain pasture growth for livestock and dairy activities.

Maximum hydropower generation

The water management system also allows optimisation of the dam operating rules to get the most out of the dam’s integrated hydropower facility, while still maintaining security of irrigation supply. The system enabled Tasmanian Irrigation to maximise hydropower generation after the end of the 2015–16 irrigation season, as the predicted rainfall allowed increased generation which also minimised the potential for the dam to spill.

Dam safety in severe weather

A further benefit of the system is improved decision-making regarding water resources and dam management during severe weather. This offers direct benefit to the health and safety of the local community, the local environment and the productivity of the local economy through reducing drought-related costs and impacts (e.g. loss of farm productivity, mental health impacts, maintenance of minimum environmental flows) and mitigating flood risks and impacts (e.g. maintaining dam safety, minimising spill, and managing downstream safety and environmental impacts).

The Meander Dam integrated water management system was the winner of the Australian Engineering Excellence Awards Tasmania 2016 in the category ‘Control Systems, Networks, Information Processing and Telecommunications’.

Entura has extensive experience supporting water managers to make the best use of their storages for multiple water uses (whether for hydropower, irrigation, environmental flows, or domestic or industrial purposes), and in creating innovative decision-support systems to manage water risks through reliable and accessible data.

To discuss how Entura can support you to increase the efficiency and security of your water storages through the right operational decisions, please contact David Fuller on +61 438 559 763 or Phillip Ellerton on +61 439 010 172.

About the authors

David Fuller is Entura’s Principal Consultant, Water Management and Technology. David has more than 30 years’ experience working on water management projects across Australia and overseas. He has successfully delivered projects for local, regional, state and national government agencies; and for private sector clients in the irrigation, coal seam gas, mining and energy generation sectors. David specialises in engineering and environmental hydrology, and water management. He also has expertise in data management systems, statistics, hydraulics, water quality, ecological risk assessment and natural resource economics.

MORE THOUGHT LEADERSHIP ARTICLES

Do your water assets hold unexplored potential?

The right data and analysis could unearth new strategies to get more from your infrastructure, and that’s too good an opportunity to miss.

The most valuable, cost-effective and sustainable power and water infrastructure is that which is thoroughly explored, properly understood, and used to its fullest capacity. This means analysing project data to design and develop solutions that are practical and meet the particular objectives of the project, while always keeping an eye open for innovative solutions that can get even more value from the investment by unleashing its full potential.

When comprehensive and accurate data is cleverly analysed to uncover new opportunities from existing infrastructure, you’ve got a solid foundation for the best business decisions.

Getting power from water assets

Water asset owners can get the very best out of their infrastructure by assessing their existing portfolio for the potential to incorporate renewable electricity generation from technologies such as wind, solar or hydro. In this article, I look at some examples of one possible solution: incorporating mini-hydropower systems into existing water supply infrastructure in cities.

![]()

Water supply networks may offer valuable opportunities to generate renewable energy through mini-hydropower generation. High pressure in water supply pipelines is usually dispersed by pressure-reducing valves or break-pressure tanks. If these devices are replaced by mini-hydropower turbines, the pressure can instead be used to generate clean, renewable electricity, which can help offset costs and reduce greenhouse gas emissions, benefiting a business’s bottom line and carbon budget.

Although the output of individual mini-hydropower systems may be relatively small, if all feasible potential sites within a water supply network are identified and developed, the combined power output can be significant, offering big wins for water managers without compromising water supply to customers. So assessing mini-hydro potential throughout a water supply system can be a rich, and often untapped, opportunity to reap more from existing infrastructure.

Although mini-hydro opportunities may look like a clear win, each water supply system is unique, and there’s no one-size-fits-all solution. Confidence is needed that the project is designed to best capitalise on the particular site characteristics, that the project can generate the right amount of both power and revenue, and that all the project assumptions are based on reliable data. Getting the right data, good analysis and tailored design are therefore crucial for confident investment in the infrastructure and for project success.

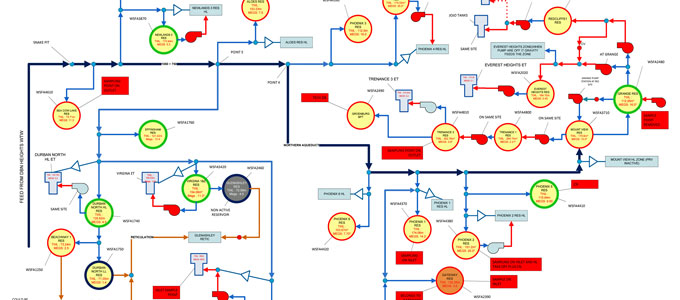

Tapping the full potential of Durban’s water supply

Entura’s study of the potential to generate hydropower from the existing water supply networks in Durban, South Africa, offers a methodology for assessing and adopting similar solutions worldwide, and provides an example of how the right data and analysis contributes to project and business success.

To assess the potential for eThekwini (Durban) Water and Sanitation to include mini-hydro systems of between 50 kW and 1 MW into Durban’s existing water supply infrastructure, Entura developed a screening process to identify viable and profitable opportunities.

The first step in the process of assessing hydropower potential in the water supply network was gathering, modelling and calibrating a broad range of data about the water supply system. Generally, existing water supply infrastructure collects pressure data, as this is used for monitoring and controlling the supply network. However, to adequately assess hydropower potential, data was also needed on the water supply system’s flows, pipe sizes, and operating regime. Once all the necessary information was collated, hydropower potential was assessed by calculating flow, head and installed capacity at each site. Next, screening criteria were applied to identify sites with the greatest potential.

A range of factors was considered in assessing the potential of existing water infrastructure assets: load centres, power generation potential, sustainability concerns, network issues, technical and construction challenges, risk assessment and cost-benefit analysis.

The project particularly considered where hydropower could directly supply pumps or be directly connected into the grid, to maximise the value and uptake of the renewable generation. Sites were identified where mini-hydro technology could be supplied in modular units (on a fixed bedframe, or in a standard shipping container) to reduce the time and cost of more traditional construction.

Of more than 150 potential sites, Entura’s screening process returned a list of 47 sites worthy of further investigation, offering a combined installed capacity of 10 MW. More work still needs to be done to fully determine the number of economically feasible sites in the eThekwini water supply network. Of the 47 shortlisted sites, eThekwini Water and Sanitation expects that more than 10 sites will be developed.

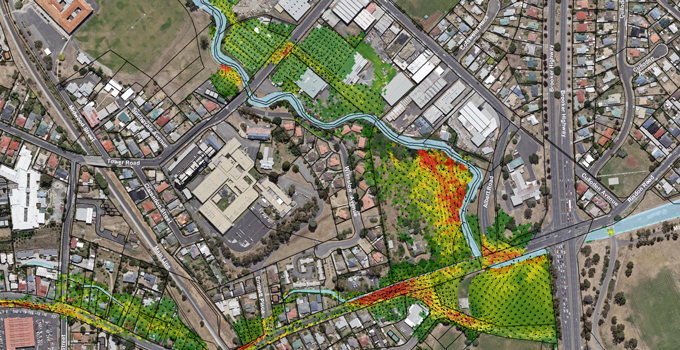

Getting more out of Melbourne’s water system

Melbourne Water, an Australian water utility, had recognised mini-hydro’s potential to recover surplus hydraulic energy, generate greenhouse reduction benefits and provide financial returns, without requiring any changes to the operation of the water supply system; without affecting flow, pressure or water quality to customers; and without any increase in operational risk.

Entura assessed the feasibility of each of the six schemes on Melbourne Water’s system to provide the necessary data to determine that the schemes were technically and economically viable. These schemes progressed to implementation and were successfully constructed to Entura’s designs, adding 6.75MW of new clean energy generation into the local electricity distribution network without disrupting water supplies.

![]()

These mini-hydro schemes have significantly contributed to Melbourne Water’s movements towards carbon neutrality and helped it to offset its costs, and Melbourne Water is continuing to explore further opportunities to identify and extract the full rewards from its water infrastructure.

To discuss how Entura can help you uncover and exploit the full potential of your water assets, contact Nick West on +61 408 952 315, Phillip Ellerton on +61 439 010 172 or Shekhar Prince on +61 412 402 110.

About the author

Nick West is a civil engineer with 15 years’ experience, primarily in the fields of hydraulics and hydropower. Nick’s skills range from the technical analysis of the layout of hydropower projects to the preparation of contractual project documents and computational hydraulic modelling. Nick’s involvement in the recently completed Neusberg Hydro Electric Project extended from the first visit to the site where the project layout was conceived right through the development of the project and now into troubleshooting operational issues. As a project manager, Nick has successfully completed projects ranging from hydraulic design for small residential developments to the feasibility study of a cascade of four large hydroelectric projects in Malaysia.

MORE THOUGHT LEADERSHIP ARTICLES

Smarter data management rewards power and water operations

For power and water businesses, information is one of the most valuable assets. But good data you can’t find or use is a wasted opportunity.

Data is most useful when it is integrated and accessible, so that it can help a business make smarter decisions about how to best operate and maintain complex assets for maximum efficiency and return on investment.

Water managers and power generators typically collect large amounts of information to help them make decisions. Organisations are also increasingly using sophisticated monitoring and communications technologies to make assets ‘visible’ around the clock and remotely, to achieve better results with less worker time, effort and travel.

However, these valuable sources of information are usually stored in disparate systems or repositories, including SCADA, telemetry, GIS, document repositories, field notes and CCTV systems. As well, these systems often predate the Internet, and, as a result, may not be easily or securely accessed, and may be confined to office or station networks.

For this asset data to yield insights and optimise operations, the different sources of information need to be unified and displayed in meaningful ways that add value to the basic data.

Managing data to maximise water flow for hydropower generation

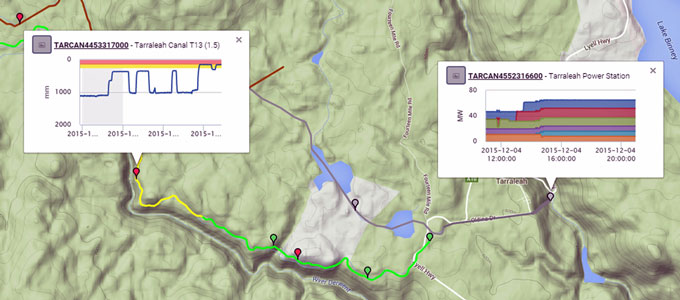

Entura worked with its parent company Hydro Tasmania, Australia’s largest water manager and producer of renewable energy, to tackle this data challenge in relation to the canal system that brings water to Tarraleah, a hydropower station in the central highlands of Tasmania.

Managing the flow of water into the canal system is critical for maximising the available water to Tarraleah (and hence its capacity to generate valuable electricity), as well as maintaining the station’s safety and reliability.

As a canal is not a natural waterway, one might assume that keeping it running at the highest possible water level should be easy and predicable. However, the combined effects of uncontrolled inflows, automatic pumps, and unwanted plant growth in the canals make management of water levels in these canals much more complex.

Water levels can rise unexpectedly, spilling valuable water and potentially damaging infrastructure such as roadways or even the canals themselves.

To achieve more efficient and remote management of the water flow into the Tarraleah canal system, Hydro Tasmania aimed to embrace and integrate the latest technology to monitor the live condition of the canals through SCADA, telemetry and manually read data, and make this data more readily available via a single online interface.

The first step towards this goal was understanding the existing limitations of the available information and access to data. GIS provided an excellent overview of the canal system, and was relatively straightforward to use and access via a web browser, but it did not contain any real-time or historical time series information.

The telemetry system contained some information about monitoring sites, but very little about how the data related to other aspects of the system. Also, it could only be accessed from specific computers, and required training and expert knowledge to use. The SCADA system recorded its data to an interface which provided little information about site relativity or purpose, and the interface could only be used within the power station. Some of the more valuable information about the canal system was kept by engineers in isolated document repositories.

These issues acted as barriers to understanding the canal system, hindered the ability to explain it to other people, and made it difficult to find the appropriate data for analysis.

Developing a data solution

To make Tarraleah’s canal information more useful, a data solution had to be interoperable, real-time, secure, synchronised, spatially integrated, contextualised and meaningful, and cost-effective.

| interoperable | To achieve interoperability across multiple devices and operating systems, a web-based platform provided the most suitable and cost-effective solution. A standards-based approach was used in developing the interface, so that the resulting system was able to work seamlessly across devices, with data accessible through a single user interface on laptops, tablets and smart phones. |

|

real-time

|

‘Seeing’ the status of infrastructure in real-time called for the data being displayed to be as current as possible, with each point in the chain of data transfer eliminating any unnecessary latency. Performance between the source of the data and the server was streamlined, and latency between the server and the user device was minimised through WebSockets, a new technology using highly efficient two-way binary connections to transfer data with minimal overhead. This allowed an extremely efficient flow of data (less than 500 ms). |

| secure | It was essential that the design did not introduce security risks for the sake of efficiency. To maximise efficiency and minimise security risks, all data was collected from the source and pushed over encrypted links via proxy servers to a cloud server, where it could then be pushed to the waiting client devices. The cloud provider chosen to store the data was considered one of the more secure in Australia, and one of only a few to feature the highest security certifications required by large utilities and mining companies. The software architecture used best-practice methodologies to isolate the data and keep it secure. |

| synchronised | With data stored in a variety of different systems, and ranging from real-time to historical, multiple systems required synchronisation, which was achieved via a configurable ‘data bridge’ solution using plug-in architecture. |

| spatially integrated | The system collated large amounts of spatial information, from maps or GIS or other business systems, into simple reusable formats for display. This required a versatile web-based mapping platform, with the ability to represent the canal, indicate its water level, represent and describe work orders, and link to other internal systems and information to allow easy visualisation of that item of work. |

| contextualised and meaningful (via metadata) |

With thousands of different data sources under management, the system needed to classify data so that users of the system could easily locate data relevant to their requirements. Meta tree structures were used to classify all the data, allowing hierarchical associations. Each data source was tagged with multiple different types of metadata (such as state, scheme, power station, data owner, site type, status), and grouping structures allowed nested grouping of information, such that users could filter information specific to their needs. The metadata structures could also be used to build dynamic security- sensitive dashboards of data, including any new data added to the system tagged with the appropriate information. This saves the time needed to configure dashboards, and makes sure all relevant data is available to the people that need access to it. |

| cost-effective | The system used technology that Entura had already developed to deliver similar projects for other clients, minimising the need to develop new software. The system itself is ‘cloud’-based, allowing the cost of the infrastructure to be shared among a larger group of customers. |

Simplifying access to data is helping Hydro Tasmania maximise the day-to-day operational efficiency of the Tarraleah canals, make better long-term operational decisions, and reap enhanced returns on investment. Employees now have a live view of the canals on iPads or tablets, enabling them to ‘tune’ the canals for maximum efficiency.

Similar solutions to those developed for this project can be used by power and water asset owners and managers to solve a range of data management challenges, including monitoring remote power stations, forecasting floods, and managing irrigation storages.

When we overcome barriers such as restrictive technologies and lack of metadata, we can make the most of our data. Interlinking multiple sources of information and displaying the results meaningfully leads to smarter decision-making and greater insights into how to operate our assets for maximum efficiency and value.

To discuss how Entura can help you manage your data to reap greater operational rewards, contact David Fuller on +61 438 559 763, Phillip Ellerton on +61 439 010 172 or Patrick Pease.

MORE THOUGHT LEADERSHIP ARTICLES

Getting the bigger picture from your data

Like having a pile of puzzle pieces but no box, are you drowning in data but unsure what it is telling you about your power and water assets?

Gathering and interpreting complex data to detect emerging problems is an important aspect of asset safety worldwide. Avenues for collecting data are becoming more sophisticated and accessible and less expensive. We routinely gather data and explore data gaps, data quality and data processing, but how often do we rethink the fundamentals of presenting and communicating data?

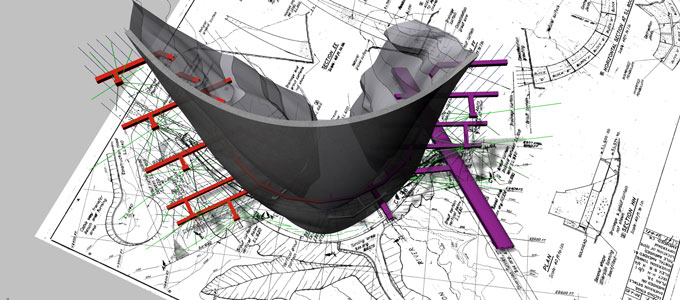

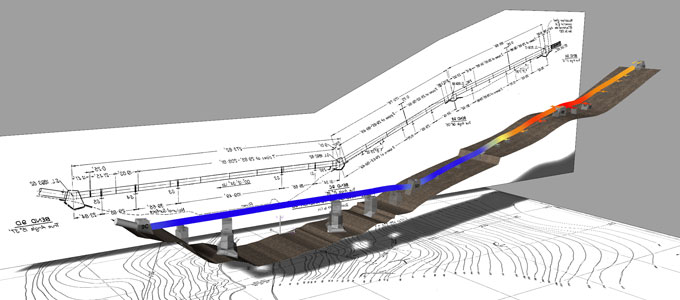

For data to be useful, it has to help us diagnose issues and design solutions to keep our assets, our operators, and the public, safe. To do this, it must be understood. Traditionally we have used 2D methods to present data, but forming a picture of an asset from 2D information is very time consuming, often requiring site visits and hours exploring drawings, drill logs and construction photos to understand the complexities of the asset’s design and construction.

Because we have evolved in a 3D world and our senses have evolved to match, the human brain has significant and sophisticated resources dedicated to visual processing and understanding objects in three dimensions. This makes 3D models a naturally efficient medium for rapidly displaying, interpreting and communicating complex information relating to our assets.

Bringing data to life

With advances in technology, we are now able to quickly convert raw data to build 3D models from 2D drawings, and also to animate data in 3D to show change and movement over time. In 3D, assets can be quickly visualised and explored digitally from any angle. This spatial representation allows us to see important things that may otherwise be hidden, or not stand out, in the context of the overall design and layout of an asset.

Features normally hidden can be drawn into a 3D model, such as internal layouts or features under the ground. These can all be independently switched on and off, so that elements critical to the analysis can be considered individually, or contextually against other features to get the bigger picture.

With 3D information at their fingertips – whether on desktops in the office or on smartphones or tablets in the field – engineers, data analysts or field inspectors can better understand assets in significantly less time, reducing costs, complications and misunderstandings.

Time changes everything

To understand our assets, we rarely look only at the here and now. Change is the key to identifying and preventing potential failures or problems – so we must look carefully at past and present data and continue to watch our data into the future. In the past, representing change over time could only be economically achieved in 2D because manually updating 3D models was laborious and time-consuming.

Specialist power and water consulting firm Entura has developed systems that allow data sets (from Excel, Access or other programs) to be automatically processed and displayed onscreen, producing 3D ‘snapshots’ or even animating data directly in 3D. The systems have been developed to allow quick tweaking of model parameters to show different data sets individually or in combination, to exaggerate movements where critical changes are too small to directly detect by eye, or to use colour coding to clearly represent critical parameters.

Perhaps the most significant advantage is that these models can be updated in a matter of minutes rather than days, by individuals with little or no CAD experience, simply by adding new data into the model’s database.

Should seeing always be believing?

Like any tool, 3D representations have some limitations. However, with experience and a little caution, the power of 3D representation can be fully exploited with minimal risk.

Just as 2D drawings can have mistakes or exclusions, 3D models are only as good as the data from which they are built. If incorrect drawings are used to build a model, or the wrong data is used in animations, 3D outputs will not represent the real world but may still look very convincing.

Like any engineering analysis, when 3D models are first produced, a clear review and approval process is needed, and model results must be verified against expected performance to ensure that the tool is robust and can be used reliably into the future.

The real challenges of complex assets

Entura has applied advances in 3D data modelling and presentation to support the management of a range of water and power assets including hydropower stations, water pipelines and dams.

In each of these three examples, 3D modelling delivered a comprehensive picture of system behaviour over time:

- Our use of 3D modelling to explore the movement of turbine plinths at Hydro Tasmania’s Gordon Power Station contributed to a clearer understanding of a pattern of ongoing movement. This helped to identify potential causes and inform future remedial works.

- Developing a 3D model of a steel pipeline made it much easier for an asset owner to understand and make decisions about the extent and possible causes of unwanted movement of the pipeline and its supports. Our model clearly indicated the extent of movement, leading to a targeted engineering solution that directly addressed the root cause of the problem without unnecessary investigation, over-design or delay.

- When we applied 3D modelling to a hydropower dam built on a geologically complex foundation including dissolvable limestone, the resulting model combined the dam’s foundation profiles, underlying geology and leakage rates, and animated 3D water levels in the foundation. The 3D model is helping the owner to quickly and fully understand the data and easily monitor the performance of this complex asset.

In each of these cases, new data can be quickly integrated, allowing easy ongoing monitoring and clearer communication of the current and likely future behaviour of these assets.

With a bit of caution and experience, 3D data presentation tools can offer powerful benefits to asset owners and their stakeholders, putting all the pieces of the data puzzle together to quickly and easily reveal the full picture of an asset’s condition and performance over time, supporting decision-making for cost-effective and timely maintenance and upgrades.

To discuss how Entura can help you get the full picture from your data to better understand and manage your assets, contact Phillip Ellerton on +61 439 010 172 or Shekhar Prince on +61 412 402 110.