THOUGHT LEADERSHIP

Monitoring tailing dams with unified data visualisation

This article is based on a recent presentation by Richard Lindqvist, a data integration specialist with Entura, at the ANCOLD Tailings Dam Operators Forum 2023. Richard describes the need, opportunities and barriers to adoption of advanced monitoring systems.

Tailings facilities are crucial for preventing any spread of mine tailings into surrounding land and waterways. Some tailings dams are among the largest engineered structures in the world. Like all dams, they must be managed to protect downstream communities and the environment from harm.

The catastrophic collapse of a tailings dam in 2019 in Brazil focused intense global attention on the safety of tailings facilities. In 2020, a new Global Industry Standard on Tailings Management (GISTM) was released.

The global standard emphasises the need for appropriate monitoring of tailings facilities throughout their lifecycle – from design to closure – to aid in the mitigation of risk.

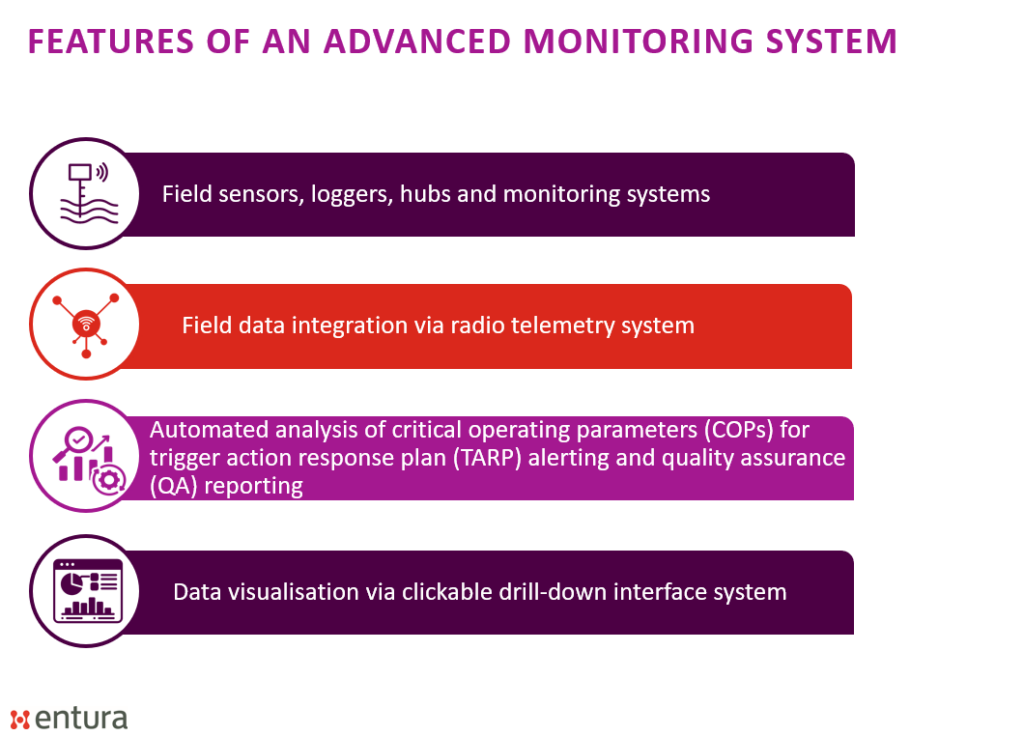

Advanced monitoring systems can assist greatly in meeting and exceeding the requirements of the GISTM. Here we’ll discuss the potential of telemetry, automation and meaningful visualisation of monitoring data – and the benefits that can flow from implementing such a system at your site.

The GISTM sets the context for monitoring

Accurate, meaningful and continual data from monitoring systems forms an important part of a comprehensive and integrated knowledge base, which is a core principle of the GISTM, particularly with respect to Principle 7 of the standard.

Monitoring data is to be assessed at the frequency recommended by the Engineer of Record (EoR). Any conditions exceeding the dam’s critical operating parameter ranges (COPs) must be addressed promptly through trigger action response plans (TARPs) or critical controls.

The COPs are parameters that if exceeded have a real risk of leading to a dam safety incident. Each COP has a TARP. Careful and regular monitoring of COPs can identify early signs of a potential safety issue and allow rapid intervention before the trigger level is reached.

These requirements set the context for monitoring methods, and reinforce the importance of accurate, up-to-date, meaningful information that tells a clear and timely story about the facility’s current state, trends and potential concerns.

New technologies have changed the face of monitoring

As technology has progressed, new opportunities have arisen for monitoring tailings facilities, with enormous benefits in efficiency, immediacy and accuracy. Now, COPs, TARPs and data quality can be assessed in near-real-time using automated processes – enabling efficient and early identification of faults, such as during construction activities. Time spent collecting field data and maintaining systems is minimised, and the saved time can be reallocated to dam inspections and deeper assessment of data trends. End-to-end connectivity allows multiple sources of telemetry data and operational data to feed immediately into a unified and user-friendly visualisation platform, supporting understanding and decision-making. Monitoring data can also feed proactive and predictive maintenance in asset management and operations.

Opportunity abounds, but barriers remain

As with any new standards and systems, there are likely to be some barriers or challenges in moving from a design or concept to reality. In our experience, some common factors include resistance to change, the potentially significant cost to invest in the new technology needed for an efficient and integrated system, and the balance of resourcing between automated versus field data collection and processing. Other common hurdles are integration with existing systems and workflows and the data security and governance standards to be met. Staff training and succession planning can also be a challenge but are essential to maintaining the necessary knowledge base.

None of these challenges are insurmountable – and the effort to overcome them will be repaid by the immense benefits in operational intelligence, efficiency and reliability that advanced, automated, integrated systems can deliver.

A real-life example of an evolving monitoring system

Entura has been on a journey with a large mining client for nearly 15 years, continually improving the facility’s monitoring solutions. Initially, we used our own Ajenti telemetry loggers and Ajenti Data Management System (ADMS) before progressing to the integration of other vendors’ logger data to the ADMS. We are now moving forward in using OSI Pi to integrate a broad array of data sources for our clients, presenting them within an accessible and adaptable visualisation platform.

Historically, data was retrieved manually from field loggers for processing into spreadsheets and manual analysis of charts. With data retrieval via telemetry, along with automated analysis and visualisation, this time can now be spent reviewing TARP alerts and in-depth assessment of data.

System reliability and robustness has been another key factor in our work with our clients – with improvements such as fit-for-purpose enclosures (316 stainless steel), solar power installation and the ability to assess operational data such as battery voltage and signal strength. This is reducing the physical maintenance needs at monitoring sites and replacement of enclosures or batteries. The focus can now be on routine inspections of dam conditions rather than managing the monitoring network.

Effective record-keeping is essential when managing a large monitoring network. The new system enables a rich knowledge base to be compiled, stored and interrogated. Site metadata and documentation can be hosted on the visualisation platform, including calibration and installation reports, FATs and SATs (factory and site acceptance tests), analysis reports, memos, photos, field observations and general site maintenance requirements. Data from various field note sources (i.e. ArcGIS, fieldmaps, Iauditor and Fulcrum) can be brought into the visualisation system for ease of access and asset management. Electronic field note apps are used on mobile devices so that data can be recorded in the field and synced directly to the system.

We have also added value to the data repository by incorporating other technologies into the integrated system and visualisation interface. These include aerial survey overlays, weather monitoring, soil moisture sensors, camera imagery and operational data – and we are always working with our client to ensure that visualisations are intuitive and easy to interpret.

The visualisation interface provides real-time and trend data for users, and can hone in on individual sensors anywhere across the facility. Faults can be analysed onsite using analysis tools – and offsite using available data trends.

We’ve also worked with our client to provide a secure data ingress pathway for remote equipment, and we’re continuing work on integrating the new system with existing traditional and emerging SCADA systems.

Throughout the long evolution of this monitoring journey, we have continually added new innovations to best serve our client’s needs – and are always looking for new ways to deliver effectively.

Every system needs continuous improvement

The existing system has brought significant benefits to our client’s ability to analyse and visualise the facility’s data. Yet technologies continue to improve and evolve at speed. For our clients, we are now using OSI Pi and Pi-Vision as a primary integration and visualisation tool, and have developed a proof-of-concept for delivering the capabilities of the current system using OSI Pi and Pi-Vision. This will allow greater flexibility to bring on-site data into a single visualisation system – agnostic of the historical databases currently in use.

With the pace of technological advances likely to accelerate, clients and consultants should all stay attuned to new monitoring developments and alert to possibilities for improving their system’s functionality and integration with a broad range of sensors and control systems.

With the right data at the right time coupled with meaningful analysis and user-friendly visualisation, every tailings facility’s management should be better able to make earlier and more informed decisions to reduce risk.

To find out more about Entura’s data and water management solutions, contact Phillip Ellerton.

MORE THOUGHT LEADERSHIP ARTICLES

8 December, 2023