THOUGHT LEADERSHIP

Saving lives and protecting assets by reducing arc flash hazards

An arc flash is one of the greatest dangers electrical workers face, with potentially tragic consequences.

Each year, workers worldwide are killed or injured by arc flash – a type of electrical explosion (like a short circuit through the air) that can produce a deadly force equivalent to detonating a bomb.

As many as 10 arc flash incidents occur every day in the USA. In Australia, two electrical workers were killed in 2015 when an arc flash occurred in the power supply to a shopping centre. In mid-2015, another two Australian mining workers were seriously injured by an arc flash underground.

Being injured by an arc flash is, thankfully, not much more common in the developed world than being hit by lightning, but the injuries can be similar. Arc flash accidents can cause burns (often very severe, and most commonly to hands and face), injuries to the airways from toxic gases, damage to the eyes and ears from intense light and sound, and impacts from being thrown or being hit by flying objects or shrapnel.

As well as the serious risks of injury or death that an arc flash hazard poses to the safety of workers and the public, it can also cause substantial physical damage to equipment and infrastructure, and prolonged outages or restricted power supply. And these impacts all add up to sizeable costs.

Including arc flash in the overall risk management strategy

To protect against the costly consequences of arc flash hazards, any owner or operator of electrical assets needs to incorporate the potential for arc flash events in their overall risk management strategy.

Wherever electricity supply is required, faults and arc flashes can occur, potentially at any time. This means that arc flash can never be completely eliminated in electrical transmission and distribution substations. However, there are known scenarios of greater risk, including times when the electrical system is under stress due to surges or faults; during maintenance; during switching or racking of the circuit breaker from the switchboard compartment; when asset condition is in decline; or when working with older types of switchgear, which typically have no arc fault containment features.

Calculating the level of risk

To understand the arc flash risk for a substation, calculations are performed to estimate the potential energy of an arc flash incident and to estimate the arc flash boundary (the distance from a live part from which a person could receive a second-degree burn). Fault clearing times are also calculated, as the time it takes to clear the fault is directly related to the energy of an arc flash. The fault clearing time depends on various factors such as the type of protection in place and the location of the fault, so a detailed analysis is required for individual sites to determine the arcing time.

Calculations are usually based on two North American standards, IEEE 1584 and NFPA 70E. Although neither of these standards applies fully to Australian workplaces, the combination of these two standards has become the de-facto local standard as no Australian standard currently exists. This lack of clear guidance means that every owner or operator of electrical assets needs to be confident that they are making the right risk management decisions by understanding current industry best practice.

Once these calculations have been made, the risk level of individual assets can be determined based on the likelihood of an arc flash (derived from factors such as asset condition and exposure of workers) and its consequence (derived from worker safety, equipment damage and loss of supply).

Lowering arc flash risk without breaking the bank

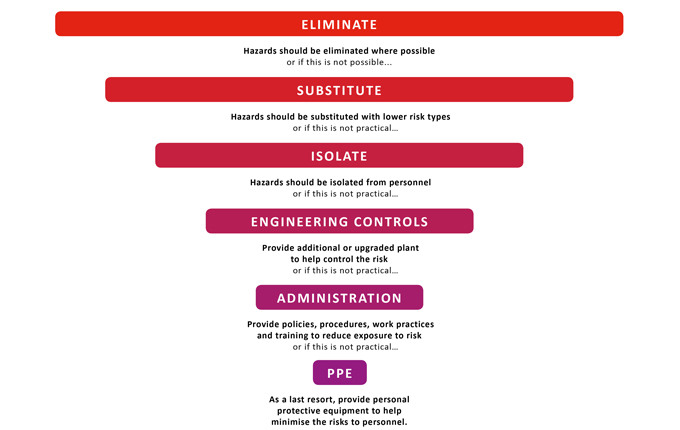

Our ultimate preference is to prevent an arc flash from occurring at all, but the inherent risks in an electrical asset may make full eradication difficult. Where the risk of arc flash is high, a combination of appropriate controls should be used to lower the risk to a more acceptable level.

Although personal protective equipment (such as an arc flash suit, or a face mask and gloves) is a necessary and relatively easy protective measure to implement, PPE will not protect a worker from impact-related injuries, nor protect equipment or reduce outages, so it is important to also fully investigate some of the higher rungs of the hazard reduction hierarchy of controls.

Other cost-effective control measures to mitigate arc flash hazards include increasing employee awareness and skills, reducing employee exposure, and reducing arc flash energy.

Given that arc flash incidents are most likely to occur when workers are present and are often caused by human error (such as dropped or mislaid tools or incorrect operation), it is important to make employees aware of the hazards and maintain employee skills through training and competence assessments.

Another easy way to improve worker safety is by limiting the exposure of workers by undertaking switching and racking remotely with no personnel near the switchgear.

A very effective engineering control to reduce the risk is by reducing the arcing time, which reduces the energy of the arc flash. This can be achieved by installing arc flash light-detection systems combined with fast-acting earthing switches. The light detection will pick up an arc flash very quickly (in around 4 milliseconds) and, by applying a three-phase connection to earth, the arc will be extinguished.

Keeping our own workers and assets safe

As part of Hydro Tasmania, Australia’s largest producer of renewable energy, Entura has been involved since 2012 in studying arc flash hazards on an extensive portfolio of electrical equipment to better understand its consequences. As asset owners, we appreciate the need to keep our workers and assets safe through achieving the best risk mitigation for the available investment of funds. We’ve brought this together with up-to-date knowledge of industry best practice and trends to assist clients develop safe and cost-effective strategies to confidently manage the risk of arc flash throughout their electrical asset portfolios.

To discuss how Entura can work with you to fully assess and address your electrical risks for greater worker safety and reduced outages, contact Patrick Pease.

MORE THOUGHT LEADERSHIP ARTICLES

1 December, 2015