THOUGHT LEADERSHIP

What do dams and bathtubs have in common?

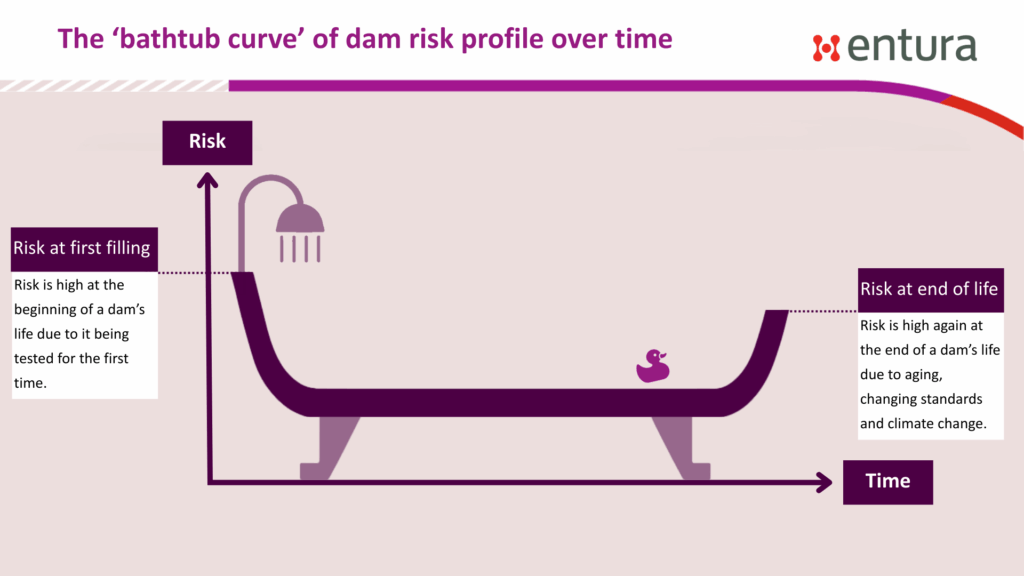

The obvious answer is that both hold water, but there’s something more, which keynote speaker Andrew Watson of BC Hydro referred to at the recent NZSOLD/ANCOLD conference. He described the risk profile of a dam over time as ‘the bathtub curve’.

The riskiest periods for a dam are during the early years of operation and in later years as the dam starts to age.

We talk a lot about managing the risks of older dams through an appropriate dam safety program. A dam portfolio risk assessment is a great way of ensuring effort is focused appropriately. If the risk profile of an aging dam reaches an unacceptable level, this can result in a dam upgrade project. Clearly, there are many well-established processes and tools to manage risks on the aging dam side of the bathtub curve, but how about for new dams?

Reducing risk during design

During the design phase of a dam, we investigate the foundations, develop geological models to represent the foundation and assign geotechnical properties to the elements in our model. We also investigate materials that will be used in the dam, undertake laboratory testing to achieve material properties, and may even undertake insitu trials. We then model the dam structure to determine how it performs for various load cases, including extreme flood and earthquake loading, ensuring it meets the required engineering standards. Although the design process has checks and balances, some uncertainties and risks may have escaped identification at this stage.

Reducing risk during construction

The next phase is constructing the dam in accordance with the design specifications. A quality control assurance program sets quality control measures to give confidence that the construction meets the design requirements. Although the quality assurance and quality control systems are in place, there is still a level of uncertainty, making it difficult to guarantee that all the materials placed meet the required specification. Additionally, the foundation and material conditions may not totally reflect the design characterisation, necessitating modifications during construction. Typically, the designer is engaged in these changes, but was sufficient supervisory expertise on site to recognise these differences and engage the designer?

Reducing risk during first filling

For a dam design engineer, the filling of a new dam is often an exciting time. It is the completion of a major project, but it is also known to be the highest risk stage of a dam’s life. Everything that has gone into the design and construction of the dam is going to be tested for the first time: the design assumptions and models, the actual material properties, the engineering calculations, the quality of construction, the quality assurance systems, etc.

How can risk be mitigated during this first filling and the early years of operation, when the dam is being tested? From our experience, these practical steps can help reduce the risk (click each step for more details):

1) Ensure good technical governance through design and construction

2) Set up quality assurance and quality control systems

3) Continue a design presence on site

4) Use a risk framework to determine a dam’s readiness to impound

5) Have a dam safety system in place before impoundment

6) Maintain a heightened level of monitoring and surveillance

7) Be prepared in case of an unlikely dam safety emergency

8) Keep a close eye on the dam in its first years of operation and during new peaks

This process for new dams should apply equally to main dams and smaller saddle dams. In larger reservoirs, water may not fill against a saddle dam for a year or two after the commencement of impoundment. In this case, the same principles should be applied to the saddle dam during the period when water is against it for the first time. These principles also apply when a dam is raised, because when water load is placed against the raised section, the raised dam is being tested for the first time.

By applying these steps through the heightened risk period during first filling and the first 5 years of operation, dam professionals can mitigate the risks associated with the early side of the bathtub curve, helping the dam get a good start in life.

ABOUT THE AUTHOR

Richard Herweynen is Entura’s Technical Director, Water. He has more than 3 decades of experience in dam and hydropower engineering, working throughout the Indo-Pacific region on both dam and hydropower projects. His experience covers all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance, and risk assessment for both new and existing projects. Richard has been part of a number of expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and was the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

11 December, 2025