THOUGHT LEADERSHIP

When is the best time to invest in deeper understanding? An example from hydraulic modelling

With projects and operations, like life, knowledge is power – the power to make informed decisions and manage risk. That knowledge can be gained in different ways, at different costs, and at different stages of a project. In an era of ever-more-sophisticated digital tools, how do we decide what’s best for the project?

The understanding of when to invest in more accurate assessments is changing. Traditionally, more accurate assessments were time-consuming and costly, and left to later in a project’s life. Now, however, improved techniques and computing power make greater accuracy both possible and affordable earlier.

Here we look at the issue of when to invest in more accurate assessment tools using the example of where hydraulic modelling is a key part of projects, often in the development of water infrastructure.

As a project evolves or a system is operated, different levels of knowledge will be needed to make informed, defensible decisions. This knowledge comes from experience and from assessments specific to the project. With water modelling, these assessments vary in complexity and data requirements. They also need to be integrated into the design and approval for the development.

Investing too early in a detailed assessment can be wasteful, as there usually isn’t the data to support the approach. Even if the data is available, a high-cost investment too early in the project can be wasteful if the project is stopped or changes direction. However, investing too late in gaining a better understanding of the system and risks can lead to poor decisions and rework later, as the design may have advanced on poor assumptions for critical elements.

There is, therefore, always a balance to be found in the timing and the approach to take. If there are too many options for solutions late in the project life, there’s a danger of analysis paralysis. Knowledge gaps, too, can paralyse a project.

Increasingly sophisticated modelling is becoming more widespread and available

Understanding the behaviour of water as it moves around us, our environment and our structures is based on physics and statistics. Hydraulic modelling of water systems can range from a single line equation that takes only seconds to calculate, to complex numerical models that take months to work through.

In the past, with limited or no computing power, modelling required hand calculations. As techniques improved and computing power increased, it became possible to conduct numerical modelling with a simplified set of physics. For surface and pressurised water systems, these were called one-dimensional models. Over time, it became practical to use two-dimensional models, then limited three-dimensional models, and then full three-dimensional ‘CFD’ models. Computational fluid dynamic (CFD) models are the current state-of-the-art tools for hydraulic modelling.

CFD and physical modelling can provide such competitive advantage that there are now rules to limit the use of these tools in the racing car industry. This is because the tools are costly, so less affluent teams are disadvantaged by not having access to them. To level the playing field, the top teams are required to use less than the bottom teams.

In the world beyond racing cars, there are also limits on using state-of-the-art tools. Limits can be financial, skills, suitable input data and time. But as they become easier to use, CFD tools are finding their way into the early stages of projects.

In hydraulic modelling, not every engineer has access to a hydraulics laboratory in their office, although we all wish we did! So when there are uncertainties about how a system may work, it’s not usual to make a physical scale model and test things to get the insights needed to fill any knowledge gaps. To give engineers early insights into a system’s behaviour – which helps us find the best solution faster – we used to use simple hand calculations or one-dimensional models, but it is now becoming more common to use CFD and other advanced tools earlier in a project’s life.

Advantages of CFD in practice

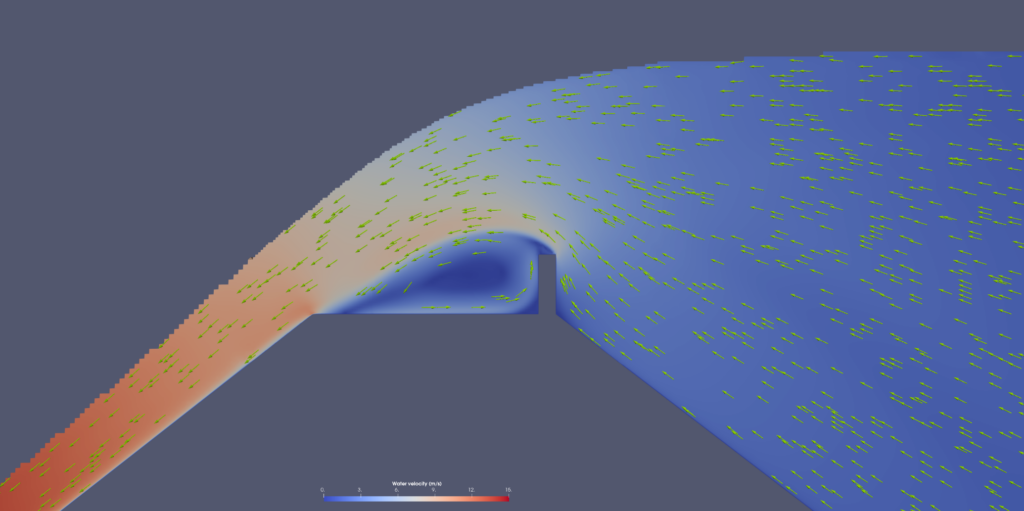

Let’s look at a real-world example: understanding the overtopping of a dam wall with an upstream parapet wall during an extreme flood.

In this project, only hand calculations were to be used to work out the relationship between water flow rate and water depth above the wall. But during the hand calculations, it wasn’t clear if the water, after flowing over the parapet wall and then flowing over the rest of the crest, would build up and affect the upstream water levels by submerging the parapet. If the parapet was submerged, this would change the hand calculation method. There was a knowledge gap.

Initially, some testing was done with a one-dimensional numerical model, but this didn’t provide much insight into the hydraulic behaviour. So a simple CFD model was quickly built based on some hand sketches. The CFD model made it clear that there was no submergence of the parapet, allowing the use of the correct hand calculations. It filled the knowledge gap.

Now that the CFD model had been built, it could also be used to help validate the key inputs to the flow–depth relationship over the dam. The CFD model therefore benefited the qualitative understanding of the system’s physical behaviour as well as providing a second approach to solving the initial problem and improving confidence in the solution.

So what’s the lesson here?

CFD wasn’t initially considered when the overall project was scoped, as CFD was traditionally considered to be too expensive. In the end, though, it was a valuable key to filling a knowledge gap and provided unplanned secondary benefits.

CFD isn’t going to be the answer for every hydraulic modelling project – but the general solution is to use the most accurate method that can be afforded as early in a project or operation as possible. There will always be a balance to be found in when to invest in accurate assessments, but the decision should be based on the contemporary lower effort to use and get results from these approaches, and the power gained by the extra knowledge they can provide.

If you’d like to talk with Entura about your water or dam project, contact Richard Herweynen.

About the author

Dr Colin Terry is a civil engineer at Entura with three decades of experience in Australia and New Zealand. His experience includes modelling, planning, design and construction support. He has worked on multidisciplinary projects across various parts of the water cycle including catchment management, water supply, hydropower, land development, transport, and water quality in natural systems – with a focus on surface and piped water.

MORE THOUGHT LEADERSHIP ARTICLES

27 March, 2023