When is the best time to invest in deeper understanding? An example from hydraulic modelling

With projects and operations, like life, knowledge is power – the power to make informed decisions and manage risk. That knowledge can be gained in different ways, at different costs, and at different stages of a project. In an era of ever-more-sophisticated digital tools, how do we decide what’s best for the project?

The understanding of when to invest in more accurate assessments is changing. Traditionally, more accurate assessments were time-consuming and costly, and left to later in a project’s life. Now, however, improved techniques and computing power make greater accuracy both possible and affordable earlier.

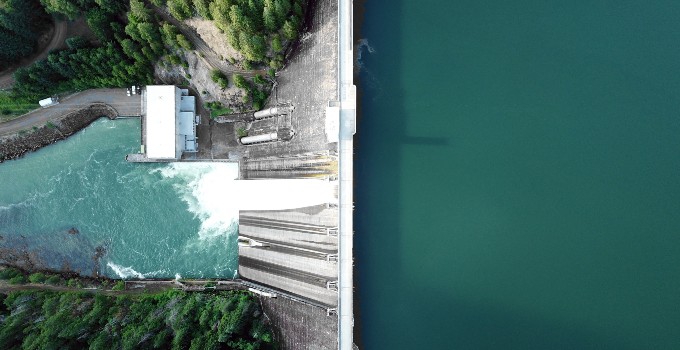

Here we look at the issue of when to invest in more accurate assessment tools using the example of where hydraulic modelling is a key part of projects, often in the development of water infrastructure.

As a project evolves or a system is operated, different levels of knowledge will be needed to make informed, defensible decisions. This knowledge comes from experience and from assessments specific to the project. With water modelling, these assessments vary in complexity and data requirements. They also need to be integrated into the design and approval for the development.

Investing too early in a detailed assessment can be wasteful, as there usually isn’t the data to support the approach. Even if the data is available, a high-cost investment too early in the project can be wasteful if the project is stopped or changes direction. However, investing too late in gaining a better understanding of the system and risks can lead to poor decisions and rework later, as the design may have advanced on poor assumptions for critical elements.

There is, therefore, always a balance to be found in the timing and the approach to take. If there are too many options for solutions late in the project life, there’s a danger of analysis paralysis. Knowledge gaps, too, can paralyse a project.

Increasingly sophisticated modelling is becoming more widespread and available

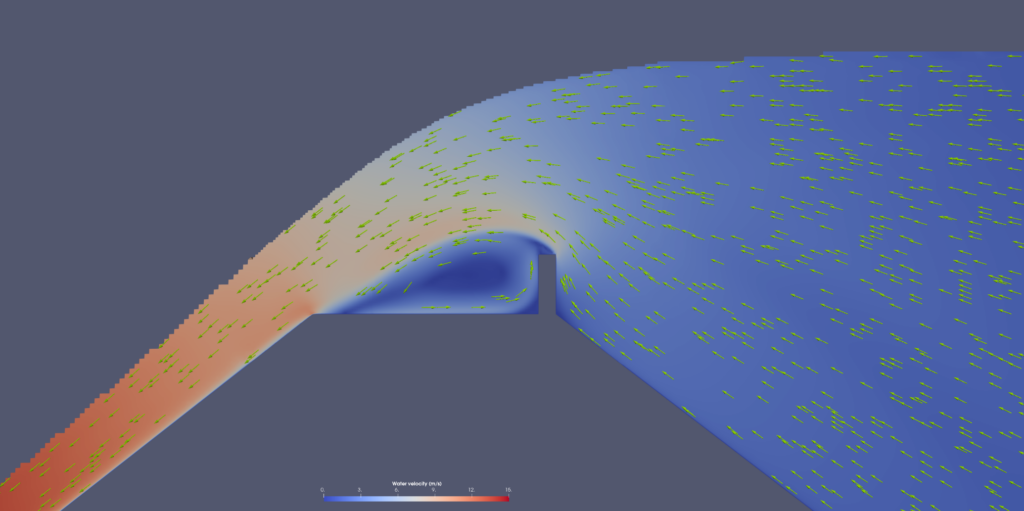

Understanding the behaviour of water as it moves around us, our environment and our structures is based on physics and statistics. Hydraulic modelling of water systems can range from a single line equation that takes only seconds to calculate, to complex numerical models that take months to work through.

In the past, with limited or no computing power, modelling required hand calculations. As techniques improved and computing power increased, it became possible to conduct numerical modelling with a simplified set of physics. For surface and pressurised water systems, these were called one-dimensional models. Over time, it became practical to use two-dimensional models, then limited three-dimensional models, and then full three-dimensional ‘CFD’ models. Computational fluid dynamic (CFD) models are the current state-of-the-art tools for hydraulic modelling.

CFD and physical modelling can provide such competitive advantage that there are now rules to limit the use of these tools in the racing car industry. This is because the tools are costly, so less affluent teams are disadvantaged by not having access to them. To level the playing field, the top teams are required to use less than the bottom teams.

In the world beyond racing cars, there are also limits on using state-of-the-art tools. Limits can be financial, skills, suitable input data and time. But as they become easier to use, CFD tools are finding their way into the early stages of projects.

In hydraulic modelling, not every engineer has access to a hydraulics laboratory in their office, although we all wish we did! So when there are uncertainties about how a system may work, it’s not usual to make a physical scale model and test things to get the insights needed to fill any knowledge gaps. To give engineers early insights into a system’s behaviour – which helps us find the best solution faster – we used to use simple hand calculations or one-dimensional models, but it is now becoming more common to use CFD and other advanced tools earlier in a project’s life.

Advantages of CFD in practice

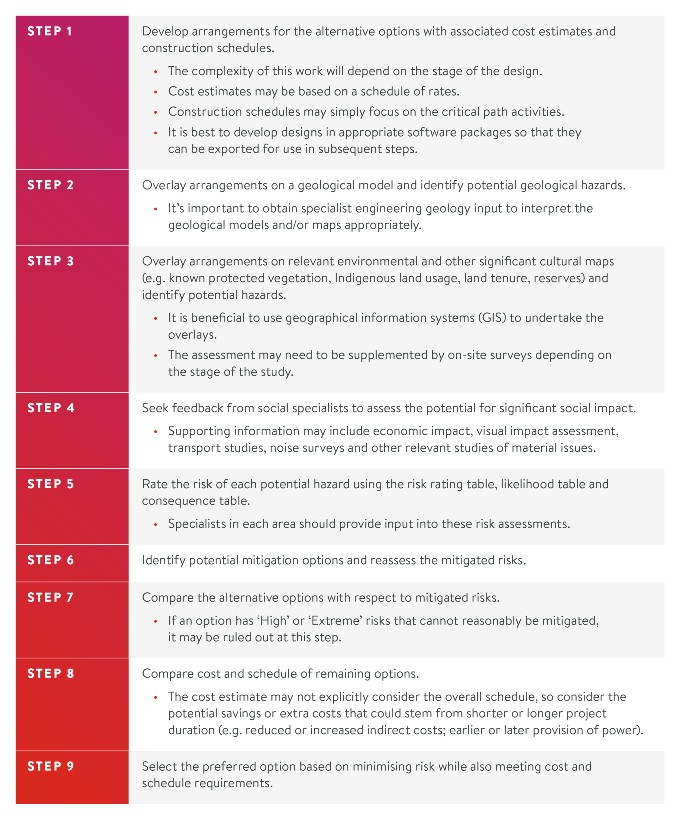

Let’s look at a real-world example: understanding the overtopping of a dam wall with an upstream parapet wall during an extreme flood.

In this project, only hand calculations were to be used to work out the relationship between water flow rate and water depth above the wall. But during the hand calculations, it wasn’t clear if the water, after flowing over the parapet wall and then flowing over the rest of the crest, would build up and affect the upstream water levels by submerging the parapet. If the parapet was submerged, this would change the hand calculation method. There was a knowledge gap.

Initially, some testing was done with a one-dimensional numerical model, but this didn’t provide much insight into the hydraulic behaviour. So a simple CFD model was quickly built based on some hand sketches. The CFD model made it clear that there was no submergence of the parapet, allowing the use of the correct hand calculations. It filled the knowledge gap.

Now that the CFD model had been built, it could also be used to help validate the key inputs to the flow–depth relationship over the dam. The CFD model therefore benefited the qualitative understanding of the system’s physical behaviour as well as providing a second approach to solving the initial problem and improving confidence in the solution.

So what’s the lesson here?

CFD wasn’t initially considered when the overall project was scoped, as CFD was traditionally considered to be too expensive. In the end, though, it was a valuable key to filling a knowledge gap and provided unplanned secondary benefits.

CFD isn’t going to be the answer for every hydraulic modelling project – but the general solution is to use the most accurate method that can be afforded as early in a project or operation as possible. There will always be a balance to be found in when to invest in accurate assessments, but the decision should be based on the contemporary lower effort to use and get results from these approaches, and the power gained by the extra knowledge they can provide.

If you’d like to talk with Entura about your water or dam project, contact Richard Herweynen.

About the author

Dr Colin Terry is a civil engineer at Entura with three decades of experience in Australia and New Zealand. His experience includes modelling, planning, design and construction support. He has worked on multidisciplinary projects across various parts of the water cycle including catchment management, water supply, hydropower, land development, transport, and water quality in natural systems – with a focus on surface and piped water.

MORE THOUGHT LEADERSHIP ARTICLES

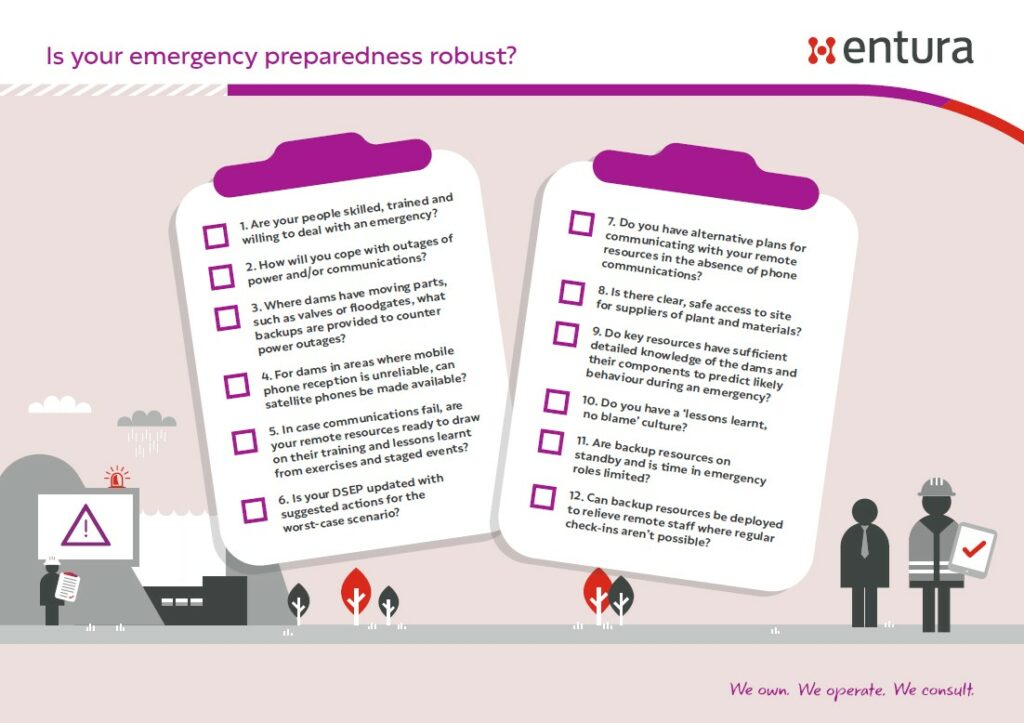

How robust is your emergency preparedness?

The old adage of ‘a company’s greatest assets are its people’ is never more true than in an emergency situation. The success of any emergency plan depends upon the skills, training and willingness of the people involved. It also relies on robust emergency preparation that takes as many scenarios as possible into account, and builds in a range of backups and alternatives for maximum agility and resilience.

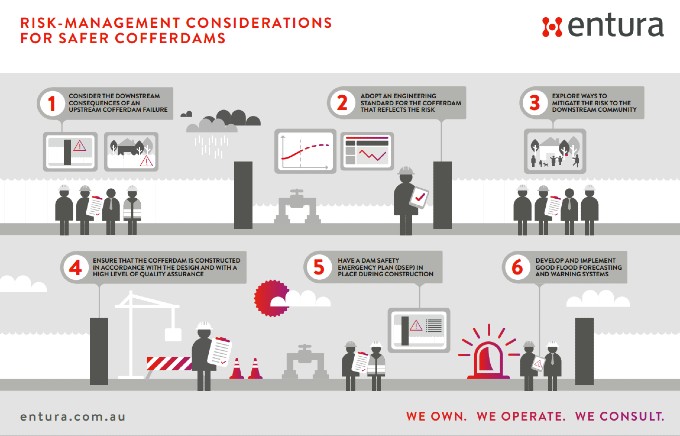

All responsible dam owners have dam safety emergency plans (DSEP) which are carefully created and tailored to the needs of the company, its assets and its available resources.

If called upon in an extreme event, these plans will likely be pushed to their limit – but it’s vital that they perform as intended to reduce risk and consequences downstream.

The ultimate test of the emergency plan is how well it can cope with outages of power and/or communications. ‘Stress testing’ emergency plans for outage scenarios and implications is key to achieving a robust plan.

Power and communications outages

Where dams have moving parts, such as valves or floodgates, backups are needed to counter power outages. Are backup generators in place, or can a portable generator be brought to site at short notice? Is there a clear, safe access route to site during emergency conditions (e.g. not flooded or blocked by fallen trees)? Where this is not possible, can the valves or floodgates be operated by hand? A further question is whether these components are readily operable and exercised regularly.

Many dams are located in remote areas, and in some cases mobile phone reception is unreliable. In these situations, can satellite phones be made available? Landline phones may be available but depend on poles and lines remaining intact and operable during emergency conditions.

Communications are vital to ensuring the emergency plans are enacted under the direction of the incident controller. Where communications with remote resources are limited or not possible, those involved must fall back on their training and on lessons learnt from exercises and site-based, staged events involving scenarios of outages of power and communications. The DSEP can be updated with suggested actions for the on-site operators and emergency management team to follow in the worst-case scenario.

Alternative means of communication and access

In situations where check-in communications are required with those working remotely, alternative means must be considered in case of an outage of communications. In the absence of satellite phones, this could involve a messenger driving to site, but this relies on clear, safe access routes and careful consideration of the time required. In extreme cases, the only means of reaching a remote site may be by helicopter. This would require pre-arrangement with the closest helicopter providers regarding emergency availability.

The situation is similar with suppliers of plant and materials that may be required to assist with conditions at or downstream of the dam. How can they be contacted, and is there clear, safe access to site? Consider having emergency stockpiles at site or nearby and ready access to earthmoving plant.

Decision-making in a SCADA outage

If a power outage results in a localised SCADA outage, there will be no current instrumentation data available to guide critical decisions. In such circumstances, decisions must be based on likely behaviour during emergency conditions or on forecasts from before the emergency is declared. This would likely require detailed knowledge of the dams and their components, which highlights the importance of regular routine monitoring and detailed studies such as comprehensive surveillance reviews and dam safety reviews.

Company culture, teamwork and support

Where there is a ‘no blame’ company culture in which employees are encouraged to speak up, point out flaws in systems and processes and identify faults with assets, there is a greater likelihood that employees will participate successfully in staged exercises and events and provide useful information regarding how an incident response team will perform during an emergency.

Another important aspect of company culture is working together as a team. It is possible that a person may become fatigued but cannot convey this due to a communications outage. It is also conceivable that during an emergency a person may be unwilling to ‘leave their post’ until the job is done, becoming fatigued in the process.

It is important to have backup resources and to limit time in any role during the emergency to minimise the chance of mistakes being made. The emergency plan is only as strong as the weakest link in the chain of command.

For all resources, including external resources, provision of backups should take into account leave, prolonged illness and the need to ensure replacement when employees leave the company.

Where a company has a strong and positive safety culture and team ethos, detailed knowledge of its assets, regular inspection and exercising of valves and gates, and a commitment to team-based emergency training, employees are more likely to overcome the challenges posed by outages of power and communications during emergency conditions. They will find a way.

No one can predict and plan for every emergency scenario, but we believe that the tips we’ve shared here can help dam owners to develop and maintain robust emergency plans that have a higher likelihood of success when called into action.

If you would like support with your emergency planning, contact Richard Herweynen or Phillip Ellerton.

About the author

Jamie Cowan is a senior dams engineer at Entura with over 2 decades of civil engineering experience in the UK and Australia. His experience includes the management of investigation, design and construction projects in the civil, dams and water industries. He has worked across all stages of project delivery, from feasibility to the commissioning of assets. He has provided construction support roles during dam construction and upgrade projects, and conducted intermediate and comprehensive inspections of dams for water authorities in Victoria.

MORE THOUGHT LEADERSHIP ARTICLES

Is there still a role for run-of-river hydropower projects?

In 2000, a major report by the World Commission on Dams shone a spotlight on large dams. At that time, some people argued that smaller, run-of-river hydropower could be a more sustainable solution than large dams with large reservoirs. Is this true? And is it still relevant more than twenty years on?

Run-of-river hydropower projects have little or no storage, which means that they don’t require the construction of a large dam, and don’t need to inundate a significant area with a large reservoir storage. Run-of-river hydropower may therefore have lower social and environmental impacts. A diversion weir is less likely to be a barrier to sediment transport, fish passage, or navigation; however, because run-of-river hydropower still involves constructing a structure in the river, these schemes are unlikely to have zero environmental impact. It is interesting to note that run-of-river hydropower projects and other small projects that do not involve the construction of large dams account for more than half of the hydropower projects supported by the World Bank.

Despite potentially having a lower environmental and social impact, run-of-river projects do have a significant disadvantage compared to large reservoir hydropower. For run-of-river projects, not all of the energy is ‘firm’, as the ability to generate depends on the availability of flow in the river. If a river catchment is highly responsive to rainfall, the daily variation of generation from a run-of-river hydropower scheme could be highly variable (similar to wind and solar).

If annual rainfall is highly seasonal, with a dramatic wet season and dry season, then a run-of-river hydropower scheme will generate much more power when seasonal river flows are high, and significantly less during drier months. So a run-of-river scheme will not necessarily be able to play the increasingly important role of firming variable renewables, and is more likely to be considered an additional source of variable renewable energy.

Run-of-river may not offer storage, but it can still have a place

But this doesn’t mean there’s no longer a place for run-of-river hydropower, as it is still a valuable and clean form of energy. In some situations, the lack of firming capacity doesn’t necessarily matter too much due to the existing diversity within the generation portfolio, or the type of generation that is being displaced. Run-of-river hydropower can still be a viable option in these circumstances:

- where the run-of-river hydro scheme is part of a larger portfolio of hydropower assets, which already has storage within the overall system – in this situation, the various hydropower generation assets can be operated together as a dynamic, integrated system, using the various assets to deliver an optimum output

- where the run-of-river hydro scheme is part of a diverse portfolio of variable renewables, including solar, wind and run-of-river hydro – in this case, it is unlikely that the mix of variable renewables will be highly correlated (i.e. it is unlikely that when there is no water in the river, there is also no wind or sun), and therefore less energy storage will be required to firm the variable generation

- where the run-of-river hydro is displacing expensive thermal generation – such as the displacement of diesel-powered generation on an island or a remote off-grid site.

Achieving sustainable storage

If there is potential to add storage to a hydropower scheme in a sustainable manner, then this is likely to create more long-term value, especially in an escalating clean energy transition. Storage will make the hydropower more flexible, agile and responsive, and able to ‘firm’ more variable renewable energy sources. With storage, hydropower can match generation with the demand for electricity. Essentially, storage can ‘unlock’ more renewables, and underpin a faster energy transition.

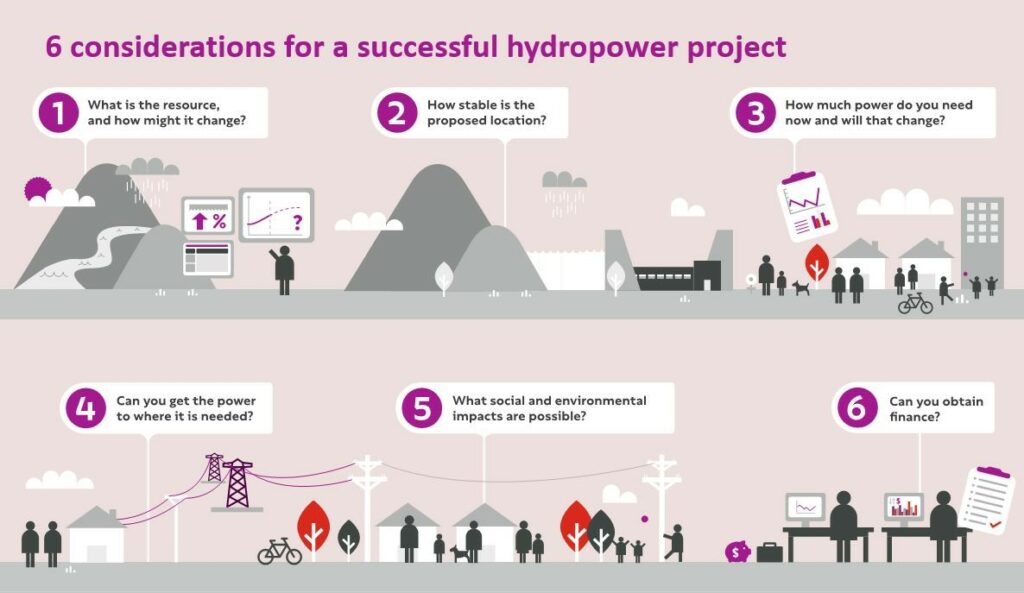

But the key is to make sure that any larger-scale hydropower projects with storage are developed right. In a previous article, we argued that a successful hydropower project requires:

- understanding the current water resource and how it might change – and building in climate resilience

- thoroughly investigating the geological and geotechnical conditions

- projecting future demand in the context of industrial development and population change

- getting the power to where it is needed through appropriate transmission and distribution infrastructure

- carefully considering the project’s stakeholders, community and environment

- securing project finance.

All of these aspects contribute to minimising risks throughout the project lifecycle and increasing the sustainability of the project in the long term, so that it can deliver social, environmental and economic benefits.

The best way to ensure that your hydropower project is developed in a sustainable manner, from the earliest stages of consideration through to operation and end-of-life, is by applying the international Hydropower Sustainability Standard.

Talk to us about achieving the right mix of renewables for your needs, and getting hydropower projects right.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

‘No dams’ or ‘right dams’? – that is the question

The construction of large dams may be controversial, particularly if the social and environmental impacts appear to outweigh the benefits. How can we create the right kind of dams in the right places to deliver maximum benefit with minimal impact?

I recently watched Franklin, a documentary in which eighth-generation Tasmanian and environmentalist Oliver Cassidy retraces his late father’s 14-day expedition to attend the Franklin River blockade in Tasmania in the early 1980s. The blockade aimed to stop the damming of the ‘Gordon below Franklin’. This was a divisive time, when many cars on the roads displayed a ‘No Dams’ sticker.

Indeed, some rivers have such high environmental and cultural heritage value that they should not be developed. However, given that water storage is a critical global issue, especially in a changing climate, is ‘No Dams’ a realistic stance?

Dams play an important role within communities by providing much-needed storage for water supply, irrigation and power generation. With greater hydrological variability due to climate change, more water storage will be vital to provide the same level of security for water, food and energy. The security of water, food and energy are inextricably linked, and all three are critical. For example, approximately 50 per cent of all large dams are used for irrigation. Without sufficient water storage, irrigated agriculture, which supplies 40 per cent of the world’s food, is at the mercy of changing patterns of rainfall and runoff. In our view, more water storage is needed for a sustainable future.

However, there are good dam sites and there are bad dam sites. In 2003, the World Bank, through its Latin America and Caribbean region, prepared a sustainable development working paper. This paper, titled Good Dams and Bad Dams, recognised that not all large dams are alike, particularly in terms of environmental and social impacts. It concluded that the level of environmental impact is largely determined by siting. It argued that while dams at good sites may be defensible, dams proposed at inappropriate sites are likely to remain problematic, even with proper implementation of all feasible mitigation measures, and are best left undammed.

Deciding on a site is not simple, and that is because sustainability challenges are complex. To help with decision-making about dams, the World Bank prepared environmental criteria for selecting sites for hydroelectric projects, building on its earlier work towards greater sustainability of dams throughout the 1980s and 1990s. In addition, the World Commission on Dams had been born out of a meeting in 1997 jointly sponsored by the World Bank and the World Conservation Union, and released its framework for dam decision-making in 2000.

International good practice has continued to evolve – and some principles are encapsulated in the Hydropower Sustainability Standard and assurance framework governed by the Hydropower Sustainability Council (drawing on the International Hydropower Association’s own tools and other sustainability principles) and underpinned by the San José Declaration on Sustainable Hydropower. Although these frameworks were created for the hydropower industry, they can be applied to any dam project.

So now, guided by these sustainability frameworks and motivated by the urgency of the clean energy transition and the multiple benefits of dams and hydropower, the challenge is to find the ‘good’, least-impactful dam sites, to enable more water storages to be developed sustainably. The need for more storage is particularly pressing in many developing countries – where there are critical needs for electrification, drinking water and flood mitigation, and where numerous and varied dam sites are available.

How do we do this? Clearly, site selection cannot simply be about cost-effectiveness alone, given that so much of what we value in life cannot be measured in dollars. At the recent Australian National Committee on Large Dams (ANCOLD) Conference, one of the keynote addresses was delivered by Gigi Foster. As an economist, she argued the importance of choosing the right ‘currency’ when making key decisions for society. She argued that we should judge a society by the extent to which it enables people to experience lives that are both long and of quality and wellbeing. A term used for wellbeing over one year is a ‘wellbeing year’ or WELLBY. Ideally, we should seek to maximise the number of future WELLBYs for people in the present generation, but also for future generations.

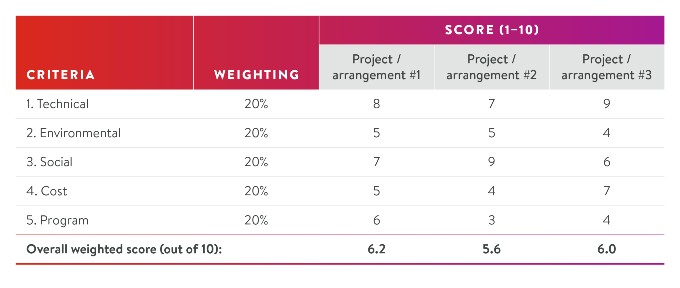

Arguably, the best dam sites may be those that maximise future WELLBYs – but this might be difficult to calculate. They may also be the dam sites which are the best based on a multicriteria assessment in which environmental and social risks are fully considered. There will be some potential dam sites where the environmental or social impacts are too great, and a dam cannot be justified. Good site selection is the most effective environmental mitigation measure.

Given that we need more water storage, we can:

- Explore opportunities to increase the storage capacity of existing reservoirs by raising dams or by improving interconnection between storages to enable them to work together in a flexible and effective manner. Often, this can be more cost-effective and have lower environmental impacts than a new dam project. Where the benefits are high and the impacts are low, the WELLBYs are likely to be high.

- Identify dam sites, either on-stream or off-stream, that will minimise environmental and social impacts. The simple quantitative indicators proposed in the 2003 World Bank Good Dams and Bad Dams paper could be used for an early preliminary rating and ranking of potential dam projects in terms of their possible adverse environmental or social impacts until more information is generated through detailed environmental and social impact assessments. The environmental and social considerations must be given appropriate weighting in the site selection multicriteria assessment, along with the financial, technical and other criteria typically included. If the assessment is well balanced, it is more likely to reach a positive outcome.

After many decades of controversy about dam development, and with increasing understanding of impacts and far greater sophistication of internally accepted sustainability protocols, it is now up to developers and planners to heed the lessons of the past and find the right dam sites for nature and communities.

If you’d like to discuss how we can assist you with planning, designing and constructing safer dams, please contact Richard Herweynen, Paul Southcott or Phillip Ellerton.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

What are some of the challenges of hydropower in South East and East Asia?

Entura’s Rajeev Raina, Resident Director India, discusses the challenges of hydropower developments in South East and East Asia, as well as how these are being overcome. This video is part of a broader discussion about the role of hydropower in a changing renewables landscape, lifted from an Entura webinar to celebrate Global Hydropower Day on October 11, 2022.

If you would like to discuss how Entura can help you with your hydropower project, please contact us.

About the author

Rajeev Raina is Entura’s Resident Director India, managing the team there and overseeing our work in the region. He has over 20 years of experience in civil engineering, specifically in detailed design for various power plant projects. Rajeev has in-depth knowledge of structural analysis and has worked on numerous hydropower developments throughout Asia, the Pacific and Australia.

MORE THOUGHT LEADERSHIP ARTICLES

Why is hydropower important for deep storage?

Entura’s Donald Vaughan, Technical Director, Power, discusses the role of hydropower in deep storage, and how this will become increasingly important in a future renewables landscape. This clip is lifted from an Entura webinar to celebrate Global Hydropower Day on October 11, 2022, where our Technical Leaders and Executive Team came together to discuss the future of hydropower.

If you would like to discuss how Entura can help you with your hydropower project, please contact us.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

What role does hydropower play in the race to net zero?

Dr Amanda Ashworth, Entura’s Director of Strategy, Sales and Commercial, discusses the role that hydropower plays in the race to net zero. This discussion took place during the webinar held by Entura to celebrate Global Hydropower Day on 11 October 2022, where our Executive Team and Technical Leaders came together to explore the future of hydropower in the renewable energy landscape.

If you would like to discuss how Entura can help you with your hydropower project, please contact us.

About the author

Dr Amanda Ashworth holds a PhD, Graduate Diploma in Environmental Studies and Bachelor of Arts. She brings together Entura’s corporate marketing, sales and commercial functions, providing direction to these teams and areas of the business, and leads strategy development and achievement. She is also the manager of the Entura clean energy and water institute. Amanda has 25 years’ experience in multi-disciplinary research and practice on a wide range of environmental, social and economic topics. She has spoken at numerous international conferences and is the author of several peer-reviewed papers.

MORE THOUGHT LEADERSHIP ARTICLES

Getting your renewable energy project through planning and approvals

The planning and approvals system is complex, and its potential impact on the cost, timeframe and overall success of your renewable energy or storage project should never be underestimated.

Investing time and energy in planning for project approvals makes it more likely that your project will get off the drawing board and into reality. The following principles can help you smooth the process and avoid common pitfalls.

Understand constraints and impacts

The planning system tends not to differentiate between various forms of renewable energy generation, constraining all forms due to the perception and experience of those forms with greater perceived impacts (such as wind farms). Yet each project is unique, as is every piece of land – so each development will bring different values, impacts and benefits into play.

Getting the earliest possible understanding of the environmental and approval constraints over the development site will help reduce risk and avoid a later re-design.

All developments have potential impacts. Communities may be concerned about potential impacts on human health, biodiversity, heritage impacts, visual amenity, noise, changes in land use, construction impacts, just to name a few. However, it is generally ecology and heritage that make or break a project because there may be underlying regulatory requirements associated with existing overlays that prohibit or limit development.

Particularly in the Commonwealth jurisdiction, but increasingly across all state jurisdictions, developers must clearly demonstrate how the project has avoided and reduced impacts, rather than merely offsetting them by purchasing parcels of land elsewhere. Some states actually require the developer’s option analysis process to be documented. Only when the authorities are satisfied that the project has actively avoided and reduced impacts, will they negotiate what mitigation methods are preferable.

Communities are often concerned about visual amenity, so this analysis should be done early as part of identifying ‘red flags’ or constraints. When used properly, visual impact assessment can be a powerful way to design sensitively and responsibly, reducing impacts on views.

The overall impact assessment often takes into account the context of the new development, such as whether it is in pristine environment or existing built-up or industrial areas. An increasing trend is to redevelop brownfield sites for renewable energy or storage projects, instead of focusing solely on greenfield prospects. There is enormous potential to re-use existing infrastructure, former industrial sites or degraded sites, such as mine sites which are no longer viable or operational or former thermal power station sites. This can complement the existing management and rehabilitation regime for these sites which often have very poor environmental conditions, making projects rewarding for the developer and the community.

Get to grips with the regulatory landscape

Depending on the scale, location and potential impacts of the project, approvals may be required at the Commonwealth level (through the operation of the Environment Protection and Biodiversity Conservation Act 1999), the state level (through the implementation of state environmental protection legislation), and the local level (through the implementation of a local development control plan or planning scheme).

These three levels interact differently in each state and for different processes. Some states have very streamlined and integrated approvals processes for large-scale projects which can coordinate Commonwealth requirements and facilitate local government discussions, making the process easier for the proponent or consultant. In other states, consultants often coordinate the different levels of processes, navigating the greater potential for conflicting or onerous requirements across the Commonwealth, state and local level.

Don’t launch into writing the approvals document without first conducting a mapping exercise and developing an approvals strategy. The approvals strategy helps map out all Commonwealth, state and local government requirements across each project component (e.g. a transmission line on a road reserve will often have different environmental values and require different approvals than a transmission line across a farm paddock). This will help you understand what approvals will likely be required and where dependencies exist. Your approvals strategy should be a live document, reviewed whenever there are changes to the project or legislation.

Building a transparent and honest relationship with the regulator/s is a worthy investment, and a consultant can lead this relationship for you. By listening to the regulator/s, paying attention to their advice, and changing the project’s design accordingly, a developer may be able to pre-empt or avoid conditions being applied to the project.

Develop a solid submission

Once the approval requirements are confirmed, detailed technical studies are essential for clearly demonstrating that the issues are understood and that the development (and any mitigation or management measures) is appropriate.

Target the application documentation to match and address the requirements of the relevant development control document, drawing on the conclusion of the technical studies. Include a summary of the proposal that identifies the key issues and mitigation measures, as well as the detailed technical studies underpinning the planning assessment.

Manage conditions

When permits are issued, it is common for there to be a number of conditions requiring further actions or additional documentation. Once you have a permit, create a conditions management plan to lay out clearly what all parties involved in the project need to do. Determine when the conditions apply (e.g. pre-construction, construction, post-construction or during operations) and who should be responsible. This will reduce the risk of not complying, which may be an oversight but could result in action by the responsible authority or, in some cases, lapsing of the permit.

Take the community with you, right from the start

It is important to differentiate between planning for and planning with communities. Those who will be impacted – whether positively or negatively, and over the short or long term – need to be involved in the process. A developer, owner or operator should identify and meet as many different stakeholders in the community as possible to get to know their individual interests and needs.

Engaging with the host community early in the development stages is key to a successful project and developers may be required to demonstrate that they have done so, even before submitting a permit application. This will help assure authorities (and potential buyers) that the project has a ‘social licence’ to operate.

By engaging early, the developer will have time to explain how the technology works, outline the construction process, and conduct a social risk assessment. Engagement should preferably be face-to-face and consistent. People are far more likely to accept projects when they feel that they have been included, heard and respected.

A particular consideration for large-scale developments is that sites are often located in areas outside of council jurisdiction, some of which are state-owned and can be subject to existing leasing arrangements. More remote areas also have greater potential to involve existing Native Title rights. Planning with genuine respect and acknowledgement of Indigenous communities is crucial, but often undervalued. First Nations/traditional owner groups should not be treated like any other stakeholder but as a land-owner (because they are, and governments are increasingly recognising this).

The task of building the community’s confidence in a project is sometimes difficult. The best approach is to communicate any foreseeable short-term and long-term impacts as early as possible and in an open and non-defensive manner. Listening to the community and working together to identify social and environmental risks will help build trust between the project team and stakeholders, and result in a development the community are proud of.

Give your project the beginning it deserves

Ultimately, there’s nothing to be gained by cutting corners or rushing these processes. Your best chance of planning success is through exploring and understanding – at the very earliest opportunity– the development control provisions, permits, consents and the levels of assessment that are required, obtaining high-quality and comprehensive specialist studies, and getting off on the right foot with the project’s stakeholder and community. Your project and your reputation will benefit from doing at least what is required and, preferably, even more. What you put into your ‘once upon a time’ will dictate whether you can reach a ‘happily ever after’.

If you would like to discuss how Entura can help you with your environmental or planning project, please contact us.

About the author

Bunfu Yu is an Environmental Planner with experience across multiple Australian jurisdictions, including Commonwealth, Victoria, New South Wales, Tasmania and Queensland. She advises on a variety of land use and development issues, and scopes environmental and planning projects with a focus on water, energy and electricity infrastructure for a range of clients, including private developers, state utility providers and government agencies. She has qualifications in planning and science, is a sessional lecturer at the University of Tasmania, and serves as a committee member for the Planning Institute of Australia Tasmanian Division and a member of the National Policy and Advocacy Committee of the Planning Institute of Australia.

MORE THOUGHT LEADERSHIP ARTICLES

Keeping close tabs on your dams

Access to quality long-term records is crucial for dam safety. Read what our specialists have to say about keeping your records under control.

The ANCOLD (Australian National Committee on Large Dams) guideline on dam safety management recommends regular reviews on different timescales – including routine inspections undertaken by the operator (daily to monthly), intermediate inspections by a dams engineer (annually), comprehensive inspections undertaken every five years by a dams engineer and other specialists (e.g. mechanical engineers specialising in gates and valves), and dam safety reviews at least every 20 years. For these less frequent dam safety reviews, the ability to access quality long-term records is crucial.

Because dams are such large structures with a very long service life, they need to be reviewed regularly to ensure that any community risks are mitigated appropriately. Dam safety reviews assess the current condition and performance of the dam in depth, and reassess the design and construction of the dam against modern standards.

When the time comes to conduct a dam safety review, dam owners need good records at their fingertips. Poor recordkeeping can lead to significant extra costs and time to conduct the review, but can also compromise a dam owner’s duty of care.

To properly analyse the performance of a dam and assess it against modern design and construction criteria, the dam engineer needs a thorough understanding of the original design and construction, any modifications to the dam since its original build, and a complete set of surveillance and monitoring data.

For some dam owners, when the time comes to complete a dam safety review, all or some of the records are missing – they may have been lost or destroyed through corporate restructures or a failure to understand the importance of the historical records, or the records may never have been created at all.

Which records are important?

In our work as dam safety consultants, we’ve encountered numerous cases in which poor recordkeeping – across many areas and disciplines – has resulted in costs for our clients. The following are critical records to keep in good order and close to hand.

Hydrological records

Records from stream flow and rainfall gauges in the dam catchment provide key hydrological information for dam safety reviews. The streamflow data can be used directly to statistically analyse the probability of the more frequent floods. It can also be used to calibrate rainfall runoff models used to estimate extreme floods for which dam spillways need to be designed. Without this data, flood studies are more difficult because data needs to be extrapolated from nearby catchments. This not only adds cost, but also reduces the reliability of the data, which may potentially lead to oversizing or undersizing the spillway.

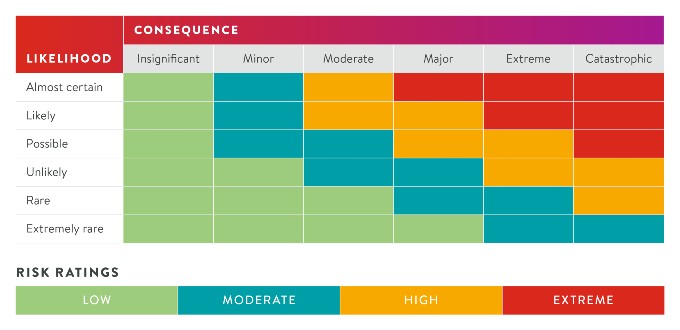

Dam break and consequence assessment records

In Australia, dams are classified according to the consequences of failure – from very low (minimal impact on the community, environment and dam owner’s business) to extreme (catastrophic impact on the community, environment and dam owner’s business). The consequence categories are used to define the level of design (e.g. spillway capacity), the surveillance and monitoring requirements and, in some states of Australia, the regulatory requirements. Where these studies are not available, ‘rule of thumb’ methods may be used to estimate the inundation extent as an interim step, but much more confidence can be obtained by using a flood hydraulic modelling package with good survey data. These studies should be reviewed regularly for currency, especially when development is occurring in the downstream catchment.

Geological and geotechnical records

A detailed understanding of the geology of the dam foundations is essential for assessing the risk of excessive leakage (piping), the presence of any low-strength zones that could cause instability, and the potential for landslides around the reservoir that could cause a wave able to overtop the dam. Investigations undertaken before construction as well as mapping and recording of the foundation during construction provide the best possible information for assessing these potential failure modes.

When these records aren’t available, it is often necessary to undertake extensive and expensive geological investigations into the foundation of the dam, usually while the dam is operational. Such investigations need to be carefully planned to preserve the safety of the dam.

The starting point is review of existing geological records of the site, including geological maps, aerial photographs/satellite images and geological/geotechnical reports from nearby locations. This should be followed by geological mapping to confirm the information obtained from the desktop search, including the rock types and joint and defect orientation spacing. From this, a preliminary geological model of the site can be developed. To reduce the uncertainty of the model, intrusive test pitting and drilling investigations can be conducted. Careful consideration of the dam safety risks of undertaking these investigations is needed, including contingency plans to deal with unexpected conditions (e.g. high-pressure water intersected in boreholes or instability of ground around test pits). ANCOLD has produced a very good guideline on geotechnical investigations of dams, their foundations and appurtenant structures, which should be considered an essential guide for dam owners.

Design records

If records of original design information are unavailable, the dam safety reviewer won’t be able to fully understand the designer’s intent and assumptions. The information required includes the design drawings showing the overall arrangement and key dimensions, as well as the specifications and the design report. If drawings aren’t available or are illegible due to poor quality scans, detailed surveys of the structure may be required to determine the actual constructed geometry. To assess the stability of the dam, the material properties of the dam will be required; but if no data is available, sampling and laboratory testing may be needed.

Construction records

To understand the types of defects that may be present in the dam, it’s important to know how the dam was constructed, whether it was actually constructed to the design, and what issues were encountered during construction. Key construction records include construction reports detailing progress, changes to the design and issues; results of quality testing; as-constructed drawings or mark-ups on the design drawings; and photographs of the construction process. If these records are not available, it may be necessary to confirm as-constructed details through survey, sampling and laboratory testing.

Surveillance and monitoring records

Time-series data – such as regular inspection reports, photographs and instrumentation readings – are invaluable in establishing if there are trends or changes over time that may indicate deterioration of the dam. Without these long term records, it can be difficult to assess whether observed features are longstanding (e.g. present since construction) and what recent developments may indicate about the condition of the dam. Without the full time-series of monitoring data, it can be difficult to observe trends and to understand the relationship between various performance parameters (e.g. leakage versus reservoir level).

Keeping your records under control

If adequate records can’t be located, a dams engineer will need to spend a great deal of time searching archives or undertaking investigations to build a historical picture of the design and construction of the dam in order to assess its safety. When records are well managed, dam owners can save time, money and frustration. To keep your records under control, make sure that they are:

- as complete as practical – which may require extensive archive searches and investigations to fill in the gaps

- securely stored (electronically as well as the original paper records) and retained for the long term (so investigations don’t have to be repeated)

- readily retrievable through efficient indexing and archiving systems.

A good dam may outlast generations of engineers, operators and owners. This makes recordkeeping a fundamental part of maintaining the safety and performance of the dam over its long service life and a key responsibility of every dam owner as part of your duty of care.

About the author

Paul Southcott has more than 34 years of experience in civil and dam engineering, as well as expertise in geotechnical, foundation, structural, hydraulic and hydropower engineering. Paul’s dam engineering experience spans geotechnical and hydrological investigation; feasibility and options studies; concept, preliminary and detailed design; engineering assessment, consequence assessment and risk assessment; safety reviews; monitoring and surveillance; and emergency planning. He has extensive experience in dam risk assessment and was a member of the ANCOLD committees that issued the Guideline on Consequence Categories for Dams in 2012 and drafted the Guideline on Geotechnical Investigations for Dams. Paul pioneered the development of a dam risk assessment methodology for concrete-faced rockfill dams (CFRD). He was the Engineers Australia (Tasmania Division) Engineer of the Year in 2021.

MORE THOUGHT LEADERSHIP ARTICLES

Field investigations in remote locations – factors for success

Conducting field investigations in remote areas is no ‘walk in the park’. On top of the investigation activities themselves, there are the complex logistics of getting personnel and equipment into hard-to-reach places, the imperatives of maintaining safety and managing community expectations, and the significant challenge of conducting works but leaving minimal impact on the landscape.

‘Leave no trace’ may not be too hard a goal when you’re heading off on a simple bushwalk. However, when it comes to conducting field investigations in remote areas with heavy specialist equipment, ‘treading lightly’ can be extremely challenging – but it is something Entura is committed to.

Entura has recently delivered geotechnical investigations for Hydro Tasmania’s feasibility study into the potential for pumped hydro development in some very rugged, remote country in western Tasmania. This is how we did it, and some success factors we can share for field work in these conditions.

Planning

Planning and contract expertise is paramount for successful execution of any project, but particularly so in remote locations. It’s important to take the time at the very beginning of a project to really understand the entirety of the scope and the project objectives. To reduce the risk of unwelcome surprises and unwanted variances, spend enough time on the ground before the works commence so that you can be sure that all the elements have been considered.

This is also the time to gain a full understanding of all the permits and approvals that will be required, the lead time to achieve them, and the range of agencies and key stakeholders who need to be engaged right from the earliest stages.

It will take time and consideration to engage carefully with all contractors to understand their expertise, capability and willingness to undertake the works; but the effort to find the right contractors will be more than repaid by the improved outcomes.

Our project involved multiple drilling investigations to 600 m in 3 separate and remote locations, including a deep ravine located between Lake Plimsoll and Lake Murchison in the heart of Tasmania’s West Coast. The goal was to achieve a clear understanding of geological conditions within the region, which had previously been identified as a fault zone. Our planning needed to encompass all the necessary desktop studies to understand as much as possible about the environment, the stakeholders, the regulations and requirements, and the conditions our contractors could expect, all in advance of sending personnel and equipment into the remote site.

The key to our success in the project was leaving no stone unturned in the planning phase, and using these preliminary insights to choose the right contractors for the job, with the right equipment and skills to achieve our objectives. When things go smoothly and look seamless or simple from the outside, it is usually because of the significant investment of effort in detailed, logical planning right at the start.

Site access

Remote access can be extremely difficult, so the success of a project will depend on establishing practical, efficient and low-impact routes at the earliest stages of planning. Time is money, so contractors will need the easiest and quickest access to the site that you can achieve without compromising on safety or the environment. This will need early and thorough engagement with land-owners to identify constraints, requirements and options. Selecting the best access options will rely on a deep understanding of the biodiversity and heritage values of the site through desktop analysis combined with intensive field observations and data collection.

We selected access routes using a variety of considerations, including what equipment would be required on site, the duration of investigations, the significance of data we gained in the planning stage, analysis of the costs and benefits of options, consideration of the longer term benefits to the land-owners, and consideration of future works.

Ultimately we used a combination of access methods including foot tracks, temporary and permanent roads, and helicopter access. Again, it was crucial that we chose the right contractors who could cope with the conditions and understand the constraints. Our excellent local contractors were integral to our success.

Environment

Conducting works in a region of high natural values demands deep consideration of strategies to avoid or reduce long-term impacts and of what remediation efforts will be necessary and effective.

In one particular instance, we identified and implemented a range of strategies to create a 1.2 km foot-access track in a very sensitive and damp area that was likely to become muddy and highly degraded under the pressure of constant foot traffic during the duration of the works. To protect against this, we hand-cleared the site, developed suitable drainage channels, stabilised the banks, then deployed geo-fabric matting onto which we laid a top coat of clean and approved local woodchips. This innovative solution proved highly successful: it provided solid, safe and reliable footing, excellent drainage and made clearing up the site relatively easy and efficient as the woodchips could be wrapped in the geo-fabric matting, bagged and removed from the site. Once the works were completed, the cut-back vegetation was relatively unscathed, and was able to re-shoot and re-establish rapidly.

Stakeholder and community engagement

Continuous and inclusive community and stakeholder engagement, tailored to the particular community or stakeholder segment, is critical for the success of any project – and the earlier it begins, the better. In our project, we went out on the front foot, building a shared understanding of our objectives, making detailed information available and inviting stakeholders to raise any concerns with our team. We even facilitated site visits for key stakeholders to gain a fuller understanding of the works and build trust.

Many project proponents will tell stakeholders and communities that they want them ‘to come on the journey’ – but we walked the talk, inviting stakeholders to check our milestones, come along to inspect aspects of the work, and to share their feedback.

Cultural heritage

Over a sustained period, Hydro Tasmania has undertaken intensive desktop and field analysis of particular regions and their history. In addition to this rich database of information, Entura has access to specialist cultural heritage consultants who document heritage sites and support us to manage these sites in accordance within the appropriate legislation requirements. Early notification and thorough assessment early in the planning phase indicates whether a heritage site or specific location is likely to be encountered, which enables processes to be established to mitigate heritage risk, minimise site damage and, in some instances, plan for total avoidance and re-siting of works.

In our project, the early engagement of reputable consultants gave us confidence that any areas of significance had been identified. We clearly defined these areas of significance and protected them from any impacts from the works.

Water supply

Drilling investigations require a significant volume of water every day. But not all, if any, remote locations have a ready supply, and if so it’s usually some distance away. Geotech drilling investigations require up to 30,000L/day depending on ground conditions, so the ability to capture and re-circulate water and reduce sediment discharge to the natural environment is crucial in remote locations. Sometimes this needs a bit of innovative thinking to achieve.

Working in a naturally wet environment and on a hillside enabled us to trap natural run-off and control flow to a small header tank (44 gallon drum), then pipe the water to 3 x 10,000L tanks at a flow rate over 24hr period. Three sandbags, float switches and low-impact plastic irrigation pipe allowed us to supply the drill rig with water for 90% of its operation, only having to stop temporarily while drilling during a 5-day period without rainfall.

The creation of a small pond on a steep downhill slope minimised environmental impact downstream and allowed a steady flow of water to continue over the micro dam. The header tank minimised air locks, while tank float switches prevented overflow on the drill site.

By capturing water above the work site, we eliminated the need for extra foot tracks to the creek down in the valley or the need to pump and re-fuel a diesel water pump or to truck water in over 2 km.

Climate conditions

Projects sometimes can’t wait for the perfect time of year to commence. In Tasmania, this brings the challenges of adverse weather conditions and extreme events such as snow and bushfire – even within the same month!

Our remote projects faced these challenges, including frozen water pipes, snowed-in access routes and the risk of bushfire. Planning, watching the weather, and evacuation plans became a daily function.

At one particular location we soon learned that water freezing overnight in pipes could cause significant delays in the morning. Our quick solution was to drain the pipes at night to avoid the problem reoccurring.

To mitigate risks in hot conditions, we had safety processes and equipment in place, such as no-work orders in extreme hot and windy conditions, evacuation plans, safe areas, designated exits, fire pumps and satellite communications.

Safety

Safety should be a top priority on all worksites, and working in very remote areas involves an extensive range of safety considerations. Our workplace health and safety plan provided an overarching document to support the program of work, providing a framework of safety planning, processes and equipment, and careful consideration of the range of potential controls. Each of our contractors developed their own safe work method statement for their own tasks.

In our project, the key identified risks were driving long distances in remote areas and working in areas at risk of bushfire. However, adding to the complexities of safety considerations was that our project was conducted in the time of COVID-19, which necessitated extra hygiene requirements, COVID testing, travel restrictions and the need to immediately stop work when any symptomatic individuals were identified. Ultimately, by implementing our safety plans and processes, we completed the project with no significant safety incidents.

Team work and problem solving

In such complex conditions, the ‘glue’ is good relationships built on trust, shared expectations and objectives, accountability and confidence in each other. This enables collaborative problem solving to overcome challenges or changes in the project. However, contractors often don’t know each other and may be meeting for the first time onsite, so these trusting relationships need to be built quickly.

This requires a level of frankness and transparency among all parties, with honest and open analysis of where things are working well, where there’s room for improvement or where more support is needed.

Particularly in remote areas, it is essential that people don’t feel isolated or alone. Regular drop-ins can help, providing continuity and fresh eyes on site.

Some of the success of a remote project will come down to experience, but just as much depends on good teamwork, regular and open communication, choosing great contractors, and meticulous planning. Not every on-site circumstance can be foreseen, but with these success factors in place, you’ll have a solid foundation and the flexibility to solve challenges on the ground as they arise.

Written by James Butler.

MORE THOUGHT LEADERSHIP ARTICLES

Dam Emergency Dewatering Outlets: A ‘Must Have’, or a ‘Nice to Have’?

One contributing factor for dam safety is the ability to rapidly lower the water level in an emergency. But how can dam designers and owners appropriately determine the need for a dewatering outlet or its optimum size in the absence of a consistent international standard?

Dam safety must begin long before the dam is filled

Dam owners are responsible for the continued safety of dams throughout their life cycle, and for maintaining acceptable levels of risk exposure for downstream communities. As we’ve highlighted in previous articles, dam safety can protect lives and drive efficiencies, having a robust approach to dam safety management must be a top priority for dam owners, regardless of the size of the dam.

A dam safety program should be underway before a dam is filled for the first time, especially if there is significant downstream consequences. This dam safety program should include details such as operational instrumentation, regular routine inspections, and personnel and systems in place to make the necessary decisions should any unusual observations occur. The dam safety manager is a key role required to escalate and make decisions in relation to this. In addition, the key dam safety documentation should have been prepared, including a dam safety management plan, dam surveillance plan, dam operation and maintenance plan, dam safety emergency plan, and evacuation plan. We’ve talked about these elements previously in our ten-point plan for safer dams.

Triggers for dewatering

During unusual events such as the first filling of the dam, major floods or major seismic events, the dam needs heightened scrutiny. If visual inspections and instrumentation monitoring indicate any sudden increase in dam deformation, leakage or internal pressures, it is important that an incident is raised and investigated. If the change progresses and may be developing into a dam safety incident, the risk mitigation strategy may be to reduce the reservoir level (i.e. the water loading on the dam).

To rapidly reduce the reservoir level, a low-level, emergency dewatering outlet is usually needed.

The need for an emergency dewatering outlet

It is good practice to provide an emergency drawdown facility in a dam. This enables the reservoir level to be reduced in a dam safety emergency, which lessens the loading on the dam and the volume of water behind the dam.

The purposes of an appropriately sized low-level outlet are (1) evacuation of the reservoir if emergency conditions occur, or inspection, maintenance and repair of the dam and appurtenant works that are normally submerged, and (2) controlling the rate of reservoir rise as required by reservoir filling criteria.

There are examples in Australia and internationally in which no emergency dewatering outlets are incorporated into the dam, or the total outflow capacity provided is inadequate. Yet there is no consistently adopted international standard for the requirement and sizing of an emergency dewatering outlet. This gap in consistent guidance is of concern, given the importance of dewatering outlets for dam safety.

Lack of consistent international standards for dewatering outlets

The International Commission on Large Dams (ICOLD) provides no reference to a specific drawdown rate; however, a number of its technical bulletins do refer to a bottom outlet to empty a reservoir.

ICOLD Bulletin 49a – Operation of Hydraulic Structures of Dams (1986) states: “It is very important for the dam operator to have outlets enabling the reservoir to be drawn down. While bottom outlets do not readily fit into some sites (as with very large reservoirs on very large rivers), there are still many cases where their absence is regrettable or where they are too small or ill designed … Besides allowing the reservoir to be emptied in periods of low river flow, bottom outlets can also provide fine control of the reservoir during the most critical period of a dam’s life, during the first filling, and draw down the level whenever necessary thereafter.”

Some guidance for emergency drawdown was given by the United States Bureau of Reclamation (USBR) in 1990, suggesting drawing down the reservoir volume to either 10% of the storage or 50% of the height in 1 to 4 months.

However, as these guidelines suggest, it may be impractical to provide the drawdown capability to meet the criteria and guidelines for certain projects. Some reservoirs may be just too large for short-term evacuation. The USBR guideline recognises that decisions relating to emergency dewatering outlets should be made considering the risks that the outlet would help to mitigate and the costs to include such an outlet.

Promoting a risk-based framework

A more recent guideline on emergency dewatering outlets for dams is the UK Environmental Agency’s Guide to Drawdown Capacity for Reservoir Safety and Emergency Planning (2017). This document provides guidance on a consistent methodology for assessing the adequacy of existing drawdown capacity at reservoirs in the UK, based on the judgement of an experienced dam engineer. This judgement should consider the proposed basic minimum recommended standards, the consequence of dam failure, the vulnerability of the dam to rapid failure, the time it may take to detect symptoms of failure and to activate drawdown, the time required to draw down the upper third of the reservoir, the ability to keep the reservoir down for repairs, and precedent practices.

The guidelines promote a risk-based assessment, considering options for mitigating those risks. The guidance document states: “The cost of increasing drawdown capacity is compared to the reduction in risk to life achieved, and only implemented where the cost is proportionate”.

These UK guidelines therefore encourage a risk-based framework for evaluating the drawdown capacity of any emergency dewatering outlet. However, the UK has very few very large reservoirs on large catchments, and the guidance provided may therefore not be applicable to very large reservoirs.

What about larger reservoirs?

The challenge in applying the existing international guidance is when the reservoir is very large and/or the dam is located on a very large river. These larger reservoirs are often associated with hydropower projects. This is recognised in the guidance documents discussed above; however, an alternative approach is not provided.

Both the UK and USBR documents do suggest, though, that the reduction in risk created by an emergency dewatering outlet should be weighed against the cost.

Given that an emergency dewatering outlet is not always possible or practical (particularly for large reservoirs), how can risks be mitigated in other ways?

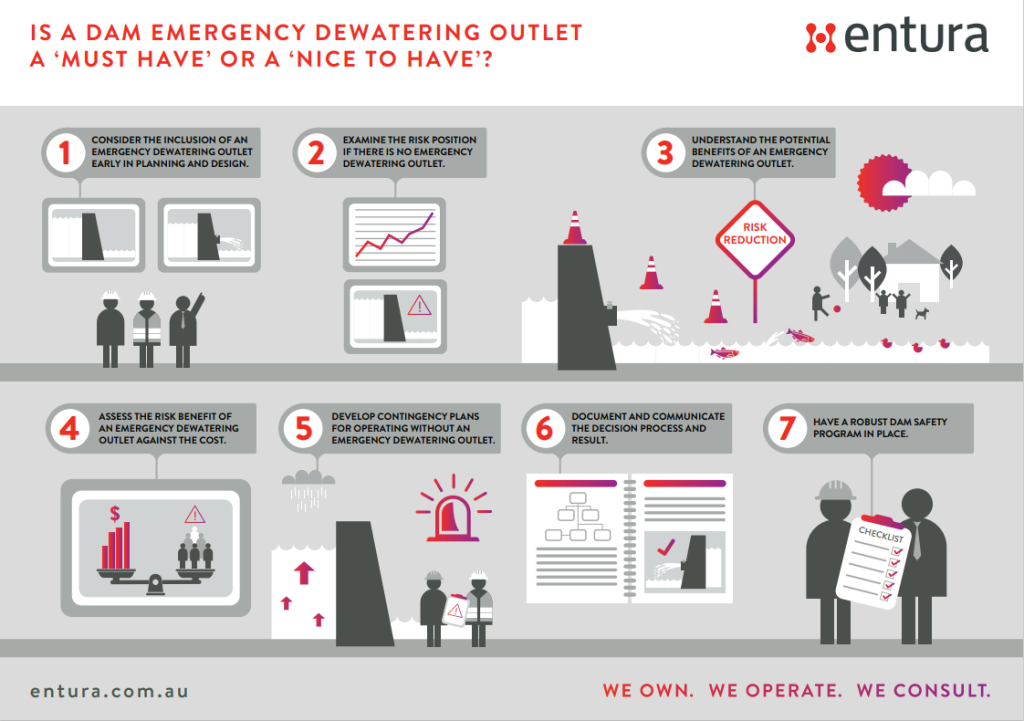

Seven considerations for safer dewatering decisions

When determining whether a dewatering outlet is a ‘nice to have’ or a ‘must have’, systematically consider the alternatives through a risk-based framework and document the decision. With or without an emergency dewatering outlet, it is crucial to develop a robust design, fully consider dam safety, and appropriately mitigate risks to acceptably low levels.

Think about these seven points:

- Consider the inclusion of an emergency dewatering outlet early in planning and design.

It is often easier to incorporate an emergency dewatering outlet into the dam’s general arrangement in the early stages of the design process, rather than later when the dam type has been locked in and all the various components (spillway, intake, diversion) have been located and defined. If it is easy to incorporate, it is good practice to include.

- Consider the risk position without any emergency dewatering outlet.

The main purpose of the emergency dewatering outlet is to be able to take some mitigating action in a dam safety emergency. It is therefore important to determine the risk position of the dam without an emergency dewatering outlet, and evaluate whether this risk is acceptable based on the downstream consequences. Every dam site is unique, so all potential failure modes for this particular dam need to be considered in the risk assessment. If the risk position is not acceptable, alternative options for mitigating the risk should be considered and built into the design and/or operational procedures. Adopt a robust design with sufficient redundancy to mitigate the risks identified through the potential failure modes analysis.

- Understand the potential benefits of an emergency dewatering outlet.

Before deciding that it is too costly to construct an emergency dewatering outlet, at least consider the potential benefits. Gain an understanding, from a holistic project perspective, of the hazards/risks that an emergency dewatering outlet could mitigate. Consider the importance of controlling the rate of initial filling of the reservoir, the ability to evacuate the water from the reservoir at a meaningful rate to make a difference in a dam safety emergency, and the ability and ease of repairing issues below reservoir level by lowering the reservoir rather than undertaking repairs underwater.

- Assess the risk benefit of an emergency dewatering outlet against the cost.

Carefully evaluate the reduction in risk due to the presence of an emergency dewatering outlet compared to the cost – is there a strong justification or not? Even if a full-capacity dewatering outlet is not possible, consider the risk benefit against cost for what is Compare the risk difference ‘value’ with the cost of the emergency dewatering outlet. This will inform a conversation about whether the ‘value’ justifies the cost, which is a strong basis for a sound decision.

- Develop contingency plans for the future.

If there is no emergency dewatering outlet that can enable the reservoir to be emptied for repair works, consider what repair actions may be required during the life of the dam. Ask the questions: What might go wrong? How would we rectify that if we cannot dewater the dam? and Is there anything else that we could build into the design to make this easier? This is ‘safety in design’ thinking, and documenting these high-level contingency plans in the operation and maintenance manual will help those managing the dam in the future.

- Document and communicate the decision.

Document the entire decision process and include the reasons for any decision. All key stakeholders should be aware of and accept the ramifications of any decision. Your organisation should have a robust process in place to assist this decision making process and ensure appropriate consideration in relation to an emergency dewatering outlet. The appropriate dam regulatory body will also need to support and accept the decision.

- Have a robust dam safety program in place.

Any dam with significant consequences downstream (as defined by ANCOLD Guidelines, or similar) should have an appropriate dam safety program in place. If an emergency dewatering outlet is not part of the facility, it is important that the other dam safety risk mitigation strategies identified in point 2 are implemented. The dam safety emergency plan should clearly state the actions to be undertaken in a dam safety emergency, as well as who is responsible for them.

A dam safety emergency dewatering outlet can enable a dam owner to be proactive in a dam safety emergency, and help to maintain or reduce the dam safety risk. As such, it is always a nice thing to have as part of a dam facility, and it should, ideally, be included in any new dam. However, if it is not possible or practical to include a dewatering outlet, be sure to make careful, considered decisions based on a comprehensive understanding of risks and consequences.

If you’d like to discuss how we can assist you with planning, designing and constructing safer dams, please contact Richard Herweynen, Paul Southcott or Phillip Ellerton.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

NEM connections, complexity, risk and tolerance: achieving a balanced approach to grid connection

With the current bow wave in publicly announced emerging and committed storage, wind and solar farms in Australia’s National Electricity Market (NEM), it is now more important than ever that your connection application processes are rigorous and efficient.

This article charts a path of least resistance within the framework of the Australian Energy Market Operator (AEMO) for connection, while also pointing out more effective approaches you could consider. The path of least resistance requires more upfront commitment of resources to ensure the application eliminates doubt or uncertainty. Other approaches take a more balanced approach to risk, accuracy and allocation of effort across the project development timeline.

Maintaining flexibility of deliverables – It’s not all about being technical

Plant dynamic and steady state parameters are likely to change and assessment requirements will evolve from the start to the end of your connection application. This is a natural process of optimising plant performance and compliance under various system scenarios, but comes at the potential cost of disordered delivery of the connection application and delays to the project. Streamlining and clear version control of the report will allow all stakeholders to easily trace changes. Furthermore, with significant updates to PSSe and PSCAD modelling requirements, robust automation of re-assessments would minimise processing time but the changing assessment requirements make investing in such automation somewhat fraught.

Finding a balance between fundamental principles, good practice and efficiency

AEMO has gone to great lengths to increase the certainty and magnitude of expectations about power plant modelling and performance standard assessment. There are paths of least resistance and good practice that can help facilitate a connection application within this framework (which we’ve outlined in the left-hand side of the table below). There are also some fundamental concepts that could help to eliminate wasted effort in the connection application process (the right-hand side below). Achieving a balanced approach is key to an effective and efficient solution not just for an individual project but for the industry as a whole.

| Don’t be scared of EMT modelling | |

| Whilst RMS (root mean square) assessments are still crucial, network service providers and AEMO are requesting significant effort in EMT (electromagnetic transient) benchmarking and analysis of wind and solar farms. Hence, it’s best to benchmark respective EMT and RMS models (using software such as PSCAD and PSS/e) at early stages of the project to identify inaccuracies. Particular focus should be given to plant responses to network and PoC (point of connection) faults with varying grid strength to ensure ride-through requirements (S5.2.5.5) are met and that active power, reactive power and voltage responses are within tolerable ranges between RMS and EMT models. |

The industry (proponents and regulators) must consider which aspects of these models need to be accurate for the development of performance standards and the determination of grid compatibility. When the overall goal is a stable connection of plant, pragmatic engineering judgment is often more beneficial than a slavish pursuit of absolute precision. We should focus more closely on fundamental issues relating to control stability, such as loop gains and time delays, than on the accuracy of switching controller triggers and sensing. |

| Understand your connection point and surrounding network | |

|

We have previously discussed the issues of congestion and system strength and how they impact grid connection. These issues can result in plant MW constraints and non-compliant fault ride-through. It is also important to remember that system strength does not equal SCR (short circuit ratio). System strength is a combination of high impedance network, high concentration of asynchronous machines and lack of nearby synchronous generation. It is a location-specific artefact that adds to the importance of assessing your plant’s control (S52.5.13) and contribution to faults (S5.2.5.5) in network models. |