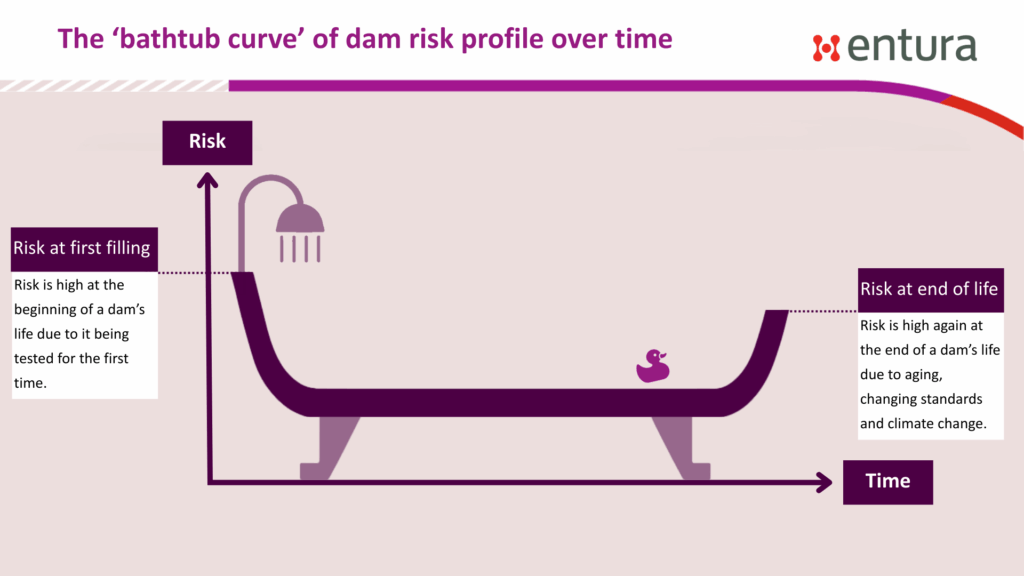

What do dams and bathtubs have in common?

The obvious answer is that both hold water, but there’s something more, which keynote speaker Andrew Watson of BC Hydro referred to at the recent NZSOLD/ANCOLD conference. He described the risk profile of a dam over time as ‘the bathtub curve’.

The riskiest periods for a dam are during the early years of operation and in later years as the dam starts to age.

We talk a lot about managing the risks of older dams through an appropriate dam safety program. A dam portfolio risk assessment is a great way of ensuring effort is focused appropriately. If the risk profile of an aging dam reaches an unacceptable level, this can result in a dam upgrade project. Clearly, there are many well-established processes and tools to manage risks on the aging dam side of the bathtub curve, but how about for new dams?

Reducing risk during design

During the design phase of a dam, we investigate the foundations, develop geological models to represent the foundation and assign geotechnical properties to the elements in our model. We also investigate materials that will be used in the dam, undertake laboratory testing to achieve material properties, and may even undertake insitu trials. We then model the dam structure to determine how it performs for various load cases, including extreme flood and earthquake loading, ensuring it meets the required engineering standards. Although the design process has checks and balances, some uncertainties and risks may have escaped identification at this stage.

Reducing risk during construction

The next phase is constructing the dam in accordance with the design specifications. A quality control assurance program sets quality control measures to give confidence that the construction meets the design requirements. Although the quality assurance and quality control systems are in place, there is still a level of uncertainty, making it difficult to guarantee that all the materials placed meet the required specification. Additionally, the foundation and material conditions may not totally reflect the design characterisation, necessitating modifications during construction. Typically, the designer is engaged in these changes, but was sufficient supervisory expertise on site to recognise these differences and engage the designer?

Reducing risk during first filling

For a dam design engineer, the filling of a new dam is often an exciting time. It is the completion of a major project, but it is also known to be the highest risk stage of a dam’s life. Everything that has gone into the design and construction of the dam is going to be tested for the first time: the design assumptions and models, the actual material properties, the engineering calculations, the quality of construction, the quality assurance systems, etc.

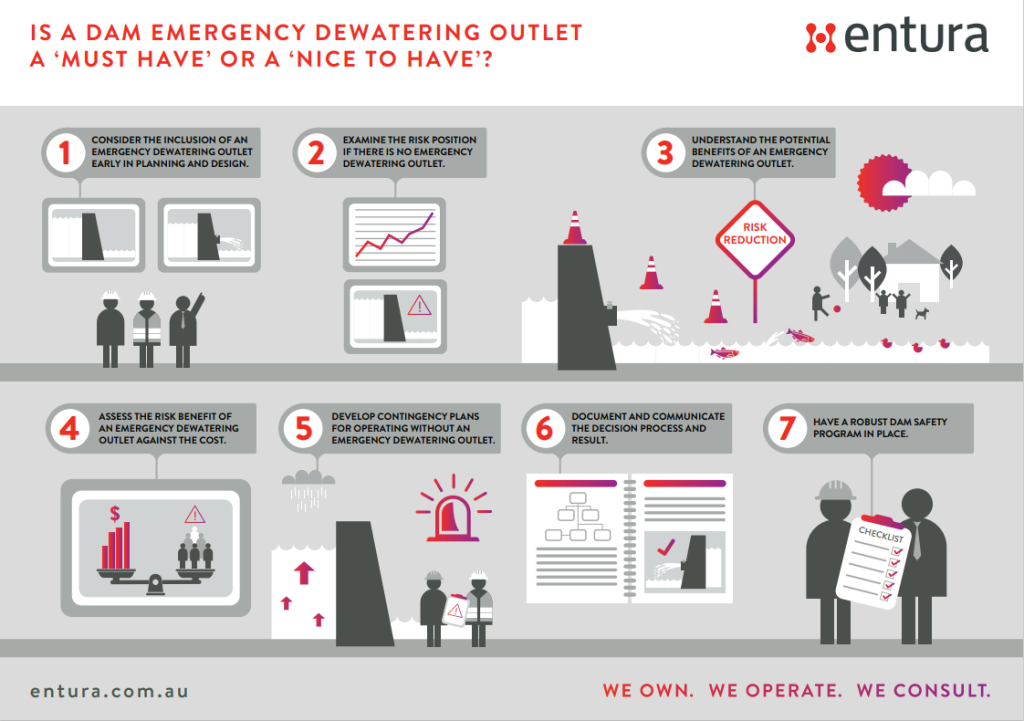

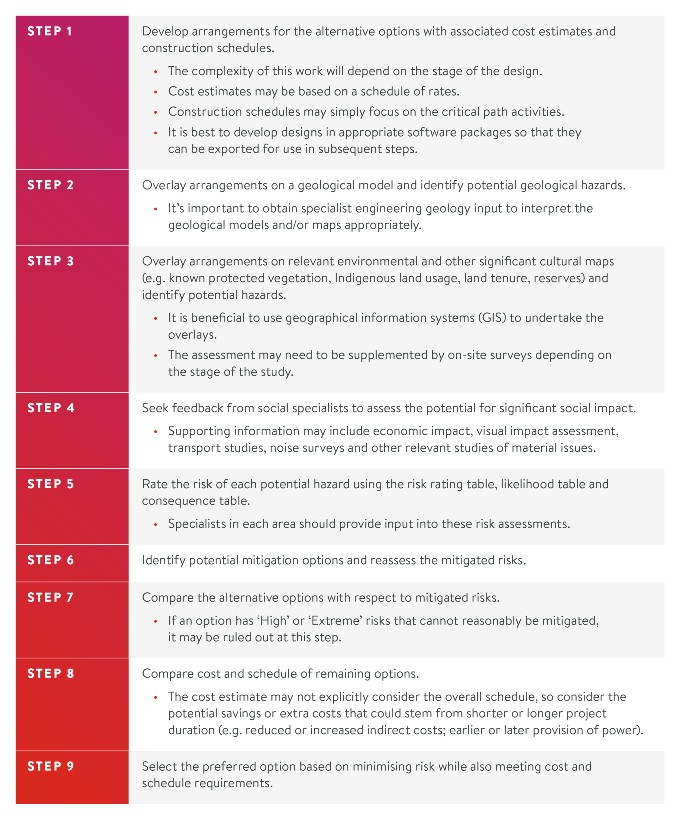

How can risk be mitigated during this first filling and the early years of operation, when the dam is being tested? From our experience, these practical steps can help reduce the risk (click each step for more details):

1) Ensure good technical governance through design and construction

2) Set up quality assurance and quality control systems

3) Continue a design presence on site

4) Use a risk framework to determine a dam’s readiness to impound

5) Have a dam safety system in place before impoundment

6) Maintain a heightened level of monitoring and surveillance

7) Be prepared in case of an unlikely dam safety emergency

8) Keep a close eye on the dam in its first years of operation and during new peaks

This process for new dams should apply equally to main dams and smaller saddle dams. In larger reservoirs, water may not fill against a saddle dam for a year or two after the commencement of impoundment. In this case, the same principles should be applied to the saddle dam during the period when water is against it for the first time. These principles also apply when a dam is raised, because when water load is placed against the raised section, the raised dam is being tested for the first time.

By applying these steps through the heightened risk period during first filling and the first 5 years of operation, dam professionals can mitigate the risks associated with the early side of the bathtub curve, helping the dam get a good start in life.

ABOUT THE AUTHOR

Richard Herweynen is Entura’s Technical Director, Water. He has more than 3 decades of experience in dam and hydropower engineering, working throughout the Indo-Pacific region on both dam and hydropower projects. His experience covers all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance, and risk assessment for both new and existing projects. Richard has been part of a number of expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and was the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

Poutès Dam – a model of sustainable dam redevelopment

Having been named as the Planning Institute of Australia’s Young Planner of the Year for 2023 and awarded a bursary, Entura’s Bunfu Yu travelled through Switzerland and France to study hydropower and energy innovation. Her tour to Poutès Dam in France made a powerful impression. Here she reflects on what Poutès Dam demonstrates about environmentally driven engineering design and how genuine engagement with stakeholders in a design process can lead to balanced outcomes …

The Poutès Dam, located on the upper Allier River, a tributary of the Loire River in central France, has become a landmark case study of how to reconcile renewable energy production with environmental restoration. It’s a project that benefitted from genuine engagement, environmental-led engineering design principles, and future-conscious leadership by its operator, Electricité de France (EDF).

The dam was built during World War II without the usual approval processes. It has long been an obstacle to migratory fish, such as Atlantic salmon from the Allier basin, blocking the return of spawners and the downstream migration of juveniles. It has also disrupted the natural sediment flow of the Allier.

From conflict to collaboration

In the 1980s, environmental organisations highlighted the impact of the dam as a cause of the drastic decline in the wild Atlantic salmon population in the Loire-Allier basin. A sustained mobilisation of environmental groups through the 1990s evolved into a lengthy anti-dam campaign. In the mid-2000s, when EDF applied to renew its operating concession, it attracted criticism and rejection from global environmental NGOs, including WWF.

After decades of debate involving local communities, environmental NGOs, the dam operator (EDF Hydro) and public authorities, a compromise was reached in the late 2000s by which the parties agreed on a commitment to sustainable hydropower. Rather than completely remove the dam, a large-scale reconfiguration project – dubbed the ‘New Poutès’ – was born.

In 2015, EDF achieved a 50-year renewal of its licence, conditional on stringent environmental performance requirements, particularly regarding fish migration and sediment transport. It marked a new life for the project: those who once stood on the site of the dam in protest were now collaboratively discussing the future of Poutès with the operator and public authorities.

The ‘New Poutès’ project

A substantial refurbishment of the dam was carried out over several years to 2021, with the renovated dam inaugurated in October 2022. The design carefully configured to improve salmon migration and achieve the desired environmental outcomes.

- The dam height was lowered from 18 m to 7 m to reduce the water head and the reservoir’s impact. The embankment is also shaped in such a way that, along with the reduced hydraulic drop, the fish have a shorter and smoother vertical barrier to overcome.

- The reservoir length was decreased from 3.5 km to under 500 m, restoring much of the river’s natural profile (including a natural river gradient that allows salmon to swim) and rebuilding downstream spawning habitat.

- Two large centrally located sluice gates were installed, which can be fully opened during fish migration seasons and for high-flow water releases, allowing sediments and aquatic fauna to circulate freely. This is considered the key innovation to rejuvenate the river’s ecological dynamics.

- Fish-pass structures (fishway and fish elevator) have been incorporated in the design, which operate every 2 minutes to ensure upstream and downstream migration is effective.

- While the turbine flow remains similar to before, generation is paused during key periods to prioritise fauna movement.

The fish ladder in action

Ecological and social benefits match technical success

The New Poutès redevelopment did more than update an old hydropower plant; it reconnected a fractured ecosystem, restoring sediment flow and providing effective fish migration routes. The New Poutès continues to supply about 85% of its original hydroelectric output.

Importantly, this project demonstrates the potential of ‘collective intelligence’; that is, collaboration among diverse stakeholders (government, operator, NGOs, local communities) to produce outcomes that are superior to those achieved through conflict or unilateral decisions.

Moreover, it challenges the notion that dams are immutable – a rigid infrastructure at odds with the environment. Instead, New Poutès embodies a modern, adaptive approach: engineering solutions that evolve over time, responding to environmental and social imperatives.

Lessons from Poutès

As many dam owners and operators consider the future of their aging dams and the need for sustainable management, New Poutès stands out as a model. It shows that:

- with thoughtful design and management, hydropower and biodiversity can coexist

- partial removal and targeted retrofitting of a dam can sometimes be a cost-effective and ecologically positive alternative to full demolition

- restored rivers can recover ecological functions like fish migration, sediment transport and dynamic flow regimes, contributing to broader goals of ecological resilience

- multi-stakeholder participatory processes combining NGOs, operators, authorities and communities can help reconcile competing interests and produce durable solutions.

For me, as a planning specialist, this last point resonated particularly powerfully. It’s exciting to see a project that has learned from the lessons of the past, engaged openly and genuinely with its community, and navigated a path toward greater long-term sustainability.

When environmental, social and heritage values are considered from the outset and integrated into dam design, upgrades and refurbishments, the outcomes are better for everyone. In the Poutès story, it took the loss of the operating licence to make a major leap. Proactive efforts to bring a better balance to the ledger of impacts verse benefits may help avoid such dramatic circumstances.

Having finished my study trip and returned to Tasmania, I’m excited to continue my involvement in Entura’s projects involving dam refurbishment, redevelopment and upgrades – including the new lease on life being planned for Hydro Tasmania’s Tarraleah hydropower station. This project is sure to find itself amongst global examples of leading practice, setting the standard for other owners of older hydropower assets.

Bunfu thanks EDF team members Benoit Houdant (Technical Director Engineering) and Sylvain Lecuna (project manager of the Poutes Dam project), and Roberto Epple (former President of the European Rivers Network) for the site tour. It was incredible to share a site tour with representatives of 2 parties that were once in opposition, but now share in the pride of Poutès.

Poutès Dam and surrounding topography

Close-up of Poutès Dam

ABOUT THE AUTHOR

Bunfu Yu is a dynamic young leader in renewable energy planning, approvals and business development. Bunfu was named the National Young Planner of the Year by the Planning Institute of Australia. This honour recognised not only her passion for planning and delivering renewable infrastructure but also her active contribution to the profession through mentoring, public engagement and knowledge sharing. She is currently a Senior Environmental Planner and a Business Development Manager at Entura.

Dam decommissioning: old dams, new opportunities

While many dams have very long lives, and could in theory operate for centuries, some dams reach a point at which decommissioning becomes a realistic final phase of the dam life cycle.

Decommissioning is not something that happens very often, given the significant value of dams and their functions, which are often multiple. Maintaining and upgrading dams, rather than decommissioning, can sometimes also be a more sustainable solution if this extracts more economic, social and environmental value to offset the initial impacts that the dam may have caused when originally constructed.

However, decommissioning may be the best option if the dam is no longer needed to deliver its original purpose, if it is no longer providing commercial or societal benefits, or if it is considered too costly to continue maintaining the dam or to undertake the necessary upgrades to stay compliant with contemporary regulations and standards.

How is a decision to decommission made?

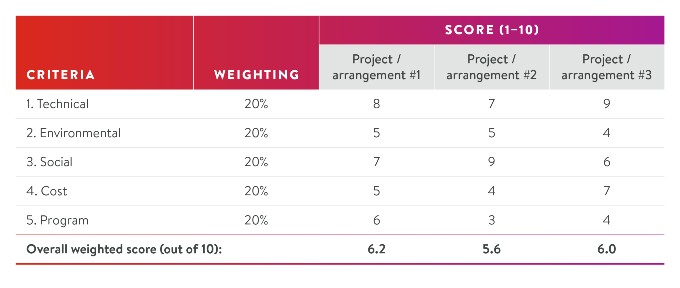

The decision to decommission a dam is usually based on a comprehensive risk assessment. Risk assessments play a critical role in managing dams throughout their life cycle. They primarily focus on ensuring safety and minimising risks associated with dam operation, failure and decommissioning.

Risk assessments estimate risks, identify hazards and failure modes, evaluate the tolerability of the risk, compare potential risk reduction measures if needed, and establish a risk reduction strategy.

If the risk is not tolerable, risk reduction measures will be recommended, and a risk reduction strategy will be established to reduce the risk. The risk reduction measures will generally involve upgrade works. When the option to undertake dam upgrade works is considered, the option to decommission the dam is often also included. The dam owner can then undertake a cost–benefit analysis to determine the most viable option, understand the level of risk reduction achieved, and consider less tangible aspects such as community concerns.

What’s involved in decommissioning a dam?

Decommissioning a dam requires considerable planning to minimise environmental impacts and reduce the chance of leaving any residual hazards in the long term. A thorough assessment of the site conditions and downstream environment is a crucial first step towards identifying the appropriate decommissioning actions.

The location of the dam and the details of the dam works will determine the planning requirements, which often include:

- engineering design – taking breach width and batters into account to remove the possibility of retaining water, and assessing the impact on flooding downstream (as dams frequently provide flood mitigation even when this is not their primary function)

- sediment and erosion control planning – as sediment release can cause significant water quality issues and harm to habitats downstream. It is important to note that the reservoir area will initially be unvegetated and will not have any topsoil that can be used to support vegetation growth to control erosion. Additionally, sediments will typically have been deposited in the dam reservoir and are generally very easily remobilised, so this needs special attention from the designers

- flora, fauna and cultural heritage studies – as decommissioning can dramatically alter ecosystems both upstream and downstream, and heritage features can often be highlighted improving the amenity of the new asset. Ecological studies such as flora and fauna assessments are important to identify any threatened species that need to be considered in the decommissioning plans, such as through exclusion zones or timing the works to minimise impacts (e.g. conducting work outside of breeding seasons)

- fluvial geomorphology assessment – which identifies how rivers interact with their landscapes and how they change over time. It is important to understand this given that the decommissioned dam will have water flowing through it rather than retaining water, changing the balance of erosion and sedimentation processes

- dam safety emergency plan for decommissioning works – to protect communities from flooding during the decommissioning works

- regulatory approvals – a dam decommissioning permit will be needed, which will include managing any specific regulatory requirements such as issuing a notice of intent prior to commencing works and providing work-as-executed reports and drawings at the completion of the works to confirm all conditions have been successfully met.

- Depending on the use and location of the dam, it is recommended to consult with a range of stakeholders, including the local community and council, during the planning process to ensure that their perspectives and concerns are considered early. If the dam is located near to residences, public spaces or other civic amenities, extensive consultation is likely to be needed due to the potential nuisance from the works (e.g. noise, dust and additional traffic in the local area). A masterplan can be developed through this process of consultation, outlining potential options for remediating and repurposing the area based on the community’s priorities, such as creating potential new community assets such as wetlands, parks or sporting facilities.

The work involved in decommissioning a dam will depend on the type of dam and the surrounding environment but commonly involves:

- re-routing inflow away from the reservoir or past the dam

- removing all or part of the dam wall

- modifying or removing the outlet works

- lowering the spillway crest level or removing the spillway control gates or stop-boards

- treating retained liquid prior to discharging it in a safe condition

- stockpiling and stabilising accumulated sediments from within the reservoir

- removing or encapsulating impounded material, such as trees and vegetation

- revegetating the reservoir area and rehabilitating the site to perform its new purpose.

Doing it safely

Decommissioning a dam is a very complex matter involving many stakeholders and often taking some time to reach its conclusion, so it is prudent for dam owners to embark early on some interim measures to rapidly reduce any identified dam safety risks. The simplest and most cost-effective risk reduction measure is usually to lower the level of the reservoir.

The next stage is identifying the planning requirements and works involved with decommissioning and developing a decommissioning plan. The engineering design, included in the decommissioning plan, will consider the necessary environmental assessments and ensure adherence to appropriate guidelines.

Common considerations when developing the engineering design include:

- hydrological and hydraulic assessment of conditions before and after decommissioning

- the necessary breach width and batters to make the site safe

- safely discharging or removing retained water and material

- the volume of any attenuated water remaining after decommissioning

- gradient of the land if the reservoir is being completely drained

- erosion and sediment control during and after decommissioning

- managing inflows and floods during the decommissioning

- careful consideration of the final land use after decommissioning including the ecological restoration and community uses.

Achieving success

For decommissioning to be considered successful, it’s crucial that the decommissioning plan and engineering design take account of the priorities that emerge from stakeholder consultation. Many communities become attached to a dam as part of their local landscape, especially if the dam is very old. They may wish for some of the dam’s heritage to be retained or acknowledged in some way, such as retaining and integrating parts of the abutment into the future form or land use where it is safe to do so, or echoing the past by incorporating smaller water features into the resulting site.

Another major consideration for successful decommissioning is controlling erosion and sediment. Reservoirs typically have a low point that can function as a temporary sediment basin once the water level is substantially lowered. Rainfall and inflows can be channelled with small bunds and hessian silt rolls to the sediment basin. Turbid water can then settle or be treated, if necessary, before being pumped out. After decommissioning, erosion and sediment can be managed by revegetating exposed areas with native plants, creating habitat features such as wetlands or log jams, and managing and monitoring wildlife to ensure their adaptation to the changing environment. Simple solutions can be implemented to achieve positive – or at least neutral – outcomes for biodiversity.

Right process, right people

Decommissioning dams takes a wide range of skills to deliver a successful outcome – from hydrology and hydraulics, environmental and heritage assessments, through to detailed construction planning and a vision for the repurposed land. With the right people and process, decommissioning can reduce safety risks to the community, protect the environment during the works, and ultimately create new, sustainable assets enhancing the amenity of the area for the benefit of communities now and long into the future.

Entura has been involved in a number of dam decommissioning projects including Waratah Dam and Tolosa Dam. To talk with Entura’s specialists about a dam decommissioning project, contact Richard Herweynen or Phillip Ellerton.

ABOUT THE AUTHOR

Joey Scicluna is a civil engineer, who began his career managing commercial and subdivision projects. Since joining Entura’s dams and geotechnical team in 2022, he has undertaken a wide range of dam safety surveillance inspections and reporting, dam safety modelling and analysis and risk assessments. Joey has been the lead author for a number of intermediate and comprehensive dam safety reviews, and has developed design concepts and conducted feasibility studies for existing and new dams projects. Joey enjoys problem solving and working with stakeholders to achieve the best outcome for every project.

Risk is the word – reflections on the NZSOLD/ANCOLD 2025 conference

From 19 to 21 November 2025, industry experts from consultants to asset owners gathered in Ōtautahi Christchurch, New Zealand, to exchange insights, challenge thinking and strengthen connections ‘across the ditch’ and beyond. Here Entura’s Sammy Gibbs reflects on the conference …

If I had dollar for every time I heard the word ‘risk’ across the two-day event, I might have been able to fund next year’s conference myself!

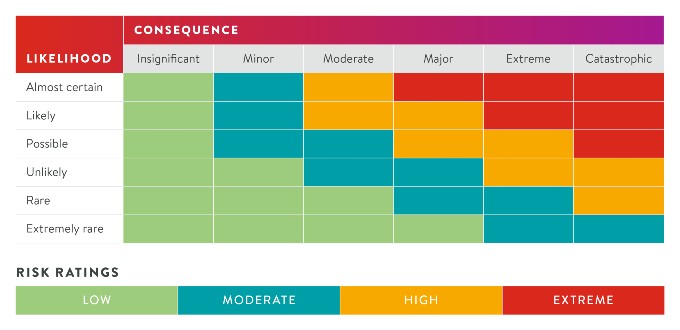

Why was this the case? As noted in many of the presentations and papers, the dam industry is facing the combined challenges of aging dam infrastructure, changing design standards, climate change impacts, community expectations and resource/cost constraints. As a result, the industry is shifting more towards risk-informed decision-making/frameworks, compared to traditional standards-based approaches,to manage and design dam infrastructure.

No dam is 100% safe and all risks can never be designed out entirely, but a sophisticated understanding of their risk can inform our decisions and actions so that we can target key issues cost-effectively and ensure resilience in our dams and water infrastructure.

Risks in asset ownership

In his opening address, Andrew Watson, Director of Dam Safety & Generation Asset Planning at BC Hydro in Canada, provided valuable insights into how BC Hydro uses a risk-informed framework to manage its dams. He discussed the use of a ‘vulnerability index’ to understand the significance of identified physical deficiencies in the dam portfolio. The higher the index, the greater the likelihood that the deficiency would result in poor performance. This index allows BC Hydro’s dam safety team to understand the overall risk profile and prioritise future works. It left us contemplating how the ANCOLD 2022 Risk Assessment Guidelines and ALARP process may be enhanced by integrating components of this approach. This could be a useful way of measuring how far the dam is from meeting ‘best practice’ and hence enhance the justification for further risk reduction or accepting the position as ALARP.

Later in the conference, Andrew Watson was joined by Peter Mulvihill, Lelio Mejia and Barton Maher to discuss legacy risk and how to manage it. Legacy risk is relevant for many asset owners (nationally and internationally) as our sector faces the complexities of inheriting aging facilities, acquired from past organisations/owners. A key challenge with these legacy structures is the transfer of knowledge to new asset owners. Important records such as monitoring data, design and construction information are often lost (or were never developed), making it difficult to understand and quantify the current risk position of the structure. These aging facilities are also unlikely to meet current design standards or withstand climate change impacts. Risk-informed decision making and phased approaches become critical in such instances, as does asking the question ‘Does it matter?’ when it comes to unknowns. Like tying surveillance programs to key failure modes, unknowns should also be associated with credible failure modes.

It was noted that for some of these structures the most appropriate solution is decommissioning, as the risk imposed by the structure (and the cost to mitigate it) may outweigh the economic benefit of the asset itself. In such instances, this decision can provide social and environmental benefits and are worth investigating.

Risk in surveillance monitoring

The conference reaffirmed the critical role of risk-based surveillance monitoring and the importance of understanding how dam instrumentation relates to key failure modes and/or performance. The most effective tool to support this is an event decision tree.

Entura’s Diego Real reiterated the importance of understanding key failure modes when implementing instrumentation upgrades. His paper presented a staged approach for the upgrades, providing clients with a cost-effective, practical solution that assists in managing dam safety risks.

Although there was discussion about various ways in which surveillance programs can be optimised, our industry is aligned in recognising the criticality of undertaking routine inspections as the first line of defence when it comes to identifying potential failure indicators.

Risk mitigation solutions

Several presenters shared examples of bespoke solutions responding to dam risks – including Entura’s Jaretha Lombaard, who highlighted how a Swedish berm was used to mitigate risks associated with piping failures at an earth and rockfill embankment dam in Tasmania.

Other risk mitigation solutions presented included non-physical works such as improvements in surveillance and monitoring. In one example, alarm systems in rivers are being used effectively to warn and evacuate the public in a swimming pool downstream in the event of a flood. Instead of relying solely on costly capital-intensive physical upgrades, the most effective strategy for reducing societal risks may lie in enhancing the speed and reliability of early warning systems.

Sharing knowledge to tackle similar problems

NZSOLD/ANCOLD 2025 was an excellent opportunity to see how specialists are tackling the complex challenges facing the dams industry. Walking away, my mind was full of phrases involving the word ‘risk’, but I felt reassured that we are all facing similar problems and by sharing our knowledge and innovations we’re continually improving our ability to design, monitor and maintain dams.

This conference will be a tough act to follow, but I look forward to the 2026 ANCOLD conference to be held in Lutruwita/ Tasmania (where I live and Entura originated).

ABOUT THE AUTHOR

Sammy Gibbs is a civil engineer with 7 years of consulting experience and joined Entura’s Dams and Geotech Team in May 2021. Sammy has a diverse background in dam and water engineering and works on a range of projects including consequence category assessments, hydrology studies, hydraulic design, risk assessments and dam design projects.

Reflections from MYCOLD 2025: Innovation, resilient dams and the evolving role of hydropower

Earlier this month, I had the privilege of joining colleagues from across Malaysia and the region at the 3rd International Conference on Dam Safety Management and Engineering (ICDSME2025), organised by the Malaysia Commission on Large Dams (MYCOLD), held in Kuching, Sarawak. There’s a particular energy that comes with a MYCOLD conference – part reunion, part technical deep-dive, part regional conversation about water, resilience and community safety.

I returned energised and inspired – not only by the technical excellence on display, but also by the sense of shared purpose across our industry and the tangible people-to-people exchanges and collaborations. With energy systems transforming rapidly, climate change accelerating and dam safety expectations strengthening, it has never been more important for dam and hydropower professionals to share openly and learn from one another. ICDSME2025 offered that in abundance.

Here are just a few reflections on some of what I heard …

Reimagining hydropower in changing markets and climates

In the ‘Advancing sustainable hydropower’ session, I shared perspectives from Tasmania’s long hydropower journey and Entura’s experience supporting the state’s major renewable energy initiatives.

My message was clear: the feasibility of pumped hydro or of reimagining conventional hydropower isn’t simply a technical question of ‘can we build it?’ but ‘what is the long-term value it creates?’ Smart choices depend on a holistic understanding of context – i.e. the markets, energy mix, climate, environmental impacts and benefits, and community perspectives and impacts. Pumped hydro is never ‘impact-free’, and it is not inherently more sustainable than conventional hydropower. What matters is how we think about the future of the energy transition, understanding what role pumped hydro can play in that context, how well we select sites, how carefully we consider environmental and social impacts, and how thoughtfully we design (and extend) assets for long-term economic and social value.

With wind and solar dominating new energy investment in Australia, hydropower’s baseload role can shift to respond to evolving market dynamics. Hydropower’s deep storage, flexibility and system stability are becoming increasingly important. We’re seeing these opportunities in Tasmania, where both conventional hydropower and pumped hydro could – with more interconnection to the mainland – help balance a renewables-rich National Electricity Market while returning extra revenue to Tasmania and increasing the reliability of supply across Australia’s south-east.

Climate change adds further complexity to feasibility considerations. Changing rainfall patterns, more variable inflows and more frequent extremes – as well as with the increasingly variable generation mix and how energy sources interact – all influence when hydropower can generate or store.

Ultimately, I believe there are not only opportunities with extending operating life, refurbishing or redeveloping dam assets; there are also obligations upon us as an industry to do our best for the sustainability of these assets. We need to focus constantly on how to optimise outcomes from the base impacts of hydropower or dam developments and seek ways to reduce impacts into the future. We also need to think about how to deliver great outcomes and value that extends across a long asset life, beyond the limited commercial timeframes considered in final investment decisions.

Technology, people and the future of dam safety

I had the honour of chairing a keynote session featuring Yang Berbahagia Prof. Datin Ir. Dr. Lariyah binti Mohd Sidek and Dr Martin Wieland.

Dr Wieland’s insights into the seismic performance of dams reminded us that strong engineering fundamentals remain as crucial as ever, even as digital tools advance. Prof. Lariyah explored how digital platforms, artificial intelligence and risk-based frameworks are shaping the next generation of dam safety practice. She emphasised the importance of the human layer: building institutional readiness, strengthening safety culture, fostering stakeholder trust, and ensuring effective engagement with communities.

Together, their perspectives reinforced that the future of dam safety will depend on both technological innovation and human-centred capability and how effectively these dimensions interact. That’s something Entura is focused on as we continue to bring deep expertise and experience, while exploring and testing the possibilities of new technology to support design and analysis.

Learning from incidents to strengthen global knowledge

Another highlight for me was chairing a session on dam surveillance, monitoring and evaluation. Seven presentations, while different in context and purpose, in combination emphasised the power of data and the importance of learning from experience.

A standout paper examined the 2022 landslide incident at Kenyir Dam, an event that occurred quite soon after Entura’s dam safety inspector training program used the dam as a site visit capstone. Despite extreme rainfall and slope instability, and some damage to appurtenant structures and spillway, instrumentation data confirmed that the dam behaved as designed. What was also clear was that, largely, the instrumentation in place and the data that was able to be collected was a positive demonstration of the importance of robust dam design and monitoring systems.

Another paper explored machine-learning approaches to forecasting short-term reservoir levels at Batang Ai Hydroelectric Project – a scheme with which Entura has long been associated. The results were impressive and point to a future where AI-supported forecasting strengthens real-time operations, especially under increasing climate variability.

These are exactly the kinds of insights our industry must continue to share openly and widely. We can never ‘design out’ all risk, but we can reduce it through good data and continual reflection and learning from real-world events.

Strengthening long-term capability in Malaysia

ICDSME2025 also highlighted the importance of building capability – something I am passionate about. It was encouraging to see Malaysia’s Certified Dam Safety Inspector program, developed with input from Entura’s training arm ECEWI, growing into a sustained and locally led pathway, launched during the conference. Strengthening dam safety ultimately depends on skilled people and strong institutions, making investment in training an investment in long-term sustainability of dam safety governance – and ultimately greater national resilience. We hope to continue to work with MYCOLD to determine how our specialised expertise can further enhance capability uplift beyond surveillance, extending to dam safety risk decision making and dam safety engineering.

A shared commitment to the future

Conferences like ICDSME2025 are timely reminders of our collective responsibility and the shared purpose we need to bring to the challenges ahead. We’re all navigating the same landscape, and when we come together – sharing data, stories and lessons – we accelerate progress for everyone.

I am grateful to MYCOLD for the invitation to contribute and for the generous knowledge-sharing throughout the event. I left Sarawak optimistic: the connection, commitment and collaboration across our sector have never been stronger as we work toward our common goal: safer, more sustainable dams and hydropower systems that support resilient futures.

Can you trust advanced tools without qualified professionals behind them?

To make confident decisions about renewable energy assets – from building a wind farm to monitoring dam performance or optimising asset management – owners and operators need precision data they can trust.

As the renewable energy sector becomes increasingly digitised, the quality of measurements matters more than ever. Digital twins, predictive analytics, AI-driven performance tools and remote operations all depend on reliable, precise and traceable data.

Good data provides visibility. It lets owners and operators detect faults or safety issues early, optimise performance, and protect reliability and revenue. For example, accurate turbine alignment during installation or refurbishment could save hundreds of thousands of dollars in downtime and maintenance.

However, data only provides value if it has the right level of accuracy for the job intended. If the data isn’t up to scratch, the decisions won’t be either.

Keeping pace with technology is a steep learning curve

Surveying has always been the backbone of infrastructure development, land management and industrial precision. From the early days of using theodolites and chains to today’s cutting-edge technologies like laser scanning, UAV photogrammetry and LiDAR, the discipline has evolved dramatically. Yet, one constant remains: the need for appropriately qualified and experienced professionals.

Surveying is far more than measuring distances – and achieving precision requires more than sophisticated instruments. It requires a deep understanding of geodesy, data integrity, error propagation and spatial analysis. Traditional instruments such as theodolites and total stations demand mastery of angular measurement and trigonometric principles. GNSS-based methods introduce complexities like satellite geometry, atmospheric corrections and datum transformations. As technology advances, the learning curve steepens: laser scanners and UAVs generate massive point clouds, while LiDAR systems demand expertise in filtering, classification and 3D modelling.

Surveying principles now extend beyond land and construction into industrial metrology, where precision is measured in microns rather than millimetres. In the renewable energy sector, the applications are vast, from assessing hydropower turbine blade wear and integrity of concrete structures to verifying the verticality of wind turbines and ensuring accurate positioning of new hydraulic equipment. Here, advanced techniques like laser trackers and terrestrial laser scanning dominate, and the margin for error is extremely small.

Precision gives confidence that the data feeding an asset’s digital models is accurate, consistent and aligned with recognised standards. When survey instruments, operational sensors and digital monitoring systems all work within a strong metrological framework, asset owners can be confident that their decisions are based on fact, not noise.

The human behind the technology

However sophisticated today’s measurement tools and technologies may be, their outputs are only as trustworthy as the professionals behind them.

Without properly qualified and experienced operators, advanced tools can become liabilities rather than assets. Misinterpretation of data or incorrect calibration can lead to costly errors in construction, infrastructure alignment or asset management.

Using the wrong technique or sensor for the use case and conditions, neglecting appropriate calibration, and a lack of adequate redundancy can lead to major issues and costly mistakes.

Specialised, qualified professionals will think through these issues early, ensuring that accuracy and tolerance requirements are clearly defined from the start and that data integrity is maintained throughout with robust quality control and assurance procedures.

Human insight provides the environmental and engineering context and assurance that automated systems alone cannot deliver. Surveying and metrology professionals can determine whether readings are valid and offsets are accounted for – and will be able to distinguish genuine change from measurement anomalies.

Ultimately, it is professional judgement that transforms accurate data into actionable insights and confident decisions.

Accuracy drives advantage

Today’s surveying advances are transforming how decisions are made. Spatial data is no longer just a technical input; when validated and interpreted by qualified professionals, it becomes a valuable source of real strategic insight and advantage. When the data is right from the start, every subsequent step becomes more certain and the outcomes have the best chance of being more efficient and sustainable. Such clarity can be the difference between success throughout an asset’s lifecycle and expensive lessons learned.

As technologies advance, so does the need for qualified professionals who understand both the science of measurement and the realities of complex, dynamic infrastructure. By ensuring accuracy, compliance with standards and efficient workflows, the qualified surveyor safeguards projects from financial and reputational risks – enabling the reliability, safety and commercial confidence that every asset owner depends on.

If you’d like to talk to us about the potential of advanced surveying and metrology on your project, contact Phillip Ellerton or a member of our Spatial & Data Services Team.

New technologies are important tools, but they need to be used properly

Entura’s Technical Director (Water), Richard Herweynen, recently attended the 2025 ICOLD Congress in Chengdu, China, themed ‘Common Challenges, Shared Future, Better Dams’. Here he shares his observations on the state of play in the international dams industry – and the opportunities emerging with artificial intelligence and automation.

My first ICOLD Congress was in Beijing, China in 2000. I was presenting some finite element analysis work that I had done on Gordon Dam, a 140m-high concrete arch dam in Tasmania. The analysis was being used to help predict and explain some cracks that had formed at the base of the downstream face of the concrete shell, roughly normal to the foundation, during first filling. In the 1980s, an attempt had been made to model the crack using finite element modelling, but with little success due to the coarseness of the mesh. However, by the late 1990s, computing power had increased and finite element programs had improved, providing the capability to construct more detailed finite element models, which were able to predict and explain the cracking that had occurred.

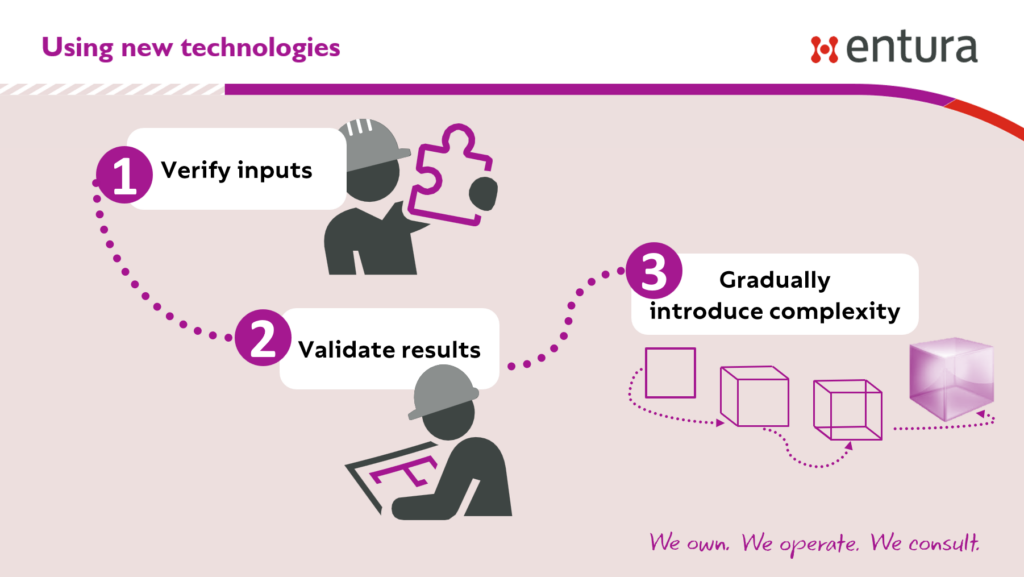

Dr Sergio Giudici, the designer of Gordon Dam, was my mentor on this finite element analysis, and he reinforced these principles:

- It is important to verify the input data to make sure the model represents, as well as possible, the actual dam parameters.

- Results should be validated using alternative techniques to give the engineer confidence in the results that the model is producing (i.e. structural hand calculations still have a place).

- Complexity should be built into these models only gradually, so that the engineer can see the impact of changes and determine whether they are reasonable.

These same principles are true for many complex engineering models and when setting up calculation spreadsheets or similar.

Now, 25 years on, I have had the privilege of attending the 2025 ICOLD Congress in Chengdu, China. At this Congress, there was much talk about the importance of dams in society for water security, the growing role dams and reservoirs play in providing resilience to climate change and the energy transition, the importance of balancing economic benefits and environmental needs, and – in all of this – the importance of ensuring that our dams are safe for communities downstream.

We have discussed many of these themes before – and they remain highly important; however, one thing I took away from ICOLD 2025 in particular was how China is embracing technology and advancing a ‘Smart Dam’ initiative.

New technologies and smarter dams

One could say that our industry has always been building smart dams, but China’s ‘Smart Dam’ concept is about using the full power of current technologies to construct, monitor and operate dams in smarter ways, and to use technologies to predict and adapt to changing conditions.

The CHINCOLD Workshop on Digital and Intelligent Technologies for Dam Construction, Operation and Maintenance, which occurred during ICOLD 2025, gave a glimpse of what may be possible.

Many projects utilise 3-dimensional digital models and building information modelling (BIM). However, the concept of having a digital twin of the dam, replicating every aspect of the physical dam in a digital form, opens the door to many possibilities, especially in light of the advent of artificial intelligence (AI).

Artificial intelligence and machine learning

Many organisations and nations have been cautious about AI, but China is increasingly adopting it to improve construction practices in dam engineering, improve monitoring and surveillance of dams, and to help adapt to extreme events as they occur.

Machine learning (ML), an element of AI, enables computers to learn from data without being explicitly programmed. ML algorithms analyse data, identify patterns, and make predictions or decisions, improving their performance over time and with more data. There are no doubt many engineering applications where ML could be used to help improve predictive modelling or optimisation, and to make these more efficient. However, the same principles that were important when we were beginning to embrace larger, more refined finite element models with the advent of faster computing remain true here:

- We must verify the input data that machine learning is utilising to ensure we don’t get ‘garbage in equals garbage out’.

- Results need to be validated. AI needs to be trained correctly, and we need experts involved at this stage to ensure that the outputs from AI are correct.

- Complexity, or the full power of technology, should be added incrementally, to provide progressive confidence in the outcomes.

Engineering is the application of science, and therefore it is critical for every engineer to understand the fundamental principles and how to apply them. The complex computer programs used for a lot of engineering modelling can become ‘black boxes’, and practitioners risk diluting or losing their understanding of the fundamental principles behind the models, and hence their ability to validate the results.

Automation brings a step change in efficiency and accuracy

At the ICOLD Congress in 2000, I co-authored a paper for the international symposium on concrete-faced rockfill dams (CFRD) entitled ‘Hydro Tasmania experience in concrete-faced rockfill dams – past, present and future’. There is no doubt that Hydro Tasmania has a strong history in CFRD, with Cethana Dam playing an important role in the development of the modern, high CFRD.

In 2000, however, the future in CFRD that we envisaged did not include unmanned construction equipment with automatic quality control feedback loops. At the 2025 CHINCOLD Workshop on Digital and Intelligent Technologies for Dam Construction, Operation and Maintenance, a presentation was given by Wang Jiajun from Tianjin University on intelligent unmanned roller systems to compact rockfill dams. Unmanned rolling compaction (URC) systems involve three core technology modules: (1) intelligent perception, (2) autonomous planning and decision making, and (3) intelligent control. These systems use automated driving technology to control the rolling process on earth and rockfill dams, improving productivity and quality. They can accurately control compaction parameters such as passes, speed, vibration and lift thickness. URC systems also enable continuous monitoring and real-time feedback for quality control, reducing human error and improving overall project performance. This automated technology was used on the 295m-high, 1.57km-long Lianghekou hydropower dam in China, with a total fill volume of 43 million m3.

The changing face of dam engineering

With AI and automation, the scope for embracing new technology in dam engineering is growing fast. It is clear that there are significant benefits that could be realised for dam design, construction, operation, dam safety and emergency response – and there’s a role for these advanced technologies at all of the stages of the life cycle of a dam. A degree of caution is appropriate and necessary, but caution should not be a reason to refuse to engage with the new technologies available to our industry.

However, with more sophisticated models – such as digital twins – being created of our dams, it is important to ensure we maintain the guiding engineering principles of verifying input data, validating models for correctness, and building complexity gradually. By doing this, we can provide the necessary assurance and confidence in our increasingly sophisticated and evolving tools.

ABOUT THE AUTHOR

Richard Herweynen is Entura’s Technical Director – Water. He has more than three decades of experience in dam and hydropower engineering, working throughout the Indo-Pacific region on both dam and hydropower projects. His experience covers all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and was the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

Planning for the future – the challenges of dam inspection and maintenance

No dam is ‘maintenance free’. Without appropriate maintenance and refurbishment at the right times, a dam may not be able to fulfil its function safely for the full length of its design life (which could be more than a century).

This presents many challenges for asset owners. To keep the dam operating as the designer intended – and get the most out of the original investment over the long term – owners will need to develop and implement a suitable operations and maintenance manual aligned with the asset management plan and reflecting a ‘whole of life’ strategy. These plans will need to consider the unique characteristics of each dam and cover all the relevant issues. And there are many!

Dams consist of a number of different elements. There are the main civil engineering components including the wall that holds back the water and the spillway – but there could also be mechanical elements (pipework, valves and gates) and electrical elements (power supply to lights, valves, gate motors and control systems). Each of these elements will have its own operational and maintenance requirements and different lifecycle duration. Ideally, all this detail needs to be captured in the operation and maintenance manual (as recommended by ANCOLD guidelines) and in an asset management plan.

Civil components

The civil components of dams have the longest life span, typically more than 100 years if well constructed and maintained. Common maintenance items that need to be regularly addressed include:

- Vegetation management

Trees and bushes will readily grow in earthfill and rockfill embankments. Regular control (e.g. annually) is necessary to ensure that roots don’t grow through the fill and initiate leaks through the embankment. Mowing the grass on the downstream face of the earthfill embankment and downstream contact is necessary so that the condition of the face can be observed. Even concrete gravity and concrete arch dams will require vegetation control along the downstream face contact with the foundation so that the dam can be easily viewed in routine inspections.

- Surface water drainage

Dam construction typically affects natural drainage lines, which is why surface water drains are a common feature around and on dams – such as along the groins (where the dam wall intersects with natural ground), along berms in embankment dams, along benches, at the top of cuttings, and along access tracks. Drains will need regular inspection for both erosion and blockage due to sediment or vegetation.

- Foundation drain cleaning

Concrete gravity dams and concrete arch dams typically have drains drilled into the rock foundations to relieve uplift pressures and help maintain stability of the wall. Over time, silt or iron-rich slime can build up as a byproduct of bacterial growth in the drains, reducing effectiveness. These drains typically require 5-yearly high-pressure flushing. Cleaning will also be needed for drains underneath spillways founded on rock and cut slopes in rock.

- Protection of the dam safety monitoring system

Protecting the dam safety monitoring system requires a range of regular activities. These include cleaning and clearing vee-notch seepage monitoring weirs, checking survey monitoring pillars and targets, and checking the calibration of level monitoring and indication devices, such as reservoir-level sensors, piezometers, tiltmeters and inclinometers. Regular functional testing will also need to be carried out on the alarming and tripping devices that form the primary protection elements of the dam, including spillway gates and scour valves.

- Clearing of trash racks

Outlet works usually have trash racks to stop debris entering the pipework and causing blockages. It’s important to check that the build-up of debris is tolerable and that any hydraulic losses won’t affect operations. Assessing and removing the debris isn’t easy, as the trash racks are often accessible only by remotely operated vehicles (ROVs) or by divers. Before the inspection, the outlet will typically need to be closed and isolated.

Inspection-driven longer term maintenance will also be required for particular elements of the dam, ideally addressing repair items promptly to minimise damage and the cost of future repairs if left untreated. For example, concrete repairs may be needed to address erosion in stilling basins and spillway chutes, or spalling of concrete due to reinforcement corrosion or freeze/thaw damage.

While regular inspections should be undertaken to detect slow deterioration, special inspections following major events – such as floods or earthquakes – should also be part of the operations and maintenance plan. Given that the key areas for inspection are often difficult to access safely, use of UAVs (e.g. to inspect a spillway crest and chute) or ROVs (e.g. to undertake underwater inspections or scanning of stilling basins, plunge pools or riverbed scour) should be considered.

When special inspections identify the need for repairs, the time is right to consider whether the dam’s design or surveillance could be improved to increase resilience for a similar event in future. For example, a higher strength concrete overlay may treat erosion of a spillway chute and increase its resistance to future erosion.

Mechanical components

Mechanical items such as steel or cast-iron pipework can also often last up to 100 years if adequately protected from corrosion. Concrete and cement mortar are very effective for this purpose as the alkaline environment provided by the cement paste provides a very low corrosion environment. Key to the effectiveness of this protection is ensuring that the cement remains in intimate contact with the steel or iron. This will require regular inspections and timely repairs. Where concrete protection is not practical, paint systems can be very effective for up to about 20 years. A suitable inspection regime will be needed so that any areas where the paint has deteriorated can be detected and patched.

Mechanical items such as valves and gates typically have an effective life of around 50 years; however, they need to be exercised regularly to keep them able to work on demand. This is not an issue of the parts wearing out from use; rather, it’s the risk of them seizing due to lack of use. Regular lubrication of bearings, gearboxes and trunnions needs to be included as part of the maintenance of these items. This is particularly important in scour valves and spillway gates that may have a very low frequency of use during normal operations but are there for use in emergencies. The wire ropes commonly used to hoist spillway gates open will need even more frequent replacement, at approximately every 20 years.

Electrical components

Electric motors are commonly used to drive the winches hoisting spillway gates or driving the shafts to open valves. Associated with the motors will be switchboards and power supply systems, typically including grid power supply and backup diesel generators. The typical life of these components is around 25 years. As with the mechanical components, lack of operation can lead to premature failure, so a regular regime of exercise is necessary to ensure maximum reliability and life.

The programable logic controllers (PLC) that are used to automate operations, allow remote operations and generate alarms will have a typical life of only 10–12 years due to changes in programming languages and rapid evolution of the hardware.

Getting the most out of life

As we’ve seen, regular maintenance is fundamental for keeping all the components of a dam operating as intended and maximising their lifespan – whether that’s 10 years or 100. This maintenance, including the exercising of the mechanical and electrical components, needs to be clearly documented in the operations and maintenance manual and recorded in an asset management system. The asset management plan must allow for regular maintenance and also budget appropriately for replacement or refurbishment when any component of the dam is due for retirement.

At Entura, we believe in getting the most out of every piece of infrastructure because that’s good for our clients, communities and the planet. With a solid regime of inspection and maintenance, all the parts of your dam will be on the strongest path to a long, reliable and sustainable life.

If you’d like to talk with us about inspecting and maintaining your dam/s, contact Phil Ellerton, Paul Southcott, or Richard Herweynen.

About the author

Paul Southcott is Entura’s Senior Principal – Dams and Headworks. Paul has an outstanding depth of knowledge and skill developed over more than 3 decades in the fields of civil and dam engineering. He is a highly respected dams specialist and was recognised as Tasmania’s Professional Engineer of the Year in Engineers Australia’s 2021 Engineering Excellence Awards. Paul has contributed to many major dam and hydropower projects in Australia and abroad, including Tasmania’s ‘Battery of the Nation’, the Tarraleah hydropower scheme, Snowy Hydro, and numerous programs of work for water utilities including SeqWater, Sun Water and SAWater. His expertise is a crucial part of Entura’s ongoing support for upgrade and safety works for Hydro Tasmania’s and TasWater’s extensive dams portfolios. Paul is passionate about furthering the engineering profession through knowledge sharing, and has supported many young and emerging engineers through training and mentoring.

‘Dams for People, Water, Environment and Development’ – some reflections from ICOLD 2024

Entura’s Amanda Ashworth (Managing Director) and Richard Herweynen (Technical Director, Water) recently attended the International Commission on Large Dams (ICOLD) 2024 Annual Meeting and International Symposium, held in New Delhi. Amanda presented on building dam safety capability, skills and competencies, while Richard presented on Hydro Tasmania’s risk-based, systems approach to dam safety management, and the importance of pumped hydro in Australia’s energy transition.

Here they share some reflections on ICOLD 2024 …

Richard Herweynen – on the value of storage, ‘right dams’, and stewardship

At ICOLD 2024 we were reminded again that water storages will be critical for the world’s ability to deal with climate change and meet the growing global population’s needs for food and water. We can expect greater climate variability and therefore more variability in river flows, which means that more storage will be needed to ensure a high level of reliability of water supply. Without more water storages to buffer climate impacts, heavily water-dependent sectors like agriculture will be impacted.

To slow the rate of climate change, we must decarbonise our economies – but without significant energy storage, it will be difficult to transition from thermal power to variable renewable energy (wind and solar). Pablo Valverde, representing the International Hydropower Association (IHA), said at the conference that ‘storage is the hidden crisis within the crisis’. There was a lot of discussion at ICOLD 2024 about pumped hydro energy storage as a promising part of the solution. It is also important, however, to remember that conventional hydropower, with significant water storage, can be repurposed operationally to provide a firming role too. Water storage is the biggest ‘battery’ of the world and will be a critical element in the energy transition.

With the title of the ICOLD Symposium being ‘Dams for People, Water, Environment and Development’, I reflected again on the need for ‘right dams’ rather than ‘no dams’. ‘Right dams’ are those that achieve a balance among people, water, environment and development. In the opening address, we were reminded of the links between ‘ecology’ and ‘economy’ – which are not only connected by their linguistic roots but also by the dependence of any successful economy on the natural environment. It is our ethical responsibility to manage the environment with care.

When planning and designing water storages, we must recognise that a river provides ecological services and that affected people should be engaged and involved in achieving the right balance. If appropriate project sites are selected and designs strive to mitigate impacts, it is possible for a dam project’s positive contribution to be greater than its environmental impact, as was showcased in number of projects presented at the ICOLD gathering. Finding the balance is our challenge as dam engineers.

The president of ICOLD, Michel Lino, reminded delegates that the safety of dams has always been ICOLD’s focus, and that there is more to be done to improve dam safety around the world. At one session, Piotr Sliwinski discussed the Topola Dam in Poland, which failed during recent floods due to overtopping of the emergency spillway. Sharing and learning together from such experiences is an important benefit of participating in the ICOLD community.

Alejandro Pujol from Argentina, who chaired one of the ‘Dam Safety Management and Engineering’ sessions, reflected that in ICOLD’s early years the focus was on better ways to design and construct new dams, but the spotlight has now shifted to the long-term health of existing dams. It is critical that dams remain safe throughout the challenges that nature delivers, from floods to earthquakes. In reality, dams usually continue to operate long beyond their 80–100 year design life if they are structurally safe, as evidenced in the examples of long-lived dams presented by Martin Wieland from Switzerland. He suggested that the lifespan of well-designed, well-constructed, well-maintained and well-operated dams can even exceed 200 years. As dam engineers, no matter the part we play in the life of a dam, we have a responsibility to do it well.

From my conversations with a number of dam engineers representing the ICOLD Young Professional Forum (YPF), and seeing the progress of this body within the ICOLD community, I believe that the dam industry is in good hands – although, of course, there is always more to be done. I was pleased to see an Australian, Brandon Pearce, voted onto the ICOLD YPF Board.

Another YPF member, Sam Tudor from the UK, reminded us in his address of the importance of knowledge transfer, the moral obligation we all have especially to the downstream communities of our dams, and our stewardship role. He was referencing his experience of looking after dams that are more than 120 years old – all built long before he was born. Many of our colleagues across Entura and Hydro Tasmania feel this same sense of responsibility and pride when we work on Hydro Tasmania’s assets, which were built over more than a century and have been fundamental to shaping our state’s economy and delivering the quality of life we now enjoy. It is up to all of us to carry the positive legacy of these assets forward with care and custodianship, for the benefit of future generations.

Amanda Ashworth – on costs and benefits, dam safety, and an inclusive workforce

Like Richard, I found much food for thought at ICOLD 2024. For me, it reinforced the need to accelerate hydropower globally, particularly in places where the total resource is as yet underdeveloped. To do so, we will need regulatory frameworks that support success – such as by monetising storage and recognising it as an official use – and administrative reforms that ease the challenges of achieving planning approvals, grid connection agreements and financing for long-duration storage. We must encourage research and development to move our sector forward: from multi-energy hybrids to advanced construction materials and innovations to improve rehabilitation.

In particular, I’ve been reflecting on how our sector could extend our thinking and discourse about the impacts and benefits equation beyond the broad answer that dams are good for the net zero transition. How can we enact and communicate the many other potential local environmental and social benefits and long-term value from dams?

Much of the world’s existing critical infrastructure came at a significant financial expense as well as social and environmental costs – so it is our obligation to pay back that investment by maximising every dam’s effective life. When we invest in extending the lifespan of dam infrastructure through effective asset management and maintenance, and when we maximise generation or the value of storage in the market, we increase the ‘return on investment’ against the financial, social and environmental impacts incurred in the past.

Of course, the global dams community must continue to prioritise dam safety and work towards a ‘safety culture’. I was pleased to hear Debashree Mukherjee, Secretary of the Ministry of Jal Shakti, celebrate the progress on finalising regulations across states to enact India’s Federal Dam Safety Act and establishing two centres of excellence to lift capacity across the nation. Dam safety depends on well-trained people with the right skills and competencies to comply with evolving standards, apply new technologies, and respond effectively to changing operational circumstances and demands.

I also enjoyed hearing from ICOLD’s gender and diversity committee on its progress, including updates from around 14 nations on their efforts to build a more inclusive renewable energy and dams workforce. This is front of mind for us, as we step up Entura’s own focus and actions on gender equity throughout our business this year.

The challenges facing our dams community – and our planet – are enormous, but there is certainly much to be excited about, and we look forward to continuing these important conversations over the next year.

From Richard, Amanda and Entura’s team, many thanks to the Indian National Committee on Large Dams (INCOLD) for organising and hosting this year’s ICOLD event, supporting our sector to build international professional networks, and facilitating the sharing of experiences and knowledge across the globe – all of which are so important for growing the ‘ICOLD family’ and supporting a safer, more resilient and more sustainable water and energy future.

Designing dams for an uncertain climate future

Dams are critical infrastructure for water supply, irrigation, energy production, flood protection, or multiple purposes. They are usually designed to last at least 100 years, yet with good maintenance and appropriate dam safety practices, dams can continue to perform as designed for centuries. But what about climate change? The circumstances in which a dam operates may be very different in the coming decades – and exactly how these changes will play out in different regions is impossible to predict with certainty.

Dams are designed to continue to perform safely in extreme events, such as major floods and earthquakes, to avoid the high economic, environmental, and social consequences of dam failure. When the consequence has the potential to be extreme, the flood that the dam will need to be designed for is, in Australia, the ‘Probable Maximum Flood’ (PMF), while in some other parts of the world it is often the 1:10,000 annual exceedance probability (AEP) flood.

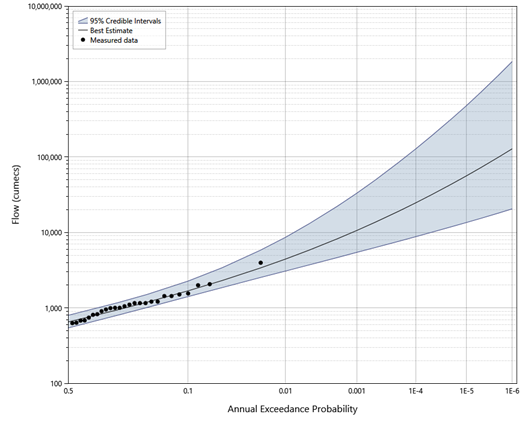

But even if standards or guidelines are clear about the ‘return period’ of flood that the dam should be designed for – is it still as simple as reading the magnitude of the flood discharge off the flood frequency curve as has been done in the past? These days, it is not so simple.

Exploring the inherent uncertainty in the flood frequency curve

Part of the reason for more complexity is that we have greater computing power today to be able to explore the uncertainty in our flood frequency curve. Predicting extreme flood events (such as the PMF) is not an exact science and involves many variables which are often not well characterised. As a result, there is significant uncertainty in predicting floods, particularly extreme floods. If this uncertainty is presented, the flood frequency curve is no longer a single line but a band. The more extreme the flood event, the wider the uncertainty band. Although the flood frequency curve shown below is fitted directly to measured flow data, the uncertainty bounds are similar regardless of the approaches implemented to derive the flood frequency curves.

So, what flood should the dam be designed for? Should it be the median best estimate, or should it take into account some of the uncertainty? This is the first challenge, and it is there whether we consider climate change or not.

Adding the extra uncertainty of climate change

Climate change doesn’t stand still. This adds even more complexity to the flood prediction challenge. What is the impact of climate change on extreme events now, and what will it be as time goes by? Numerous studies of climate change impacts suggest that there will be greater variability in extreme temperatures and extreme rainfall, and that extreme events may become more frequent. As a result, the magnitude of extreme flood events, for which dams must be designed, will likely increase with time.

Changes in the magnitude or frequency of extreme floods will depend on projections of future temperature, emission scenarios and the models used to simulate the changes. Even with a ‘middle of the road’ emission scenario (such as the IPCC’s SSP2–4.5 scenario) that results in a median global temperature increase of 3 °C (compared to preindustrial temperature baseline) by the end of this century, there could be a 23% increase in 24-hour extreme rainfall depth. But this is only one of the scenarios; some are more extreme, some show less increase, some show more. The increase is greater for higher emission scenarios and for shorter duration storms. Ultimately, an increase in rainfall depths results in an increase in flood magnitudes.

Guidance on climate uncertainty in dam design is limited

Currently, most standards and guidance documents are silent on how climate change should be applied in the design of spillway capacities for dams to safely pass these extreme flood events. However, the International Commission on Large Dams (ICOLD) Bulletin 142 on the Safe Passage of Extreme Floods (2012) indicates that there is uncertainty associated with the resulting flood estimates because of uncertainties in the hydrometeorological data used in determining the design flood. In addition, there may be changes in future methods for the development of design floods, changes in the future condition of the catchment (e.g. due to deforestation), and changes in rainfall conditions due to climate change. All of these have the potential to increase the magnitude of the future design flood.

This 2012 bulletin encourages strategies for planning spillway arrangements with consideration of floods exceeding the design flood (i.e. checking the robustness of the spillway flood design capacity from a dam safety risk perspective). This demonstrates that more than a decade ago the international dam engineering community was already promoting consideration of climate change resilience when designing new dams and upgrades of existing dams.

The more recent ICOLD Bulletin 170 on Flood Evaluation and Dam Safety (2018) states that although projected changes in climate are generally expected to increase flood risk in many parts of the world, understanding the impact on flood risk is subject to considerable uncertainty. It states that one of the main impacts of climate change will be to increase the uncertainty associated with the estimation of extreme floods.

There are tools available now that can be used to look at climate change impacts on extreme rainfall events, mainly around changing rainfall inputs to rainfall–runoff models based on climate advice, or else through using stochastic climate generators. However, this 2018 ICOLD bulletin also warns about complex numerical modelling and the ‘black box effect’ of accepting results without verification or critical consideration. It stresses that the intrinsic hydrological uncertainty will always remain no matter how clever or complex the numerical modelling.

Practical suggestions for dealing with uncertainty

Given that dams are designed for the long-term, it is crucial to consider the uncertainty of floods and the potential impacts of climate change. Climate impacts are being discussed increasingly by dam owners, dam engineers and dam regulators – and guidance on how best to deal with climate change will come eventually. This review article, ‘Climate change impacts on dam safety’, provides a good summary and some thoughts about approaching the issues in a framework based on dam safety risk.

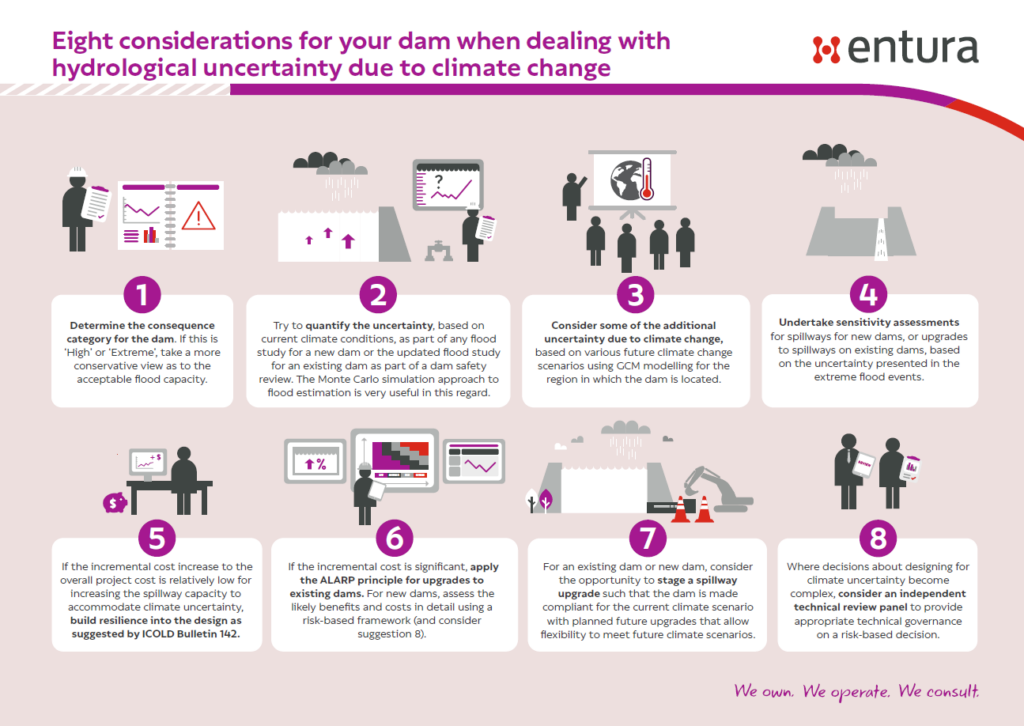

In the meanwhile, we’ve developed some practical suggestions for dealing with intrinsic hydrological uncertainty and the increased uncertainty due to climate change, whether you’re working on new dams or upgrades to existing dams:

- 1. Determine the consequence category for the dam. If this is ‘High’ or ‘Extreme’, take a more conservative view as to the acceptable flood capacity.

- 2. Try to quantify the uncertainty, based on current climate conditions, as part of any flood study for a new dam or the updated flood study for an existing dam as part of a dam safety review. The Monte Carlo simulation approach to flood estimation is very useful in this regard.

- 3. Consider some of the additional uncertainty due to climate change, based on various future climate change scenarios using GCM modelling for the region in which the dam is located.

- 4. Undertake sensitivity assessments for spillways for new dams, or upgrades to spillways on existing dams, based on the uncertainty presented in the extreme flood events.

- 5. If the incremental cost increase to the overall project cost is relatively low for increasing the spillway capacity to accommodate climate uncertainty, build resilience into the design as suggested by ICOLD Bulletin 142.

- 6. If the incremental cost is significant, apply the ALARP principle for upgrades to existing dams. For new dams, assess the likely benefits and costs in detail using a risk-based framework (and consider suggestion 8 below).

- 7. For an existing dam or new dam, consider the opportunity to stage a spillway upgrade such that the dam is made compliant for the current climate scenario with planned future upgrades that allow flexibility to meet future climate scenarios.

- 8. Where decisions about designing for climate uncertainty become complex, consider an independent technical review panel to provide appropriate technical governance on a risk-based decision.

If you would like to speak with us about how climate change could affect your new or existing dam, please contact Richard Herweynen or Prafulla Pokhrel.

About the author

Richard Herweynen acknowledges the input of his colleagues Prafulla Pokhrel (Principal Consultant, Hydrology) and Paul Southcott (Senior Principal, Dams and Headworks) in writing this article.

Richard is Entura’s Technical Director, Water. He has more than three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and was the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

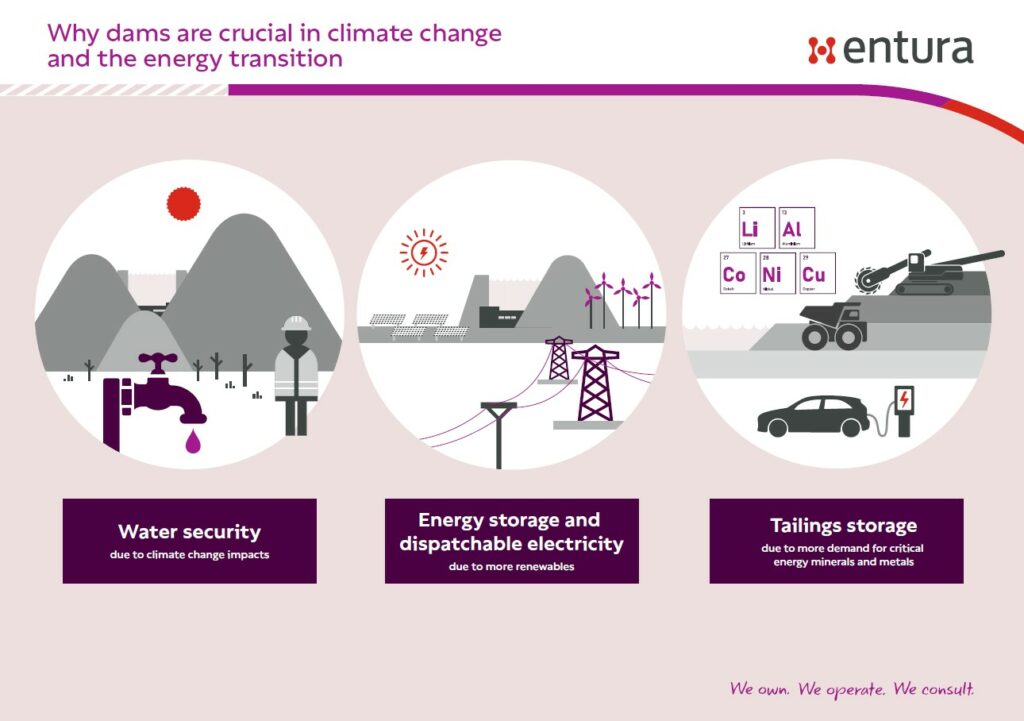

Dams are crucial to climate change response and the energy transition