Identifying Australia’s best sites for pumped hydro development

There are many thousands of potential sites for pumped hydro energy storage developments across Australia, but how can a developer filter these down to the best few?

As Australia’s energy market progressively transitions from ageing thermal generation to increasing amounts of wind and solar, there are ample chances to explore and develop the energy storage solutions needed to mitigate the challenges that may come with the introduction of more renewables into the energy market.

With increased intermittent renewables, we will require more storage to smooth out the variability of weather-dependent generation so that energy is available on demand. As well, we will need storage that provides the inertia, voltage and frequency control required for a stable, reliable grid.

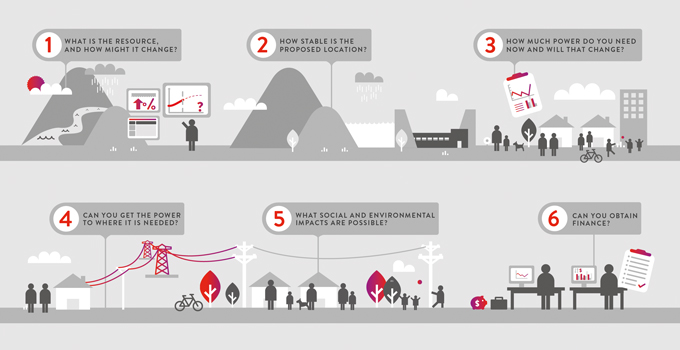

The key to successfully embracing these energy storage opportunities will lie in identifying the right mix of technology, capacity and site; however, pinpointing potentially viable projects is complex. A theoretical or academic approach won’t be enough to ensure a future project’s success in the real world.

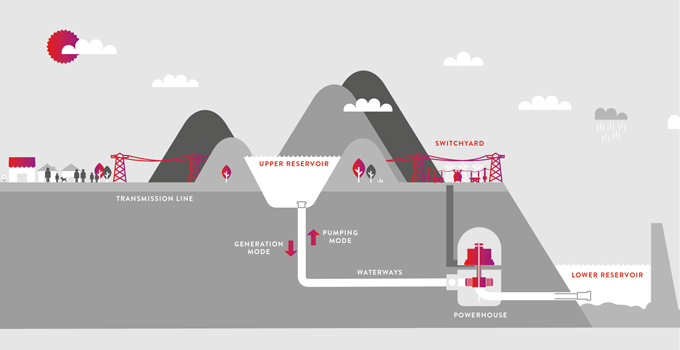

Pumped hydro is a highly efficient, longer-duration solution with a proven track record, and its future is bright as Australia seeks cost-effective, reliable options to make intermittent renewables ‘dispatchable’.

There are thousands of potential pumped hydro sites across Australia. This means that developers and investors need smart methods of filtering to reduce the many possibilities to just a few ideal sites.

A pumped hydro project is a major capital investment. Getting site selection right is the foundation for success, as it will determine the likelihood of achieving a design that is both technically and commercially feasible with the right mix of capacity and costs.

Pumped Hydro Atlas of Australia offers a head start in site selection

Entura has produced a practical atlas of pumped hydro energy storage opportunities to support development of dispatchable renewable energy generation across Australia’s National Electricity Market (NEM).

Through an exhaustive process, the atlas filtered many thousands of potential sites down to the best 20 around Australia. It is already being used by leading renewable energy company Hydro Tasmania to shortlist potential pumped hydro sites for the ‘Battery of the Nation’ initiative (a major Tasmanian initiative looking at how Tasmania could deliver more clean, reliable and cost competitive energy to Australia’s NEM). Identification of promising pumped hydro sites through the atlas also offers opportunities for developers in states such as South Australia and Queensland, which have set ambitious renewables targets and must maintain energy security.

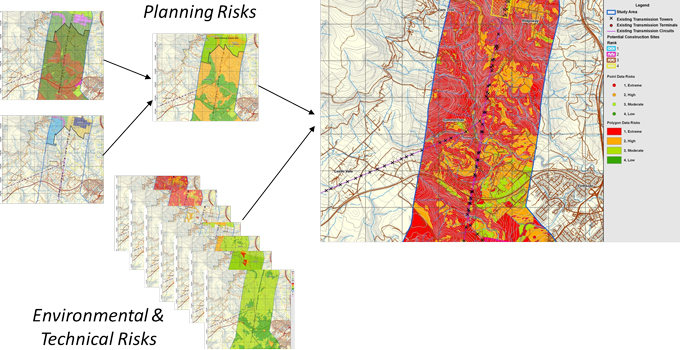

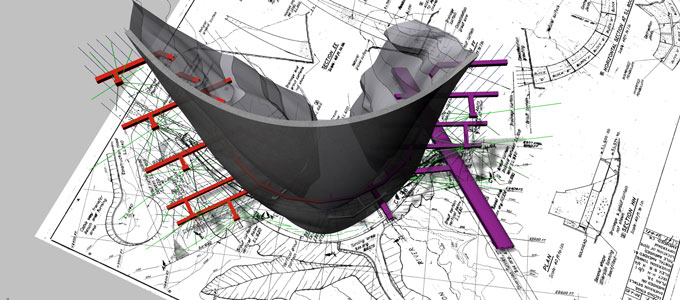

Entura’s Pumped Hydro Atlas of Australia takes into account far more than the basics of identifying ideal topography and a source of water. It also accounts for other practical factors that can make or break a project: such as proximity to and location within the transmission network, land-use constraints and environmental risks, and the practicalities and costs of construction and ongoing operation. This makes it a real-world, relevant resource identifying the best sites for pumped storage projects across the NEM.

Developing the Pumped Hydro Atlas of Australia

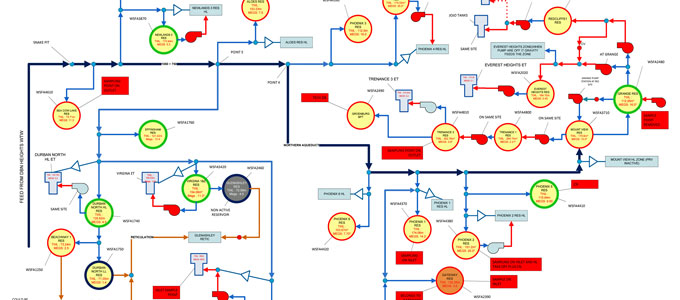

Originally commissioned by Hydro Tasmania, the Pumped Hydro Atlas of Australia was completed in October 2017. The journey began with a literature review, appraising previous studies. This informed the development of a set of rules, assumptions and algorithms for a GIS-based study of different reservoir types and pairing mechanisms, which were tested on pilot sites.

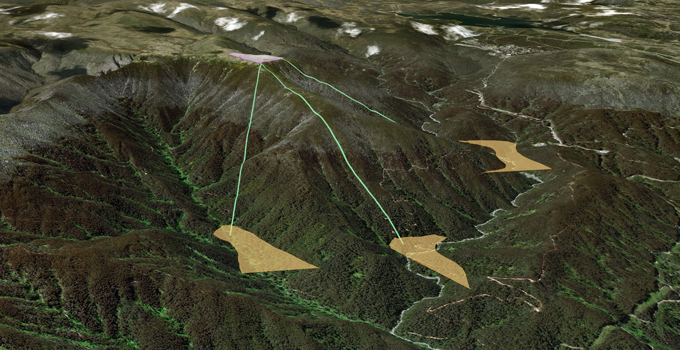

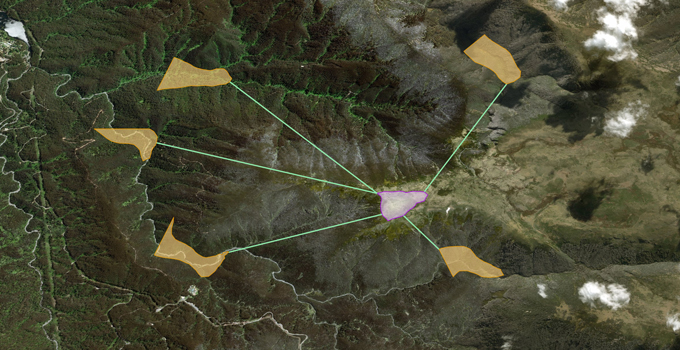

Using these algorithms, more than 200 000 pairing reservoirs were identified across the NEM states (Queensland, New South Wales, Victoria, Tasmania, South Australia and the Australian Capital Territory). State-based heat maps of potential sites for pumped hydro development were prepared, along with a summary of all key characteristics for each pairing reservoir set, such as installed capacity, energy storage, distance from the nearest substation, gross head, approximate headloss in the waterways, and active reservoir volume.

A subsequent stage of refinement prioritised high-potential sites in some states. This process took into account greater practical detail, such as costings, practical engineering aspects, environmental approvals and risks, realistic high-level arrangements, proximity to other generators, and characteristics of hydrology and energy storage. This stage identified more than 5000 unique potential sites, which were then further refined with a set of rules to select the best pairing reservoir at each site. The approximately 5000 sites were reduced to approximately 500 of the most attractive options: those with an average head of more than 300 m with relatively short distances between the reservoirs.

This exhaustive refining process ultimately resulted in a shortlist of twenty promising sites across different states, with a desktop review of geology, high-level engineering arrangements, and approvals requirements. For each site a map was prepared including locality, land use, planning zones, and key characteristics of the potential pumped hydro project.

The Pumped Hydro Atlas of Australia is an example of how applied hydropower engineering can be used to create practical outputs, which are ready to be applied in the real world. Overlaying the outputs of this atlas with any new wind and solar development across the NEM could result in opportunities to invest in dispatchable renewable energy generation hubs capable of replacing thermal generation assets as they retire.

Pumped hydro energy storage will no doubt play a major role in the development and expansion of networks powered by renewable energy – in Australia and around the world. As Australia’s electricity mix evolves, so will the economics of storage. While forecasting revenue for storage projects in the Australian electricity market is still somewhat uncertain, there are many opportunities in both the existing and emerging markets to guarantee project revenues to a level sufficient to satisfy a lender’s requirements. The opportunity for investors seeking a head start in this emerging market is now.

If you would like to discuss how Entura can help you with your pumped hydro or renewable energy project, please contact Richard Herweynen on +61 429 705 127 or Phillip Ellerton on +61 439 010 172.

MORE THOUGHT LEADERSHIP ARTICLES

Dispatchable renewables: a contradiction in terms?

As Australia replaces retiring coal generation with renewables, can we achieve an energy future that is affordable and sustainable as well as reliable?

The role of renewable energy in achieving affordability and sustainability is clear. As coal-fired power stations approach retirement in Australia, renewable generation from wind and solar PV appear to be the most cost-effective options for new energy generation. Wind and solar power now offer the lowest cost of energy, have low ongoing operational costs, and emit the least greenhouse gases across their lifecycle – and therefore hold the greatest potential for rapid decarbonisation of the energy sector.

But what about achieving the third element in what has been termed the ‘energy trilemma’: reliability?

Replacing coal-fired power stations with wind and solar PV is not a like-for-like swap in terms of availability of power when it is needed by consumers. Coal-fired power stations produce firm baseload power, but generation from renewable resources varies due to the availability of the natural resource. Wind and solar PV power vary according to the weather and the time of day, and even if we consider new hydropower opportunities, most of these are small ‘run-of-river’ systems, the output of which varies with rainfall and the inflows to rivers.

Yes, these renewables certainly produce energy, but is the power produced when it is needed?

The variability in power from renewables makes matching supply and demand a challenge. This challenge increases as more renewables enter the market. With moderate amounts of renewables, it is still possible to maintain system reliability through clever solutions – in particular, targeted grid support designed through careful planning and study of generation profiles, and supported by solid communications, control, power systems studies and forecasting. However, there is a limit to such approaches, and ultimately Australia will need ‘dispatchable renewables’ in the energy mix to achieve all the elements of the energy trilemma – in other words, renewable generation that is available whenever consumers require it. The time to start planning for this transition is now.

For generation to be dispatchable it needs to be available at the request of power grid operators or the plant owner according to the needs of the market. Dispatchable generators can be turned on or off, or can adjust their power output according to market need. If a generator is dispatchable it can be used to match load, meet peak demands, or fill the gap if another generator suddenly goes offline. Dispatchable generation is very valuable to the market because it can be used to match the profile of energy demand.

Effectively, baseload fossil fuel generation can be replaced by the combination of variable renewables, dispatchable renewables, smart high-voltage network support and planning to ensure sufficient transmission capacity, and change in use of existing hydropower.

How can we make variable renewables ‘dispatchable’?

The concept of dispatchable renewables seems almost contradictory: how can something generated from an inherently variable resource be dispatchable? There are two parts to this: the first is to look at how well different wind and solar PV sites naturally work together to firm supply (i.e. how likely it is that dips in one source are filled by peaks in another). Once this is understood, we need to consider how much storage is required to manage residual variability. Storage is critical here as it provides flexibility to store excess or low-value energy for times when it is really in demand.

When patterns of renewable generation are highly correlated (in other words, the timing of generation is very similar), more storage is required. For example, if the east coast of Australia develops a very high proportion of solar PV generation capacity, then all of these will be generating within about two hours of each other during the day (because of similar sunrise and sunset times across this region), and not at night. To fully utilise this energy, much of it would need to be made ‘dispatchable’ by adding substantial storage for the night-time hours, or we would need to firm the supply using another generation source, such as a gas turbine. But with a suitable proportion of wind in the mix (and stronger interconnectors to solar generation from other regions), the same dispatchability can be achieved with a more moderate amount of storage. This example demonstrates the importance of achieving a mix of renewable generators to meet the goal of dispatchability.

Various studies of generation in the NEM over time have demonstrated that wind and solar generation are not highly correlated. These studies have shown that even with low to moderate correlation, when considered over a large geographical area, a combination of such generators reduces variability and increases reliability of supply. Understanding this effect enables appropriate sizing of storage to create a dispatchable renewable portfolio with maximum value. There will always be some times when multiple generators produce near maximums, as well as some times when both wind and solar produce near minimums; these occasions are not common, but could have significant consequences. This is a risk that needs to be managed by the system.

The amount of firm capacity can be increased by over-installing generation, and curtailing its output when there is too much generation. However, there are still those infrequent periods when multiple generators are at their minimum and parts of the grid need extra support. Having this support available during these rare occasions will be critical to managing risk and maintaining reliable supply.

This indicates that the mixture of different renewables won’t take us all the way to the goal of achieving ‘dispatchable renewables’; storage remains a critical ingredient.

What’s the future for energy storage?

The media is awash with reports of new energy storage options. It is important to recognise, though, that different types of storage solutions vary widely in their ability to discharge power over different time frames. Therefore one type of storage will not necessarily deliver the same solution as another type of storage. Understanding this is critical to the concept of dispatchable renewables.

The power and duration of the storage are the two key variables in determining the most suitable solution. Low-power, short-term storage is currently more cost-effective using batteries, but longer periods and larger power requirements are likely to rely on bigger storage options, such as pumped hydro energy storage and traditional hydropower.

With individual wind and solar plants pushing 1 GW, pumped hydro and modified traditional hydropower solutions need to be considered. Smoothing out the daily variability in renewables can be achieved effectively through pumped hydro, but multi-day storage to supplement periods of extreme events of both low wind and low solar will require traditional hydropower with very large reservoirs.

In the long run, short-term storage will not be sufficient alone to achieve the aim of ‘dispatchable renewables’. Achieving full dispatchability of combined wind and solar PV power will depend on utilising pumped hydro storage and existing hydropower storages to their full potential.

When will we need dispatchable renewables?

The question of when we’ll need dispatchable renewables is complex. It’s driven by a combination of commercial, regulatory and technical considerations as well as changing customer behaviour (all of which are in motion).

The short answer is now.

There are already isolated opportunities in which dispatchable renewables offer distinct advantages, and where the business case may stack up. With increasing wind and solar PV developments in the network without dispatchable capability, such opportunities will only expand. However, the lead time required to include large-scale storage in these ‘dispatchable renewables’ projects means that planning must begin well in advance.

If you would like to discuss how Entura can help you explore potential opportunities for dispatchable renewables, please contact Phillip Ellerton on +61 439 010 172, Richard Herweynen on +61 3 6245 4130 or Chris Blanksby on +61 408 536 625.

About the authors

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

Dr Chris Blanksby is a Specialist Renewable Energy Engineer at Entura, and Entura’s lead solar energy specialist. He has undertaken and published research on the solar resource in Australia, and has led several due diligence and owner’s engineer projects for wind, solar and microgrid projects in Australia, the Pacific and Asia.

MORE THOUGHT LEADERSHIP ARTICLES

Maximising the benefits of GIS for better business decisions

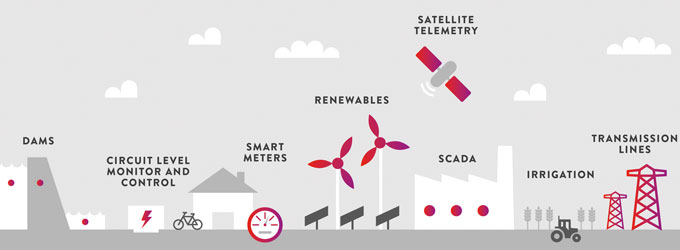

‘Location, location, location!’ It’s a familiar catch-phrase in the real estate industry, but it’s just as relevant in the power and water sector. Wherever there’s location-related data, a geographic information system will guide better business decisions.

Mobile devices and apps are increasingly using location-based data collected via satellites, drones, LIDAR and other rapidly developing sensing and data capture technologies. With these advances, we are able to find relevant information more quickly and draw on that information to make informed decisions. We’re seeing this proliferate in everyday life through apps that help us navigate, find services and products, and make decisions ranging from the trivial to the profound.

Developers and managers of power and water infrastructure projects who embrace GIS (geographic information systems) stand to gain benefits on an even greater scale. Gathering high-quality spatial information and analysing it to guide business decisions will certainly improve productivity and the bottom line.

Better decisions are the necessary foundation for increased revenue, lower costs, greater efficiency and productivity, and reduced risks. So, if the technology is available and there’s so much to gain, why isn’t GIS being as widely used in the power and water sector as it could be? What may be holding businesses back from fully embracing this powerful and dynamic technology?

Do we really need to use GIS for this project?

All power and water projects involve location – from finding an optimum site for your project, to analysing combinations of spatial data to make the best management decisions or to predict events. Whenever you ask a ‘where?’ question, GIS can help. Where is the asset best located? Where are the constraints or hazards? Where are the reports of previous work done in this area? Where are the customers or opportunities?

In other words, rather than asking whether GIS is needed on a project, consider making GIS a default for every project. The real question should be “how can we maximise the benefits of using spatial data and GIS on this project?” GIS can offer business benefits far beyond the most commonly understood use: making a map.

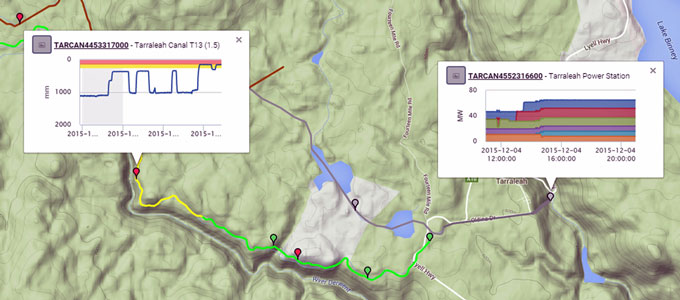

Data capture in the field can now be streamlined – gone are the days of capturing field data with pen and paper. Users can now collect data on mobile devices, sync to databases while in the field, share data, and generate their own maps, queries and reports. Embracing these advances will save time and enable faster and better decisions.

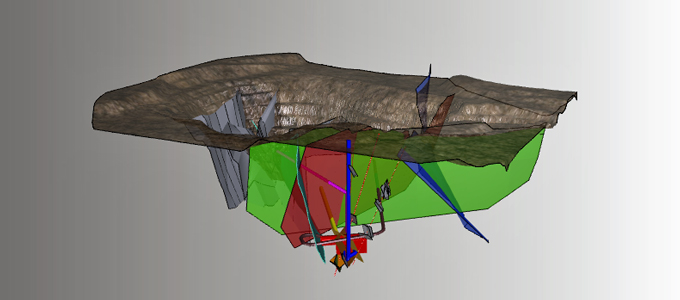

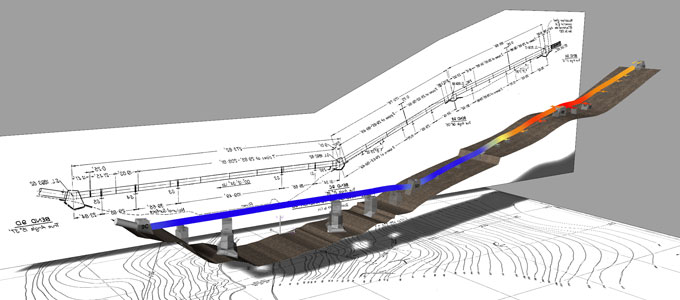

As well as providing valuable business insights, spatial analysis and location intelligence can greatly improve communication and knowledge sharing – within project teams, with the broader business, and with the community and stakeholders – via tools such as web maps and apps, visual analysis and 3D modelling.

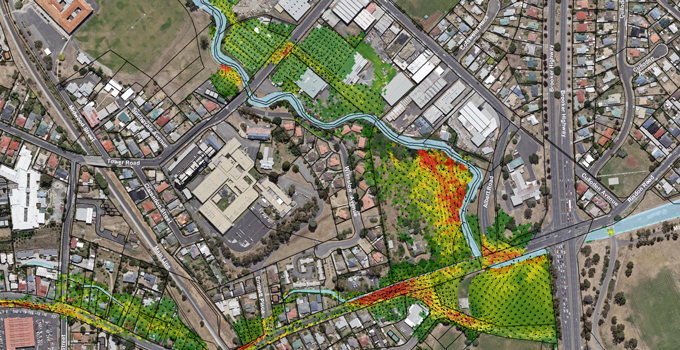

One of the most important applications is the simultaneous analysis of different spatial datasets to provide the best solutions or choices between alternative options, locations, objects and so on. This process is better known as multi-criteria analysis (MCA) and it can be used for many applications.

For example, MCA can be used to find the optimum site for your project taking into account a range of values such as local geology, threatened species, resource availability, land use and terrain, planning restrictions, communities and demographics. Using MCA, you can establish areas of best fit for your project based on thematic overviews of areas of constraint, cost of construction, access and transportation routes.

Risks such as bushfire, weeds, threatened species, pollution sources, landslides and erosion can also be more easily and fully understood, supporting your ongoing site management of such issues.

GIS also links with document management, asset management, business intelligence and enterprise resource planning (ERP) systems. It can act as a portal, creating a central point of easy access, pulling together information and making it available on one of the simplest forms to interpret – a map.

Of course GIS is not the answer to everything, and it is not a standalone platform. However, there’s much it can offer across many different business activities, working together with other business systems.

What about the costs?

The return on investment of using GIS should be positive if it is used appropriately. For site selection of power and water projects, using GIS is a no-brainer. For example, using GIS to find the best site for a wind farm – locating the best winds, minimal constraints, good proximity to existing infrastructure and appropriate land use – will obviously result in vastly greater returns than siting the wind farm in an inferior location.

Some examples may be less immediately apparent, but equally valuable – for example, using GIS to increase efficiencies in everyday workflows. If your workers are taking an extra half hour every time they need to find previous work completed in an area, this time can add up quickly. Or perhaps they can’t find previous information, so work is re-done unnecessarily. These costs will keep adding up. Instead you could use a GIS web map to locate all your previous reports and projects, so that a simple click on a map finds the files and saves hours (if not days) of time.

Do we need specialist software or skillsets?

With most things, you do need specialised skillsets and software to get good results, and of course bad data in equals bad data out. Users of GIS do need to understand and assess the spatial data needs in each application.

You could undertake some GIS work yourself using free or open-source software. However, be aware of the risks of using data or tools that aren’t fit for purpose. Just because you know how to use Microsoft Word, doesn’t mean you could write a detailed report outside your area of expertise!

We have seen cases where coarse-resolution data has been used to infer finer project details and costs, resulting in poor decisions. We have also seen inexperienced operators make invalid assumptions. To get the best results, you need to be sure that you’re using the technology wisely.

If you are engaging a power, water or environmental consultant on a project, they are likely to have access to GIS capability; however, GIS is still often underutilised. When deciding who to engage on your project, ask your consultant how they will maximise the benefits of GIS to produce better outcomes for your project.

To discuss how Entura can help you harness the potential of GIS to improve your power and water project decisions and outcomes, contact Stephen Thomas on +61 3 6245 4511, Patrick Pease or Phillip Ellerton on +61 439 010 172.

About the authors

Stephen Thomas is Team Leader and Senior Technical Officer with Entura, specialising in geographic information systems, 3D visualisation and CAD software. Steve has over twenty-six years of technical experience and specialises in environmental assessments and approvals for engineering surveys and property. He has created 3D models and animations of proposed developments including wind farms, urban landscapes and city frameworks. Steve’s work on the Hobart Waterfront 3D model won an international award in geospatial modelling.

MORE THOUGHT LEADERSHIP ARTICLES

Is there an economic case for pumped hydro?

As the proportion of renewable energy in the grid continues to grow, pumped hydro energy storage offers a solution for greater reliability. But can the business case for storage stack up?

The future is bright for pumped hydro in Australia, and for storage in general. However, no energy solution can exist outside of the real and competitive pressures of the market. Technical viability and environmental benefits won’t be enough to get projects over the line if they can’t demonstrate their financial soundness.

So how can pumped hydro generate sufficient revenue to be attractive to investors? And will that revenue continue to be predictable enough over the longer term?

No doubt there are opportunities, but developers may need to explore a range of different revenue sources in both existing and emerging markets since the arbitrage opportunities of the past may not be present in the future.

Where to for energy arbitrage?

The traditional revenue source for pumped hydro is arbitrage – in other words, making the most of generating when the spot price is high, and pumping when the spot price is low. But this relies on a certain level of predictable variability in the electricity market, and for that variability to continue into the future.

The upcoming retirement of several coal-fired power stations and the continued investment in renewables are likely to cement a market in which variability in power generation and the consequent volatility in energy prices are the norm.

Forecasting revenue – no easy task

Financing an energy project requires a firm revenue forecast. Lenders may consider ‘firm’ to be a 90% confidence limit, which means the developer must demonstrate that the project can generate a certain amount of revenue 90% of the time, or, say, in 9 out of 10 years. This means that a robust and reliable forecast of project utilisation must be made.

Forecasting revenue for an asset with a lifecycle of up to 100 years requires detailed modelling of a wide range of factors influencing the electricity market, including supply (factoring in new entrants, storage, retirements and developments in the thermal sector, etc.), demand (including changes in industrial load, impacts of electric vehicles, etc.), fuel prices, government policies, and bidding strategies for large-scale wind and solar projects.

A business case for pumped hydro relies on all the assumptions that go into regular power plant financial modelling and adds the complexity of arbitrage.

A further complication is the impact on market prices of the presence of the developer’s own project. In other words, how will the proposed project influence the market in which it participates?

For a storage project, the influence is likely to be both an increase in low prices and a decrease in high prices. If the market is robust enough and the proposed project is relatively small, the influence could be minor. However, a very large project is likely to influence the market to such an extent that the utilisation of the project may significantly reduce, which would reduce project returns.

Building a bankable business case

How can the confidence in a forecast be increased enough for a lender to commit funding to a project, given that variance of any one of these assumptions could disrupt the revenue streams for the project? While the transition to a renewables-dominated market continues, it may be that lenders need assurance that other revenue streams exist to reduce the project risk.

Price insurance

High price events in the electricity market will certainly continue to occur, but it’s impossible to predict their timing. Energy storage projects can provide insurance to exposed customers (such as retailers and major industrial customers) through a cap contract in a similar way to gas turbines and other peaking plant. In practice, this may mean that the storage project rarely operates unless the price regularly exceeds the cap.

Network support services

Storage projects have the ability to provide network support services such as frequency control, inertia and fault level control. These services have increasing value in a grid with significant amounts of non-synchronous generation. At this stage, the markets for these network support services are very shallow and competition is increasing. However, the need for such services is likely to increase to the point where more significant markets are required.

Renewable firming

Government energy policy continues to be fluid, yet under the proposed National Energy Guarantee it is possible that there will be value in providing firming services – in other words, pairing ‘dispatchable’ generators (such as storage projects or open-cycle gas turbines) with ‘intermittent’ renewable sources of energy to improve reliability.

‘Behind the meter’ generation

Storage projects are exposed to market prices during both modes of operation (pumping/charging and generating). If, however, there was an option to pump/charge for ‘free’, wouldn’t that reduce the risk?

Genex Power’s world-first Kidston ‘K2 Project’ will pair a 250 MW pumped hydro project with a 270 MW solar PV farm. During the day, solar energy can be used to power the pumps in the pumped storage project. The pumped hydro project will then generate into the evening (and morning) peak. If the upper storage is ‘charged’ during the day, the K2 solar project can generate into the Queensland market and realise the benefits of large-scale generation certificates (LGCs). Of course, this arrangement relies on sufficiently high prices during peaks to recover the additional cost of the solar farm, transmission losses and any LGC liability.

As our electricity mix evolves, so will the economics of storage. While forecasting revenue for storage projects in the Australian electricity market is still an uncertain business, there are many opportunities in both the existing and emerging markets to guarantee project revenues to a level sufficient to satisfy a lender’s requirements.

If you would like to discuss how Entura* can help you with your pumped hydro project, please contact Nick West on +61 408 952 315 or Donald Vaughan on +61 3 6245 4279.

*Entura provides technical advisory services to prospective investors and developers. Financial advisory is not part of our suite of services, however, we partner with financial advisory firms supporting our clients. Entura is the consulting arm of Hydro Tasmania. Hydro Tasmania is licensed (AFSL 279796) to provide general financial product advice. Hydro Tasmania is not licensed to provide nor will it provide advice which considers a person’s objectives, financial situation and needs and you must therefore rely on your own assessment or seek your own independent advice in respect of decisions in relation to any financial product offered.

About the authors

Nick West is a civil engineer at Entura with more than 16 years of experience, primarily in hydraulics and hydropower. Nick’s skills range from the technical analysis of the layout of hydropower projects to the preparation of contractual project documents and computational hydraulic modelling. Nick was a key team member of the Kidston Pumped Storage Project Technical Feasibility Study.

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

‘Nexus thinking’ for a secure and sustainable future

As the global population continues to grow, how can utilities and water managers balance the increasing and interrelated pressures on water, energy and food?

The complex triangular relationship among these three pillars of life is known as the ‘water-energy-food nexus’. It’s an intricate puzzle, in which the increased demand for each limited resource can significantly affect the security of all three.

According to the International Renewable Energy Agency, over the next few decades, global growth in population, economic development and urbanisation are expected to raise demands for water and food by 50% and to double the demand for energy. Water, energy and food are all fundamental to growing economies, alleviating poverty, and improving health and educational opportunities worldwide. To create a sustainable future, we must seek holistic and integrated solutions for water, energy and food challenges , as well as the appropriate balances amongst them.

With water being so central to food security and energy security, the potential impacts of climate change on water resources are of increasing concern. Climate change is likely to raise average temperatures in many locations, change the patterns of rainfall and inflows, and affect the frequency and severity of extreme weather events such as drought or floods – all of which increase vulnerabilities for water, food and energy resources already under strain.

A nexus approach

Our experiences throughout Australia and the Asia-Pacific region demonstrate that there is no single solution to the challenges of this nexus. It is really about a way of thinking and approaching decisions rather than a fixed solution or response.

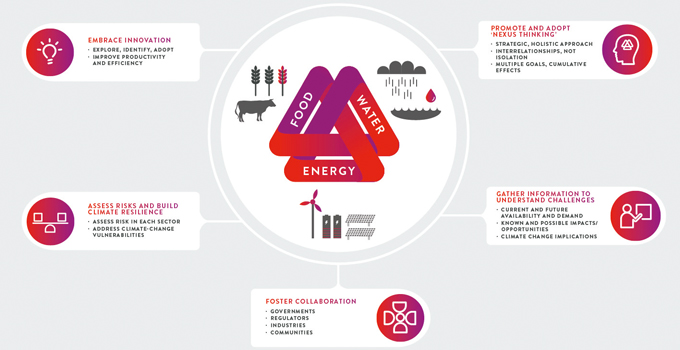

These five broad considerations are likely to contribute to improved nexus outcomes.

Promoting and adopting ‘nexus thinking’

‘Nexus thinking’ means considering and understanding water, food and energy and their interrelationships, rather than viewing any in isolation. It is a strategic and holistic style of thinking that considers long-term implications across the nexus, weighing up and balancing social, economic and environmental goals.

Nexus thinking looks at the big picture: considering the whole catchment or river basin, trans-boundary issues, multiple uses (existing and future) and cumulative effects. It also involves thinking across agencies and organisations where responsibilities for water, food and energy lie.

Gathering the best information to understand nexus challenges

Responses to nexus challenges are more likely to be effective and sustainable if they are based on an informed and risk-based understanding of present conditions and possible future scenarios (taking into account interrelationships across sectors and regions).

This means that decision-makers need to understand the resource availability, current demand, known impacts, development opportunities and potential climate change implications in a given situation. They also need to understand what stakeholders and communities need, and explore opportunities for additional benefits to be realised.

Fostering collaboration among government, regulators, industry and communities

All stakeholders can benefit from collaborative and cooperative responses to the nexus and to stewardship of resources. The potential wins include better economic outcomes, improved reputation, reduced risks, avoided conflict, and opportunities for greater synergies. Reaping the benefits will require partnerships and cooperation among food-producing industries, the energy sector and other water-dependent industries, as well as local communities.

It’s also essential that governments, regulators and communities are closely involved in all decisions and developments affecting water, energy and food resources so that different priorities and opportunities can be considered. At a policy and regulatory level, cohesive and stable governance, policy and strategies are needed to facilitate and encourage the right collaboration that brings benefits to all stakeholders.

Assessing risks and building climate resilience

The water-energy-food nexus brings risks as well as opportunities . Interrelationships between water, energy and food, and the threats posed by climate change, should be built into risk assessments in each sector. State-of-the-art data collection, modelling and forecasting can assist businesses, governments and communities to better understand and mitigate their specific climate-related vulnerabilities and take action towards building greater resilience to future climate change impacts.

Innovating

In the water, energy and food sectors, technological and other innovations continue to expand the opportunities for improving productivity and resource efficiency for long-term sustainability of pressured resources.

Nexus challenges may also bring opportunities

The nexus is not only a dynamic of ongoing resource competition. Integrated planning offers opportunities for potential synergies and benefits among sectors.

For example, in the hydropower sector, electricity generation is intrinsically linked with water availability. The need for water for irrigation to produce food and to drive agricultural productivity may compete with water requirements for hydropower generation. Hydropower’s water needs may also compete with the requirements of urban water supply, other industries and environmental and social needs.

However, renewable energy resources such as hydropower can also offer benefits to the water and food sectors through improving water resource management, providing multipurpose storages, contributing to the development of water supply infrastructure and, of course, generating the electricity critical to food-producing industries.

Many existing hydropower storages, both in Australia and internationally, were developed solely to supply water for energy generation. However, over time and with increasing competition for water and food, the storages have become multipurpose, often providing water for domestic supply, irrigation, and commercial and recreational fisheries.

In South-East Asia, some hydropower storages are now more important as a source of irrigation water for downstream communities than for the energy they generate. By providing water to the downstream communities, irrigation and food production has increased significantly since development of the schemes, lifting the economic development of the region and providing benefits across the community.

Integrating other renewable energies into water supply, irrigation and food production can also provide mutual benefits, such as utilising renewable energy for pumping on farms or for water desalination. Incorporating small hydropower into existing water infrastructure can improve efficiencies and create new low-carbon income streams to support effective water supply delivery. Another innovation of attaching solar PV to covers on water storages provides electricity for pumping while minimising evaporation and maximising water availability.

Whether at small-scale single utility or local geographic area or at a national or multinational scale, nexus thinking can bring about mutual benefits for energy, water and food outcomes .

If you would like to find out more about how Entura can help you develop a sustainable water or energy solution or respond to the challenges of the water-energy-food nexus, contact Dr Eleni Taylor-Wood on +61 3 6245 4582.

About the authors

Dr Eleni Taylor-Wood is Entura’s Principal Consultant, Environmental and Social Science. Eleni has more than 20 years’ experience successfully managing large-scale, complex projects that run over several years, as well as providing expert advice and independent review for a range of infrastructure and planning projects. She has worked on projects around the world including in Australia, Mozambique, South Africa, Iceland, Colombia, India, Malaysia, Mekong, Solomon Islands, Fiji and Papua New Guinea. Her experience covers a vast gamut of studies including: environmental and social impact assessment and management; strategic management of wetlands and waterway; feasibility and approvals for new hydropower projects, environmental flow determination and assessment, and sustainability assessments. Eleni is currently one of eleven Accredited Assessors under the Hydropower Sustainability Assessment Protocol worldwide.

MORE THOUGHT LEADERSHIP ARTICLES

Batteries vs pumped hydro – are they sustainable?

A sustainable grid needs sustainable energy sources. While there’s no doubt that it makes sense to store renewable energy, whether in batteries or in a pumped hydro scheme, just how sustainable are these technologies?

As we move rapidly towards ever-greater levels of wind and solar power in the network, increasing quantities of storage are needed to smooth intermittency and ensure secure supply. Pumped hydro energy storage and batteries are likely to do much of the heavy lifting in storing renewable energy and dispatching it when power demand exceeds availability or when the price is right.

We’ve previously compared the two technologies in terms of their costs, the speed with which they can be deployed, and their ability to support the grid. Here we compare their sustainability in terms of storage efficiency and capacity, safety, use of scarce resources, and impacts through all stages of their lifecycle.

Storage efficiency and capacity

For both batteries and pumped hydro, some electricity is lost when charging and discharging the stored energy. The round-trip efficiency of both technologies is usually around 75% to 80%. This level of efficiency for either technology represents a significant displacement of non-renewable generation if we assume that the stored generation would not otherwise occur.

A particular consideration for batteries is degradation. Batteries degrade as they age, which decreases the amount they can store. The expected life of the batteries that will be used for the recently announced battery storage project in South Australia is about 15 years (depending on how the batteries are operated). By the end of that time, the capacity of the batteries is expected to have dropped to less than 70% of their original capacity.

To maintain a reliable and steady capacity for storage as batteries age and degrade, large-scale battery plants will require ongoing staged installation and replacement of batteries. In comparison, the degradation of pumped storage is close to zero. With appropriate maintenance, peak output can be sustained indefinitely.

Safety

No storage solution can be considered sustainable unless it is safe. The greatest risk relating to pumped storage is dam safety. If it occurs, dam failure can affect downstream communities and the environment, with its impact potential likely to be far greater than a battery safety incident. Nevertheless, pumped hydro technology is mature, dam risks are generally well understood and managed, and the frequency of dam safety events is low.

The main safety concern for batteries is thermal runaway leading to explosions and fires. The severity of this risk will depend on how a battery project is implemented. In a modular arrangement, thermal runaway would be localised, not affecting the whole bank. However, because of the very rapid deployment of evolving battery technologies, safety standards may not be rigorously enforced.

Impacts on land and water

Pumped hydro and grid-scale battery plants may have environmental and land-use impacts. These impacts would vary depending on the sensitivity of the site selected.

A grid-scale battery facility needs a relatively small parcel of land and is likely to be able to be created very close to the energy demand or where generation occurs. Land in these areas has often already been disturbed and the new operations may have little extra environmental impact. Land and water impacts of batteries relate more to their disposal at the end of their effective life, and to the extraction of the resources to produce new batteries.

Pumped hydro requires a relatively larger parcel of land with a very particular topography, and may be far from the location of the demand. Any potential environmental impacts associated with construction and operation need to be considered and mitigated, including those immediately associated with the site, as well as downstream.

In most construction of new pumped hydro, sites are selected where impacts can be mitigated to acceptable levels, for example by using existing reservoirs, or locating ‘closed loop’ systems away from rivers. Although these arrangements will have lower overall impacts, some environmental challenges may still occur during construction when existing water is removed from the site as well as finding a source of water without impacting the environment and other users.

Environmental impacts during operation of pumped hydro are minimal. However, the ecology within the reservoirs will need to adapt to frequently changing water levels, reducing diversity in the system especially within fringing communities.

In all pumped hydro systems, water is re-used over and over again, extracting maximum value from the resource. Nevertheless, depending on the configuration of the pumped hydro project, there may be an ongoing demand for water to top up the storages to counter evaporation.

Minerals and materials

Batteries and pumped hydro require a range of different resources and materials. Lithium-ion batteries use common materials such as plastic and steel as well as chemicals and minerals such as lithium, graphite, nickel and cobalt. Although pumped hydro mainly relies on common building materials such as concrete and steel, the quantities of these materials and the construction impacts can be significant.

Image courtesy of Greensmith, a Wärtsilä Energy Solutions company.

Determining the ultimate sustainability of the required resources and materials for both technologies needs to take account of the full lifecycle and supply chain (mining, processing, refining and manufacturing) as well as end-of-life issues such as recycling, disposal or decommissioning.

Currently, the environmental and health impacts of mining are a significant sustainability concern for the battery industry, and impacts are likely to intensify as worldwide demand for the necessary minerals rapidly increases. Short-term availability of many of the necessary minerals for battery development, such as lithium, appears sufficient, yet security of supply could be compromised by geo-political factors, and long-term availability will depend on levels of demand.

Ultimately, the minerals used in lithium-ion batteries are finite resources, so limiting or reducing their extraction (for example, through greater recycling or substitution for another battery technology) would increase longer term sustainability.

End of life

A battery’s life depends on the technology and on frequency of charging and discharging. Once their effective life is up, the batteries must be disposed of and replaced. Disposal of batteries is a problem we’re yet to face, but as large-scale battery storage proliferates, increasing numbers of batteries will enter the global waste stream. Without careful management of disposal, what cannot be recycled may end up in landfill and may be corrosive, flammable, or could leach toxins into soil and water.

The development of cost-effective and efficient battery recycling methods is still in its infancy.

Although most of the components of batteries can be recycled to some extent, recycling is currently expensive and there is insufficient volume to encourage commercial enterprises to take on recycling the new generation of batteries. In time, improved recovery and re-use of materials will certainly increase the sustainability of battery storage, preserving virgin resources and reducing the impacts of extraction and processing.

End-of-life considerations for pumped hydro seem very distant right now due to hydropower’s longevity, but sustainable decommissioning still needs to be planned for, including managing the impacts on the downstream environment if a dam is removed and rehabilitating the reservoir area.

Lifecycle analysis

At this early stage of development of large-scale battery technology, comprehensive lifecycle analysis is limited by the diversity of battery materials and widely different scenarios of charging, battery life and recycling.

In contrast, the full lifecycle of pumped hydro is better understood due to the maturity of the technology. Pumped hydro is not without impacts, but the risks are known and generally manageable. A major advantage of pumped hydro over batteries is that the expected life of pumped hydro is more than 100 years, or effectively unlimited with appropriate maintenance.

Batteries may have a lower upfront cost than pumped hydro and be easier to approve and install; however, they are likely to require greater management over time. If a projection is made based on current information, the full lifecycle cost and impact of batteries may be greater than hydro across the long term, particularly when mining, recycling and disposal are taken into account. Yet, battery technology is likely to improve very rapidly, which would tighten the gap on pumped hydro’s current lifecycle advantage.

A greener grid

Worldwide, increased levels of renewable energy will lead to a greener grid. It is easy to recognise the sustainability benefits of using a storage solution such as pumped hydro or batteries to further enable the decarbonisation of the network through greater uptake of renewable energy. However, the storage solutions that enable more renewables must also be sustainable – not only in the use phase, but also upstream and downstream.

It is difficult to make a straightforward comparison of the sustainability credentials of pumped hydro and battery storage technologies at their very different stages of maturity. As battery technology is still evolving, its overall sustainability is still somewhat uncertain, but this will change with experience and improvements in battery life and recycling. Meanwhile, pumped hydro projects can last up to a century and associated risks are known and can be mitigated.

Either way, as we redevelop the electricity grid, we will also need a mature approach to lifecycle analysis of our storage solutions.

About the authors

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

Nick West is a civil engineer at Entura with 16 years of experience, primarily in hydraulics and hydropower. Nick’s skills range from the technical analysis of the layout of hydropower projects to the preparation of contractual project documents and computational hydraulic modelling. Nick was a key team member of the Kidston Pumped Storage Project Technical Feasibility Study.

MORE THOUGHT LEADERSHIP ARTICLES

Building climate resilience into operations: Hydro Tasmania’s journey

Climate change presents major risks for power and water businesses. To best prepare for the impacts of extreme or changing weather conditions, asset managers need to act now to build climate resilience into operations and ongoing risk management.

Around the world, businesses and communities face the many risks of climate change such as higher temperatures, changes in water availability and rainfall, more frequent and severe weather events. For power and water businesses, these may lead to major infrastructure damage and financial and environmental consequences.

In 2015 to 2016, these hypothetical risks became a challenging reality for Hydro Tasmania, Australia’s largest renewable energy producer and water manager. Hydro Tasmania faced unprecedented extreme weather conditions from September 2015 to June 2016 – and managed to come through the crisis while still safeguarding Tasmania’s ongoing access to high-quality, reliable water and power, and limiting environmental consequences and asset damage.

Entura supported Hydro Tasmania’s response to this major climate-related challenge through a range of earlier best-practice resilience-building measures, and significant interventions across a range of areas during the crisis itself.

What happened in 2015-2016?

Although Hydro Tasmania had experienced some variability in the past in Tasmania’s climate patterns, and despite understanding the risk of increasing future climate variability, the extreme dry conditions of September 2015 to April 2016 were unseasonal, unexpected and unprecedented. In Tasmania, summer inflows are traditionally low, but in this case, the usually dry summer was preceded by record-low spring inflows. Below-average rainfall across both spring and summer was the lowest recorded in 50 years.

In normal operating conditions, low inflows could have been mitigated by importing power from mainland Australia across the undersea interconnector cable, Basslink, so that storages could be maintained. Yet, in another unprecedented scenario, in December 2015 the Basslink interconnector became inoperable just as summer arrived. Hydro Tasmania was now no longer connected to Australia’s national electricity market and many months remained before expected autumn/winter rains.

By late April 2016, Hydro Tasmania was experiencing its lowest storage levels ever, down to 12.5% total energy in storage, and serious environmental risks were emerging in some of its sites.

To compound the challenges, in January and February 2016 at least 70 separate fires were listed in Tasmania’s north-west, west, south-west and central highlands.

These extraordinary circumstances combined to present Hydro Tasmania with a major operational challenge. How could it keep the lights on and keep businesses operating in Tasmania while also protecting the environmental values associated with water storages and preserving the condition of its assets?

When the drought broke, conditions shifted from one extreme to another. Floods in June 2016 in northern Tasmania hit historic highs, exceeding all previous flood records in many locations. Several river-level measurement stations experienced the highest water levels on record.

How was the crisis managed?

Hydro Tasmania’s climate resilience and risk management strategies were called into action. Entura actively supported Hydro Tasmania through the energy supply challenge across a range of measures.

Generation planning and supply

To maintain adequate power supply, Hydro Tasmania drew on generation modelling and planning based on rainfall forecasts, climate model outlooks, and known and predicted electricity demand.

Voluntary reductions in major industrial loads were negotiated, and actions were taken to assess and instigate alternative generation options, such as restoring gas generation and implementing 200 MW of temporary diesel generation to bolster power generation. Entura assisted Hydro Tasmania to identify and assess feasible generation options and sites, and to progress these options through approvals and into operation.

Through these integrated and rapidly executed measures, Hydro Tasmania was able to maintain electricity supply for Tasmania without any outages for domestic users.

Environmental management and multiple water use

Another critical aspect of the successful result drew on Entura’s expertise in environmental management. Environmental impacts were monitored throughout the crisis. Lake-level risk bands were reassessed to better protect water quality and threatened species and to limit the long-term impacts on environmental values.

Water management also considered and mitigated impacts on other water users, such as boating, recreational fishing and water supply.

Bushfire management

The bushfires experienced across the state during the summer period did not adversely affect Tasmania’s energy security, as Bushfire Preparedness Fire Management Plans were already in place, and were activated to protect individual power stations and key assets through fuel reduction and other measures.

Dam safety and monitoring

Despite the extreme flood conditions, dams and spillways operated well within their design parameters, indicating that Hydro Tasmania’s ongoing dam monitoring and dam safety systems were robust. Safety inspections after the floods found only minor damage to non-critical elements of some dams.

During the high rainfall conditions, monitoring of dams and waterways provided alerts to downstream communities.

Road and asset management

Another consequence of the flooding was damage to some of Hydro Tasmania’s secondary assets (roads, canals) due to landslips, and the loss of some river-flow monitoring sites. Entura assisted with assessment and rectification of this damage.

Success drew on prior climate-resilience preparation

Ultimately, the example of Hydro Tasmania demonstrates climate resilience in practice. It shows how an investment in climate resilience enables a power and water business to be better prepared, more flexible and more robust in the face of a climate ‘shock’.

Hydro Tasmania’s management of the crisis required a comprehensive understanding of Tasmania’s climate and catchments. Entura’s involvement in 2007 in developing a Climate Change Response Strategy had provided a basis for this understanding, and a crucial input into identifying the risks and opportunities stemming from climate change.

Further inputs for climate resilience came through the collaboration in 2008 to 2010 between Entura and the CSIRO (Australia’s national scientific research organisation) on the first fine-scale climate and river system modelling for Tasmania, through the Climate Futures for Tasmania and the Tasmania Sustainable Yields projects.

The results of that research were state-of-the-art regional climate modelling and hydrological models to project future catchment yields for Tasmania. The modelling indicated that under climate change Tasmania could expect gradual temperature rises, changes in rainfall patterns over coastal regions, reduced rainfall over central Tasmania, changes to run-off patterns, and changes to the frequency and severity of extreme weather events including increased rainfall intensity and floods.

This modelling was critical in enabling Hydro Tasmania to plan and balance generation and storage levels over a range of demand and inflow scenarios and to assess environmental impacts during the extended period of drought.

Another key aspect of managing the energy supply challenges through the drought involved setting up supplementary diesel generation. This drew on Entura’s expertise and extensive involvement in developing hybrid off-grid renewable energy systems.

Hydro Tasmania’s climate resilience also involved being prepared for the drought to break. Key contributions from Entura included flood forecasting and flood support systems, ongoing support of Hydro Tasmania’s dam safety and emergency planning programs, and prior involvement in upgrading dams and designing spillways to withstand predicted increases in the frequency and magnitude of floods.

Entura also supported Hydro Tasmania’s procedures and ongoing activities to manage the secondary impacts of the fires and floods (such as damage to infrastructure), as well as the risks posed by low lake levels to social and environmental values. Entura’s environmental scientists monitored threats to aquatic flora and fauna through the 2015/16 crisis. To ensure the least likelihood of long-term or irreversible environmental damage, Hydro Tasmania’s environmental risk bands were revised.

Investing in your climate resilience

Any proactive and sustainable power or water business needs to invest in understanding the range, likelihood and consequences of the potential impacts of climate change for their current and planned systems and operations – whether for hydropower, transmission, dams, irrigation or water supply – and how to avoid or mitigate the impacts.

The more businesses understand the potential impacts of climate change and risks to their projects and operations, the better they can prepare, adapt, and build resilience to climate change impacts.

If you would like to learn more about building greater climate resilience into your project or operations, please contact Dr Eleni Taylor-Wood on +61 3 6245 4582, Phillip Ellerton on +61 439 010 172 or Shekhar Prince on +61 412 402 110.

About the authors

Tammy Chu is the Managing Director of Entura, one of the world’s most experienced specialist power and water consulting firms. She is responsible for Entura’s business strategy, performance and services to clients, and is part of Hydro Tasmania’s Leadership Group. As a civil engineer, Tammy specialised in the design and construction of mini-hydro and hydropower systems, project management, hydropower investigations, prefeasibility and feasibility studies, environmental assessments and approvals, resource investigations and resource water management. Tammy is a member of the Board of the International Hydropower Association. She was the first female and now past president of the Tasmanian Division of Engineers Australia, and was an Engineers Australia National Congress representative.

Dr Eleni Taylor-Wood is Entura’s Principal Consultant, Environmental and Social Science. Eleni has more than 20 years’ experience successfully managing large-scale, complex projects that run over several years, as well as providing expert advice and independent review for a range of infrastructure and planning projects. She has worked on projects around the world including in Australia, Mozambique, South Africa, Iceland, Colombia, India, Malaysia, Mekong, Solomon Islands, Fiji and Papua New Guinea. Her experience covers a vast gamut of studies including: environmental and social impact assessment and management; strategic management of wetlands and waterway; feasibility and approvals for new hydropower projects, environmental flow determination and assessment, and sustainability assessments. Eleni is currently one of eleven Accredited Assessors under the Hydropower Sustainability Assessment Protocol worldwide.

MORE THOUGHT LEADERSHIP ARTICLES

Batteries vs pumped hydro – a place for both?

Two very different storage technologies – one old, one new; one that takes years to build, one that can be built ‘within 100 days (or it’s free)’. How else do they differ, and is there a place for both?

The rapid growth of renewable energy generation has been driven by two concurrent factors: the falling levelised cost of the energy produced by wind and solar, and the retirement of a number of coal-fired power stations. The recently released Finkel Review notes that by 2035, approximately 68 per cent of the current fleet of Australian coal generating plants will have reached 50 years of age.

The Clean Energy Target proposed by Dr Finkel is not yet confirmed but it recommends incentives for technologies with low or zero carbon emissions. More renewable energy generation brings new challenges in an increasingly complex grid. Dr Finkel therefore also proposes that energy storage be mandated for solar and wind farms.

Renewables can’t, on their own, meet the fluctuations in demand that occur throughout the day without some regulation as to when power reaches the grid. Power needs to be dispatchable. Dispatchable means that energy can be provided upon request. If the sun is not shining or the wind is not blowing, renewable energy cannot be dispatched unless it has been stored in some way.

There are a number of different types of storage but the two being discussed most widely right now are batteries and pumped hydro energy storage. These two technologies are very different and there are some limitations involved in comparing a well-known and established technology with one that is new and developing rapidly.

How do they support the network?

Pumped hydro is based on well-established synchronous generation, providing critical ancillary services to the grid, through the provision of inertia, frequency and voltage support and sufficient fault level support.

Battery inverter technologies are still catching up on most of these fronts. The potential for batteries to provide ‘synthetic inertia’ or fast frequency response is high but this is balanced by their reliance on system strength to be able to deliver this support. They offer minimal support with fault levels but can still provide some support to system frequency and voltage regulation.

How fast can they happen?

There’s no doubt that battery storage is quicker to implement than pumped hydro. South Australia has provided an example of just how quickly battery storage can be deployed.

In March 2017, the South Australian Government called for expressions of interest for the supply of grid-connected battery storage to be connected by the end of 2017. The overwhelming response from 90 interested parties tells us that this speed of deployment is within the realms of possibility.

Battery image courtesy of Greensmith, a Wärtsilä Energy Solutions company.

Pumped hydro, by comparison, is a technology that takes much longer to implement. Typically, development activities (including optimising the technical solution, environmental and social assessments, arranging finance and finalising design) take two years or more to complete, and construction takes another two to three years.

How do the capital costs compare?

Pumped hydro boasts a very low price per megawatt hour, ranging from about $200/MWh to $260/MWh. Currently, battery costs range from $350/MWh to nearly $1000/MWh, with this cost reducing rapidly (costs reduced by about 25% during 2016).

According to the Lazard’s Levelized Cost Of Storage report, capital costs for pumped storage projects around the world range from about $1.5 million to $2.5 million per MW installed. The report also reveals that the cost of installing a grid-scale battery solution ranges from about $3.5 million to $7.5 million. This wide range of pricing for batteries is typical of a developing technology that is implemented in a variety of applications.

Ultimately, it’s difficult to predict how low the cost of batteries may go, but reports predict costs of lithium-ion batteries at somewhere around $120/MWh by 2025.

Considering that batteries need to be replaced once or twice a decade, with the currently available technologies, a battery facility will need to be replaced a number of times during the potential 100-year life of a pumped storage project. For batteries, assuming an economic life of 40 years, the initial cost plus replacements may mean whole-of-life costs fall in the range of $200/MWh to $330/MWh.

So, what does the future hold?

The rise of renewables will inevitably lead to a diversity of storage and supply solutions. The range of these solutions will depend on the resources of particular regions and locations. It is highly likely that the future for both batteries and pumped storage technologies will be extremely bright.

Batteries are here to stay and will undoubtedly play a significant role in future power systems as the technology develops and costs fall. However, while batteries can provide fast response times, they are yet to demonstrate their ability to provide the full range of ancillary services needed to support the grid. Pumped hydro remains a landmark, proven and reliable technology, able to meet the needs of the grid and provide sustained output for up to a century.

Ultimately, there is room for both batteries and pumped storage hydro, and they may even complement each other. Batteries are more cost-effective at delivering small amounts of stored energy over a short time at high power levels. Pumped storage is more cost-effective at storing and releasing larger amounts of stored energy. Achieving the optimum storage solution will depend on careful planning and finding the best fit for the particular circumstances.

What is certain is that both technologies will play important roles in the development and expansion of a network powered by renewable energy.

If you would like to discuss how Entura can help you with your next utility-scale battery or pumped hydro project, please contact Donald Vaughan on +61 3 6245 4279 or Nick West on +61 408 952 315.

A version of this article was first published in RenewEconomy.

About the authors

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

Nick West is a civil engineer at Entura with 16 years of experience, primarily in hydraulics and hydropower. Nick’s skills range from the technical analysis of the layout of hydropower projects to the preparation of contractual project documents and computational hydraulic modelling. Nick was a key team member of the Kidston Pumped Storage Project Technical Feasibility Study.

MORE THOUGHT LEADERSHIP ARTICLES

Shifting directions for hydropower in Asia-Pacific

The issues and trends we’re seeing playing out right now relating to hydropower and the clean energy sector are not unique to our region.

Having recently returned from a meeting of the Board of the International Hydropower Association, I’ve been reflecting on the challenges and opportunities facing the global hydropower sector.

It seems that there’s a global shift occurring in hydropower. Traditionally, hydropower has been viewed as a stand-alone, established renewable technology. Now we’re seeing a much greater sense of integration with other renewable technologies as part of broader ‘clean energy’ systems. With the rapid global increase of wind and solar power developments, hydropower needs to review its place, and its opportunities, within the wider energy sector.

Wind and solar tend to have shorter construction and implementation periods than hydropower projects. When the wind is blowing and the sun is shining, the power flows. But, as we know, the intermittency of these sources of power creates the need for some sort of storage to firm up the system.

Hydropower has traditionally provided both baseload and peaking capacity, but now we also have the opportunity to provide much-needed storage and the firming capacity urgently required to help stabilise grids as they integrate increasing levels of intermittent renewable technologies. Pumped storage hydropower may be particularly useful in this context.

In recent weeks the Australian federal government has expressed new interest in pumped storage options to help alleviate grid pressures, such as those experienced recently in South Australia. But it’s not only in Australia that we’re seeing increased discussion and enthusiasm about opportunities for pumped storage hydropower to integrate with other intermittent renewable technologies by offer firming power and assistance with stabilising the grid. It’s a global trend.

Also under discussion at a policy level in Australia right now is the energy ‘trilemma’ of security, equity (accessibility and affordability) and environmental sustainability. These three factors need to be in balance to ensure a secure power sector that meets the present and future needs of energy consumers while moving towards a lower carbon future. These three big issues that are so relevant right now in the Australian context are just as urgent in the global setting too, and need careful long-term planning, and the right mechanisms in place to support appropriate development.

It is interesting to review the World Energy Council Energy Trilemma Index, noting country rankings through the lens of hydropower and pumped storage integration. Not surprisingly, most countries ranked at the top of the list have been using these technologies for decades, which perhaps signals a direction for others to consider.

Another worldwide trend is the ongoing shift towards development of small to medium hydropower systems because many of the larger opportunities have already been exploited. For example, in China, many of the large hydropower schemes (10 000 MW, plus) have already been identified or developed, so new hydro developments are more likely to fall within the small to medium range, with the added advantage of shorter construction and implementation times. In Australia, smaller pumped hydro systems, or hydropower systems built into irrigation systems or water supplies, also have a significant role to play in the ongoing development of the hydropower sector.

Renewable energy and hydropower is a specialised field, so it’s critical that we also focus on the human resources and the capacity development needed to ensure a healthy future for the global hydropower sector. This is particularly so in regions which are new to hydropower and renewables, as the world shifts towards stronger support for renewables and replacing carbon-intensive power generation.

Hydropower is a mature, established technology, but that doesn’t mean we can’t be flexible and responsive to shifts in the global energy sector. As we strive towards the goal of affordable, reliable and sustainable power for all, hydropower has much yet to offer as a stabilising element of an integrated clean energy vision.

About the author

Tammy Chu is Entura’s Managing Director. She is responsible for Entura’s business strategy, performance and services to clients, and is part of Hydro Tasmania’s Leadership Group. Tammy joined the business in 2000 and has held a range of positions at Entura, from Technical Professional to Project Manager, Business Development Manager and Water and Environment Group Manager.

She has extensive managerial and business development experience in the consulting engineering industry within Australia and internationally, focusing on business strategy, change and transformation, international sales, culture, and profit and revenue growth.

As a civil engineer, Tammy specialised in the design and construction of mini-hydro and hydropower systems, project management, hydropower investigations, prefeasibility and feasibility studies, environmental assessments and approvals, resource investigations and resource water management.

Tammy is a member of the Board of the International Hydropower Association. She was the first female and now past president of the Tasmanian Division of Engineers Australia, and was an Engineers Australia National Congress representative.

Tammy holds a Master of Business and Administration from Chifley Business School, is a Fellow of Engineers Australia, and a graduate of the Australian Institute of Company Directors.

MORE THOUGHT LEADERSHIP ARTICLES

Overcoming the barriers to pumped storage hydropower

With energy reliability a hot topic in Australia, eyes are now turning to pumped storage hydropower… but what has been holding it back?

There are only three pumped storage hydropower projects in Australia, with the most recent completed more than thirty years ago. This is despite the ability of pumped storage hydropower projects to provide the large-scale storage that would complement increasing levels of renewable energy. Why is this, and what are the barriers to developing more Australian pumped storage hydropower projects?

Around the world, pumped storage hydropower projects make up the vast majority of grid energy storage and have traditionally been used by energy utilities to supply additional power to a grid during times of highest demand.

As part of a portfolio of power stations, a utility might operate a pumped storage project infrequently only, if the cost of pumping the water back to the upper storage exceeds the revenue that can be generated from its release.

The main issue facing developers trying to prove the viability of a new pumped storage project is that a sufficient price differential is required to pay for the pumping and to account for the efficiency losses in transmission, pumping and generation. The generation price needs to be sufficiently higher than the pumping price just to repay the variable pumping costs. To repay the heavy capital investment, a margin is required over and above the break-even cost of pumping. This is particularly true where proposed developments are ‘stand-alone’ and cannot be optimised as part of a corporate generation portfolio.

In recent years, electricity price spikes have been irregular with few occurrences each year. Due to the significant capital costs, a pumped storage scheme would require a certain number of pumping/generation cycles at high or maximum pricing to pay a return on investment. These price spikes are unpredictable, so building a business case around these events is risky.

Historically, the daily fluctuation of power prices has not been sufficient or regular enough to attract pumped storage developers. This is beginning to change with increasing penetration of renewable energy leading to an increase in both low and high price periods. More frequent, sustained periods of hot weather (as predicted by climate change models) will also drive up demand for power and therefore the market price.

In the last few months, volatility has greatly increased, creating a greater differential between baseload and peak pricing. This will increase the viability of pumped storage schemes, although the unpredictability and challenges of financing capital intensive assets will remain.

But, even when the economics are right, there are still some other barriers that proponents of pumped storage projects need to overcome:

Finding the right site

Pumped storage projects require significant capital for development. Minimising the cost of construction and operation is key to the successful development of a project. Choosing the right location is a matter of identifying a site with ideal topography, a source of water and good proximity to and location within the transmission network.

A wealth of information is available that is relevant to identifying potential pumped storage hydropower sites. Concept studies for pumped storage hydropower sites can screen potential sites quickly and offer developers greater insight into possible opportunities.

Negotiating access to appropriate sites for pumped storage