What is the best dam type for my dam site?

Asking ‘what is the best dam type for my dam site?’ is a key question in the early stages of planning a dam project.

A number of dam types are being used around the world, such as concrete-faced rockfill dams (CFRD), roller-compacted concrete (RCC) dams, and asphalt-core rockfill dams, amongst others. Consultants that specialise in a particular dam type may offer a biased answer to the question, which is not in the best interests of the project.

The most appropriate response is that the best dam will depend on the unique characteristics of the dam site – available materials, climate, geology, topography, river flows, seismic risk – just to name a few. This may sound obvious, yet it is surprisingly often ignored.

Although it is important that we take our experience and learnings from other projects and apply them to any new dam project, it is equally important that we do not force a past solution to fit a new dam site without considering that particular site’s uniqueness.

So, for any dam site, it is important to undertake an unbiased dam-type assessment that takes into account the range of site-specific conditions balanced against the broader project constraints (such as cost optimisation, and the availability of local design and construction expertise).

The following examples of dams with which I’ve been involved show how particular characteristics of each dam site determine the appropriate dam type.

Responding to local climate, geology and materials in Tasmania

On the west coast of Tasmania, Australia, where the rainfall is around four metres per year, Hydro Tasmania, Australia’s largest renewable energy producer and water manager, has constructed nine CFRDs. Good rockfill was available at all of these sites. Key reasons why CFRDs were used at these sites, rather than central-core earth and rockfill dams, included both the lack of quality clay material and the high rainfall in this region. High rainfall would significantly disrupt and delay the construction of clay-core dams due to issues with the compaction of the clay material, whereas construction of CFRDs could continue during rain. Asphalt-core dams might also have been possible in these local climate conditions, but would have presented different challenges for river diversion.

One of these CFRDs, the 82m-high Crotty Dam, faced potential instability should a traditional side-channel spillway be cut into the abutment slope, due to the steep abutment slopes and identified geological defects. As a result, for the first time in the world, a spillway was created over the top of a high CFRD wall, combined with a large-capacity bottom outlet gate installed in the diversion tunnel. This solution included an articulated concrete slab that would allow the spillway to move without cracking as the rockfill settled over time.

The solution at Crotty Dam was unique, but it was heavily influenced by the characteristics of the dam site and the construction materials available, which allowed a very stiff rockfill to be constructed, minimising the amount of settlement. The solution has proven a good choice, operating well for more than 20 years.

However, the particular solution that was successful for Crotty Dam may not be appropriate for other dam sites, where the dam might be significantly higher, where rockfill may be of poorer quality, or at a site with greater flood discharge or higher seismic risk.

A process of elimination in Papua New Guinea

In 2012, Entura undertook a detailed dam-type assessment for a site in Papua New Guinea, and in this case, the ultimate decision about the best dam type emerged from considering many site characteristics and then eliminating inappropriate dam types to reach a subset of viable possibilities.

The site was in an extremely high rainfall area (with approximately ten meters of rain each year), the rock foundation had relatively low strength and low stiffness, river flows were consistently high, there was deep alluvial material that would need to be removed or sealed, and the site was in a region with relatively high seismic risk. Sources for concrete aggregate and rockfill were available. However, due to the lack of strength and stiffness of the foundation rock, a conventional concrete gravity dam was not possible; and the extremely high rainfall posed significant challenges for a central clay core and rockfill dam.

As a result, the choices narrowed to a CFRD, an asphalt-core rockfill dam or a thick, trapezoidal RCC (or hard-fill) dam. Ultimately, an asphalt-core rockfill dam was chosen as the preferred solution, as the core could be placed during high rainfall, the load would be adequately spread over the foundation, and it was considered a resilient design for the seismic loading.

Another important factor influencing the choice was that an asphalt-core rockfill dam would minimise problems and delays should the upstream temporary cofferdam overtop, because asphalt-core rockfill dams are always complete up to the current height of construction with no further work required below this level. Some other dam types require further work on the dam’s upstream face after the dam wall is constructed to its full height, requiring flood water to be pumped away to enable final-stage activities to proceed.

![]()

Challenges influencing RCC dam design and construction

Many design and construction decisions for RCC dams can be significantly influenced by specific site conditions – for example, should the proportion of cementitious material (cement and fly-ash) in the RCC mix be low or high? Should one use conventional facing concrete, grout-enriched RCC or a PVC upstream membrane? Is RCC best delivered by truck or conveyor?

A significant influence on the design of the Wyaralong Dam in Queensland was the benefit of using an onsite, but inferior, sandstone aggregate for the RCC aggregate. Using the onsite aggregate would reduce costs and benefit the local community through avoiding major aggregate haulage on public roads.

Using the onsite aggregate also influenced the investigations that occurred as part of the normal trial program used to develop an appropriate RCC mix. This in turn influenced the design of the dam because the trial mix program identified an issue with the surface durability of the RCC. Grout enrichment of the facing RCC was not suitable, so a conventional concrete using a high-quality basalt aggregate was used to provide the necessary durability.

The topography of the left abutment provided a natural ramp for an articulated truck delivery system. This delivery system proved to be very flexible, but it was important to develop a suitable RCC mix for truck delivery.

One size doesn’t fit all

There is no easy or immediate answer to the question posed at the start of this article. No single dam type offers the best solution for every dam site. Although lessons learnt from other dam sites can help to rapidly narrow down a set of preferred dam types to consider in more detail, the appropriate dam type must be influenced by the unique conditions of the dam site.

Specialist power and water consulting firm Entura has significant experience with a wide range of dam types across the Asia-Pacific and southern African regions, particularly CFRDs and RCC dams.

You can read more about the way in which we responded to specific site characteristics for three RCC dams and the reasoning underpinning our design decisions in my 2012 ICOLD Conference paper “Unique challenges influencing the design and construction of three recent Australian RCC dams”.

If you would like to discuss how we can assist you with selecting the most appropriate dam type for your dam site, please contact Richard Herweynen on +61 3 6245 4130 or Shekhar Prince on +61 412 402 110.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

Breathing new life into ageing assets: asset management in practice in PNG

The remote Ok Menga hydropower station in the Western Province of Papua New Guinea is vital to the operation of the Ok Tedi mine (OTML). It offers an example of just how expensive it can be when ageing power stations deteriorate and become increasingly unreliable.

The Ok Menga hydropower station provides almost three-quarters of the power needed to operate the mine, with the remaining power generated using expensive diesel fuel. The local power network is isolated and not connected to any of the country’s electricity grids, so any failure of the Ok Menga power station is costly.

If one of Ok Menga’s two generating sets is out of action, replacing that amount of hydropower (about 30 MW) with diesel-generated power could cost around AUD$650 000 a day in fuel alone. Worse still, a full outage of the power station could cause the mine to shut down, losing copper, silver and gold production worth around AUD$4 million per day!

The Ok Tedi mine had been scheduled to close in 2015, so preventative maintenance had not been a high priority for its owners, and the Ok Menga power station had become run down. When the mine’s proposed closure was delayed to 2025, a new operational strategy was needed to wring at least another ten years of useful and reliable life out of the more-than-30-year-old Ok Menga power station.

OTML needed the help of skilled asset management experts to extend the life of the Ok Menga power station, so it engaged specialist power and water consulting firm Entura to conduct an extensive condition assessment and come up with a risk mitigation plan to get the best out of the station in a cost-effective way. This also included building the skills and knowledge of OTML staff who had not had any formal training for years.

Ok Menga’s unique challenges

Although Ok Menga had many of the same asset management issues as any other hydro plant, it also presented some unique challenges in terms of risks and maintenance strategies. Its isolation and association with a large mining operation challenged many of the conventional rules fundamental to asset management in larger power utilities.

Leigh Smith, specialist consultant in asset management at Entura, explained: “In our asset management approach, we needed to take into account how the particular characteristics and circumstances at Ok Menga created differences for aspects such as the design life, planning outages, access to the plant, the holdings of critical spare parts, and the consequences of faults. For example, because outages at Ok Menga incur such high costs, we needed to replace rather than refurbish machinery, because they couldn’t have the machines offline for long.”

Bringing risks under control

Entura applied its best-practice asset management approach at Ok Menga by thoroughly assessing the condition, performance and remaining useful life of all aspects of the station, and developing a risk mitigation plan including urgent actions to remedy serious risks, and ‘quick wins’ to improve the state of the station quickly, cheaply and effectively.

As Leigh explained, “We report the condition of the plant in terms of business risk, and the mitigation strategies we propose are all about reducing risk to a level that’s acceptable to the business in cost-effective and practical ways”.

Quick wins and priority actions

At Ok Menga, two ‘quick win’ projects were identified to mitigate critical risks. The main inlet valves were difficult to access and in poor condition with no critical spare parts on site, and the original analogue turbine governors installed in the 1980s needed replacing but no governor spare parts were available.

“A failure in either or both of these areas was seen as likely in the foreseeable future and would create serious consequences of a prolonged forced outage for one unit or even the complete station,” said Leigh.

Replacements for the main inlet valves would take more than 18 months to deliver, so an emergency repair kit containing critical spares was ordered immediately. Replacement of the governor controllers with newer digital technology was also rapidly initiated to quickly reverse declining reliability.

Leigh said, “Getting these ‘quick win’ projects going straightaway was imperative and immediately reduced very significant risks.”

As well, at Ok Menga, three priority asset risk mitigations were identified relating to the station’s rock trap, unit 1 turbine and the dewatering and drainage system. The rock trap was found to be full, and cleaning it out was initiated quickly. Ok Menga’s unit 1 turbine was worn so the unit 1 runner and cassette were replaced. The security of the dewatering and drainage system had been degraded and it was at risk of failure so Entura recommended that it be upgraded to a system with greater reliability and redundancy.

“Because these priority actions minimised damage to turbines, avoided possible turbine malfunction, and reduced the risk of the powerhouse being flooded, they made a big contribution to reducing the owner’s overall risk exposure,” said Leigh.

![]()

Building capacity

To fill skill gaps at the Ok Menga power station, Entura developed an Australian-accredited program to train new and existing hydro operators. Local staff were included in the asset management process and have now had first-hand exposure to best-practice techniques.

“The owner of this power station is very committed to a sustainable future, and this extends to its staff. The platform is now set for local staff to build on their newfound knowledge and continue to improve their understanding and skills in asset management,” explained Leigh.

Entura has developed its knowledge of asset management through our involvement over the past 100 years with the extensive power and water assets of Hydro Tasmania, Australia’s largest renewable energy producer. Our approach to asset management is recognised as best practice.

“We have spent considerable time learning and developing our systems and knowledge, and this enables us to deliver cutting-edge asset management techniques to our clients without the expense they’d incur if they started from first principles,” said Leigh.

Entura’s holistic best-practice asset management approach at the Ok Menga power station delivered a range of benefits including reducing immediate and longer term risks, and increasing the knowledge and skills of local staff – saving OTML the time and cost of developing its own in-house programs.

If you would like to discuss how Entura can assist you with assessing your hydropower plants or other power or water assets to minimise risk and maximise efficiency and useful life, please contact Leigh Smith on +61 419 884 318 or Shekhar Prince on +61 412 402 110.

MORE THOUGHT LEADERSHIP ARTICLES

Less risk, more benefit: managing assets for long-term gains

Hydropower stations, like all technology or infrastructure, won’t stay efficient, reliable or safe without regular and ongoing attention.

Outages and failures caused by ageing or deteriorating infrastructure can be extremely expensive and serious, and far outweigh the costs of a well-targeted asset management plan. The costs of unreliability are even more significant for hydropower stations in isolated locations or where the power is relied on to run industrial or commercial operations.

But asset management isn’t only about avoiding disasters … It’s also about getting the most out of asset life or ‘getting more bang for your buck’. Owners and operators stand to reap rewards from improved performance and greater reliability if they protect and extend the lives of their investments using best-practice asset management techniques.

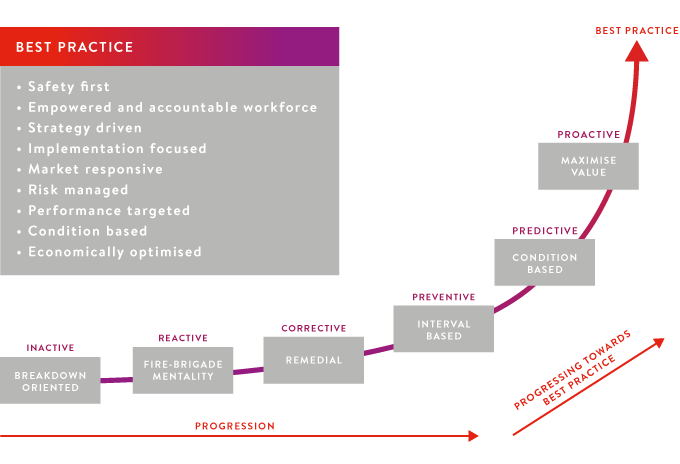

From basic to best practice

In today’s industry, significant amounts of time, energy and effort are invested in achieving desired plant performance at the lowest possible cost without exposing the business to unacceptable risk. Truly sustainable and successful businesses have found ways to balance these priorities, and have strategies in place to adjust the balance as needed when facing changing conditions.

Besides the large financial consequences of outages, failures of systems and equipment can also place the lives of workers at risk. Repairing and upgrading equipment and systems only after they fail is an extremely costly and dangerous way to manage assets. This kind of basic ‘breakdown-oriented’ or reactive asset management is likely to result in unreliable plant and increased human and financial risks.

As businesses mature in their approach to asset management, they progress from a breakdown-oriented approach, through reactive and corrective approaches, towards preventive, predictive and proactive approaches.

Best-practice asset management focuses on reducing risks and improving condition and performance to get the best results. It is driven by strategy and responds to the market, empowers the workforce and makes workers accountable, and always puts safety first. It also needs to be flexible enough to accommodate the individual characteristics of different hydropower stations.

Save time, save money, save lives

Specialist power and water consulting firm Entura thoroughly understands the complexities and benefits of asset refurbishment, upgrade, modernisation and extension of life. As part of Hydro Tasmania, Australia’s largest renewable energy producer and water manager, Entura has day-to-day experience of the challenges of maintaining and upgrading assets to get the best performance, reliability and economy over the long term, through dealing with 30 hydropower stations built and maintained over the past 100 years.

Entura’s asset management techniques are based on condition, performance and risk – designed to save companies time and money. This approach is underpinned by an optimised system that combines reliability-centred maintenance (RCM) and failure modes and effects analysis (FMEA) using generic failure mode databases that can be applied to various different assets with quick results.

Entura’s asset management approach has helped other asset owners across Australia, New Zealand, Papua New Guinea and Malaysia to reduce their costs, reverse declining reliability, obtain better returns through increased performance and improved technology, increase personnel safety, decrease fire and flooding risk and other hazards, increase skills of their staff, and ensure the long-term viability of their valuable infrastructure.

Three steps to best-practice asset management

Entura’s approach to best-practice asset management has three steps that fully consider your assets’ past, improve their present operation and risk profile, and position them for their best possible futures.

Step one: Assessing assets

To fully assess an asset, we undertake detailed inspections and consider the four parameters of:

- condition (observed and measured condition, and maintainability, which takes into account the availability of spare parts, technical ability, and industry compliance)

- performance (both capability and reliability)

- confidence (the level of detail or rigour of the assessment)

- remaining useful life (an estimate of the rate of deterioration of the asset, indicating where the particular asset is on its lifecycle curve, and whether a refurbishment or upgrade can improve its position on this curve, even effectively returning it to as-new condition).

We present a high-level ‘water-to-wire’ summary of the condition and performance assessment results that quickly and graphically displays the known asset condition and remaining useful life, and identifies components for which the condition is not adequately known.

Step two: Developing a risk and mitigation plan

Once an asset has been fully assessed, we develop a risk and mitigation plan.

First, we gather and review a comprehensive set of information on the operation, design and construction of the station and its assets. We explore both the asset history and generic databases to determine probable failure modes.

Once we’ve gathered this information and analysed it against the requirements of the power station, we report the known condition of the plant in terms of business risk and develop practical and cost-effective mitigation strategies to reduce risk to a level that is both achievable and acceptable for the business.

We identify and undertake mitigation actions including ‘quick wins’ (actions that can be undertaken quickly and easily to achieve major improvements) and immediate priority activities to reduce risks. We also detect assets or components that need further investigation.

Step three: Optimising future performance (tailoring the balance)

Best-practice asset management takes a broad view of the life and operation of an asset, not only reducing immediate risks, but also promoting long-term efficient performance and sustainability. Our approach optimises the capital and operational costs over the remaining life of the asset.

A valued part of Entura’s asset management approach is our ability to offer a review of likely efficiency and capacity gains, and other general suggestions for improving performance and systems.

An important step in our holistic approach to achieving long-term safety, reliability and efficiency is training local hydro operators to fill any identified skill gaps and better safeguard the maintenance of assets. We build the capacity of our clients through on-site or formalised training through our Entura clean energy and water institute.

If you would like to discuss how Entura can assist you with assessing your hydropower plants or other power or water assets to minimise risk and maximise efficiency and useful life, please contact Shekhar Prince on +61 412 402 110.

This article was written by Ambrose Canning, Entura’s Principal Consultant, Mechanical Engineering (retired 2025).

MORE THOUGHT LEADERSHIP ARTICLES

Dam safety: protecting lives and driving efficiencies

Humans have been damming rivers since 3000 BC for water retention and supply.

People can fish in the lakes formed by dams, sail on them, swim in them. They are important to life, providing water supply, irrigation for crops and power generation. But if a dam fails, causing devastating flooding downstream, the results can be catastrophic.

The worst dam failure in history occurred in China in 1975 when the Banqiao Reservoir Dam and other dams in Henan province failed, killing an estimated 171 000 people, with 11 million people losing their homes.

Safety is the key

Dam safety is a crucial aspect of modern dam building. Ensuring the safety of existing dams is a key concern of any dam owner, whether the dam is for generating power, protecting a nearby population from potential flooding or for the age-old reason of water supply.

Specialist power and water consulting firm Entura provides dam safety programs for Gordon Dam, the largest concrete arch dam in Australia, and other assets owned by Entura’s parent company, Hydro Tasmania, and for government and corporate clients around Australia, south-east Asia and southern Africa.

Hydro Tasmania is Australia’s largest water manager, so it needs to ensure that the risk of a failure across the portfolio is very, very small. With 55 large dams and many smaller ones, Hydro Tasmania needs to be able to identify the highest risk dams, so it is able to prioritise work on maintenance and refurbishment. This is achieved using a process undertaken by Entura called a portfolio risk assessment (PRA).

Hydro Tasmania is committed to the safety of its assets for the people of Tasmania and its PRA enables the business to prioritise where it focus its financial resources, management and dam safety efforts.

What’s the level of risk?

Energy and water asset owners are increasingly choosing to implement a dam safety program to quantify and manage operational risks, evaluate high risks and find solutions for identified risks or deficiencies. Entura believes that a risk-based framework like a PRA is the best way to achieve an efficient and effective dam safety program.

Older dams or dams located upstream from populated areas are often high risk. The inspection regime for high-risk dams is understandably more robust and rigid than for low risk dams. However, it’s not just ageing that creates risks for dams. In Australia, the methods used to predict and anticipate floods are equally important, as is the increased knowledge that we’ve gained of the various causes and mechanisms through which dams can fail.

Entura’s PRA reviews the consequences of failure of a dam by looking at the impact that it may have on downstream populations, and also looks at the chance of failure occurring by considering extreme events such as floods and earthquakes, taking into account the specific site conditions. It is the combination of the chance of failure with the resulting consequence that determines the level of risk.

A world-wide issue

A number of dam owners across the Asia-Pacific region are now looking at Entura’s PRA program, especially when they have a significant dam portfolio already developed. Our clients in the region are exploring how they can best use their resources and how to prioritise expenditure on their assets.

Having undertaken safety reviews and dam safety work in the Philippines, China, Indonesia, Malaysia, New Zealand, Papua New Guinea, Fiji and India, Entura understands the typical safety needs and drivers of dam owners across the world.

Australia has well-developed dam safety legislation in which Malaysia, for example, with its increasing number of dams, is very interested. Malaysia has experienced the tragic results of a dam safety incident, with the death of a number of people due to water releases through the spillway gates of Sultan Abu Bakar Dam.

On behalf of the Ministry of Public Utilities, Sarawak, Malaysia, Entura used its dam risk framework, similar to that used in a PRA, to assess whether the Bakun and Murum dams were ready to be impounded as construction reached conclusion. This dam risk framework looked at the potential scenarios that could lead to the sudden release of reservoir water, the likelihood of these scenarios occurring, and the corresponding consequences. Through this process the key dam safety risks were identified, and actions were determined to either eliminate or reduce the risks to an acceptable level. These actions needed to be addressed prior to impoundment.

Dam safety is an ongoing concern

The safety and risk-level of a dam can change with time. As dams or assets age, the way they are managed needs to change and they often need upgrading to ensure continued safe operation and desired life expectancy. But undertaking upgrades can potentially increase the risk of the dam during the construction phase – due to the removal of shoulder material from an embankment, or restricting the discharge capacity in a spillway chute. To contain the risks during the construction phase, operational practices might need modification, for example, operating a dam at a lower lake level during the period of construction to ensure the overall risk is not significantly increased. This is why it is so important to have a plan to manage the safety of the dam during its entire lifecycle.

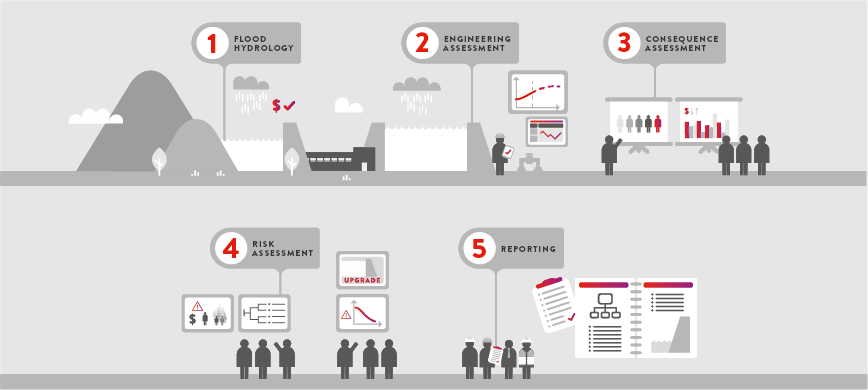

Five steps to assess dam safety risks

Risks can be reduced in a range of ways and, in many cases, a number of risk treatment options are used together:

- reducing the likelihood of the risk occurring (e.g. strengthen a dam)

- reducing the consequences if the risk does occur (e.g. upgrade emergency planning)

- staging risk treatments (e.g. address most cost-effective risk mitigation works first)

- balancing the resources required to treat a risk with the benefits of reducing the risk (e.g. examine various levels of investment and their respective risk reductions).

Entura’s portfolio risk assessment approach has five key steps:

| 1 – Flood hydrology | Flood hydrology is a key input as it is used in both the engineering and consequence assessments. Generally the hydrology is based on current best practice. For some low-hazard dams, an innovative regional flood hydrology approach has been developed that provides sufficiently robust answers at minimal cost. |

| 2 – Engineering assessment | The engineering assessment is a critical part of the process as it requires all potential failure modes to be identified and then the probability of failure to be estimated for each mode. The engineering assessment gathers all the information about the dam including design, construction, geology and operations that may assist in defining the potential failure modes. This is presented as response curves (i.e. conditional probability of failure). The level of detail varies with the hazard category of the dam (i.e. a high-hazard-category dam receives more intense scrutiny than a low-hazard dam). The engineering assessment also ensures an assessment of compliance with current engineering standards. |

| 3 – Consequence assessment | Key steps in the consequence assessment method include developing a dam break model; mapping the inundation zones; assessing the population at risk and probable loss of life; assessing the financial and economic losses; and qualitatively assessing the environmental, social and intangible consequences. |

| 4 – Risk assessment | The risk assessment uses event trees that evaluate societal and individual life risk and financial risks. Risks can be aggregated across a range of load conditions and failure modes to give a total risk position, retaining visibility of the scenarios that contribute to the total risk. Where the risks are unacceptable, upgrade concepts are developed and their impact on reducing risk is plotted. |

| 5 – Reporting | The results of the risk assessment are reported, summarising the potential failure modes, consequences and risk profile for each individual dam. Summary data across the portfolio is also presented, including information on the failure modes, and risk of all the dams against societal life risk and financial risk criteria in a simple but meaningful format. |

Resource levelling

All businesses need to share resources across many activities besides risk mitigation works. For a hydropower company, a significant reinvestment in generating plant is required to both manage risk and maintain asset capability. Resources are also needed for investment for growth and diversification.

Within the dam portfolio, it is important to ensure that resources, both human and financial, are not applied to risk mitigation projects at the expense of the fundamentally important surveillance and monitoring activities. A balance is needed between reducing risk and maintaining and enhancing surveillance and monitoring instrumentation.

An ongoing effort

Finally, it is important to realise that the capital works program for dam safety risk reduction is not a static program, locked in and then implemented without change. Rather, it is an active program that is reviewed regularly, actively managed and needs to remain responsive to new or changed risks, developing understanding of dams engineering, shifts in business priorities, delays to projects, and new developments in risk management processes.

The same process can be applied to other assets

The PRA process can also be used for other assets that have a low chance of failure but high consequences if failure were to occur. At Entura, we have successfully applied our PRA process to penstocks and pipelines, and to canal systems, identifying key risks and prioritising the actions needed in a way that most effectively manages resources.

If you would like to discuss how we can assist you with assessing your dam risks or developing a resource-effective and comprehensive dam safety program, or apply the same PRA process to other key assets, please contact Richard Herweynen on +61 3 6245 4130.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

The hidden risks in hydropower projects

Hydropower is increasingly becoming a major source of renewable energy for emerging markets throughout Asia.

Managing the not-so-obvious risks associated with developing and operating hydropower schemes is often a key challenge in securing project finance and gaining or maintaining a social licence to operate.

“Power projects, especially in developing countries, are increasingly scrutinised by international financing organisations when providing project funding” said Dr Eleni Taylor-Wood, Principal Consultant, Environmental and Social Science at specialist power and water consulting firm Entura.

“These entities, such as the Asian Development Bank, the International Finance Corporation and the World Bank, recognise that growth must be both inclusive and environmentally sound to reduce poverty and build shared prosperity for today’s population and future generations.”

Managing risk across all stages of a project can improve the viability of a project and the overall project outcomes.

What are the risks?

It is critical that both governments and hydropower entities understand the opportunities and risks of major projects, not only at the development stage, but also throughout the ongoing operation and management of the scheme.

Typically, some of the key risks to be considered include:

- Is there an identified need, what is the future demand, and is there a market?

- What is the best energy option?

- Could any political or public sector issues affect the project?

- Is there the institutional capacity to advance the project?

- How available is the resource? Will climate change affect availability?

- Is the site appropriate? Are there other options?

- Can you connect into the grid, and where? What systems enhancements might be required?

- Who are the key stakeholders and how can they be engaged?

- What are the possible environmental and social impacts, and how can they be avoided, mitigated, offset or compensated?

- What safety issues are associated with development, construction and operation, and how can they be managed?

- What are the ongoing operational costs?

- What are the ongoing operational requirements, such as compliance requirements, condition assessments, performance monitoring, maintenance strategy and planning, and training to build operator skills?

- How will you manage unforeseen stakeholder, technical, financial, social and environmental issues?

Using international standards and sustainability assessment frameworks to manage risks

International standards and sustainability assessment frameworks can help guide a comprehensive review of risks and, in some cases, identify further opportunities to increase positive outcomes from projects.-

In 2010, the International Hydropower Association launched the Hydropower Sustainability Assessment Protocol, a framework for assessing the sustainability of hydropower projects across the world. This framework can be used to help guide a hydropower project from the early stages of consideration through to operation, identifying issues and gaps for consideration, as well as be used to assess the project’s sustainability performance.

There are only eleven accredited assessors able to officially apply the Protocol worldwide. Entura’s Dr Eleni Taylor-Wood and Dr Helen Locher are among this select group of accredited assessors, having undertaken assessments of hydropower projects in Europe, South Asia, South-east Asia and South America.

One step at a time

“Evaluating the risks in stages means that the cost of evaluation can be minimised should the project be judged unviable at any point. Not all risks can be avoided, but many can be minimised or mitigated,” explained Dr Taylor-Wood.

Early identification of key risks allows companies to manage these risks throughout a project, minimising corporate, technical, environmental and social impacts and their associated costs, including damage to corporate reputation should an unmanaged risk develop into a crisis.

Self-assessment and capacity building

“I believe that for hydropower developments to be sustainable, we need to use the lessons of the past to innovate in the present and protect the future,” said Dr Taylor-Wood.

“This means learning from mistakes and carefully assessing and managing technical, corporate, economic, environmental and social risks right across the project lifecycle, so that developments contribute positively to social, environmental and economic goals.”

Entura uses a unique, tailored self-assessment tool to assist power companies and developers to understand the risks and opportunities facing their projects and to build capacity to assess, monitor and report on those projects.

This tool is based on the assessment criteria identified in guidelines and standards such as the Hydropower Sustainability Assessment Protocol and those used by the International Finance Corporation.

In addition, it can be adapted to include other standards or to assess compliance with criteria relevant to a client’s requirements or obligations (such as internal policies and/or permit or concession conditions).

Benefits include easier access to finance, better ability to anticipate and respond to stakeholder concerns, and avoidance of delays and problems through the project development pipeline.

Entura provides expert advice to help clients:

- develop a better understanding of risk identification, assessment and sustainability, across all project stages

- self-assess a project against recognised guidelines and standards to identify whether key issues, risks and opportunities have been considered and identify potential gaps for further consideration

- meet international financing requirements

- assess viability or conduct a due diligence of a project

- undertake assessments against the Protocol

- address risk issues to improve the overall sustainability performance of projects

- build institutional capacity to develop, operate and/or maintain power schemes.

eleni.taylor-wood@entura.com.auIf you would like to discuss how we can assist you with assessing your project or how you can assess and track your own progress towards improved risk minimisation and sustainability, please contact Dr Eleni Taylor-Wood on +61 3 6245 4582 or Shekhar Prince on +61 412 402 110.

About the author

Dr Eleni Taylor-Wood is Entura’s Principal Consultant, Environmental and Social Science. Eleni has 20 years’ experience successfully managing large-scale, complex projects that run over several years, as well as providing expert advice and independent review for a range of infrastructure and planning projects. She has worked on projects around the world including in Australia, Mozambique, South Africa, Iceland, Colombia, India, Malaysia, Mekong, Solomon Islands, Fiji and Papua New Guinea. Her experience covers a vast gamut of studies including: environmental and social impact assessment and management; strategic management of wetlands and waterway; feasibility and approvals for new hydropower projects, environmental flow determination and assessment, and sustainability assessments. Eleni is currently one of eleven Accredited Assessors under the Hydropower Sustainability Assessment Protocol worldwide.

MORE THOUGHT LEADERSHIP ARTICLES

Reliable, renewable energy now powering South Africa

In many developing nations, governments and utilities are scrambling to bring much-needed power to their people and industries to improve quality of life and drive economic growth.

Small hydro (around 40 MW or under) from run-of-river schemes is an ideal solution to contribute to growing and greening the energy mix in developing countries, providing clean and reliable power from a country’s rivers without the significant environmental or social impacts of large dams or the economic and environmental costs of fossil fuels.

The Neusberg hydropower project – a run-of-river small hydropower project near Kakamas in the Northern Cape of South Africa – is one small but effective step towards South Africa’s ambitious goals of raising the living standards of its growing population and supporting vital economic activity through encouraging the development of renewable energy by independent power producers.

What is the Neusberg hydropower project?

Using the power of the mighty Orange River, the Neusberg hydropower project creates electricity by diverting some water for a short distance as it runs downstream from the existing Neusberg Weir, returning the water back to the river after it runs through the hydroelectric plant’s three 4010 kW turbines.

The Neusberg project is highly efficient, producing 10 MW of reliable and sustainable baseload power for the equivalent of up to 5000 homes with no adverse impacts on irrigation, fish or environmental flows.

Success through collaboration, innovation and expertise

The Neusberg project needed a particularly innovative design solution and effective planning and collaboration for it to meet the needs of the region, satisfy the requirements of all major authorities and stakeholders, and still achieve the objectives of the developer.

And that’s where specialist power and water consulting firm Entura drew on its extensive experience in hydropower development to find the right answers to move the project towards successful completion.

For example, developing all the necessary tender and contractual documentation and negotiating and achieving regulatory approvals are critical administrative steps but can prove challenging. Entura’s owner’s engineer services helped the Neusberg project overcome these development-stage hurdles – such as helping to achieve the vital water use licence by proposing suitable designs for the project and then working through a collaborative process to modify the designs to meet the authority’s requirements while still achieving the developer’s objectives.

Tailored solutions for tricky challenges

A major challenge for the Neusberg project was to produce economical and reliable power to relieve pressure on the electricity network at the same time as ensuring adequate water supply for irrigation by local fruit-growers throughout the construction and operation of the project. Other specific local requirements also needed to be met, such as maintaining the ability of the Neusberg Weir to meaningfully measure river flow, maintaining the aquatic environment and minimising the impacts from construction activities.

- To guarantee an uninterrupted supply of water to the local irrigation scheme, construction of the hydro project called for clever planning. Since an existing irrigation canal ran through the powerhouse site and needed to remain in operation, a temporary diversion canal was created to allow the powerhouse and forebay to be constructed in two stages without interrupting irrigation supply.

- To ensure that the flows into both the hydroelectric project and the irrigation canals are sufficient, a weir was placed at the offtake for the hydro project providing passive protection against the water level in the reservoir being drawn down. The level of the top of the weir was carefully designed so that the length of the weir was reduced – lowering construction costs while providing the protection required for the irrigation canal and allowing sufficient flow into the headrace canal.

- The Neusberg Weir is a very important flow measuring structure as it provides accurate information on the flow in the Orange River to both South Africa and Namibia. The hydro project takes water away from the weir, so to restore the ability to measure flows, two devices were installed – an instrument in the canal upstream of the powerhouse, and the weir in the tailrace. The measuring weir in the tailrace provided an extra benefit for the aquatic environment, by acting as a barrier to fish movement and enabling fish to find their way to the existing fish ladder to travel upstream.

- To minimise costs and impacts of construction, the design of the Neusberg project dispensed with the typical aboveground powerhouse structure. Instead, the concrete roof of the powerhouse has a removable hatch allowing equipment to be lowered through the roof by crane into the turbine chamber.

Community benefits both now and into the future

The Neusberg project has brought an ongoing social and economic boost to the local community that goes well beyond providing an important source of electricity. During the construction phase, it created much-needed local employment in a region in which opportunities are scarce, and supported local and national businesses through spending on goods and services.

But the benefits keep flowing long after construction is finished, as the local community has a

15 per cent ownership stake in the hydropower scheme and an 8 per cent stake in operation and maintenance contractors, ensuring that the community trust will share in the project’s success for many years to come.

Entura’s role in the Neusberg project

Entura has played a vital role in the successful civil design and was also responsible for the electrical and mechanical construction of the Neusberg project by drawing on our day-to-day experience of owning, operating and maintaining hydropower assets for more than 100 years as part of Hydro Tasmania, Australia’s largest renewable energy producer and water manager, and an equity stakeholder in the Neusberg project.

If you would like to discuss how Entura can help you develop a hydropower scheme that can meet your power needs in a cost-effective and sustainable way, please contact Christoff LeGrange on +27 21 202 2231 or Shekhar Prince on +61 412 402 110.