Renewables in remote mines – a litmus test for the wider renewables transition

Entura’s Greg Koppens has recently returned from the Energy and Mines Summit in Perth, where he led the ‘Think Tank’: a collaborative session addressing the challenge of powering process steam requirements from renewables-generated electricity. Here he shares his observations on the rise of renewables in the mining industry …

Australia’s mining industry is beginning the peak phase of its energy revolution. However, I find it unfortunate that this exciting fact is invisible to regular people. It is happening in remote areas on mining leases, inaccessible to the public. Each project alone is not sensational enough for media attention, but added together these projects are nothing short of a technology revolution. For remote mining sites to have a solar farm is now standard practice. In many cases this is backed up by battery storage and a handful of mines have onsite wind turbines.

The past: fossil-fuel driven mines

Australia is world-renowned for our mining industries, with mines of virtually every resource throughout our country. Up until about ten years ago, nearly all of Australia’s mines ran completely on diesel or gas. In most cases diesel was trucked in, or gas was brought in via pipeline. Most of these mines have energy expenses in the tens of millions of dollars per year. A small change in the oil price can drastically impact the mine’s bottom line.

If there’s one doubtless fact about mining, it’s that miners are practical people. They are problem solvers, and they know what works. With the boom-and-bust nature of resource markets and shareholder responsibilities, finances must be well managed.

The present: hybrid renewables power generation

At the Energy and Mines Summit, there was no discussion about whether it’s a good idea to consider renewables in the mix of power generation – it was simply a given. This is an industry in ‘early maturity’: it is no longer pioneers running a trial. Several systems are in the order of 100 MW capacity. Renewables are a tested and proven business decision. Everyone has crunched the numbers on their sites and, while each project has unique site-specific requirements, the conclusions are unanimous. The frontier is now getting access to skilled people, there is community engagement for siting of large assets and mutual benefits, and the industry is exploring emerging technologies such as electric fleet.

We now have all the technology needed to harness the power of the wind and the sun in an 80/20 mix with fossil fuels. Or a 50/50 mix when the system has solar power alone. And this is what is being implemented in practice all over Australia. We can do it in a way that achieves targets for price, reliability, service life, operability, maintainability and environmental impact. This greatly reduces the costs and risks of intermediate services such as refining and transportation as well as exposure to the global oil price. Mining companies are taking control of their energy supply by either owning the energy and storage assets or building well-defined low-risk partnerships.

The big project: transitioning the Pilbara to renewables

At the conference there was some focus on the Pilbara, which is a huge and complicated energy consumer, consuming 16 TWh (16 million MWh) of electricity per year, mostly coming from gas.

On the surface, it seems to be very low hanging fruit to quickly construct a few solar and wind assets to shift this picture. However, in the interests of the best long-term outcomes, the area needs planning, consultation and coordination. The Western Australian Government has developed a plan for ensuring that common-use infrastructure is used where possible, rather than risking having multiple redundant assets owned by different corporations. Aboriginal and community participation is recognised as crucial for the appropriate siting of wind, solar and transmission equipment.

The near future: electric fleet

Approximately half of a typical mine’s energy needs can be met by onsite electricity generation. The other half currently requires diesel fuel to run a fleet of light vehicles, monstrous ‘haul’ dump trucks such as the 250 tonne CAT 793, and every piece of mobile machinery in between. These mobile machines are the next target for reducing costs, carbon emissions and labour. Several trial projects are happening. For underground mines, where diesel has previously been used, huge ventilation fans will need far less power when there are no exhaust fumes to expel.

Machine manufacturers are developing a wide array of specialised battery electric products. In some applications, there is battery swap technology, as in modern power tools. In other applications, a fixed battery plugs in to recharge, like in an electric car. There are also trolley systems, akin to a tram or train. The best system for each job depends on the application.

Transitioning to a fully electric fleet will significantly increase a site’s electricity needs, with the biggest chargers running at 6 MW at full power. We are expecting to see sites’ electrical grids upgraded soon to integrate this high-power charging.

What is Entura doing?

At Entura, in addition to electrical generation and distribution design, we have specialised capabilities in control systems and power system studies for mining projects. Our microgrid control system (MCS) uses standard and reliable industrial Allen Bradley hardware to monitor and control the power station assets. We have a field-proven core algorithm for maintaining a priority of reliable power supply including backup/reserve supply, while making the greatest use of wind and solar where available. We’ve proven this process in our existing installations in the field and we lead the industry in methodology, practicality and voltage/frequency management.

We’ve seen the real benefits these systems bring to our clients and communities, both at mining sites and in other remote locations. Entura has a long history of design, formation and operation of microgrids throughout Australia (such as King Island, Flinders Island, Rottnest Island, and at mining sites such as the Agnew gold mine) and in the Pacific region (including the Cook Islands, the Federated States of Micronesia, Tonga, and the Solomon Islands, to name just a few).

Contact us if you’re interested in unlocking the full potential of microgrids for your operation or community, or if you’re interested in ways to increase your use of renewable energy.

[Image immediately above] Entura’s Patrick Pease, Greg Koppens and Mark Richardson at the 2025 Energy and Mines Summit

[Top of article] Greg Koppens (centre) onsite at Jabiru Power Station, Northern Territory

ABOUT THE AUTHOR

Greg Koppens is Entura’s Principal Control Engineer Hybrid Renewable Systems and previously led Entura’s secondary electrical engineering team. Greg’s experience spans power, oil and gas, and mining, including onsite roles. With over two decades of detailed design experience, Greg facilitates collaboration between engineering disciplines and other stakeholders to solve complex problems. He regularly shares his extensive expertise with the mining sector to advance their decarbonisation goals. Find out more about Greg in our podcast series here.

When the lights go out

Major power outage events, like the one that affected Spain and Portugal this April, can be enormously disruptive and even deadly. Here Entura’s Technical Director Power, Donald Vaughan, considers the complex factors at play and their implications for grids everywhere ...

The recent power outage on the Iberian Peninsula provides a serious opportunity for reflection. Many articles have been published that try to explore the seconds and milliseconds after 12:32 PM on 28 April 2025 while only having access to the grainy frequency plots and approximate timelines that have been released (to date). This is not one of those articles. Nor is it an article that will lay blame on a particular technology or energy source. Instead, I will expand on the physics at play in this instance and reflect on whether current network security practices are adequately catering for changes to the power grid.

The physics

The power system is governed by the laws of physics, as is normal in the physical world. Quite a few of these laws tend to gang up on us during a power system event[1].

(i) conservation of energy

(ii) Ohm’s law

(iii) Newton’s laws of motion

and, of course,

(iv) Murphy’s law.

We’ll talk about the first three now and the last one later.

We learn very early that energy can neither be created nor destroyed (law i, above). This is at the heart of a power system event. The power system supplies loads by supporting voltage across the network that supplies millions of parallel loads. Each of these loads converts electrical energy into another form of energy based on the voltage it sees and its internal characteristics. This will continue as long as the voltage profile is maintained (law ii). So, demands take energy out of the power system regardless of what generation events occur.

We know that the main trouble in the recent Iberian event started when a large amount of generation stopped in southern Spain. This led to an imbalance between generation and demand in that region. That imbalance is immediately addressed through the inertial action of synchronous generation across Europe (law iii).

If interconnection were perfect, the burden of this inertial response would be shared perfectly across Europe and we probably wouldn’t be talking about this event quite as much as we are. Yet interconnection is rarely perfect (law ii). The frequency in Spain started to move away from frequency to the east and the AC interconnection to the east opened (which avoided the disturbance that stems from loss of synchronism). This should have been some help to the falling frequency in Spain given the eastward flows at the time. Under-frequency load shedding (UFLS) occurred around this time and should also have helped. It seems that the voltage disturbance that then occurred as a result of all these trips was the last straw.

Network security practices

It would be a gross over-simplification of network security practices to say that the power system should not lose customer load for the loss of one generation or network element (N-1 redundancy). The event on 28 April is way beyond that. Typically, for larger events, the grid should fail safely. We’ll look at that definition of ‘safely’ later. For now though, we can see that the grid did, in fact, try to fail gracefully:

- The AC interconnectors opened to avoid damaging loss of synchronism.

- The under-frequency load shedding operated to try to preserve supply to some customers and keep the grid up, so as to reduce the duration of the interruption.

- Other generating unit controls acted to either increase output or trip to avoid damage.

We see in the Iberian Peninsula outage, as we did in the major South Australian blackout in 2016, lots of independent protection operations slowly but surely weakening the grid to the extent that it is no longer viable. Each of these protection operations undergoes scrutiny after an event of this nature, and will likely lead to some changes in Spain and France as was the case in South Australia.

The 28 April event appears to be quite slow in comparison to some other network blackout events. Even so, the event lasted less than 20 seconds and had 2–3 stages within it. One of the bases of design of the AC network is that it can generally operate with minimal, fast coordination even under large events. Control relies on observation, computation and action. So, to manage an event, a control system must measure what it needs to reliably determine what control actions it must make, and then take those control actions (assuming it can control all the elements it might need to control) in time for them to have an effect. If we think about a need to deftly control the response of individual units (or control systems) in an unusual way in a short period of time, then we can quickly conclude that this may not be possible.

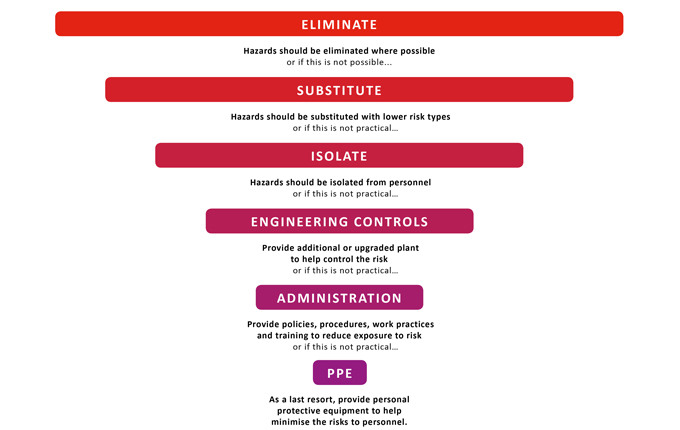

If we can’t manage these events in real time, we have three courses of action:

(i) Physical plant

We could design networks, network supports, and network and generator protection and control systems to be more robust in the face of large power system events, thus decreasing the likelihood of unnecessary cascading protection operation.

This would include better interconnection, more dynamic reactive support (separate from generating units and demand), system-level protection schemes, and a review of generating unit protection settings to ensure generator capability rather than network requirements setting operating limits

(ii) Dispatch rules

We could change dispatch to provide greater margin for real and reactive power control as determined by the security risk and the cost to mitigate it.

We could continue the traditional N-X approach to system supports or we could use a stochastic approach to determining system support requirements (weighting the probability of an event occurring against its impact). Either way, we’d have to pay an ‘insurance’ premium at each dispatch interval to make large-scale system outages less possible.

(iii) Restart planning and capability

We could make recovering from major blackout events easier and faster.

We think about these events in terms of how often they occur (which is what the first two course of action cover) and how long they last. System operators typically have generic plans for system restart that rely on starting synchronous plant and re-energising transmission systems and eventually customer demand. This can be made easier with interconnection. It can also be made easier with good visibility of voltages and voltage profiles across regions (and the tools to control them). Often, for big events like in South Australia in 2016, the network is left somewhat stricken from equipment damage. System restart efforts are often hampered in this scenario because plans need to be improvised to adapt. This depends on the skill, knowledge and experience of the operators. Some jurisdictions have simulated such events as part of training operators.

The fourth law

We know that ‘anything that can go wrong will go wrong’. Seemingly simple things can undermine the best laid plans and the best intentions. We often can’t plan for these things specifically, although HAZOPS, root-cause analyses, scenario simulations and reviews can help us understand where the problems may lie and give us a chance to close loop-holes before they become SNAFUs.

Major power outage events are serious. They often lead to loss of life or injury, and the recent Iberian Peninsula event was no exception. They also always have an economic impact, which is not always fairly distributed. As an industry we need to improve how we manage them. We also need to get better at talking about technical issues in a political environment. If there’s a risk of blackouts, we have a duty to not only mitigate that risk within the current rules but also advocate for rule changes if that mitigation is inadequate. To be most productive, this conversation should happen in a techno-economic environment. The automatic debate after power system events often focuses on the role of renewables, commercial interests and the like, which may sometimes be entertaining but inevitably affects the techno-economic outcomes in a negative way for everyone.

ABOUT THE AUTHOR

Donald Vaughan has over 20 years’ experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. He has worked for all areas of the electrical industry, including generators, equipment suppliers, customers, NSPs and market operators. Donald specialises in the performance of power systems. His experience in generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves.

Image: Basil James on Unsplash

[1] There are more laws, but these are the main and most accessible.

What have we learnt about renewable microgrids and remote area power systems?

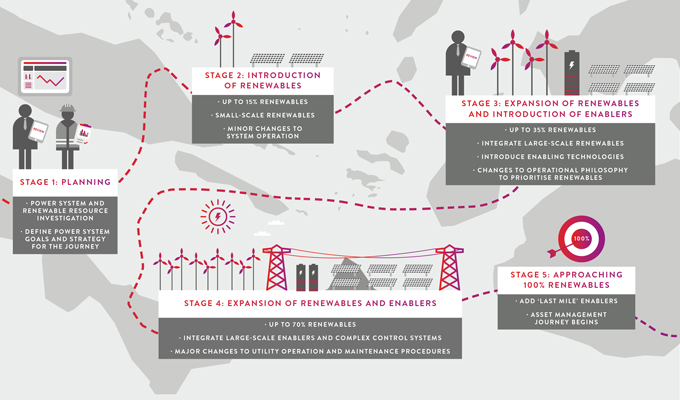

With the evolution of modern inverter and renewable energy technologies, it’s become possible to build microgrids with very high renewable penetration. These renewable solutions are revolutionising electricity sustainability, reliability and access in many far-flung locations – such as Pacific islands, remote locations around Australia, and on mining sites.

High renewable penetration allows operators of off-grid microgrids to extract maximum value from their installed solar, wind or other renewable generation while minimising the use of fossil fuels, such as diesel. It’s a win-win for the financial bottom line and emissions-reduction goals. If the microgrid connects with a broader power system, the benefits of reducing reliance on externally sourced energy are significant too.

Establishing a relatively simple microgrid with modest fuel-saving targets doesn’t have to be particularly complex. It’s within the reach of current technology and practice to be able to optimise microgrids to all but eliminate the use of fossil fuel (with the related advantages of eliminating fuel handling, shipping, etc.). However, careful thought must be given to the distinct nature of the microgrid: its customers, energy sources and storage options.

To make a microgrid successful, some technical challenges will need to be managed. Resolving these challenges in a cost-effective way becomes more difficult as the renewable energy balance approaches 100% – but they’re not insurmountable. Let’s explore.

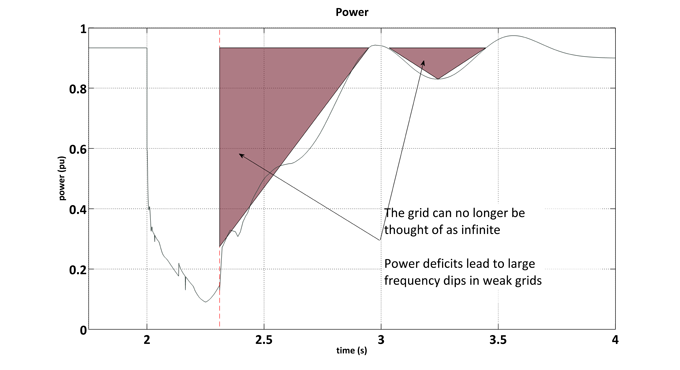

Challenge 1: Ensuring quality of supply and an acceptable customer experience

The small size of microgrids and the fact that they are usually dedicated to a single ‘customer’ makes engineering a microgrid a sensitive task. While larger grids can operate with tight voltage and frequency tolerances and multiple levels of redundancy, microgrids often cannot. This inevitably means negotiating acceptable system standards for islanded operation that are within the tolerance of customers’ equipment and expectations. Microgrids powered by fossil fuels typically have more difficulty maintaining tight frequency and voltage tolerances than renewables-based microgrids.

Understanding customer and stakeholder expectations relating to reliability and robustness (energy availability and the ability to ride-through faults) is key to the establishment of a successful microgrid. Where the microgrid exists with no possibility of interconnection to another power network (i.e. in an ‘island’), there is more flexibility and less operational complexity. Discerning acceptable standards and practices is still not easy but it can be a more productive discussion than when the microgrid must comply with less tailored standards due to interconnection.

When the microgrid is interconnected, many of the technical requirements for the microgrid will be specified and/or mandated by the network service provider, electricity code requirements, and some operational requirements for electrical safety. If additional communication and inter-tripping with network equipment remote to the microgrid are required, these can add further complexity.

Challenge 2: Managing different modes of operation requiring different controls

In the previous section, we discussed how complicated it is to determine system standards. A great deal of care is also needed when contemplating which standards and controls are most appropriate to the microgrid’s specific characteristics. This is where cookie-cutter solutions could under-deliver and a more insightful approach is required.

A microgrid must manage the voltage, frequency and quality of supply while it is islanded as well as during periods of interconnection. Islands can remain satisfactory for longer if there are energy sources, storage and load controls within the island. Each of these elements comes at a cost and, depending on the frequency and duration of islanded operation, must have a value outside of the islanded scenario.

Our experience with microgrids is that semi-autonomous operation of each of the power sources using standard power system control approaches (solar, BESS and other power sources on voltage and frequency droop control) leads to the simplest and most secure response to transients (load or generation trips, network or network faults). Slower controls can be put in place to balance generation and rates of battery charge or discharge. If the battery power rating is large enough relative to the largest disturbance, it can manage most frequency disturbances within acceptable limits. If the battery energy capacity is large enough, it can always maintain a state of charge that allows fast reaction to variations in customer demand or VRE. Alternatively, auxiliary plant such as switched resistors, synchronous condensers and customer-level load control can be used to minimise battery power, storage and other energy inputs.

Operating microgrids in different modes requires careful engineering of the controls and equipment. The solutions and approaches described above have proven successful across multiple projects, but the key is to always be open to new solutions as new problems arise or new technologies emerge.

Challenge 3: Understanding the marginal value of resistors, synchronous condensers and/or demand management

Auxiliary equipment can help to extend the range and effectiveness of a microgrid to rely solely on renewable energy. The challenge is to understand the actual value of extension in this context. Where it has a direct bearing on fossil fuel use, the benefits are clear. Where it might cause an incremental improvement in the robustness of the islanded operation only, it’s important to consider whether any operational benefits or security benefits gained from the additional capital investment are valuable enough to justify the cost.

If the robustness of islanded operation is to be increased by managing customer demand, customer storage and/or embedded generation (e.g. rooftop solar), the value of the extended island longevity should be weighed against the perceived cost (direct or indirect) to the customer. This requires careful consideration of the diversity within the community, their openness to energy management, and the relationship between true costs and benefits.

Microgrids that maximise local use of renewable resources represent a relatively cost-effective option for lowering carbon emissions and/or reducing energy costs. Isolated communities, remote industrial sites, unreliably connected rural communities and others could benefit greatly from considering microgrid opportunities.

Entura has a long history of design, formation and operation of microgrids throughout Australia (such as King Island, Flinders Island, Rottnest Island, and at mining sites such as the Agnew gold mine) and in the Pacific region (including the Cook Islands, the Federated States of Micronesia, Tonga, and the Solomon Islands, to name just a few). We’ve seen the real benefits these systems bring to our clients and communities.

Contact us if you’re interested in unlocking the full potential of microgrids for your operation or community, or if you’re interested in ways to increase your use of renewable energy.

ABOUT THE AUTHORS

Donald Vaughan has over 20 years’ experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. He has worked for all areas of the electrical industry, including generators, equipment suppliers, customers, NSPs and market operators. Donald specialises in the performance of power systems. His experience in generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves.

Greg Koppens is Entura’s Principal Control Engineer Hybrid Renewable Systems and has led Entura’s secondary electrical engineering team. Greg’s experience spans power, oil and gas, and mining, including onsite roles. With over a decade of detailed design experience, Greg facilitates collaboration between engineering disciplines and other stakeholders to solve complex problems. He regularly shares his extensive expertise with the mining sector to advance their decarbonisation goals. Find out more about Greg in our podcast series here.

We built this synchronicity … but what now?

The alternating current (AC) transmission age started in 1891 through collaboration and perseverance. This transmission method has transformed the world, led us to the brink (or over the brink) of a climate disaster, and provides the backbone for a future founded on abundant renewable resources (in Australia, at least). Collaboration and perseverance are now required to ensure the continued utility of the grid.

Synchronous machines have always been the driving force in the grid. These elegantly simple electrical machines sit in powerhouses around the globe using their century-old technology (nearly 150 years, in fact) to convert mechanical energy into electrical energy to power the computer that I’m using to type this.

There’s a romance to these machines. It’s more than nostalgia. They spin, as the name suggests, in synchronism. If one of them falters, all the rest pick up the slack. The only connection they need is the power lines. This robustness is central to the way our electricity grids have operated for over 130 years – but the influence of synchronous machines is slowly being eroded.

The most obvious erosion of the influence of synchronous machines is their displacement by inverter-based renewable (IBR) technologies as solar, wind and battery energy storage (BESS) installations proliferate. A less obvious erosion of their influence is the diminishing understanding and appreciation of synchronous technology within the industry. This lack of understanding by engineers, planners and regulators of the fundamental building blocks of the electricity grid is starting to show.

This might sound like the curmudgeonly ranting of yesterday’s engineer as technology passes them by. Maybe it is … but, rather than dwell on negatives, let’s look at what synchronous machines bring to the power system.

- System strength

The fundamental difference between synchronous machines and IBR is thermal inertia. Typical synchronous machine design can sustain high levels of over-current for a relatively long time (seconds) compared to IBR units (milliseconds). This difference allows synchronous machines to provide a strong ‘natural’ response to voltage variations in the power system without threat of overload and damage. Transmission protection systems – and therefore grid security and safety – rely on this characteristic.

There are alternatives. Overload capacity can be built into inverters, but this is expensive. Dedicated inverter-based devices such as static synchronous compensators (STATCOMs) can be used to provide fault response.

- Inertia

Synchronous machines spin. Their spinning bits (rotors) have mass, so they have mechanical inertia. This mechanical inertia doesn’t require a control system to provide an inertial response. The inertial response from a synchronous machine is a known, predictable quantity, regardless of voltage.

IBRs can provide synthetic inertia and, when voltage is healthy, can out-perform synchronous units. When voltage is not nominal, the same current limitations that affect the IBRs’ ability to deliver fault level can also restrict the effectiveness of synthetic inertia delivery.

- Robustness

The previous two characteristics – system strength and inertia – show the support that synchronous machines can provide to the power system during disturbances. The synchronous machine can deliver these supports across a wide range of power system disturbances to voltage and frequency.

IBRs typically rely on fast controls to manage their response to system disturbances. Under some extreme conditions these controls may not be fast enough or well enough tuned to manage. While tuning is important to synchronous machine performance, often it has a second-order effect or adds robustness over and above the natural response.

Displaced but not superseded

Understanding the inherent dynamics of synchronous machines gives power system engineers a better appreciation of these machines’ contribution to power system stability. Regulators should be mindful of the reduced risk (and mostly advantages) to system security that synchronous machines offer relative to IBRs. This is despite the uncontrollable nature of synchronous machines. That is, physics dictates the stabilising effects from synchronous machines whereas control algorithms determine whether an IBR can stabilise or destabilise. Controller model accuracy is therefore more important for IBRs than it is for synchronous machines where transient stability or electro-mechanical transient time frames are considered.

Better understanding of synchronous machines should lead to more appropriate rules relating to dynamic response to system events. Overly specific requirements for fault ride-through, power recovery post-fault, and maintenance of real and reactive power during voltage disturbances may all lead to needless protracted negotiations over access standards. This slows down the progress of the energy transition, frustrates otherwise helpful development, and diverts resources towards trivial considerations rather than focusing on issues of greater importance.

Synchronous machines will play a role in the energy grid of the future. Our industry needs to maintain expertise and regulatory frameworks that allow this technology to continue providing the grid with vital stabilisation and robustness.

ABOUT THE AUTHOR

Donald has over 20 years’ experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. He has worked for all areas of the electrical industry, including generators, equipment suppliers, customers, NSPs and market operators. Donald specialises in the performance of power systems. His experience in generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves.

NEM connections, complexity, risk and tolerance: achieving a balanced approach to grid connection

With the current bow wave in publicly announced emerging and committed storage, wind and solar farms in Australia’s National Electricity Market (NEM), it is now more important than ever that your connection application processes are rigorous and efficient.

This article charts a path of least resistance within the framework of the Australian Energy Market Operator (AEMO) for connection, while also pointing out more effective approaches you could consider. The path of least resistance requires more upfront commitment of resources to ensure the application eliminates doubt or uncertainty. Other approaches take a more balanced approach to risk, accuracy and allocation of effort across the project development timeline.

Maintaining flexibility of deliverables – It’s not all about being technical

Plant dynamic and steady state parameters are likely to change and assessment requirements will evolve from the start to the end of your connection application. This is a natural process of optimising plant performance and compliance under various system scenarios, but comes at the potential cost of disordered delivery of the connection application and delays to the project. Streamlining and clear version control of the report will allow all stakeholders to easily trace changes. Furthermore, with significant updates to PSSe and PSCAD modelling requirements, robust automation of re-assessments would minimise processing time but the changing assessment requirements make investing in such automation somewhat fraught.

Finding a balance between fundamental principles, good practice and efficiency

AEMO has gone to great lengths to increase the certainty and magnitude of expectations about power plant modelling and performance standard assessment. There are paths of least resistance and good practice that can help facilitate a connection application within this framework (which we’ve outlined in the left-hand side of the table below). There are also some fundamental concepts that could help to eliminate wasted effort in the connection application process (the right-hand side below). Achieving a balanced approach is key to an effective and efficient solution not just for an individual project but for the industry as a whole.

| Don’t be scared of EMT modelling | |

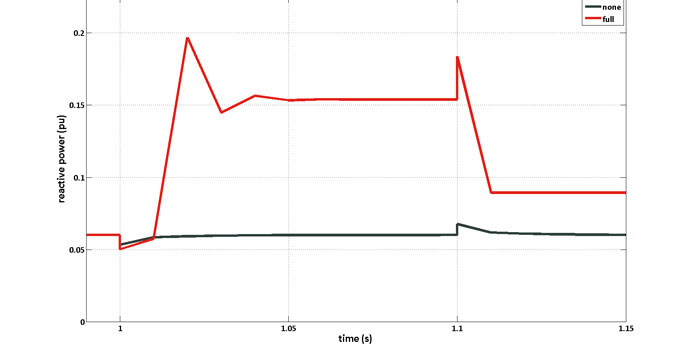

| Whilst RMS (root mean square) assessments are still crucial, network service providers and AEMO are requesting significant effort in EMT (electromagnetic transient) benchmarking and analysis of wind and solar farms. Hence, it’s best to benchmark respective EMT and RMS models (using software such as PSCAD and PSS/e) at early stages of the project to identify inaccuracies. Particular focus should be given to plant responses to network and PoC (point of connection) faults with varying grid strength to ensure ride-through requirements (S5.2.5.5) are met and that active power, reactive power and voltage responses are within tolerable ranges between RMS and EMT models. |

The industry (proponents and regulators) must consider which aspects of these models need to be accurate for the development of performance standards and the determination of grid compatibility. When the overall goal is a stable connection of plant, pragmatic engineering judgment is often more beneficial than a slavish pursuit of absolute precision. We should focus more closely on fundamental issues relating to control stability, such as loop gains and time delays, than on the accuracy of switching controller triggers and sensing. |

| Understand your connection point and surrounding network | |

|

We have previously discussed the issues of congestion and system strength and how they impact grid connection. These issues can result in plant MW constraints and non-compliant fault ride-through. It is also important to remember that system strength does not equal SCR (short circuit ratio). System strength is a combination of high impedance network, high concentration of asynchronous machines and lack of nearby synchronous generation. It is a location-specific artefact that adds to the importance of assessing your plant’s control (S52.5.13) and contribution to faults (S5.2.5.5) in network models. |

The strength or otherwise of the connection point must also be taken into account when considering whether the performance standards are reasonable. Issues such as fault current injection rates, rise and settling times, voltage regulation ranges and the like depend heavily on the surrounding network and often on other nearby generating units.

|

| Ride-through is not enough on its own | |

| Gone are the days of plant only being required to ride through PoC voltage dips for various periods of time. Recent versions of the National Electricity Rules require rigorous reactive current injection assessment including amount and rate of injection for varying voltage profiles, and for balanced or unbalanced faults. Hence, work is needed to tune the plant and inverter-based controls to meet these requirements (predominantly in clause S5.2.5.5) and maintain post-fault voltages within network tolerances (commonly 0.9-1.1pu). | These more technical requirements of the rules take an inordinate amount of work to achieve compliance with a particular performance standard across the range of operation and system events to which the plant will be exposed. A more standard test could be considered to benchmark the performance of the plant against a small and finite range of events. |

At Entura, we bring as much judgement and experience to the work of connection applications as we can. The process does not always reward this approach, but we maintain that understanding the intent of analysis, as well as the need and importance of it, allows us to target and emphasise some analyses over others – and this helps to manage the connection risks for our clients with a high level of efficiency.

If you’d like to discuss how we can assist you with your grid connection projects, please contact Donald Vaughan on +61 427 721 558 or Wayne Tucker.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. He has worked for all areas of the electrical industry, including generators, equipment suppliers, customers, NSPs and market operators. Donald specialises in the performance of power systems. His experience in generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves.

What to consider when you’re thinking about a synchronous condenser

Depending on when and where you want to connect your new solar farm or wind farm, the network service provider or your consultant may tell you that you’ll need a synchronous condenser. That may not be good news, because these machines don’t come cheap and they usually don’t provide a direct revenue stream. What should you do next?

Do you understand why you need a synchronous condenser?

The first step is to understand why you need the synchronous condenser. The inverters at the heart of most solar farms and most modern wind turbines need a strong electricity grid to push their energy into. If the network is not strong, the inverter is likely to fail to switch at the required times, swing against the power system like a pendulum, and distort the waveform, causing harmonics. The synchronous condenser overcomes this, strengthening the power system in the local area by forcing the network voltage into a near-perfect sine wave of the required size.

Is it possible to predict the need for a synchronous condenser earlier?

There are ways that you can predict at the project pre-feasibility stage that a synchronous condenser might be needed, before the network service provider becomes involved. Take a look at other renewable energy installations that have been constructed recently in the same region; if they needed a synchronous condenser, you almost certainly will too.

Consider where the installation is in the grid, and if the answer to any of the following questions is yes, you will likely need a synchronous condenser: Is your installation remote from all traditional generating stations? Has a large traditional generator shut down in the area recently? Are other generators in the area routinely constrained due to network stability challenges?

Simple calculations can be completed based on information that most network service providers publish on their websites, including network constraints and fault levels. These calculations aren’t always definitive, but they will offer significant insight.

What do you need to specify?

It is best to specify the exact function that the synchronous condenser must achieve. Typically, this means specifying the fault current contribution that is required from the machine and leaving it up to the manufacturer to decide the optimal machine design including the headline MVA rating. Once these headline values have been determined, consider the following questions, each of which has a substantial cost impact:

- How much reactive power do you need the synchronous condenser to absorb? Typically these machines can only absorb approximately half of their headline rating, so don’t ask for too much unless you have deep pockets.

- Do you really need inertia that is greater than the manufacturer’s standard? Synchronous condensers are known for having inertia, but asking for inertia that is greater than the manufacturer’s standard will result in substantial additional cost and usually results in no additional revenue stream.

- The synchronous condenser is being installed to provide system strength, so do you really want it to be able to supply reactive power indefinitely? Perhaps 60 seconds would be enough.

Are some cost savings not worth making?

For a synchronous condenser project, there are some measures that, on the surface, might appear to be potential cost-saving considerations. Can you omit the transformer tap changer? Could the cooling equipment be downsized or even omitted? Can you connect to the station 33 kV busbar? Detailed analysis is needed to answer these questions definitively. In our experience, however, the answers to each question have been emphatically no.

If you need the synchronous condenser to operate close to its rated reactive power absorption limit, you’ll need a transformer tap changer. Similarly, if the machine connects to a 33 kV busbar, fault levels will become unreasonable and an even larger machine will be required.

What’s the best contracting model?

Your choice of contracting model will depend on your appetite for risk and the sensitivity of your schedule. A typical solar or wind farm project is very schedule-sensitive, which suits an all-inclusive turnkey project delivery including everything from civil foundations, fencing and drainage through to integration with the farm’s control system. But this delivery mode comes at a price, and there are few Tier-1 equipment suppliers prepared to take on this model. The lowest cost suppliers will be likely to want to put your machine onto a ship, point it in your general direction, and send you the invoice.

Whatever your contracting model, one of the largest risks to projects is the adequacy of the power system models. You need to be confident that the original equipment manufacturer understands the market operator’s model requirements and has the skills to comply with them.

Can the machine offer economic benefits?

Two possible revenue streams could potentially flow from installing a synchronous condenser. By sizing the synchronous condenser to provide the reactive power required from a solar farm by the electricity rules, it is possible to operate the solar inverters and the main transformer at a higher power factor. This has the potential to increase the power output and consequently the revenue from the farm by up to 7%. A proponent could also install an oversized synchronous condenser and sell the spare system-strengthening capacity to another renewable farm in the same region. In the future, inertia and system-strength markets may evolve in ways that provide direct revenue streams for the synchronous condenser.

Is there an alternative?

The inverters at the heart of most solar farms and most modern wind turbines are changing. Until recently, they have exclusively used a technology called ‘grid-following inverters’, but a newer ‘grid-forming inverter’ is breaking into the market. These inverters are more expensive at the moment, but that’s likely to change rapidly. The newer inverters are much less sensitive to system strength. It is likely that applications will soon emerge in which changing the inverter will eliminate the need for a synchronous condenser. We predict that this could occur for small installations first and evolve over time to include larger renewable farms.

Putting it all together

The most cost-effective projects are often those that link multiple technologies – such as a wind farm with modern wind turbines, static VAr compensators and more than one synchronous condenser. These technologies were not designed to work well together, but with carefully coordinated controls they have done so in practice, providing the required system strength, voltage control and inertia for a successful minimum-cost project.

If you would like to find out more about how Entura can help you overcome electrical challenges for wind farms or solar farms, please contact David Wilkey on +61 3 6828 9749 or Patrick Pease.

About the author

David Wilkey is Entura’s Principal Consultant, Secondary Electrical Engineering. He has more than 20 years of consulting experience in electrical engineering across Australia and New Zealand, focusing on the delivery of advisory on secondary systems and power systems engineering. David’s expertise spans all areas of electrical engineering with a particular focus on electrical protection, power system studies and rotating electrical machines.

MORE THOUGHT LEADERSHIP ARTICLES

Engineering – by humans, for humans

When engineers think about the future, do we get so engrossed in the complex technical problems that we don’t attend enough to the human angle?

Engineers have a reputation, whether rightly or wrongly, for being poor communicators, working obsessively and in isolation, and focusing on the immediate goal rather than its impacts on communities. Often, clichés have a basis in truth. If we are going to shift perceptions, we need to start by thinking about the way we work and the leadership we show to the next generation of engineers.

There’s no way we can predict the major developments, challenges or solutions of the next five or six generations of engineering careers. What we should focus on is what we can do right now to lead change in our profession and our communities – and I think the keys are communication, collaboration and community.

Communication

I recently listened to a podcast in which two energy market experts talked with a power system engineer. They discussed all sorts of technical matters relating to frequency and voltage control. I love those topics, but this conversation was limited and uninspiring because the participants simply didn’t have a common language or understanding.

We need to learn to communicate in ways that a variety of people can understand. That will mean better conversations with the people who can help our work have greater impact, and it will help our communities to appreciate the importance of our work in their lives.

It’s too easy for us as a profession to sit at our desks or stand under our hard hats and luxuriate in how clever we are, and then bemoan how so many people have no idea what we do and don’t value our work.

When things that involve engineers go wrong, a flurry of opinions erupts. Failures such as the blackout in South Australia, or the cladding issues at the Grenfell Towers, or issues with airlines or bridges or dams all lead to our communities questioning and debating engineering practice. Engineers tend to try to stay out of this rough and tumble for fear of being misrepresented. Yet maybe it’s better that we do engage where we can, since being misrepresented on a small issue is better than allowing a groundswell of misguided public opinion due to a lack of understanding of engineering principles.

We need to try to better explain our work and find simple ways to convey the complexities of the decisions that we make.

Collaboration

The world is far more complex now than it was a century ago – but it is impossible to imagine what level and pace of change future generations will experience. If we want to transform our world or help build a better future, we can’t do it by ourselves.

Engineering no longer operates in isolation, if it ever did. We must collaborate across the engineering team and across other professional disciplines to achieve truly effective development for our communities. Sometimes we may need to focus a little less on technical delivery as a primary outcome, and increase our recognition of the value gained by engaging successfully with the communities on whom the project relies for success.

Collaboration makes our work more effective, and exposes us to a wider range of inputs and values that we can incorporate into our designs and processes. Engineering can be a leader but it can also be a facilitator for better outcomes when we draw on, listen to and learn from the other experts involved in other aspects of our projects.

Community

Engineering work almost always benefits more people than merely the one who pays the bill. Much of my work is in connecting wind farms and solar farms to the grid. Mostly my work is paid for by the owner of the farm, and while it delivers direct benefits to the owner through return on investment, it also affects everyone connected to the nearby network. It affects the network service provider and market operator, it pays salaries, and it supplies the clean energy that helps the country reduce emissions and meet its international targets. In other words, my work, which may seem intangible, has tangible effects in the real world.

If we agree that our labours produce real impacts, we need to take better care to fully consider the wider consequences of our work, which often has the potential to cause ‘collateral damage’. We can’t build a road or a wind farm without changing the landscape. When we build a machine, it uses energy and may emit pollutants; and it reduces reliance on manual labour, which may put someone out of a job. There may be a risk to lives, livelihoods or the environment if something goes wrong.

Do we always make decisions about these matters with the community front of mind, or do we place our clients on the higher pedestal? This is a tricky area and I’m not espousing a puritanical approach. However, if we knew in 1919 what we know now about lead poisoning, acid rain, greenhouse gases, scarcity and general sustainability principles, what different choices could have been made?

In a time of automation, we need to think about benefits and risks and how they affect our communities. On one occasion early in my career, I designed a controller to turn on and off a couple of compressors at a power station. I wrote some code to balance the run hours. A few months after the new system was commissioned, I asked one of the operators how the system was going, in terms of the run hours management, and he said ‘you’ve done me out of a job’. I hope he was joking. The task he’d been doing wasn’t particularly important, but there was value in having a person who was in tune with the equipment to take care of it, and there was also value in giving that person dignity through work.

My point is that we must keep our communities foremost in our minds as we go about our work. It’s not just about what we produce. It is the way we work and the people we choose to work with and for. Our influence on the development of the next generation of engineers perhaps has more impact on communities than our actual work outputs.

Through communication, collaboration and community, engineering can be both ‘more human’ and ‘for humans’.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Can the power grid weather the weather?

Even a single day of load shedding makes people doubt the national grid’s robustness. How will the grid cope if we experience extreme weather conditions more often?

Things get hot in Australia. They can get smoky, or wet, or cold. Australia’s beauty is in its ruggedness, its unpredictability and its diversity of natural environments. It’s what Dorothea Mackellar captured so well in the famous Australian poem ‘My Country’ – a ‘sunburnt’ land of ‘flood and fire and famine’, with ‘droughts and flooding rains’.

As dramatic weather patterns become more intense and more frequent, the electricity grid must be robust, or at least be managed to adapt to short-term challenges.

If we get the design standards right and if conditions fall within the expected extremes contemplated by the framers of the standard, then everything works. However, what happens when conditions are abnormal? In heatwaves, we see people hosing the rail network to stop expansion. We’ve seen hosing to cool distribution power transformers at peak times too. But there’s only so much water and so many hoses that we can deploy when the heat is on. It’s not a sustainable solution.

Can we manage?

Yes … but we must manage actively. Business as usual will not be enough. Consumers will not tolerate lower levels of reliability based on the weather. So something has to change.

There are a few mutually supporting paths we could take, including (1) considering extreme temperature ratings and improving the reach and spread of weather monitoring and weather-dependent grid management; (2) adjusting standards to contemplate higher temperatures; and (3) reducing our reliance on high flows to deliver peak demand.

1. Consider extreme temperature ratings

Incentives already exist for our network service providers (NSPs) to release hidden capacity in networks. The incentives remain a small percentage of the overall regulated income they receive. The contemplation and control of realistic ratings under unusual weather conditions could be made more attractive to our NSPs. The NSPs would then be more likely to make these opportunities for capacity benefits transparent to the regulator and the public.

Generators are now being required to stipulate capacity at higher temperatures, but this is not being applied universally across existing plant. As we saw in Victoria this summer, the market is very reactive to the unplanned withdrawal of power from large thermal units – as much, if not more, than it is to variations in wind and solar power. Thermal machines have shown themselves to be sensitive and not always robust in prolonged hot spells.

2. Change the standards

If maximum temperatures continue to climb, our standards or ratings may need to be adjusted to suit. In a global market, we have to be careful about being too ‘special’ or we’ll end up paying for specifications that cost more than the benefits they deliver. A half-way position may be for generators to estimate their capacity in relation to temperature conditions and require tuning of these estimates over time. This would at least give us an idea of the temperature effects on production across the fleet. The results of this might then inform the need for changes to standards or at least build quality to relieve unmanageable reductions.

3. Reduce reliance on high flows

We’ve seen the effect that emergency events such as storms and fire have on the grid. Storms are managed through localised declarations of special constraint sets. They’re also generally short-lived. As we saw with the Tasmanian bushfires this summer, smoke and fire can affect a transmission corridor for weeks at a time. Because intense storms and fires tend to be rare, the market can take some time to adapt. Some planning or scenario work by AEMO might help prepare the market and reduce the impact on supply.

Reducing our reliance on high flows to regulate price or maintain supply may also be valuable. This suggests a need for storage/s at opposite ends of tie lines and interconnectors so that short periods of constrained flow can be compensated partially or fully by the far-end storage.

We may also need some flow-path diversity on critical corridors or on corridors that link dispatchable generation sources with loads.

There’s little doubt that Australia will experience more frequent and intense floods, fires and heatwaves. In our ‘sunburnt country’ we need to keep our eyes firmly on the future of our climate, and we must build resilience into our generators, grid and market systems.

If you would like to find out more about how Entura can help you navigate your challenges in the electricity market, please contact Donald Vaughan on +61 3 6245 4279.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Limber up for a more flexible electricity grid and market

Integrating renewables into grids and markets is a hot topic worldwide, with many challenges and approaches to explore.

In late June 2018, a series of meetings run by the International Energy Agency (IEA) in Yokohama, Japan, brought together a wide range of electricity industry regulators and participants to discuss the IEA’s current work in this arena. There was a lot of ground to cover. I shared the Tasmanian experience of managing frequency using inertia and governor tuning.

For me, three main takeaways from the discussions are that we need to improve Australia’s market arrangements, increase flexibility, and we should try to re-imagine the grid as an interaction.

Improving Australia’s market arrangements

Anyone who’s been watching the Australian electricity sector over the last few years will recognise that there’s room for improvement in our market arrangements.

The National Electricity Objective (NEO) aims to promote the long-term interests of electricity consumers through efficient investment in, and operation of, electricity services. These consumer interests include the price, quality, safety, reliability and security of supply of electricity. It also means ensuring the reliability, safety and security of the national electricity system. However, commercial and environmental drivers are beginning to affect the security of electricity, and in some instances affecting the price as well.

It’s hard to see why we’ve ended up where we are. What’s important is what we do next, and why.

Understanding and pursuing flexibility

All sources of generating plant have flexible and inflexible attributes. We have always worked around the limitations and taken advantage of the benefits. Now, with disruption, prosumers, micro-grids and all the other ‘scary’ status-quo-busters, we have much more freedom to achieve flexibility than we have had in the past. That is, generators, grids and customers can all provide flexibility and add to the overall value of the electricity market.

Designing new plant, retrofitting old plant and improving controls to increase flexibility must all form part of planning and regulation as we continue to decarbonise electricity production.

Imagining the grid as interaction, not assimilation

The philosophy of grid revolution to date has been assimilation. That is, where possible, new generators need to look and feel like traditional generators.

As system security margins decrease, this is becoming even more the case. It sets up a sometimes false dichotomy in terms of market share, political ideology, technical requirements and standards, and assessment of value. And this is unhelpful as we move towards an electricity sector with increasing proportions of renewables. One reason why Australia may have ended up where we are now may be that the NEO is silent on environmental impact.

When we think of the grid and the market as spaces for interaction rather than assimilation, these dichotomies break down and we’re more likely to achieve fruitful outcomes. Interactions are not just technical (electrons and Ohm’s law) or commercial (tariffs and hedges) but also human.

The electricity transformation will be able to occur faster and more successfully when the electricity industry embraces the power of the demand side, interacts in a more beneficial way with human-scale usage patterns and requirements, and thinks about the flexibility that exists or is required in demand, storage and production.

Finding a new approach

This all sounds marvellous, doesn’t it? It is the sort of regulatory utopia that could only come from a group of government officials sitting around a table a long way from home. But for me, it was refreshing. The thought that the market serves a higher ideal can only inspire. Certainly, the developing countries that presented at the meetings are firmly motivated by the immediate benefits and opportunities that reliable access to electricity will provide to their people.

In some ways Australia, too, is a developing country in the electricity sector. In the status quo, the path to future sustainability is blocked by the threats of climate change and, in some respects, by resource scarcity (depending on your view of the horizon). We need to develop a new approach to electricity production and consumption just as developing countries do.

If we think of the market as a facilitator for humans to flourish, then we must be careful to design markets for this purpose. Is the Australian market hampered in this respect by the dominance of a limited number of large players? Is there sufficient direct participation of individuals in the market? Does the regulatory framework accurately and adequately reflect the needs of all market players? Does the market inherently promote and reward flexibility?

Market power, democracy and flexibility

My feeling is that there’s work to do across each of these areas.

A former Australian trade minister once remarked that Australia would always be somewhat of an oligopoly. We will never have large-enough markets that won’t be dominated by a few players. In some sectors we’ve enshrined protections that almost guarantee it. The current market design has led the electricity sector down this path.

This is okay so long as the behaviour of these players remains able to be influenced by their customers through choice of provider and volume, but this isn’t always the case.

Allowing more players to provide greater diversity of energy and grid services will help to erode the power of the oligopoly and will also increase the flexibility of the grid and the market. Various system incidents in South Australia and the Northern Territory have highlighted the need for flexibility. If we understand flexibility properly, we will understand a way to meet the need for it.

Greater flexibility can mean different usage patterns, different contributions from a wider number of players and more give and take between the grid and the various generating technologies. Providing rewards for flexibility will encourage diverse contributions, slow the retirement of existing plant, and bring new players into the mix.

Markets, grids and power plants must be planned and will need to allow for greater flexibility to provide better outcomes for customers. It’s time for the electricity sector, its regulators and its customers to limber up.

If you would like to find out more about how Entura can help you navigate your challenges in the electricity market, please contact Donald Vaughan on +61 3 6245 4279.

This article was first published in RenewEconomy.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Congestion and losses: more than a blocked nose for new renewable generation

Anyone who’s ever had a cold understands the discomfort of blocked airways. Congestion challenges, albeit slightly different ones, also face developers of new renewable energy generation.

The nature of powerflows around the grid is changing rapidly with a lot of new generation being built on the edges or middle of the transmission system. This is increasingly being recognised as a problem, but quantifying the impact can be tricky.

Developers are asking: “What other generation will or can be built in the area? Will there or can there be collocated storage? When may these things be built? Will other projects in the area have a similar generation pattern to my plant?” And these questions are becoming harder to answer with the wave of renewables development.

Answering these questions

There’s no real substitute for analysis and an understanding of the degree of certainty required.

A simple example of adding generation in north-east New South Wales illustrates the point. Naturally, developers think first about competition: “Will added generation displace existing generation in NSW or generation on the interconnector? What is the most conservative assumption? What is the balance of probabilities?”

Even this simple example leads to many assumptions and choices, so proponents and owners need to understand how certain they need to be – and therefore how thorough the investigation of congestion needs to be.

What other questions are there?

Traditionally, congestion has been considered a problem of network thermal capacity. The nature of renewable energy generation adds other factors into this mix, such as: “Will fault levels remain high enough to support short-circuit ratios? Will critical clearance times be maintained to allow the full thermal capacity to be used? Will imbalance of generation development on parallel paths reduce pre-contingency loading limits?”

These sorts of questions require complex analysis, adding further uncertainty and additional dimensions to the results.

There’s talk of additional network provision being required to support changes to the flows in the transmission system. Such changes will no doubt be helpful, but questions of when, how much and who pays must be asked.

We can see that calculation of congestion has real impact on expected revenues – but with so little certainty, it is hard to determine how critical any impacts may be on the overall business case.

What about losses?

The other effect of large generation on transmission flows is greater network losses. The marginal loss factor (MLF) regime that accounts for losses in the National Electricity Market (NEM) relies on many of the assumptions of congestion analysis, with similar levels of uncertainty of the input increasing the uncertainty of the output.

MLF has always appeared punitive for new renewable generation distant from the load centre, since long transmission distances (often over low-capacity lines) lead to inefficient power delivery.

The MLF regime is supposed to incentivise development of efficient and timely generation and demand. The drivers for renewable generation are less about actual demand and more about displacement, so the MLF inhibits the building of new generation in favour of the status quo. A simplistic analysis, however, shows that, on average, new renewables see slightly higher MLFs than the established generation and new thermal assets.

There could be a number of explanations for this but it shows that the density of generation has remained low enough thus far. Increased build and in-fill will ultimately lead to MLFs becoming a bigger and bigger factor for new and existing plant.

Other congestion issues

There’s another form of congestion looming or already starting to impede the rapid deployment of solar and wind technology: a lack of capacity of network service providers (NSPs) and other regulators to deal with the influx of applications for new connections.

Add to this the increasingly technical analysis required to demonstrate compliance of these connections with the rules and a real bottleneck is created.

Blow your nose

The truth is, the only answer to any congestion issue is to remove the blockage .

In terms of network congestion, in the short-term, we need to continue to think about the likely requirement for renewable developments (with storage) to meet the challenges of the energy trilemma – replacing coal-fired generation following retirements with reliable, affordable and more sustainable generation.

And we will need to better understand the value of transmission re-enforcement to support a changing generation fleet.

It may also force a return to the Hub or Scale Efficient Network Extension (SENE) type of thinking that gives a clear signal to proponents to ‘build here’, as we can now see in New South Wales.

Network re-enforcement may also improve MLFs, slightly. However, if MLFs are low across the board in a region, the pool price will adjust to reflect this over time. In the short term, local or regional storage may be cost-effective in raising MLFs to investment-tolerable levels.

In terms of resource issues, training and applying more skilled resources to this sector must be a focus for NSPs and regulators.

Our approach as consultants is to not always recommend more analysis but, alternatively, the right and the most efficient form of analysis.

The challenge for NSPs and regulators is to act more commercially and embrace an engineering approach to analysis, tolerating some uncertainty – just as proponents do.

We always feel better once the fog of congestion lifts. Sometimes we try to fight through it, but it’s often better to take deliberate action to treat it and to avoid complications, just as when you are suffering the symptoms of a cold.

If you would like to find out more about how Entura can help you navigate network challenges, please contact Donald Vaughan on +61 3 6245 4279.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Tackling renewable energy integration: five lessons from Sri Lanka

Ambitious renewables targets, movements away from thermal generation, increasing demand for electricity … it’s boom time for renewables around the world. Yet the global energy transformation brings some challenges, particularly for network stability and security.

Sri Lanka offers an interesting case study in the complexities of quickly integrating a large proportion of renewables and how some of the hurdles may be overcome. The lessons we can learn from the Sri Lankan experience are applicable worldwide.

In 2016 the government of Sri Lanka set a very ambitious renewable penetration target, with 100% of power generation to come from renewable sources by 2050. Coal and oil generation, currently accounting for around 50% of all generation, will cease by 2045. If this isn’t challenge enough, add in the projection of maximum demand rising above 7000 MW (from a current daily maximum of 2500 MW) by 2040.

Between September 2015 and March 2016, three nation-wide blackouts threatened to significantly undermine Sri Lankan industry and foreign investment prospects. The challenge for the Ceylon Electricity Board (CEB, which runs Sri Lanka’s power system) now is to achieve the country’s power transformation while still ensuring network security and reliable electricity. Any future unexpected system outage would be likely to erode public confidence in renewable development, regardless of whether the outage relates to renewables or not.

What can we learn from the Sri Lankan experience of the 2015/16 blackouts and Sri Lanka’s current challenges in its journey to a renewable energy future?

1 – Focus on accurate modelling of the power system

The first lesson to be taken from the 2015/16 blackouts is the need to focus on power system modelling. The first blackout occurred after a trip of the largest generating plant under light load. The next was due to a trip of a major transmission line when two parallel circuits were taken offline for maintenance. Neither of these events were envisaged through system model simulations. If a utility’s simulation tools won’t predict such events, planning engineers will struggle to anticipate or guarantee system security under system contingencies.

For system planning and operations, CEB has developed a power system model consisting of major hydropower, oil, coal and wind plants. However, no model accuracy requirements are specified in the national grid code, which leads to the use of generic models with unknown modelling accuracy. Prior to Sri Lanka’s 2015 blackouts, limited tests were conducted to tune the models to accurately represent behaviour. During 2017, CEB embarked on a project to test the model validation for at least some of the major hydro units. These tests need to extend to all major power plants so that engineers can trust the actual performance of every major generator in the system.

2 – Determine a clear, single responsibility for the system model

The second lesson from Sri Lanka’s system modelling is the need for a single owner of the system model files, with responsibility to maintain the model and ensure its accuracy. If different departments of a utility have different system models, results of an event analysis may vary.

Ideally, the entire power system should be modelled accurately and the model controlled by a single team. This is vital for maintaining integrity of the system studies conducted by various parties.

3 – Consider minimum generation

When making decisions about the size of power plants, it is quite common for the focus to be on maximum generation. However, to minimise any unwanted constraints, it is really important to consider the lowest level of generation at which the plant can operate.

Three coal plants in Sri Lanka each have capacity of 300 MW with minimum generation of 180 MW. During periods of low demand, all three coal plants need to remain at their minimum of 540 MW (3 x 180 MW) even if other generation is available in the system.

4 – Ensure the network code looks to the future

When determining the grid code, it is essential to keep an eye on the development of non-conventional renewables. The grid code needs to be able to manage power quality issues in the future while minimising unnecessary costs to developers. In other words, it must have enough regulatory power to impose required technical targets, yet be flexible enough to minimise unnecessary mandatory capital expenses.

5 – Set up an ancillary service market

Sri Lanka does not currently have an ancillary service market, so the fall-back position is mandatory interruption to the system load under certain contingencies. This will not be acceptable in the longer term and customers will demand higher reliability. A way of categorising system support, especially frequency control ancillary services, will enable CEB to maintain system reliability as well as understand the quantities and price to deliver the required reliability.

Some tightening of Sri Lanka’s current technical and connection policies and practices will be needed as the country embarks on drastic change in its generation mix in pursuit of its renewables target. Yet the lessons we’ve explored in this article are readily applicable to any network keen to accelerate substantial integration of renewables, especially solar PV and wind, for a successful energy transformation and a future of reliable and sustainable power.

If you would like to find out more about how Entura can help you overcome network challenges when integrating renewables, please contact Ranjith Perera on +61 3 6245 4272, Shekhar Prince on +61 412 402 110 or Patrick Pease.

About the author

Ranjith Perera is a Specialist Power Systems Engineer at Entura. He has over 22 years of experience in Australia and South-East Asia, working on customer and generation connections and broader power system analysis. Ranjith has provided power system advice on a wide range of network augmentations, network planning and system stability in Australia and internationally. These studies included option analysis in transmission planning, constraint analysis, determination of reactive support (dynamic or static) in system stability / TOV and detail load modelling in voltage stability. Ranjith also developed voltage recovery guidelines to TNSP based on regulatory requirement and customer equipment tolerances.

MORE THOUGHT LEADERSHIP ARTICLES

Do you have the right SCADA strategy for your business?

Installing a SCADA system is a major outlay. With the ever-increasing pace of technological change, how can you ensure your new system or upgrade will repay your investment and deliver maximum benefits?

It’s almost impossible to imagine running a business in the power or water sector without SCADA and automation. The significance of the benefits of visibility and automation of plant and processes, particularly for remote assets, is unquestionable. However, to get the best return on your investment, your system needs to be functioning at its best.

Loss of SCADA means loss of visibility, production, time and money, but basic functionality is not enough. If your SCADA system is functional but not optimal, it is still opening you to risk . You could be missing out on valuable opportunities to increase your business efficiency, make smarter decisions and continuously improve your processes to achieve less downtime and more effective maintenance.

This means that any new system needs to be reliable, up to date, and future proofed – able to be effectively expanded and updated to accommodate developments in technology and changes in your business. And, for an older system, it means that you need to assess whether your system is still meeting your requirements or if it could be upgraded to do more for your business and protect you against risks. If an older system is still reliable and robust, you may not need to retire it or make wholesale changes.

Choosing a new system or approaching an upgrade