Renewables in remote mines – a litmus test for the wider renewables transition

Entura’s Greg Koppens has recently returned from the Energy and Mines Summit in Perth, where he led the ‘Think Tank’: a collaborative session addressing the challenge of powering process steam requirements from renewables-generated electricity. Here he shares his observations on the rise of renewables in the mining industry …

Australia’s mining industry is beginning the peak phase of its energy revolution. However, I find it unfortunate that this exciting fact is invisible to regular people. It is happening in remote areas on mining leases, inaccessible to the public. Each project alone is not sensational enough for media attention, but added together these projects are nothing short of a technology revolution. For remote mining sites to have a solar farm is now standard practice. In many cases this is backed up by battery storage and a handful of mines have onsite wind turbines.

The past: fossil-fuel driven mines

Australia is world-renowned for our mining industries, with mines of virtually every resource throughout our country. Up until about ten years ago, nearly all of Australia’s mines ran completely on diesel or gas. In most cases diesel was trucked in, or gas was brought in via pipeline. Most of these mines have energy expenses in the tens of millions of dollars per year. A small change in the oil price can drastically impact the mine’s bottom line.

If there’s one doubtless fact about mining, it’s that miners are practical people. They are problem solvers, and they know what works. With the boom-and-bust nature of resource markets and shareholder responsibilities, finances must be well managed.

The present: hybrid renewables power generation

At the Energy and Mines Summit, there was no discussion about whether it’s a good idea to consider renewables in the mix of power generation – it was simply a given. This is an industry in ‘early maturity’: it is no longer pioneers running a trial. Several systems are in the order of 100 MW capacity. Renewables are a tested and proven business decision. Everyone has crunched the numbers on their sites and, while each project has unique site-specific requirements, the conclusions are unanimous. The frontier is now getting access to skilled people, there is community engagement for siting of large assets and mutual benefits, and the industry is exploring emerging technologies such as electric fleet.

We now have all the technology needed to harness the power of the wind and the sun in an 80/20 mix with fossil fuels. Or a 50/50 mix when the system has solar power alone. And this is what is being implemented in practice all over Australia. We can do it in a way that achieves targets for price, reliability, service life, operability, maintainability and environmental impact. This greatly reduces the costs and risks of intermediate services such as refining and transportation as well as exposure to the global oil price. Mining companies are taking control of their energy supply by either owning the energy and storage assets or building well-defined low-risk partnerships.

The big project: transitioning the Pilbara to renewables

At the conference there was some focus on the Pilbara, which is a huge and complicated energy consumer, consuming 16 TWh (16 million MWh) of electricity per year, mostly coming from gas.

On the surface, it seems to be very low hanging fruit to quickly construct a few solar and wind assets to shift this picture. However, in the interests of the best long-term outcomes, the area needs planning, consultation and coordination. The Western Australian Government has developed a plan for ensuring that common-use infrastructure is used where possible, rather than risking having multiple redundant assets owned by different corporations. Aboriginal and community participation is recognised as crucial for the appropriate siting of wind, solar and transmission equipment.

The near future: electric fleet

Approximately half of a typical mine’s energy needs can be met by onsite electricity generation. The other half currently requires diesel fuel to run a fleet of light vehicles, monstrous ‘haul’ dump trucks such as the 250 tonne CAT 793, and every piece of mobile machinery in between. These mobile machines are the next target for reducing costs, carbon emissions and labour. Several trial projects are happening. For underground mines, where diesel has previously been used, huge ventilation fans will need far less power when there are no exhaust fumes to expel.

Machine manufacturers are developing a wide array of specialised battery electric products. In some applications, there is battery swap technology, as in modern power tools. In other applications, a fixed battery plugs in to recharge, like in an electric car. There are also trolley systems, akin to a tram or train. The best system for each job depends on the application.

Transitioning to a fully electric fleet will significantly increase a site’s electricity needs, with the biggest chargers running at 6 MW at full power. We are expecting to see sites’ electrical grids upgraded soon to integrate this high-power charging.

What is Entura doing?

At Entura, in addition to electrical generation and distribution design, we have specialised capabilities in control systems and power system studies for mining projects. Our microgrid control system (MCS) uses standard and reliable industrial Allen Bradley hardware to monitor and control the power station assets. We have a field-proven core algorithm for maintaining a priority of reliable power supply including backup/reserve supply, while making the greatest use of wind and solar where available. We’ve proven this process in our existing installations in the field and we lead the industry in methodology, practicality and voltage/frequency management.

We’ve seen the real benefits these systems bring to our clients and communities, both at mining sites and in other remote locations. Entura has a long history of design, formation and operation of microgrids throughout Australia (such as King Island, Flinders Island, Rottnest Island, and at mining sites such as the Agnew gold mine) and in the Pacific region (including the Cook Islands, the Federated States of Micronesia, Tonga, and the Solomon Islands, to name just a few).

Contact us if you’re interested in unlocking the full potential of microgrids for your operation or community, or if you’re interested in ways to increase your use of renewable energy.

[Image immediately above] Entura’s Patrick Pease, Greg Koppens and Mark Richardson at the 2025 Energy and Mines Summit

[Top of article] Greg Koppens (centre) onsite at Jabiru Power Station, Northern Territory

ABOUT THE AUTHOR

Greg Koppens is Entura’s Principal Control Engineer Hybrid Renewable Systems and previously led Entura’s secondary electrical engineering team. Greg’s experience spans power, oil and gas, and mining, including onsite roles. With over two decades of detailed design experience, Greg facilitates collaboration between engineering disciplines and other stakeholders to solve complex problems. He regularly shares his extensive expertise with the mining sector to advance their decarbonisation goals. Find out more about Greg in our podcast series here.

When the lights go out

Major power outage events, like the one that affected Spain and Portugal this April, can be enormously disruptive and even deadly. Here Entura’s Technical Director Power, Donald Vaughan, considers the complex factors at play and their implications for grids everywhere ...

The recent power outage on the Iberian Peninsula provides a serious opportunity for reflection. Many articles have been published that try to explore the seconds and milliseconds after 12:32 PM on 28 April 2025 while only having access to the grainy frequency plots and approximate timelines that have been released (to date). This is not one of those articles. Nor is it an article that will lay blame on a particular technology or energy source. Instead, I will expand on the physics at play in this instance and reflect on whether current network security practices are adequately catering for changes to the power grid.

The physics

The power system is governed by the laws of physics, as is normal in the physical world. Quite a few of these laws tend to gang up on us during a power system event[1].

(i) conservation of energy

(ii) Ohm’s law

(iii) Newton’s laws of motion

and, of course,

(iv) Murphy’s law.

We’ll talk about the first three now and the last one later.

We learn very early that energy can neither be created nor destroyed (law i, above). This is at the heart of a power system event. The power system supplies loads by supporting voltage across the network that supplies millions of parallel loads. Each of these loads converts electrical energy into another form of energy based on the voltage it sees and its internal characteristics. This will continue as long as the voltage profile is maintained (law ii). So, demands take energy out of the power system regardless of what generation events occur.

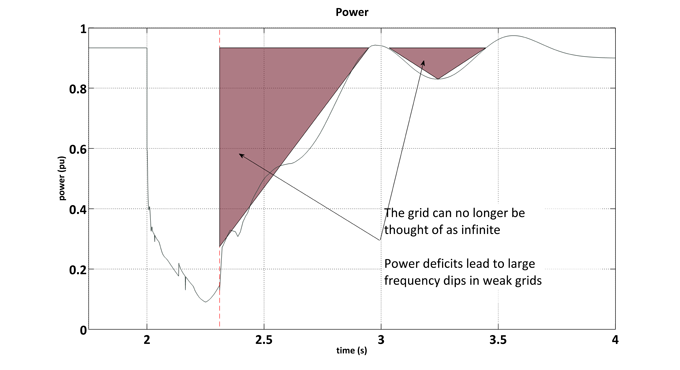

We know that the main trouble in the recent Iberian event started when a large amount of generation stopped in southern Spain. This led to an imbalance between generation and demand in that region. That imbalance is immediately addressed through the inertial action of synchronous generation across Europe (law iii).

If interconnection were perfect, the burden of this inertial response would be shared perfectly across Europe and we probably wouldn’t be talking about this event quite as much as we are. Yet interconnection is rarely perfect (law ii). The frequency in Spain started to move away from frequency to the east and the AC interconnection to the east opened (which avoided the disturbance that stems from loss of synchronism). This should have been some help to the falling frequency in Spain given the eastward flows at the time. Under-frequency load shedding (UFLS) occurred around this time and should also have helped. It seems that the voltage disturbance that then occurred as a result of all these trips was the last straw.

Network security practices

It would be a gross over-simplification of network security practices to say that the power system should not lose customer load for the loss of one generation or network element (N-1 redundancy). The event on 28 April is way beyond that. Typically, for larger events, the grid should fail safely. We’ll look at that definition of ‘safely’ later. For now though, we can see that the grid did, in fact, try to fail gracefully:

- The AC interconnectors opened to avoid damaging loss of synchronism.

- The under-frequency load shedding operated to try to preserve supply to some customers and keep the grid up, so as to reduce the duration of the interruption.

- Other generating unit controls acted to either increase output or trip to avoid damage.

We see in the Iberian Peninsula outage, as we did in the major South Australian blackout in 2016, lots of independent protection operations slowly but surely weakening the grid to the extent that it is no longer viable. Each of these protection operations undergoes scrutiny after an event of this nature, and will likely lead to some changes in Spain and France as was the case in South Australia.

The 28 April event appears to be quite slow in comparison to some other network blackout events. Even so, the event lasted less than 20 seconds and had 2–3 stages within it. One of the bases of design of the AC network is that it can generally operate with minimal, fast coordination even under large events. Control relies on observation, computation and action. So, to manage an event, a control system must measure what it needs to reliably determine what control actions it must make, and then take those control actions (assuming it can control all the elements it might need to control) in time for them to have an effect. If we think about a need to deftly control the response of individual units (or control systems) in an unusual way in a short period of time, then we can quickly conclude that this may not be possible.

If we can’t manage these events in real time, we have three courses of action:

(i) Physical plant

We could design networks, network supports, and network and generator protection and control systems to be more robust in the face of large power system events, thus decreasing the likelihood of unnecessary cascading protection operation.

This would include better interconnection, more dynamic reactive support (separate from generating units and demand), system-level protection schemes, and a review of generating unit protection settings to ensure generator capability rather than network requirements setting operating limits

(ii) Dispatch rules

We could change dispatch to provide greater margin for real and reactive power control as determined by the security risk and the cost to mitigate it.

We could continue the traditional N-X approach to system supports or we could use a stochastic approach to determining system support requirements (weighting the probability of an event occurring against its impact). Either way, we’d have to pay an ‘insurance’ premium at each dispatch interval to make large-scale system outages less possible.

(iii) Restart planning and capability

We could make recovering from major blackout events easier and faster.

We think about these events in terms of how often they occur (which is what the first two course of action cover) and how long they last. System operators typically have generic plans for system restart that rely on starting synchronous plant and re-energising transmission systems and eventually customer demand. This can be made easier with interconnection. It can also be made easier with good visibility of voltages and voltage profiles across regions (and the tools to control them). Often, for big events like in South Australia in 2016, the network is left somewhat stricken from equipment damage. System restart efforts are often hampered in this scenario because plans need to be improvised to adapt. This depends on the skill, knowledge and experience of the operators. Some jurisdictions have simulated such events as part of training operators.

The fourth law

We know that ‘anything that can go wrong will go wrong’. Seemingly simple things can undermine the best laid plans and the best intentions. We often can’t plan for these things specifically, although HAZOPS, root-cause analyses, scenario simulations and reviews can help us understand where the problems may lie and give us a chance to close loop-holes before they become SNAFUs.

Major power outage events are serious. They often lead to loss of life or injury, and the recent Iberian Peninsula event was no exception. They also always have an economic impact, which is not always fairly distributed. As an industry we need to improve how we manage them. We also need to get better at talking about technical issues in a political environment. If there’s a risk of blackouts, we have a duty to not only mitigate that risk within the current rules but also advocate for rule changes if that mitigation is inadequate. To be most productive, this conversation should happen in a techno-economic environment. The automatic debate after power system events often focuses on the role of renewables, commercial interests and the like, which may sometimes be entertaining but inevitably affects the techno-economic outcomes in a negative way for everyone.

ABOUT THE AUTHOR

Donald Vaughan has over 20 years’ experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. He has worked for all areas of the electrical industry, including generators, equipment suppliers, customers, NSPs and market operators. Donald specialises in the performance of power systems. His experience in generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves.

Image: Basil James on Unsplash

[1] There are more laws, but these are the main and most accessible.

Breathing new life into Australia’s aging wind farms

The wind industry, well-established in Europe for decades, took baby steps onto Australian soil in the late 1980s and 1990s. By the early 2000s, Australia’s new wind industry was ready to take off. Given that wind farms usually have a design life of anywhere between 15 and 30 years, our earliest wind farms are now reaching retirement age. The industry therefore faces a new set of challenges. Can these older wind farms continue to serve their important role in Australia’s clean energy transition or are they at their end of life?

So far, few wind farms in Australia have been decommissioned, dismantled and removed from the land. With many of our older wind farms sited to capture the best wind resources, there’s every reason to try to continue using these sites to harness wind energy.

One option is to squeeze more years out of the wind farm through effective maintenance and supportive analysis to ensure it is safe to do so while accepting that there may be increasingly frequent outages and increased maintenance costs to keep the wind turbines in service. However, although operation beyond the nominal life of a wind turbine is theoretically feasible, old wind turbines can’t keep spinning forever and will need to be stopped at some stage.

Other options for aging wind farms are refurbishment of some parts of the turbines, or full ‘repowering’ with completely new machines. This could also include a full redesign to accommodate larger turbines or to incorporate solar or battery energy storage systems.

An example of rejuvenation

Small grids may be some of the first to need to consider what to do about old wind farms. As an example, Hydro Tasmania’s Huxley Hill Wind Farm on King Island has three 250 kW wind turbines that were installed in 1998, and two 850 kW wind turbines that were installed in 2003.

For Huxley Hill Wind Farm, the King Island electricity load has not changed much over time, and offsetting diesel using renewable energy continues to make perfect sense.

For this site, the owner opted for a like-for-like replacement of nacelles (generator, gearbox, yaw system) of the Nordex 3 x N29 250 kW and potentially for the 2 x Vestas V52 850 kW wind turbines. This decision was partly about the good economics and sustainability of reusing existing infrastructure, and also because wind turbines of this size continue to suit the project so well.

When the wind farm was constructed 20+ years ago, the installed wind turbines were considered modern, large wind turbines. These days, the same suppliers do not offer anything less than 2 MW in capacity, with rotor diameters greater than 110 m. The lack of availability of what are now considered smaller wind turbines (say 1 MW) poses challenges for some small projects. At the scale of less than 1 MW, there are now few proven wind turbine options. At an even smaller scale (<100 kW), solar PV now dominates.

When any existing infrastructure is to be retained to support life extension of old wind turbines, such as at Huxley Hill, it’s crucial to confirm that it is still suitable and safe. This can include various techniques and activities, including:

- physical inspection by technicians and engineers

- excavation of the foundation backfill cover to reveal the tower-foundation joint and inspect corrosion and remediation

- surveying the tower and blade condition using drones

- surveying the tower verticality

- surveying the thickness of tower sections

- ultrasonic testing of bolts

- eddy current testing of welds to detect any flaws

- reviewing data from the turbines to refresh understanding of the actual wind regime, reassess fatigue loads and estimate remaining life.

Another important consideration when rejuvenating older wind farms is to consider the potential for adding solar or battery energy storage. With solar now more viable than when Huxley Hill Wind Farm was conceived, a 1.5 MW solar farm has been added to augment the wind generation.

Starting over with full repowering

Because the Australian wind industry is still relatively young, there is not yet an established practice or precedents for full repowering. However, in Europe, hundreds of wind farms have been repowered, often massively increasing output by using fewer but much larger modern turbines.

Repowering at around 25 years seems the most likely timeframe for most Australian wind farms – but few have yet reached this age. Ultimately, market factors will determine when repowering provides the best financial return.

Even though we’re still just on the brink of Australia’s repowering journey, it’s never too early to start considering the complexities and implications and assessing all options.

Repowering won’t be simple or quick. The development process for repowering NEM-connected wind farms is likely to be just as challenging as developing a new wind farm on a greenfield site.

The concept of ‘repowering’ involves a range of options for replacing old wind turbines and associated footings and electrical balance of plant with new, but it’s unlikely that much of the existing infrastructure and balance of plant will be able to retained if larger, modern turbines are selected. The layout of the wind farm is also likely to need revision to accommodate longer blades.

Planning approvals need to start just as early, as should the process of renegotiating with hosts, neighbours and communities. People may be concerned about the impacts of much taller turbines and the logistical issues of getting them to the site, as well as arrangements for the dismantling, removal and disposal of the superseded technology and infrastructure.

Repowering with bigger and more powerful turbines is also likely to involve re-permitting and negotiating a new grid connection agreement – neither of which are certain, given the cumulative impacts that may have emerged over time and any changes to rules and regulations since the wind farm was first developed.

By planning early for repowering, developers can get ahead on these issues as well as on condition assessment of the assets, decommissioning plans for old turbines, new studies that might be needed (such as bird monitoring), and new wind measurements for taller, modern wind turbines, perhaps using modern wind measurement technology such as lidar.

While some repowered wind farms will very likely incorporate new battery energy storage systems (BESS), they are less likely to deploy large-scale solar as a default, given that many of the best original wind sites in Australia are coastal or hilly, particular those in the south of the country. Nevertheless, the potential for co-located renewable generation, storage and loads is worth exploring.

Don’t wait for trouble – start planning now

We suggest that wind farm owners take action now to deepen their understanding of the condition and present value of their assets, and explore the full range of short-term and long-term options available through a feasibility and options study. After all, in such a dynamic market and technology landscape, and with the potential for aging assets to deteriorate or fail, decisions about end of life may need to be made earlier than expected.

About the author

Andrew Wright is Entura’s Senior Principal, Renewables and Energy Storage. He has more than 20 years of experience in the renewable energy sector spanning resource assessment, site identification, equipment selection (wind and solar), development of technical documentation and contractual agreements, operational assessments and owner’s/lender’s engineering services. Andrew has worked closely with Entura’s key clients and wind farm operators on operational projects, including analysing wind turbine performance data to identify reasons for wind farm underperformance and for estimates of long-term energy output. He has an in-depth understanding of the energy industry in Australia, while his international consulting experience includes New Zealand, China, India, Bhutan, Sri Lanka, the Philippines and Micronesia.

MORE THOUGHT LEADERSHIP ARTICLES

What to consider when you’re thinking about a synchronous condenser

Depending on when and where you want to connect your new solar farm or wind farm, the network service provider or your consultant may tell you that you’ll need a synchronous condenser. That may not be good news, because these machines don’t come cheap and they usually don’t provide a direct revenue stream. What should you do next?

Do you understand why you need a synchronous condenser?

The first step is to understand why you need the synchronous condenser. The inverters at the heart of most solar farms and most modern wind turbines need a strong electricity grid to push their energy into. If the network is not strong, the inverter is likely to fail to switch at the required times, swing against the power system like a pendulum, and distort the waveform, causing harmonics. The synchronous condenser overcomes this, strengthening the power system in the local area by forcing the network voltage into a near-perfect sine wave of the required size.

Is it possible to predict the need for a synchronous condenser earlier?

There are ways that you can predict at the project pre-feasibility stage that a synchronous condenser might be needed, before the network service provider becomes involved. Take a look at other renewable energy installations that have been constructed recently in the same region; if they needed a synchronous condenser, you almost certainly will too.

Consider where the installation is in the grid, and if the answer to any of the following questions is yes, you will likely need a synchronous condenser: Is your installation remote from all traditional generating stations? Has a large traditional generator shut down in the area recently? Are other generators in the area routinely constrained due to network stability challenges?

Simple calculations can be completed based on information that most network service providers publish on their websites, including network constraints and fault levels. These calculations aren’t always definitive, but they will offer significant insight.

What do you need to specify?

It is best to specify the exact function that the synchronous condenser must achieve. Typically, this means specifying the fault current contribution that is required from the machine and leaving it up to the manufacturer to decide the optimal machine design including the headline MVA rating. Once these headline values have been determined, consider the following questions, each of which has a substantial cost impact:

- How much reactive power do you need the synchronous condenser to absorb? Typically these machines can only absorb approximately half of their headline rating, so don’t ask for too much unless you have deep pockets.

- Do you really need inertia that is greater than the manufacturer’s standard? Synchronous condensers are known for having inertia, but asking for inertia that is greater than the manufacturer’s standard will result in substantial additional cost and usually results in no additional revenue stream.

- The synchronous condenser is being installed to provide system strength, so do you really want it to be able to supply reactive power indefinitely? Perhaps 60 seconds would be enough.

Are some cost savings not worth making?

For a synchronous condenser project, there are some measures that, on the surface, might appear to be potential cost-saving considerations. Can you omit the transformer tap changer? Could the cooling equipment be downsized or even omitted? Can you connect to the station 33 kV busbar? Detailed analysis is needed to answer these questions definitively. In our experience, however, the answers to each question have been emphatically no.

If you need the synchronous condenser to operate close to its rated reactive power absorption limit, you’ll need a transformer tap changer. Similarly, if the machine connects to a 33 kV busbar, fault levels will become unreasonable and an even larger machine will be required.

What’s the best contracting model?

Your choice of contracting model will depend on your appetite for risk and the sensitivity of your schedule. A typical solar or wind farm project is very schedule-sensitive, which suits an all-inclusive turnkey project delivery including everything from civil foundations, fencing and drainage through to integration with the farm’s control system. But this delivery mode comes at a price, and there are few Tier-1 equipment suppliers prepared to take on this model. The lowest cost suppliers will be likely to want to put your machine onto a ship, point it in your general direction, and send you the invoice.

Whatever your contracting model, one of the largest risks to projects is the adequacy of the power system models. You need to be confident that the original equipment manufacturer understands the market operator’s model requirements and has the skills to comply with them.

Can the machine offer economic benefits?

Two possible revenue streams could potentially flow from installing a synchronous condenser. By sizing the synchronous condenser to provide the reactive power required from a solar farm by the electricity rules, it is possible to operate the solar inverters and the main transformer at a higher power factor. This has the potential to increase the power output and consequently the revenue from the farm by up to 7%. A proponent could also install an oversized synchronous condenser and sell the spare system-strengthening capacity to another renewable farm in the same region. In the future, inertia and system-strength markets may evolve in ways that provide direct revenue streams for the synchronous condenser.

Is there an alternative?

The inverters at the heart of most solar farms and most modern wind turbines are changing. Until recently, they have exclusively used a technology called ‘grid-following inverters’, but a newer ‘grid-forming inverter’ is breaking into the market. These inverters are more expensive at the moment, but that’s likely to change rapidly. The newer inverters are much less sensitive to system strength. It is likely that applications will soon emerge in which changing the inverter will eliminate the need for a synchronous condenser. We predict that this could occur for small installations first and evolve over time to include larger renewable farms.

Putting it all together

The most cost-effective projects are often those that link multiple technologies – such as a wind farm with modern wind turbines, static VAr compensators and more than one synchronous condenser. These technologies were not designed to work well together, but with carefully coordinated controls they have done so in practice, providing the required system strength, voltage control and inertia for a successful minimum-cost project.

If you would like to find out more about how Entura can help you overcome electrical challenges for wind farms or solar farms, please contact David Wilkey on +61 3 6828 9749 or Patrick Pease.

About the author

David Wilkey is Entura’s Principal Consultant, Secondary Electrical Engineering. He has more than 20 years of consulting experience in electrical engineering across Australia and New Zealand, focusing on the delivery of advisory on secondary systems and power systems engineering. David’s expertise spans all areas of electrical engineering with a particular focus on electrical protection, power system studies and rotating electrical machines.

MORE THOUGHT LEADERSHIP ARTICLES

Is there still a role for small wind turbines in hybrid systems?

Many governments, industries and businesses worldwide are pursuing greater sustainability, reliability and affordability of their electricity sources, and transitioning away from fossil fuels.

In remote or isolated locations such as Pacific islands or remote desert mining operations and communities, hybrid renewable energy systems offer an effective option for meeting these energy goals.

Commonly, hybrid systems include a mix of solar PV, wind turbines, battery energy storage systems (BESS) and other enabling technologies. The inclusion of wind and solar generation in the mix is far more than an investment to earn money for the owner. These sustainable sources of energy reduce the traditional heavy reliance on fossil fuel, with its associated costs, insecurity of supply, and high emissions.

Why wind?

With the plummeting costs of solar PV and its ease of installation, is there still a role for wind turbines in the design of a hybrid system? Our answer is yes; however, there are a number of factors to consider when choosing the best configuration for your location and needs. It’s a combination of available solar and wind resource, the degree to which the load matches these resources across a full day, and the level of renewable energy targeted. In essence, the sun is out only during the day, but the wind is likely to be available across the full day.

So, why not solar and batteries? This combination can be fine for smaller percentages of renewable energy, but it is still the case that for the non-sun hours it is cheaper to directly source renewables from wind energy than it is to store solar energy in a battery and to retrieve it later in the day.

Right site, right size

For developers of large commercial wind farms, the first consideration and top priority has usually been finding a site with an excellent wind resource and good grid connection, as this is what will drive profitability. However, for micro-grid projects, wind turbine siting is largely dictated by the location of the project. There may be a small degree of siting flexibility at the local level (e.g. an adjacent hilltop, or the preferred side of an island), but generally the wind turbine has to fit in within the given conditions.

For larger remote hybrid systems that power mining operations, large wind turbines may be feasible, given the high level of electricity demand as well as the availability of the relevant infrastructure to enable delivery of large components. The recent Agnew Hybrid Renewable Power Station, with 5 x 3.6 MW wind turbines, is an example.

However, for sites with lower electricity demand or difficult access, the delivery and integration of a wind turbine greater than 1 MW can become exponentially more difficult and costly, and doesn’t necessarily convey extra value.

Bigger isn’t always better

For a commercial wind farm operating on a large grid, an extra 1% in power output often translates directly to energy generated, and revenue, at little cost to the project. In contrast, for a wind turbine connected to a micro-grid, an extra 1% in power generation often translates to a great proportion of energy ‘spilled’ (energy not generated because the grid can’t accept any more). Therefore, as a general rule, the sensitivity to variation of financial metrics such as Investment Rate of Return for a wind turbine on a micro-grid is much less than for a grid-connected wind farm.

Furthermore, from the perspective of system operations and redundancy, having many smaller machines is typically preferable to having only one or two large machines, particularly in more remote locations with greater time involved in repairs. If one of only two or three larger turbines is out, this represents a higher percentage of increased fuel use and operational cost compared to an outage of one of many smaller turbines.

A small problem

So far, so good. But now we run into a challenge. There simply aren’t many small wind turbines now available. Wind turbines have been constantly increasing in size. This is because wind turbine manufacturers target the large grid-connected wind farm market, in which larger wind turbines push down the cost of wind energy. Larger rotors and blades and greater height make mega-turbines much more effective than smaller turbines at harvesting power from sites with low wind speeds, allowing greater opportunities for wind farm sites.

This is fine for larger hybrid systems at outback mines where there are large spaces, good infrastructure and access to install 150 m diameter rotors on 120 m tall towers. However, it’s not so helpful for small Pacific island nations and remote communities, with relatively low wind speeds, lower electrical loads and under-developed infrastructure.

The lack of availability of smaller wind turbines poses challenges for some small projects. At the scale of less than 1 MW, there are now few proven wind turbine options. At an even smaller scale (<100 kW), solar PV now dominates.

For some, second-hand wind turbines that have been refurbished might be attractive. However, remote sites require a high level of reliability, so this option will not suit all operators.

At a minimum we suggest early engagement with potential suppliers. And in some cases early procurement may even need to be considered to lock in supply.

Repowering an old system

It’s a similar situation for existing small grids with wind turbines that are nearing the end of their design lives.

The typical nominal design life of a wind turbine is 20 years. Although operation beyond the nominal life of a wind turbine is feasible, old wind turbines will at some stage need to be replaced, either with new wind turbines or by alternative forms of energy generation.

The term ‘repowering’ captures a range of options for replacing old wind turbines and associated footings and electrical balance of plant with new. Because the wind industry is relatively young, there is not yet a clear established practice for repowering. However, in our view, the most likely options are:

- Extend the life of existing assets until the costs of maintenance make this uneconomical. In practice, this may be well beyond the original 20-year life, and further repowering decisions can be delayed.

- When Option 1 becomes untenable, completely replace wind turbines and footings, and electrical balance of plant. Because of the continuing increase in the size of wind turbines over the past 20 years, reuse of existing balance of plant is unlikely.

Small grids may be some of the first to need to ‘repower’ old wind sites. As an example, Hydro Tasmania’s King Island Power Station has three 250 kW wind turbines that were installed in 1998, and two 850 kW wind turbines that were installed in 2003. For that site, it is likely to be feasible to consolidate the generation using several large modern wind turbines. However, in other long-standing smaller hybrid systems, the challenge of finding replacement sub-1MW wind turbines will be all too real.

For any redevelopment there will be a range of considerations, including permitting, existing power station equipment, and the rapidly decreasing costs of battery energy storage systems. We suggest that owners should at least develop a good understanding of the condition and the present value of their assets, and what options might be available (e.g. through a feasibility and options study). After all, the unexpected does happen, and the failure of a major component such as a gearbox may require decisions to be made about end of life, earlier than expected.

If you would like to discuss how Entura can help you with your hybrid or wind project, develop an asset management strategy or support you with due diligence services for proposed or operational projects, contact Patrick Pease or Silke Schwartz on +61 407 886 872.

About the author

Andrew Wright is a Specialist Renewable Energy Engineer at Entura. He has more than 15 years of experience in the renewable energy sector spanning resource assessment, site identification, equipment selection (wind and solar), development of technical documentation and contractual agreements, operational assessments and owner’s/lender’s engineering services. Andrew has worked closely with Entura’s key clients and wind farm operators on operational projects, including analysing wind turbine performance data to identify reasons for wind farm underperformance and for estimates of long-term energy output. He has an in-depth understanding of the energy industry in Australia, while his international consulting experience includes New Zealand, China, India, Bhutan, Sri Lanka, the Philippines and Micronesia.

MORE THOUGHT LEADERSHIP ARTICLES

Keeping international projects moving, even when we’re grounded

With no set date for when life will return to usual after COVID-19, nor any guarantee of whether life will ever return to what we previously knew as ‘usual’ at all, there are very few areas in the consulting life in which we can simply say ‘we’ll wait until this is all over’. Life, and projects, must go on.

Although we can’t avoid the disruption and uncertainty that the coronavirus has unleashed, we can increase our resilience and agility. We can also embrace opportunities to innovate and to create new ways (or reinvigorate old ways) to achieve our goals.

Here, Entura’s Environment and Planning team continue to apply their proactive approach to keeping projects alive in the current circumstances, and explain how they are continuing their activities on two international projects despite the travel restrictions that are making it impossible to visit the project sites.

Old ways for new times – Engaging communities in Tonga

For many countries across the globe, the immediate challenge is building resilience to fight through the pandemic. However, for some small island nations that have managed to stay out of the virus’s path so far, such as Tonga and the Federated States of Micronesia, the concept of resilience has a broader context.

Climate resilience is a core objective, as these nations are feeling the increasing impacts of rising sea levels and more frequent and intense weather events. In this context, robust power infrastructure that is suited to extreme weather is one component of greater resilience, as is transitioning from diesel dependence to higher levels of renewables, which builds greater security of energy supply at a lower longer term financial and environmental cost. More access to stable, reliable and clean electricity is also critical for the health, wellbeing and education of local communities, and is the foundation for economic development. Entura has been fortunate to be involved in some meaningful resilience-building projects in the Pacific, supporting many of our neighbouring nations to implement sustainable energy solutions.

However, with a current project in Tonga, coronavirus has thrown our travel plans into disarray. The challenge we’re facing now is how to continue the planning, engagement and environmental activities required by such a project when we can’t physically get there, can’t hold town hall meetings and can’t host information sessions with locals.

While the pandemic is forcing many practitioners to extend and expand their use of digital forms of engagement (such as websites, Facebook, Twitter, ‘Bang the Table’ or moderated ZOOM-based focus groups), some projects are located in communities that do not enjoy easily available or reliable internet or telephone access. In these cases, such as our project in Tonga, we need to think differently about ways to facilitate engagement from a distance.

For the Tongan project, we’re heading back to basics: the tried and tested solution of providing information on paper. Working with the local project management unit, along with our client, we are designing and implementing a newsletter to be printed in the local language and distributed to regulators and communities. It will provide snapshots of the project, latest updates on scheduling, and will even feature some interviews to provide greater coverage of ongoing community engagement.

As the construction company for the project is, like us, unable to travel internationally at the moment, construction is yet to take place. Nevertheless, we are continuing to facilitate all aspects of the project remotely, such as lining up approvals with regulators, and guiding engagement on the ground. With the help of our Tongan counterparts, we can still keep information and updates flowing despite the physical limitations on our involvement ‘in the flesh’.

Buying time and building partnerships in South-East Asia

Just as COVID-19 started closing borders and halting international travel, our team was reaching the culmination of many weeks planning an impact assessment for a large infrastructure project in South-East Asia. Our discipline experts were about to book their tickets and embark on the journey to site to survey environmental and social impacts. However, we placed the site surveys on hold indefinitely to comply with travel restrictions, ensure the safety of our people and contractors, and not risk spreading the virus in remote communities.

This abrupt shift in our plans afforded us the chance to take a breath, reflect on the project and its broader risks, and then develop an alternative plan to keep progressing aspects of the work that could be done remotely. We are now proactively undertaking desktop approval studies and initial public consultation from our desks. We’re ‘buying time’ now to save time later.

When travel restrictions lift and it is once again safe to physically attend the site, we will be ahead of where we would have been pre-COVID-19. We will better understand potential issues and have a more thorough insight into the local and community context. We’ll have already carefully planned our field studies with more targeted approaches. We’ll be better prepared for stakeholder questions that may arise, and will have already considered ways in which the project might manage challenges and risks going forward.

But there’s something more that we’re seeing emerge in this COVID-19 period. We’re finding that the shared need to adapt to trying times and the mutual desire to find workable solutions is strengthening our relationships with our clients, building even greater trust and collaboration, and it is leading to ‘partnership’ relationships that transcend the more common transactional paradigm of client–consultant. We are working closely together to openly discuss issues and options, and to determine how best to manage emerging challenges to benefit the project.

Would this have happened without COVID-19? Perhaps – but under the usual pressure of timelines, expectations, standardised processes and the drive for efficiency, there isn’t often the same flexibility or space to build different qualities and layers in our relationships or to consider potential issues quite so broadly or creatively.

Will the project benefit from the changes made necessary by COVID-19? Probably – despite the difficulties caused by the limitations on travel, it can only be positive to have had the chance to take the time to more thoroughly and holistically consider all the issues and risks before we proceed to field studies and stakeholder engagement.

Will timelines change significantly because of COVID-19? Not necessarily – we will inevitably lose some months by not being able to go into the field, but we will have ‘bought’ some time by compiling a good portion of the project documentation prior to the field studies, so that the time required in subsequent stages is lessened.

Wherever in the Indo-Pacific region our international projects are located, our clients can be confident that we’re seeking all the ways we can – new or old – to keep making progress in these uncertain and complicated times … and to come through them stronger together.

If you would like to discuss how Entura can help you with your environmental or planning project, please contact us.

Don’t let COVID-19 stop your project

A vital part of the success of all projects, whether they are new or operational, is maintaining progress towards milestones and retaining currency in the social and regulatory realms. How can we achieve this during a global pandemic?

With the COVID-19 crisis affecting people and businesses across the globe, employers and employees alike are racing to find normalcy. Fortunately for Entura, we’ve already been working and collaborating virtually for many years across country and state borders, with dispersed office, client and project locations. So, even though our teams are working from home, it is still business as (mostly) usual, in unusual times!

Although COVID-19 hasn’t thrown us completely, travel restrictions have pushed us to think differently about many of our projects and methods. This is the time to explore proactive ways to ensure projects do not come to a grinding halt or fall off a community’s or regulator’s radar.

Keeping environmental and planning projects moving forward

Entura’s environment and planning team works frequently in the field – lakes, forests, roadsides, development sites and many more – so COVID-19 travel restriction have taken a hit at our ability to undertake survey and monitoring programs or to conduct site visits, but it hasn’t led to tools down.

We may miss out on our chance to hit the frosty outdoors this autumn and winter, but there are still many ways that we can and will continue to make progress and deliver value. It’s about thinking creatively about how we can be proactive. And that means finding measures and activities for the short and medium term that will keep the project moving towards the longer term project milestones and goals (without the anticipated longer term extending into the much further horizon!)

For example, there are proactive things we can do to prepare us better for when we can once again visit the site. We have access to a wide range of data and can undertake thorough desktop investigations early in the project. We will then be able to step on site well prepared and looking to fill knowledge gaps or to verify what should be there. That puts us in a better position to be alert to anything unexpected we might find when we’re physically on site in future. Unusual discoveries and observations will be more pronounced. Such approaches can help shorten project timelines post-COVID-19 compared with the inevitable blowouts that would be caused by downing tools completely.

Policy and regulatory reforms are also still happening across the country – some as a result of COVID-19, others associated with larger reform programs to update antiquated legislation. Our discipline experts continue to engage with the regulators and relevant government agencies and authorities to ensure we understand the nuances of these changes and how they may influence the scope of existing and future projects and programs of work.

More proactive, less reactive

The restrictions caused by COVID-19 have highlighted the need to be proactive so that we can be better positioned for the longer term. It’s natural for a consulting paradigm to tend towards the reactive and process-driven, but this is the time to shift such tendencies.

With a future-focus and forward thinking, we can all seek out proactive solutions to keep projects and processes running as smoothly as possible, to meet any milestones that are still feasible, and to do everything that is reasonably possible in the present circumstances that will minimise delays once the pandemic has eased.

This needs to be a shared process. If as consultants and clients we put our heads together, we can develop shared understandings of the opportunities, risks and issues affecting all parts of the project and all the players involved. With team work and good communication, together we’ll find the most innovative and workable solutions, and together we will survive and thrive.

Beyond the immediate

The circumstances of the pandemic are also an opportunity to think beyond the immediate projects on our desks. This is a great time for our clients to review their projects and environmental and social management practices, to be better positioned for the post-COVID-19 future. This could include being more informed about potential risks or thinking through changes that you could make to your management practices to better address ongoing or emerging issues.

In our next article, we will highlight some of the projects we are currently working on, and how we have adapted them in light of COVID-19. We will also dig down into some of the key regulatory reforms happening across the country, and what implications they may have on projects during the COVID-19 period and beyond.

At Entura, we will continue to respond to government measures as they surface, and we will continue to be here to assist all our clients to better understand the opportunities, risks and issues associated with keeping your project alive during COVID-19.

A message from our team to yours

And to finish on a light note – Entura’s environment and planning team has nimbly settled into their new branch offices, from urban Melbournian set-ups to peri-urban workplaces at the foothills of the majestic kunanyi/Mount Wellington in Tasmania. From our team to you or yours, here are a few handy tips which we have found to help with this transition to working from home:

- Stay connected – drop your colleague or manager a line and ask how they are going, and where possible (bandwidth permitting), turn on the video during your virtual meetings.

- Schedule regular team catch-ups, and why not end the week with an optional virtual gathering to kickstart some weekend banter?

- Don’t be embarrassed if your pets or children make an appearance – it helps lighten the mood and may provide the laugh that someone really needed.

- Get some fresh air before you start work – imitate that commute to work by going for a walk or cycle.

If you would like to discuss how Entura can help you with your environmental or planning project, please contact us.

Pictured, clockwise from top left:

- Senior Social and Stakeholder Consultant, Dr John Cook

- Land Use Planner, Bunfu Yu

- Senior Aquatic Scientist, Dr Malcolm McCausland (and friends)

- Team Leader Environment and Planning, Raymond Brereton

- Senior Environmental Planner, Cameron Amos

- Senior Planning and Environmental Consultant, Scott Rowell (about to head out for a ride)

- Environmental Consultant, Rachael Wheeler

MORE THOUGHT LEADERSHIP ARTICLES

Engineering – by humans, for humans

When engineers think about the future, do we get so engrossed in the complex technical problems that we don’t attend enough to the human angle?

Engineers have a reputation, whether rightly or wrongly, for being poor communicators, working obsessively and in isolation, and focusing on the immediate goal rather than its impacts on communities. Often, clichés have a basis in truth. If we are going to shift perceptions, we need to start by thinking about the way we work and the leadership we show to the next generation of engineers.

There’s no way we can predict the major developments, challenges or solutions of the next five or six generations of engineering careers. What we should focus on is what we can do right now to lead change in our profession and our communities – and I think the keys are communication, collaboration and community.

Communication

I recently listened to a podcast in which two energy market experts talked with a power system engineer. They discussed all sorts of technical matters relating to frequency and voltage control. I love those topics, but this conversation was limited and uninspiring because the participants simply didn’t have a common language or understanding.

We need to learn to communicate in ways that a variety of people can understand. That will mean better conversations with the people who can help our work have greater impact, and it will help our communities to appreciate the importance of our work in their lives.

It’s too easy for us as a profession to sit at our desks or stand under our hard hats and luxuriate in how clever we are, and then bemoan how so many people have no idea what we do and don’t value our work.

When things that involve engineers go wrong, a flurry of opinions erupts. Failures such as the blackout in South Australia, or the cladding issues at the Grenfell Towers, or issues with airlines or bridges or dams all lead to our communities questioning and debating engineering practice. Engineers tend to try to stay out of this rough and tumble for fear of being misrepresented. Yet maybe it’s better that we do engage where we can, since being misrepresented on a small issue is better than allowing a groundswell of misguided public opinion due to a lack of understanding of engineering principles.

We need to try to better explain our work and find simple ways to convey the complexities of the decisions that we make.

Collaboration

The world is far more complex now than it was a century ago – but it is impossible to imagine what level and pace of change future generations will experience. If we want to transform our world or help build a better future, we can’t do it by ourselves.

Engineering no longer operates in isolation, if it ever did. We must collaborate across the engineering team and across other professional disciplines to achieve truly effective development for our communities. Sometimes we may need to focus a little less on technical delivery as a primary outcome, and increase our recognition of the value gained by engaging successfully with the communities on whom the project relies for success.

Collaboration makes our work more effective, and exposes us to a wider range of inputs and values that we can incorporate into our designs and processes. Engineering can be a leader but it can also be a facilitator for better outcomes when we draw on, listen to and learn from the other experts involved in other aspects of our projects.

Community

Engineering work almost always benefits more people than merely the one who pays the bill. Much of my work is in connecting wind farms and solar farms to the grid. Mostly my work is paid for by the owner of the farm, and while it delivers direct benefits to the owner through return on investment, it also affects everyone connected to the nearby network. It affects the network service provider and market operator, it pays salaries, and it supplies the clean energy that helps the country reduce emissions and meet its international targets. In other words, my work, which may seem intangible, has tangible effects in the real world.

If we agree that our labours produce real impacts, we need to take better care to fully consider the wider consequences of our work, which often has the potential to cause ‘collateral damage’. We can’t build a road or a wind farm without changing the landscape. When we build a machine, it uses energy and may emit pollutants; and it reduces reliance on manual labour, which may put someone out of a job. There may be a risk to lives, livelihoods or the environment if something goes wrong.

Do we always make decisions about these matters with the community front of mind, or do we place our clients on the higher pedestal? This is a tricky area and I’m not espousing a puritanical approach. However, if we knew in 1919 what we know now about lead poisoning, acid rain, greenhouse gases, scarcity and general sustainability principles, what different choices could have been made?

In a time of automation, we need to think about benefits and risks and how they affect our communities. On one occasion early in my career, I designed a controller to turn on and off a couple of compressors at a power station. I wrote some code to balance the run hours. A few months after the new system was commissioned, I asked one of the operators how the system was going, in terms of the run hours management, and he said ‘you’ve done me out of a job’. I hope he was joking. The task he’d been doing wasn’t particularly important, but there was value in having a person who was in tune with the equipment to take care of it, and there was also value in giving that person dignity through work.

My point is that we must keep our communities foremost in our minds as we go about our work. It’s not just about what we produce. It is the way we work and the people we choose to work with and for. Our influence on the development of the next generation of engineers perhaps has more impact on communities than our actual work outputs.

Through communication, collaboration and community, engineering can be both ‘more human’ and ‘for humans’.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Asset management trends for profitable wind farms

How can a wind farm realise its full lifetime potential in an increasingly cost-sensitive market?

Until now, improving the wind industry’s profitability equation has been driven by increasing the size and efficiency of wind turbines, resulting in more energy produced for every dollar of capital expenditure. However, there’s only so far we can go with this approach.

To keep driving costs down and maintaining your wind farm performance, we now need to turn our focus to another aspect of the equation: a wind farm’s significant ongoing operational and maintenance (O&M) costs, which are set to increase as wind assets age. Achieving maximum yield at minimum risk and cost across a wind farm’s full operational life is a major asset management challenge, and much is yet to be learned.

In 2018, at the Wind O&M EU conference in Germany, I observed some international trends and perspectives on O&M that can offer useful insights for the wind industry in Australia. Although some aspects of the topic generated a deal of consensus, other areas are far less certain with many questions and possibilities yet to be fully explored.

Learn from other industries

Across the wind industry, there’s strong agreement that commercial returns for wind farms are not as high or as easy to obtain as they once were, and that reducing O&M costs on wind farms is critical when profit margins are being squeezed.

This may seem obvious, but the fact that we still need to articulate this point demonstrates that the wind industry has a significantly less sophisticated O&M approach than more mature industries such as oil, gas, other energy and heavy industries, and the IT and telecommunications sectors.

The wind sector should, and no doubt will, look to these more mature industries in the coming years for innovations that can be applied successfully to streamline our O&M and asset management strategies.

Plan for a longer life

Another implication of the relative youth of commercial wind farm development is that the industry has little practical experience with ageing wind farms – yet wind farms are set to get even older. Where it was previously the norm for a wind farm’s business case to be based on a 20–25 year life, it is becoming increasingly common for business case scenarios and asset management strategies to consider lifetimes up to and potentially beyond 30 years.

We need to be developing thorough and sophisticated asset management strategies that fully embrace the later stages of a wind farm’s life – not only the earlier stages in which O&M may have been conducted under contract with risks managed very effectively.

When we think about ageing wind farms, we weigh up the choices of continuing operations, decommissioning, or repowering with new turbines. From our understanding, it seems that wind farm repowering is only happening in locations with very friendly tariffs (such as a few areas in Germany), or where the existing project is fundamentally unsound from a technical and commercial perspective.

In Australia, full repowering with new wind turbines is not currently a commercially attractive proposition, and may not be widely considered for at least another decade. So, a wind farm’s extension of life will need to be achieved through effective O&M and refurbishment. I observed that some wind turbine owners and suppliers are beginning to think in more sophisticated ways about whole-of-life asset management strategies that maximise project value for the longer term, but it is still early days across the sector.

I also noted a range of diverging opinions about whether it is preferable for an owner to manage O&M through long-term comprehensive O&M contracts or whether risk is better mitigated by owners taking on the management of O&M themselves. Approaches vary depending on portfolio size, experience, capability and the general philosophy of the business. Clearly, this is not an area in which one solution will work for all.

Share information to build knowledge

Given the relative newness of the large-scale wind industry, and the need to squeeze every last drop from existing infrastructure, there is much to be gained from learning from and with each other.

Many industry players at the conference expressed a desire to see increased cooperation and sharing of information between different owners, operators and manufacturers.

The industry as a whole will benefit if SCADA system data is the property of the wind farm owner and shared more openly across the industry. Greater openness and availability of data will allow better benchmarking across turbine models scattered across the globe, enabling operators to better predict future costs and performance and incorporate reliability-centred maintenance.

Better benchmarking may offer insights into the extent of the performance improvements that could be gained on existing projects by adopting some available upgrade options. Many service providers are offering control system upgrades, aerodynamic improvements, yaw alignment systems, and advanced condition monitoring systems for increased availability – yet the industry is still learning how to translate this dizzying variety of rapidly developing technologies and options into a robust business case.

It can be difficult for owners to justify expenditure when the gains are uncertain, difficult to measure, and sometimes accompanied by drawbacks that are hard to quantify directly. For example, do you take increased generation at the risk of a reduced lifetime or increased maintenance costs?

If performance improvements of wind projects were more easily measured, we could more realistically quantify their impact on profit.

From these trends, observations and uncertainties, it’s clear that in any wind farm project – whether developing a new project or changing ownership of an existing project – we need to look very carefully at ongoing O&M costs, particularly as the increasing costs of end-of-life loom large. Thorough due diligence and realistic assumptions in this area will be vital for developing viable business cases across an increasing range of possible lifespans.

If you would like to find out more about how Entura can help you optimise your wind farm, develop an asset management strategy, or support you with due diligence services for proposed or operational projects, contact Patrick Pease or Silke Schwartz on +61 407 886 872.

About the author

Andrew Wright is a Senior Renewable Energy Engineer at Entura. He has more than 15 years of experience in the renewable energy sector spanning resource assessment, site identification, equipment selection (wind and solar), development of technical documentation and contractual agreements, operational assessments and owner’s/lender’s engineering services. Andrew has worked closely with Entura’s key clients and wind farm operators on operational projects, including analysing wind turbine performance data to identify reasons for wind farm underperformance and for estimates of long-term energy output. He has an in-depth understanding of the energy industry in Australia, while his international consulting experience includes New Zealand, China, India, Bhutan, Sri Lanka, the Philippines and Micronesia.

MORE THOUGHT LEADERSHIP ARTICLES

Congestion and losses: more than a blocked nose for new renewable generation

Anyone who’s ever had a cold understands the discomfort of blocked airways. Congestion challenges, albeit slightly different ones, also face developers of new renewable energy generation.

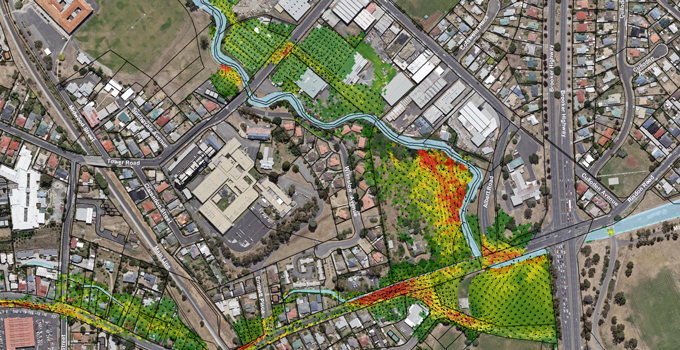

The nature of powerflows around the grid is changing rapidly with a lot of new generation being built on the edges or middle of the transmission system. This is increasingly being recognised as a problem, but quantifying the impact can be tricky.

Developers are asking: “What other generation will or can be built in the area? Will there or can there be collocated storage? When may these things be built? Will other projects in the area have a similar generation pattern to my plant?” And these questions are becoming harder to answer with the wave of renewables development.

Answering these questions

There’s no real substitute for analysis and an understanding of the degree of certainty required.

A simple example of adding generation in north-east New South Wales illustrates the point. Naturally, developers think first about competition: “Will added generation displace existing generation in NSW or generation on the interconnector? What is the most conservative assumption? What is the balance of probabilities?”

Even this simple example leads to many assumptions and choices, so proponents and owners need to understand how certain they need to be – and therefore how thorough the investigation of congestion needs to be.

What other questions are there?

Traditionally, congestion has been considered a problem of network thermal capacity. The nature of renewable energy generation adds other factors into this mix, such as: “Will fault levels remain high enough to support short-circuit ratios? Will critical clearance times be maintained to allow the full thermal capacity to be used? Will imbalance of generation development on parallel paths reduce pre-contingency loading limits?”

These sorts of questions require complex analysis, adding further uncertainty and additional dimensions to the results.

There’s talk of additional network provision being required to support changes to the flows in the transmission system. Such changes will no doubt be helpful, but questions of when, how much and who pays must be asked.

We can see that calculation of congestion has real impact on expected revenues – but with so little certainty, it is hard to determine how critical any impacts may be on the overall business case.

What about losses?

The other effect of large generation on transmission flows is greater network losses. The marginal loss factor (MLF) regime that accounts for losses in the National Electricity Market (NEM) relies on many of the assumptions of congestion analysis, with similar levels of uncertainty of the input increasing the uncertainty of the output.

MLF has always appeared punitive for new renewable generation distant from the load centre, since long transmission distances (often over low-capacity lines) lead to inefficient power delivery.

The MLF regime is supposed to incentivise development of efficient and timely generation and demand. The drivers for renewable generation are less about actual demand and more about displacement, so the MLF inhibits the building of new generation in favour of the status quo. A simplistic analysis, however, shows that, on average, new renewables see slightly higher MLFs than the established generation and new thermal assets.

There could be a number of explanations for this but it shows that the density of generation has remained low enough thus far. Increased build and in-fill will ultimately lead to MLFs becoming a bigger and bigger factor for new and existing plant.

Other congestion issues

There’s another form of congestion looming or already starting to impede the rapid deployment of solar and wind technology: a lack of capacity of network service providers (NSPs) and other regulators to deal with the influx of applications for new connections.

Add to this the increasingly technical analysis required to demonstrate compliance of these connections with the rules and a real bottleneck is created.

Blow your nose

The truth is, the only answer to any congestion issue is to remove the blockage .

In terms of network congestion, in the short-term, we need to continue to think about the likely requirement for renewable developments (with storage) to meet the challenges of the energy trilemma – replacing coal-fired generation following retirements with reliable, affordable and more sustainable generation.

And we will need to better understand the value of transmission re-enforcement to support a changing generation fleet.

It may also force a return to the Hub or Scale Efficient Network Extension (SENE) type of thinking that gives a clear signal to proponents to ‘build here’, as we can now see in New South Wales.

Network re-enforcement may also improve MLFs, slightly. However, if MLFs are low across the board in a region, the pool price will adjust to reflect this over time. In the short term, local or regional storage may be cost-effective in raising MLFs to investment-tolerable levels.

In terms of resource issues, training and applying more skilled resources to this sector must be a focus for NSPs and regulators.

Our approach as consultants is to not always recommend more analysis but, alternatively, the right and the most efficient form of analysis.

The challenge for NSPs and regulators is to act more commercially and embrace an engineering approach to analysis, tolerating some uncertainty – just as proponents do.

We always feel better once the fog of congestion lifts. Sometimes we try to fight through it, but it’s often better to take deliberate action to treat it and to avoid complications, just as when you are suffering the symptoms of a cold.

If you would like to find out more about how Entura can help you navigate network challenges, please contact Donald Vaughan on +61 3 6245 4279.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Tackling renewable energy integration: five lessons from Sri Lanka

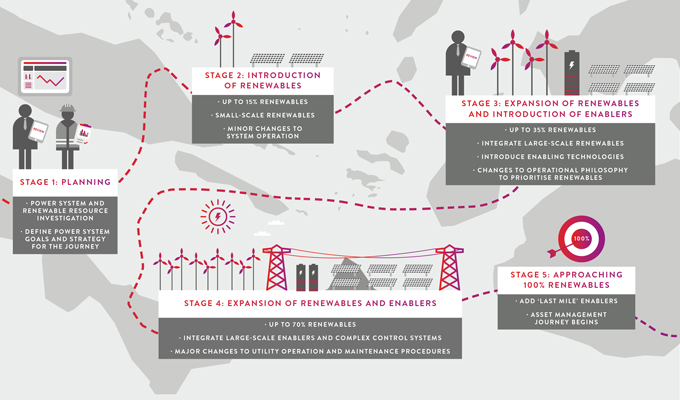

Ambitious renewables targets, movements away from thermal generation, increasing demand for electricity … it’s boom time for renewables around the world. Yet the global energy transformation brings some challenges, particularly for network stability and security.

Sri Lanka offers an interesting case study in the complexities of quickly integrating a large proportion of renewables and how some of the hurdles may be overcome. The lessons we can learn from the Sri Lankan experience are applicable worldwide.

In 2016 the government of Sri Lanka set a very ambitious renewable penetration target, with 100% of power generation to come from renewable sources by 2050. Coal and oil generation, currently accounting for around 50% of all generation, will cease by 2045. If this isn’t challenge enough, add in the projection of maximum demand rising above 7000 MW (from a current daily maximum of 2500 MW) by 2040.

Between September 2015 and March 2016, three nation-wide blackouts threatened to significantly undermine Sri Lankan industry and foreign investment prospects. The challenge for the Ceylon Electricity Board (CEB, which runs Sri Lanka’s power system) now is to achieve the country’s power transformation while still ensuring network security and reliable electricity. Any future unexpected system outage would be likely to erode public confidence in renewable development, regardless of whether the outage relates to renewables or not.

What can we learn from the Sri Lankan experience of the 2015/16 blackouts and Sri Lanka’s current challenges in its journey to a renewable energy future?

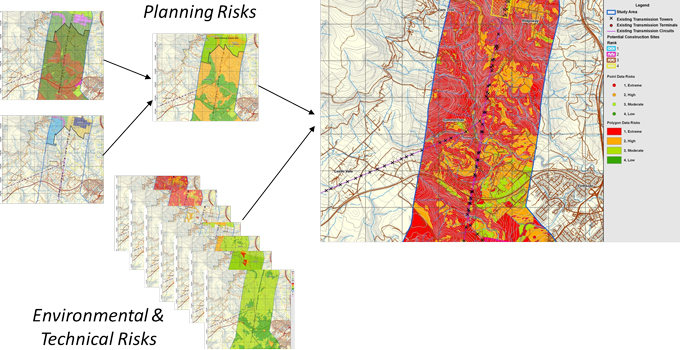

1 – Focus on accurate modelling of the power system

The first lesson to be taken from the 2015/16 blackouts is the need to focus on power system modelling. The first blackout occurred after a trip of the largest generating plant under light load. The next was due to a trip of a major transmission line when two parallel circuits were taken offline for maintenance. Neither of these events were envisaged through system model simulations. If a utility’s simulation tools won’t predict such events, planning engineers will struggle to anticipate or guarantee system security under system contingencies.

For system planning and operations, CEB has developed a power system model consisting of major hydropower, oil, coal and wind plants. However, no model accuracy requirements are specified in the national grid code, which leads to the use of generic models with unknown modelling accuracy. Prior to Sri Lanka’s 2015 blackouts, limited tests were conducted to tune the models to accurately represent behaviour. During 2017, CEB embarked on a project to test the model validation for at least some of the major hydro units. These tests need to extend to all major power plants so that engineers can trust the actual performance of every major generator in the system.

2 – Determine a clear, single responsibility for the system model

The second lesson from Sri Lanka’s system modelling is the need for a single owner of the system model files, with responsibility to maintain the model and ensure its accuracy. If different departments of a utility have different system models, results of an event analysis may vary.