THOUGHT LEADERSHIP

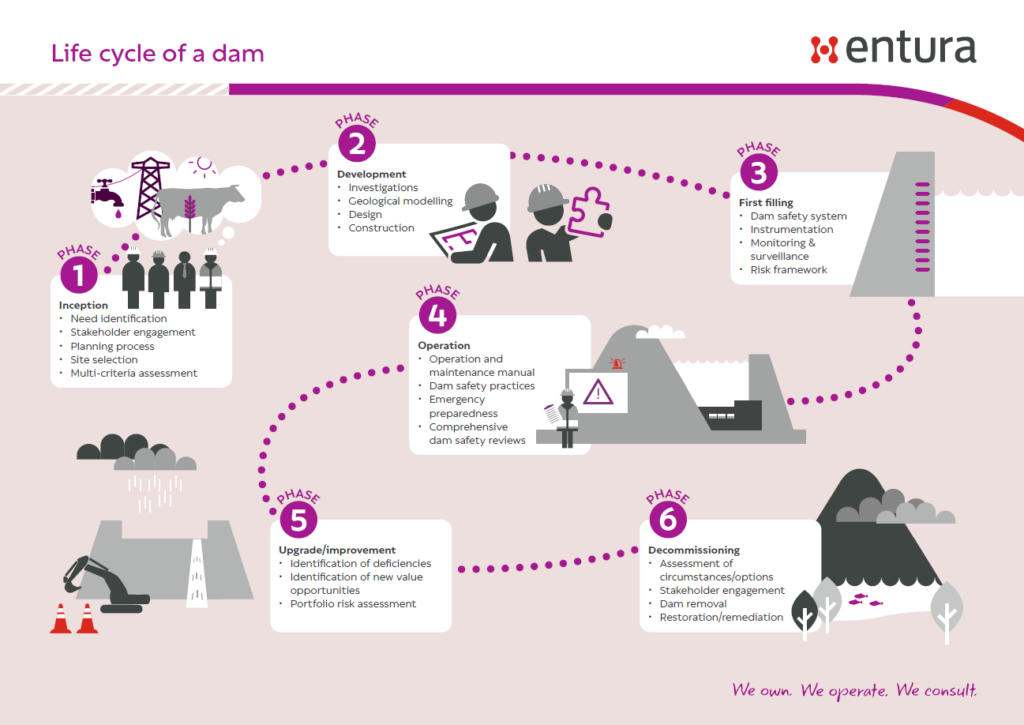

The life cycle of a dam – Bringing it all together

Dams, like all of us, go through several life stages. Some dams have harder lives. Some age more quickly. Some need a lot of attention, and some are more robust. Let’s talk a bit about a dam’s life – and revisit some of our previous articles on dam engineering.

Phase 1: Inception

The starting point of the dam life cycle is the planning process – where a need is identified and it is determined that the way to meet that need is to create a water storage by constructing a dam. It is essential that this planning process involves effective stakeholder engagement. Although there may be a primary purpose for the dam, it is very common through the stakeholder engagement process to consider other benefits that the dam could provide, making it a multipurpose dam.

The planning process will lead to the site selection stage. Choosing a suitable site which is both technically sound and environmentally and socially acceptable will have a significant impact on the remaining stages of the dam’s life. Multi-criteria assessment can help get the selection right, ensuring technical, financial, environmental and social aspects are considered in a balanced way.

Read our articles:

- ‘No dams’ or ‘right dams’? That is the question

- Make better decisions about hydropower and dam project options using risk-based multi-criteria assessment

Phase 2: Development

The development phase includes the investigation, design and construction of the dam. Every dam site is different, and it is important to understand this. As a result, the ideal dam type for one location will not be the same as for another location.

Read our article:

It is important that the risks associated with the dam site are known and understood. A key risk is the geological aspects of the dam’s foundation. Are there defects that could impact the stability of the dam? Are the foundations erodible? Could permeability be an issue? A staged investigation program formulated around the geological model will help to provide this understanding.

Read our article:

Design must be in accordance with current practice, guided by engineering standards and guidelines such as ANCOLD guidelines and ICOLD bulletins. Construction needs to be in accordance with the design and should be conducted using an appropriate quality assurance system and quality control program. An Independent Technical Review Panel (ITRP) helps avoid anything falling through the cracks. (The Queensland Dam Safety Management Guideline provides some guidance about this.) An ITRP will provide strong technical governance during design and construction, utilising the collective knowledge and experience of its members.

Read our article:

Phase 3: First filling

The next phase of the dam’s life is the first filling. This is a very exciting time, but it is also known to be the highest risk stage of a dam’s life. As a result, we need to be prepared. A dam safety system needs to be in place, along with the necessary instrumentation to monitor the dam during this first fill.

Read our articles:

In case of any incident occurring during first filling, it’s crucial that the dam safety emergency plan has been prepared and the dam safety manager identified. As the dam fills, there should be a heightened level of monitoring and surveillance, using this information to compare the actual performance against what was expected.

Entura has used a risk framework to determine a dam’s readiness to impound, such as for Murum Dam in Malaysia. Of course, some reservoirs take a long time to fill, potentially over a number of years, so this heightened level of monitoring and surveillance could go on for some time. There could also be saddle dams that experience water against them much later than the main dam.

Phase 4: Operation

Now begins what, hopefully, will be a long phase of normal operation. The dam will have an operation and maintenance manual to ensure that the dam is operated as intended and regular routines occur. Good dam safety practices must continue throughout the operational life, including dam surveillance, routine inspections, and ongoing emergency preparedness should any dam safety incidents, major floods or seismic events occur. Emergency plans should be tested regularly to ensure they are appropriate and robust.

Read our articles:

- What can dam owners do to better manage floods and avoid the blame game?

- How robust is your emergency preparedness?

- Planning for the future – the challenges of dam inspection and maintenance

During the operational phase of a dam, it is also important that comprehensive dam safety reviews (DSRs) occur every 20 years, or whenever there has been a major event or a change in standards or guidelines. The intent of a DSR is to determine the safety of the dam against current practice and the current condition of the dam. It’s important that the DSR considers the potential failure modes for the dam.

To undertake a DSR, good historical documentation for the dam will be needed. If the records aren’t great, or there are significant gaps, the DSR may require additional investigations and analysis to be undertaken.

Read our article:

In addition, it is critical that the public is kept safe around dams and throughout the operation of dams. In 2012 ICOLD established a working committee to identify these public safety risks, describe the international state of practice to manage and mitigate the risks, and develop a guidance bulletin on best-practice measures and public education about safety around dams.

Read our article:

Phase 5: Upgrade and improvement

If the DSR identifies deficiencies in the dam, a dam safety upgrade may be needed. This is the next stage of a dam’s life. A risk framework can often be used to justify and guide these upgrades.

Read our article:

Dam upgrades may not always be due to a dam safety issue; they may also be driven by the opportunity to increase value, which may be able to be achieved through measures such as raising the height of the dam. They can also be driven by changing design standards, changes to legislation, greater understanding about extreme hazards, or (more recently) climate change impacts.

Read our article:

With a large portfolio of dams, the demand on resources (both capital and human) can be significant. A portfolio risk assessment (PRA) allows owners of dams and other water assets to see the bigger picture of how to prioritise their efforts and resources to achieve the best safety results across the whole portfolio.

Read our articles:

- Portfolio risk assessment takes dam safety programs to the next level

- Safer dams are a matter of priority

Phase 6: Decommissioning

This final phase of a dam’s life may actually never occur, as most dams continue to provide a valuable service to society indefinitely. But, with time, the needs of the community may change, or the commercial benefits of the dam may reduce. In these circumstances, the dam may be decommissioned and removed. This decision is not likely to be made quickly, and for good reason, as this is a very complex matter involving many stakeholders. A recent example is the landmark decision to remove 4 dams along the Klamath River in northern California and southern Oregon. This is the most extensive dam removal and river restoration project in US history.

Although some dams may at some stage be decommissioned and removed, more dams will always be needed to meet the world’s needs for water security, clean energy, and storage of mining tailings.

Read our articles:

And so the life cycle begins, all over again.

Reflections from the global stage

As the industry evolves to meet the challenges of aging infrastructure and the transition to clean energy, staying connected to international best practices is more important than ever. Participation in the International Commission on Large Dams (ICOLD) provides a unique vantage point on how these global trends are shaping the future of dams.

Read our articles:

- New technologies are important tools, but they need to be used properly

- ‘Dams for People, Water, Environment and Development’ – some reflections from ICOLD 2024

If you would like to speak with us about your dam project, please contact Richard Herweynen.

About the author

Richard Herweynen is Entura’s Technical Director, Water. He has more than three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and was the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

13 August, 2024