Are you investing in your most valuable asset?

There is banter doing the rounds on social media: One person asks, ‘What if we develop our people and they leave?’ The retort that quickly follows is, ‘What if we don’t develop our people and they stay?’

If we ask senior managers at power and water utilities about the critical factors in managing their assets, they might refer to balancing business risk with financial constraints while maintaining mandatory statutory compliance. They might list things such as asset management strategy, plant capability, plant reliability, plant performance, spares inventory, adequate OPEX budget, real-time data and effective software platforms.

Prompted further, leading utilities are making the link between delivering key functions and developing their people. Utilities are starting to see the need to invest in the development of their people as well as their systems and processes to help ensure implementation of sound business strategy. They may go as far as including people resources on their asset management breakdown structure.

Power and water utilities the world over, whether public or private, are entrusted with managing important infrastructure providing a range of essential services to their customers. The effective operation of these utilities is a concern for governments, shareholders and communities alike, and utilities are increasingly focusing on being customer-centric, commercially focused, and operationally efficient.

Many openly specify a vision or mission that requires the business to embark on a ‘change journey’, using words such as responsiveness, innovation, reliability, modernisation, optimisation, safety, communication, sustainability, operational excellence, commercialisation and continuous improvement.

There is a commonality in many of these words, and that is people. It takes people to be responsive and commercially focused, to behave safely and to communicate. It also takes people to understand current performance and identify innovations.

Effective and efficient delivery and operation rely on people having the right skills and the competency to bring about change. The change may include new technologies and systems that people will need to learn to apply. So, cultural change is at the heart of any such journey, taking into consideration the desired future state, the behaviours (as well as the skills required to get there), and effective engagement and empowerment of employees along the way.

Over the years, I have worked with various power and water utilities, as well as developers and financiers, to lift capability across technical and managerial levels. I notice that, while people and their capability is on the minds of senior managers, there can be a disconnect with strategic direction, with no real integration with operational performance or workforce planning, and often a skewed view on what lift in capability is really required.

Change is coming

Around the world, a more integrated approach to utility operations is emerging. Globally, organisations are working toward change through integrated ‘asset management’ approaches that combine consideration of physical, people and process assets.

For many utilities, the natural assets are also important as an input that must be managed sustainably (e.g. water resource) or managed to meet regulatory and customer expectations.

Other frameworks help organisations to link human, financial, social and manufactured capital when implementing strategy. Whatever the framework, the integration of all ‘assets’ or ‘capital’ is important in achieving the somewhat elusive ‘operational excellence’.

We know that fundamental to the success of a transformation journey is a sustainable workforce aligned to achieving the vision, mission and strategy of the business through the development of appropriate knowledge, skills and behaviours that focus on the business’s longer term goals. Thus, a whole-of-business approach to learning and development can play a critical role in successful implementation of strategy. Integration is needed across the various typical functional areas: strategy, finance, operations, human resource management and so on.

Success requires integration and alignment

Clients often ask the Entura clean energy and water institute to assist them with particular training in one of our key technical topics. Through further conversation, I often find there are other aspects in the holistic picture that need to be painted first. Are the procedures in place around which to train? Will this capability be important in the future? Will the learning and development activity address key risks? Who else in the business needs to understand these issues? Does it align with the strategic direction?

Integrating learning and development into business planning and operations is one way to ensure that capability development programs are designed in the context of strategy and initiatives, workforce planning, operational plans, HR systems, functional structures and mechanisms, and risk management activities.

Through facilitated workshops, senior management teams can set the broad direction for learning and development. This direction can then feed into more detailed capability assessments and training needs analyses. Through such an approach, investment in training is effectively apportioned in the right direction with the greatest chance of ultimately improving organisational success.

Taking the time and effort to prioritise capability development and ensuring it is aligned with strategic direction will bring ultimate rewards for utilities and bring a real return on investment. Not only will investment in capability development be better directed, it will assist with the wider challenge of engaging employees in the change journey itself.

If people grow fatigued with change, learning can rejuvenate and inspire. As Leonardo da Vinci once said, ‘Learning is the only thing the mind never exhausts, never fears and never regrets’.

If you would like to discuss how to integrate learning and development objectives with business strategy or to design a training program to suit your organisation, contact Dr Amanda Ashworth on +61 417 503 692.

About the author

Dr Amanda Ashworth is the Business Manager for the Entura clean energy and water institute. She is responsible for strategic development and operations including partnerships, client engagement, course development and oversight. Amanda also provides strategic advice on learning and development frameworks and contributes to leadership and management training for clients. Combined with her passion and commitment for capability development and training, Amanda’s research background and more than 20 years’ experience in environment, clean energy and water consulting and strategic planning, enables her to support clients to understand their capability and identify the right program of activity to meet their needs and bring organisational success.

MORE THOUGHT LEADERSHIP ARTICLES

Managing risks for successful, sustainable projects

All power and water projects involve risks. The key to project success and sustainability is being able to anticipate, monitor and manage the full range of risks throughout the project lifecycle.

For power and water asset developers, sustainability is increasingly recognised as a key marker of project success and corporate reputation. Whether you’re building a hydropower station, a dam, a wind farm or a solar farm, achieving sustainability means ensuring that projects appropriately balance technical, environmental, social and economic considerations to deliver benefits and minimise risks across all these areas.

Power projects, especially in developing countries, hold great potential to contribute to the greater good by increasing prosperity and alleviating poverty, but growth must be balanced against any current and future impacts on communities or the environment. Sustainability is therefore a key concern for responsible developers, and for international financing organisations such as the Asian Development Bank, the International Finance Corporation and the World Bank.

Managing risks carefully, ethically and transparently can improve the financial and technical viability of the project, the ability to secure finance, the ability of key stakeholders to make informed decisions about the project’s future, the likelihood of community acceptance or ‘social licence to operate’, and the overall project outcomes, both now and for long-term success and sustainability.

What are the risks?

Some of the key risks to be considered throughout the design, development and operation of a power or water asset include factors such as the need or market for the project, the future energy or water demand, the best technology or design for the project, and the current and future availability of the resource.

It is also critical to consider the project’s stakeholders and broader community, particularly whether the project could involve potential social or environmental impacts and how these could be avoided, mitigated, offset or compensated, not just during development of the project but also during operation. Safety is also a key issue to be managed throughout a project’s life, including that of employees as well as the broader community.

Although not all risks will necessarily be able to be fully predicted, businesses are likely to gain substantial benefits from making structured and systematic efforts to foresee risks across the spectrum of financial, technical, stakeholder, community and environmental issues.

Assess risks early and often

Many project risks can be minimised or mitigated if they are properly anticipated early in the project, and progressively monitored and evaluated throughout the design, development, construction and operational phases.

Identifying key risks early allows companies to manage these risks throughout the project, minimising corporate, technical, environmental and social impacts and their associated costs, including damage to corporate reputation should an unmanaged risk develop into a crisis.

Assessing the risks progressively or in stages can minimise not only the cost of formal evaluation, but also save significant time and costs that could be wasted if a project were to be judged unviable during development.

Sustainability assessment, both formal and informal

Being able to formally or informally assess and comprehensively document risks and actions towards project sustainability offers significant advantages. While it can help guide a comprehensive review of risks, it can also help to identify further opportunities to increase positive outcomes. As well, it provides an easy way to regularly assess progress towards sustainability goals against established baselines, and offers a format for clear reporting both internally and to external funding bodies and stakeholders. In other words, sustainability assessment and reporting is a valuable step in demonstrating a genuine commitment and responsible approach to achieving greater sustainability.

Entura uses a unique, tailored self-assessment tool to help power and water companies and developers understand the risks and opportunities facing their projects and build their capacity to assess, monitor and report on those projects. This tool is based on the assessment criteria identified in internationally recognised guidelines and standards such as the Hydropower Sustainability Assessment Protocol and those used by the International Finance Corporation.

The sustainability scanning tool can be used by an organisation to self-assess a project to identify whether key issues, risks and opportunities have been fully considered and to identify potential gaps needing further attention. This can be done internally following training on how to assess the criteria or undertaken by Entura’s trained assessors.

In addition, Entura’s sustainability scanning tool can be adapted to include other standards relevant to a project or client, or to assess compliance with criteria relevant to a client’s requirements or obligations (such as internal policies and/or permit or concession conditions). It can be used at any stage, or multiple stages, of a project, and for any level of sustainability goal (i.e. good practice or best practice). It can also be repeated over time for the same project to assess ongoing improvement, or to compare projects across a client’s portfolio.

The potential benefits to power and water asset developers of a systematic and thorough identification and management of the full range of project risks include easier access to finance, reduced corporate risks and costs, greater ability to anticipate and respond to stakeholder concerns, and avoidance of delays and problems through the project’s life.

This holds promise for delivering power and water infrastructure projects that are more likely to contribute positively to social, environmental and economic goals both now and into the future.

If you would like to discuss how Entura can assist you with assessing the sustainability of your project or support you to assess and track your own progress towards minimising risks and increasing sustainability, please contact Dr Eleni Taylor-Wood on +61 3 6245 4582 or Shekhar Prince on +61 412 402 110.

About the author

Dr Eleni Taylor-Wood is Entura’s Principal Consultant, Environmental and Social Science. Eleni has 20 years’ experience successfully managing large-scale, complex projects, as well as providing expert advice and independent review for a range of infrastructure and planning projects. She has worked on projects around the world including in Australia, Mozambique, South Africa, Iceland, Colombia, India, Malaysia, China, Solomon Islands, Fiji and Papua New Guinea. Her experience includes environmental and social impact assessment and management, strategic management of wetlands and waterways, feasibility and approvals for new hydropower projects, environmental flow determination and assessment, and sustainability assessments. Eleni is currently one of eleven accredited assessors worldwide under the Hydropower Sustainability Assessment Protocol.

MORE THOUGHT LEADERSHIP ARTICLES

Using risk assessment to guide dam safety upgrades

Whether your focus is on a single dam or a whole portfolio, a risk assessment process helps you decide how best to intervene, and when, to get the maximum improvement in safety from your investment.

Using a risk assessment process to assess a whole portfolio of dams helps asset owners prioritise their limited resources for safety upgrades. Richard Herweynen, Entura’s Principal Civil Engineering, introduced our portfolio risk assessment program in his article ‘Dam safety: protecting lives and driving efficiencies’. Now we explore how a similar process can be used for a single dam to guide investigations, prioritise the order of a staged upgrade, and manage safety risks during construction, using the example of Hydro Tasmania’s Rowallan Dam.

The challenges of an ageing dam

Rowallan Dam is a 43m-high earth and rockfill dam built in the late 1960s, with two embankments on either side of a spillway located on a knob of very hard quartzite. The reservoir plays a key role in Hydro Tasmania’s hydropower system: it is a large storage at the top of the catchment and operates over a large range of water levels, capturing the high winter flows and then releasing them over the summer months through a cascade of five power stations downstream.

A dam portfolio risk assessment (PRA) completed by Entura in 2006 had identified Rowallan Dam as one of the potentially higher risk dams in Hydro Tasmania’s portfolio, with a number of suspected but not confirmed deficiencies. The potential deficiencies included a relatively high probability of a piping failure (internal erosion of the earthfill) as the filters were suspected to not meet modern standards and the dam had suffered a piping incident adjacent to the spillway walls when it was first filled.

As well, the PRA identified other potential deficiencies including questions regarding the spillway capacity, liquefiable foundations, potential for landslide hazards at the reservoir rim, structurally deficient spillway walls, and a limited capacity for dewatering.

With multiple potential deficiencies such as these, a range of challenges arise: Which deficiencies do we tackle first? Do we need to address all the deficiencies? To what level do they need to be addressed? How quickly should we address the deficiencies? And how do we justify to the business a large capital expenditure that will not generate any additional returns?

Reducing uncertainty

The original scope of the PRA was to assess the dam portfolio based only on the existing available information with the exception of preliminary dam-break modelling and consequence assessment. To allow the PRA to be completed within a reasonable timeframe and budget, this inevitably meant that significant gaps in our knowledge of the dams were filled with assumptions and best estimates.

A very targeted investigation program was then required to fill the gaps in our knowledge of Rowallan Dam’s particular possible failure modes and to prepare a fully justifiable business case. Entura led the investigation and concept development phase, working closely with external parties. The necessary investigations included:

- geological mapping of the potential landslide features (to determine whether they were in fact glacial features and not of concern)

- investigation into the core, filters and rockfill of the embankment (to confirm their properties)

- more detailed dam-break modelling (to confirm whether the original estimates of consequences of failure were correct)

- drilling of the left embankment foundation (to demonstrate whether liquefaction was a significant concern)

- full modelling of the flood hydrology (to confirm the flood risk)

- structural analysis of the spillway walls supporting the embankment on either side of the spillway chute

The spillway wall failure mode had not been identified in the PRA and was included in the investigation program to demonstrate that it was not a concern; however, it turned out to be the failure mode with the highest probability, and became the highest priority of the upgrade program.

Developing the upgrade program

When the specific investigations for Rowallan Dam were complete, the risk assessment for the dam was revised. The revised risk assessment determined the potential failure modes (in order of probability) to be failure of the spillway walls; piping along the spillway walls; piping through the upper part of the embankments; piping through the lower part of the right embankment; and overtopping of the dam during an extremely rare flood (rarer than a 1 in 10 000 year flood).

Developing an integrated, effective and progressively implemented solution that would not increase the dam safety risks during construction was a major challenge. Many alternatives for the outlet works, spillway augmentation and spillway walls were developed by Entura for resolving each dam safety risk while considering the construction flood risks and overall project risks. This allowed Entura to find the right package of solutions to minimise the risks as well as the capital outlay. The ultimate solution included:

- increasing the monitoring of the spillway walls: To provide early warning of a possible failure, inclinometers were telemetered and alarmed. Monitoring picked up a possible deterioration in one wall, which was temporarily propped until a permanent solution could be implemented.

- increasing the dewatering capability of the dam: The riparian valve was replaced with one of greater diameter, and the controls of the turbine relief valve were modified to allow emergency bypass. This increased dewatering capacity was critical to managing flood risks during the later stages of construction and improved the ability to control any potential piping failure.

- strengthening the spillway walls on the inside of the existing walls: This approach incurred less risk of overtopping during construction than if the walls were strengthened on the embankment side. The replacement walls were designed to accommodate higher future discharges.

- installing modern, compliant embankment core filters: Installing these filters would protect the embankment from piping, but required major localised excavation adjacent to the spillway walls, including from the embankment crest to foundation, and reconstruction of the top seven metres of the embankment.

Lower risks, greater compliance

The major upgrades at Rowallan Dam have now reduced the dam’s safety risks. By considering a wide range of upgrade options and demonstrating that the selected option would significantly reduce the risk of failure through very targeted capital works, the Rowallan Dam risk assessment played a key role in developing a sound business case to demonstrate that the capital investment was both necessary and efficient – for a safer dam, both now and long into the future.

To find out more about how Entura can work with you to assess and remedy the safety risks of your dams or other water infrastructure assets, please contact Paul Southcott on +61 3 6245 4145, Phillip Ellerton on +61 439 010 172 or Shekhar Prince on +61 412 402 110.

About the author

Paul Southcott is a specialist civil engineer at Entura. He has more than 28 years of professional expertise in civil and dam engineering, as well as expertise in geotechnical, foundation, structural, hydraulic and hydropower engineering. Paul’s dam engineering experience spans geotechnical and hydrological investigation; feasibility and options studies; concept, preliminary and detailed design; engineering assessment, consequence assessment and risk assessment; safety reviews; monitoring and surveillance; and emergency planning. He has particular expertise in dam risk assessment and project managed the Hydro Tasmania portfolio risk assessment of 55 large dams, Southern Water’s 18 dams and most recently SA Water’s 18 large dams. He was the technical leader for the Rowallan Dam upgrade project overseeing all aspects of the project including the detailed design of the spillway wall upgrades.

MORE THOUGHT LEADERSHIP ARTICLES

Prioritising safety at Rouna 2 hydropower station, PNG

As the saying goes, ‘safety doesn’t happen by accident’.

The measures taken to address safety risks at the underground Rouna 2 hydropower station in Papua New Guinea offer a timely reminder of the basic requirements for adequately managing safety risks and protecting workers when upgrading older hydropower stations or when developing new ones.

The upgrade of Rouna 2 – including adequate exits, flood protection, fire and smoke detection and control, and emergency management – illustrates that much more than just the main generating equipment needs attention to adequately identify and address safety risks and hazards in a hydropower station.

A run-down, risky hydropower station

Rouna 2 is one of four stations operating in a cascade down the Laloki River. It has five 6 MW vertical-axis hydro units from the late 1960s housed in an underground machine hall. Although only a small station, Rouna 2 has all the complexity and requirements of a much larger station.

By the time specialist power and water consulting firm Entura began working on the project to upgrade Rouna 2, the power station was old, run down by years of hard work, and was presenting its owners and workers with safety risks typical of many older hydropower stations.

The initial project concept was simply to refurbish the machines, but it quickly became clear that repairing or replacing only the generating units wasn’t going to be enough to sustain the power station’s operation, and that safety concerns needed to be urgently remedied.

Upgrading station evacuation

The Rouna 2 power station originally had only one access and exit route for the underground machine hall via open stairs in a 200 metre-deep vertical access shaft. No alternative emergency exit route was available. As the access shaft also contained all the power and control cables, it further intensified fire and safety risks.

To improve evacuation, a new emergency escape route was created via new ladders and platforms down the tailrace surge shaft to the tailrace tunnel, which normally carries water out of the power station.

Within the machine hall, the emergency escape route was made safer by being enclosed and made fire resistant, and kept smoke-free by a fan started automatically. Smoke hoods (emergency evacuation masks that reduce the risks of inhaling toxic smoke and gas) are provided to offer temporary protection for personnel needing to cover large distances to the start of the safe escape route.

To provide adequate lighting and signage for emergency escape, the DC-powered emergency lighting was upgraded. Evacuation alarms were improved, including strobe lights as well as audible sirens.

Improving flood protection

An underground power station surrounded by huge quantities of water under high pressure is particularly vulnerable to flooding. Rouna 2 had poor flood protection and dysfunctional evacuation alarm systems.

The evacuation alarms were upgraded and linked to flood detection within the machine hall. An automatic flood protection scheme was implemented to shut down the underground generating units and close the surface intake gate.

Improving fire and smoke detection and control

Hydropower stations are at risk of fire because they are full of electrical equipment. The Rouna 2 station had no fire detection system and minimal fire protection systems, so urgent attention to all fire measures was needed.

New fire panels and a new fire detection system were installed, as well as a new fire-fighting water supply, fire hydrants and hose reels. Sprinklers were installed in the access shaft and the machine hall. Older carbon-dioxide-based fire-protection systems for generator fires were replaced with water-spray systems. Fire doors were rehabilitated to close automatically.

Implementing an innovative new ventilation system

Ventilation systems in hydropower stations seldom provide any adequate smoke removal, despite the dangers of smoke inhalation. Technical innovations in the upgrade of Rouna 2’s safety systems included methods for smoke control integrated with the station’s ventilation system and its new fire panels and doors.

We upgraded the ventilation and smoke exhaust system by automatically reversing the ventilation fans during a fire, so that they exhaust smoke from the machine hall to the surface, and draw fresh air back down into the machine hall. At the same time, automatic fire doors close within the machine hall.

A safer power station for a safer future

Although new, large hydropower developments typically embrace complex and comprehensive safety standards and features, around the world many older stations are seriously deficient, presenting hazards that urgently need to be identified and resolved. Through our improvements to its ancillary services and safety systems, Rouna 2 is no longer in this extreme risk category.

However, adequate safety facilities are not the only requirement to maintain a safe hydropower station. Workers need the knowledge to maintain safety features, equipment and systems, and the skills to use them effectively. Entura has provided contract operators and station managers to work alongside local employees to help improve emergency and crisis management systems, provide local training and build capacity to ensure that Rouna 2’s future promotes a safer power station and safer workers.

To discuss how Entura can assist you with assessing hydropower station risks or developing a hydropower safety program or upgrade, please contact Shekhar Prince on +61 412 402 110.

This article was written by Ambrose Canning, Entura’s Principal Consultant, Mechanical Engineering (retired 2025).

MORE THOUGHT LEADERSHIP ARTICLES

Safer hydropower stations for safer workers

“Practices related to dam safety are well-defined and accepted throughout the world. However, hydropower safety encompasses more than just the dam … while hydropower safety is of critical importance, there is little shared knowledge on good practices around the concept of hydropower safety.” – International Hydropower Association

Hydropower stations can pose significant safety risks to those who work in them, but there is no excuse for injury or death in our workplaces. Whatever the history or location of the hydropower station, safe plant and safe work practices are critical.

Developers, owners and operators of hydro plant all need a strong commitment to workplace health and safety, and the insight and vigilance to control safety risks. As the saying goes, ‘safety doesn’t happen by accident’.

The hazards of hydropower stations

Some of the hazards at hydropower stations differ from those at thermal power stations or commercial installations. For example, hydro stations typically have limited access and no natural lighting, lower floors are often below the outside water level, and many are underground.

Hydropower hazards include fire, explosion (e.g. of pressure vessels), electrocution, flood, entanglement, slips and falls, chemicals (e.g. sulfur hexafluoride, hydrogen sulfide) and hazardous products (e.g. asbestos), and asphyxiation (e.g. carbon dioxide).

The level of risk presented by each hazard is a combination of its likelihood of occurring and the consequences if it did occur.

Seven ways to make a hydropower station a safer place

Designing safety into hydropower stations

When designing and implementing a new hydro scheme, or when upgrading an existing station, we need to carefully consider the standard of workplace health and safety to be achieved and the scope of work necessary to achieve it. This means understanding the relevant legislation, building codes and standards, and the requirements of the insurer; and being clear about the responsibilities of all the parties involved (such as the designer, developer, owner and contractors).

But while standards, codes and guides are a good starting point, the final solution needs to be tailored for the particular circumstances and level of risk. Safety systems for hydro plant can be complex and sophisticated, but they can also be as simple and robust as appropriate for the hydro facility being protected.

The primary consideration should be to provide safety facilities to get personnel out of a hydro station safely before conditions inside become dangerous. The second consideration should be providing facilities to get people out safely after conditions become dangerous. Only thirdly do we think about safety facilities to prevent damage to plant.

Planning ahead to control risks

A general approach taken to minimise workplace risks to the lowest practical level involves planning ahead for prevention of workplace accidents, injuries and illnesses, by ensuring that systems of work are safe, equipment is safe and properly maintained, and employees receive health and safety information and training and are properly supervised.

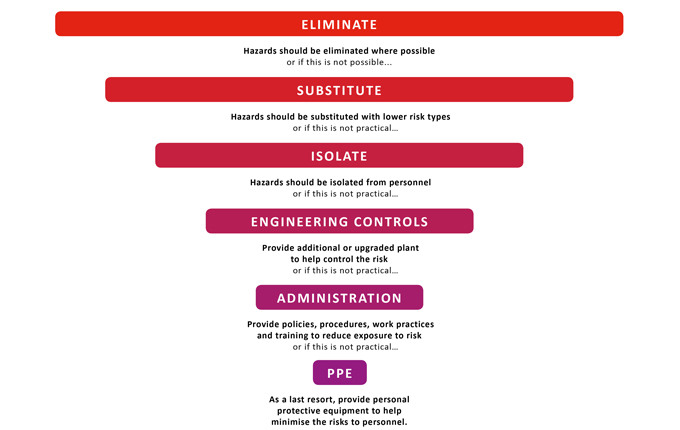

This approach is usually expressed through a ‘hierarchy of controls’:

Safety upgrades for older hydropower stations

Typically, new hydro stations are well designed and comply with appropriate safety standards and local building codes. Larger hydro stations can have safety systems as complex and thorough as those in modern multi-floor commercial buildings. However, older hydro installations were often designed with little regard to safety, and now need urgent attention to comply with modern workplace health and safety standards.

While safety facilities are readily incorporated into new hydropower schemes, they may be more difficult to retro-fit into existing schemes. The scope of work will need to take into account the interfaces with existing facilities and the tailoring required to suit the specific site and location.

Sharing our hydropower safety insights

Entura is part of Hydro Tasmania, Australia’s largest producer of renewable energy and manager of more than 30 hydropower stations with an enviable safety record. As a specialist power and water consulting firm, we’ve applied this real-world experience of designing safe hydropower stations and upgrading older plants to meet modern safety standards as we work with clients all over the world to improve the safety of their assets.

In our experience, these four very important aspects of hydropower safety should be considered as a first step towards building good practice for designing and operating safer hydropower stations:

| Station evacuation | Whatever the nature of the crisis, people must be able to get out of a hydropower station safely. All stations should have at least two independent ways to exit. If one route becomes inaccessible, an alternative emergency escape route should always be available. Adequate lighting is essential for emergency escapes. |

| Flood protection |

Hydropower stations can and do flood. Failure of drainage pumps can lead to a slow increase in the water level and eventual flooding of the station. Alternatively, a plant failure and leakage that drainage pumps cannot manage can cause rapid flooding of the station. This makes high-water-level alarms, flood alarms and evacuation alarms a necessity for life safety. Flood protection schemes can be implemented to automatically close intake gates or hilltop valves and keep turbines operating to attempt to drain the headworks and penstocks of water to control flooding, and to automatically stop hydro plant before the water levels become critical. |

| Fire and smoke control |

For life safety, we need to detect fires as early as possible, prevent them from spreading, alert all personnel, and provide safe and well-lit means of evacuation as soon as possible. Smoke control and ventilation are also extremely important. Fire will rapidly fill a hydro station with thick, black, acrid smoke, which is often a far greater hazard to personnel than the fire itself, as it obscures vision (preventing occupants from finding safe escape routes, as well as hindering search and rescue operations). It can also asphyxiate or poison people well before the temperature of the fire or smoke causes injury. A holistic fire protection system needs to attend to the full range of passive measures (e.g. fire-rated construction materials and methods), active measures (e.g. sprinklers, venting, fire-fighting equipment) and operational measures (e.g. plans, systems and training for fire prevention and response). |

| Emergency and crisis and management |

Safety at hydro stations involves more than simply having the correct equipment or hardware present at the site. It involves an ongoing commitment by the owner, management, operator and employees to provide and maintain a safe and healthy work environment. This commitment should be documented in writing and form part of a workplace health and safety policy supported by safe work systems and documentation. These should include a written risk control program and fire protection program, hazard register, site induction procedures, attendance boards, permit to work systems, local safety teams, and a detailed crisis and emergency plan. |

To discuss how Entura can assist you with assessing hydropower station risks or developing a hydropower safety program, please Shekhar Prince on +61 412 402 110.

This article was written by Ambrose Canning, Entura’s Principal Consultant, Mechanical Engineering (retired 2025).

MORE THOUGHT LEADERSHIP ARTICLES

Flood forecasting for a safer dam upgrade

An effective flood forecasting system is a vital tool for managing the significant risks that floods pose to communities, infrastructure and the environment.

If you can clearly understand the likelihood and scale of potential flooding and get accurate and timely warnings, you can better manage water infrastructure and implement safety plans in time to protect assets and communities at risk.

For hydropower businesses such as Hydro Tasmania, flood forecasting is a critical part of managing dam risk. Specialist power and water consulting firm Entura provides real-time inflow and flood forecasting and data management solutions to help manage Hydro Tasmania’s extensive catchments and 55 major dams.

Our most recent example of the risk-reducing benefits of flood forecasting systems is the major upgrade in 2014–15 of the Rowallan Dam on the Mersey River in Tasmania’s north, first built in 1968. The 43m-high earth and rockfill dam needed total refurbishment to be sure of a long, safe future.

Significant work was needed to bring the dam up to modern engineering standards and to increase its capacity to withstand large floods. To complete the necessary upgrade works, Rowallan Dam had to be excavated from crest to foundation on both sides of the spillway walls, exposing the heart of the dam.

The Rowallan Dam flood forecasting system allowed operators to confidently manage the flood risk during construction, ensuring the safety of construction workers and the public downstream, and protecting infrastructure and the environment from major flood damage.

The need for flood and lake-level forecasting at Rowallan Dam

During the construction phase of the major upgrade, Rowallan Dam faced a higher than normal risk of exposure to floods. Overtopping of the temporarily lowered dam crest during construction would compromise dam safety.

Kim Robinson, Senior Hydrologist and Project Manager for the Rowallan Dam flood forecasting system, said “This work was unprecedented in Australia because it was undertaken on a live dam, holding back Lake Rowallan – with a capacity of 130 000 megalitres.”

Kim explained that forecasts of lake levels were needed so that Lake Rowallan could be kept at the appropriate target level during the major excavation and refurbishment works. For safe work, the lake level needed to be lowered significantly by periodically opening a bypass valve to release water from the lake.

“The lake level needed to be low enough for safety, while also not losing too much valuable water, and potential revenue, by releasing too much water through bypass valves rather than through the power station,” Kim said.

As well as the required forecast of lake levels, a flood forecast was needed to indicate when emergency backfilling of the dam crest may be needed.

“The sensitivity of when to trigger this kind of action was a particular challenge” said Kim. “If backfilling was not carried out in time and a flood breached the construction works, the dam would be at risk of failure, with serious consequences for the storage downstream and potential impacts on communities.”

On the other hand, triggering an emergency backfill would be likely to delay construction by a year, with large financial impacts. “Backfilling is expensive and would risk extending the construction period into the wet season and the following summer,” said Kim, “which would be very costly both in terms of construction and from losing water that could have been used to generate power”.

A robust, effective flood forecasting solution

The solution to maintaining optimum lake levels and flood preparations during the Rowallan Dam upgrade was to develop a best-practice flood forecasting system, combining measured data from sensors at key locations with rainfall forecasts from weather forecasting agencies into a hydrologic model of the catchment.

“The modelling predicted lake levels and the time it would take for water to reach critical levels that could jeopardise the dam, always ensuring sufficient time for emergency backfilling,” Kim Robinson said. “The critical level varied depending on the depth of construction works, and maintained the same level of flood risk at all times.”

The entire modelling process ran automatically and provided an updated forecast every two hours during the construction period. Plots were developed showing the best-estimate forecast of inflow and lake level and rainfall over the catchment. The operators and construction managers used these plots to guide the operation of the valves to keep the lake at appropriate levels and to ensure appropriate preparation for emergencies.

Kim Robinson explained that alerts were set to trigger if the forecast exceeded the critical level. Plots were disseminated continually via email and a website. In an emergency, SMS and SCADA flood alerts would be sent out to relevant parties. If a flood alert was issued, the dam safety emergency plan would be activated.

“The system was made more robust by building in redundancies in the modelling and developing a stand-alone system at the dam site that did not require continuous connection to the database. This could be used if communications with the dam site were lost,” said Kim.

Striving for accuracy and certainty

For users to have confidence in the outputs of the flood forecasting system, it was important that the input data and hydrologic modelling were as accurate as possible, and that the level of certainty of the forecasts was clear.

“A plan was put in place to ensure that critical rainfall and flow gauges for the modelling were operational and that any maintenance required was undertaken within strict timeframes,” Kim Robinson said. “We developed routines to automatically check all input data for errors or missing data, and send alerts if inconsistencies were detected.”

Kim explained that the flood forecasting outputs included indications for operators of the uncertainty of both the rainfall forecasts and the modelling. “We developed the rainfall forecast uncertainty measures by comparing forecast rainfall to rain-gauge data over a historical period. The model uncertainty was estimated by running the model over a historical period with historical rainfall as input, and comparing outputs with measured lake levels,” he said.

The model has permanent ongoing value to the business and is being transitioned into the ongoing inflow and flood forecasting system which is used by Hydro Tasmania to manage power generation and dam safety risk. Learnings from this project are also being rolled out across the rest of a forecasting system which produces forecasts for 31 storages across Hydro Tasmania’s portfolio.

To discuss how Entura can partner with you to develop a best-practice flood forecasting system to help you better manage your flood-related risks, contact David Fuller on +61 438 559 763, Phillip Ellerton on +61 439 010 172 or Shekhar Prince on +61 412 402 110.

MORE THOUGHT LEADERSHIP ARTICLES

How can the grid survive distributed generation and storage?

A lot of the talk about the ‘death spiral’ in the demand for electricity from the grid in Australia has centred on the distribution end of the equation and the downside or asset risk associated with ‘disruptive’ technologies such as solar PV and storage.

I’ve suggested before that talk of the death of the grid may be premature. But how can the electricity industry respond to the advent of distributed generation and storage to embrace its potential benefits?

The grid is still required in some form

Historically, we have moved from a decentralised or local model of electricity generation and consumption to a more centralised generation model through the development of large-scale synchronous machines (hydro and thermal). This was driven by efficiencies and the high energy demands, both in volume and reliability, of industry.

The reduction in cost of distributed generation and storage is changing the efficiency equation for smaller users. But distributed generation and storage is not a viable alternative for all energy users, so the grid must remain in some form.

Balancing the value and cost of grid connection

All connected parties benefit to some extent from being connected to the grid. Generators get a delivery mechanism for their product. Industry gets an important input to production with high levels of reliability. Small businesses and homes get access to controllable and comparatively inexpensive energy. Customers with distributed generation and storage get access to a sink or source that can increase the value of their investment and cap their exposure to resource or equipment failure.

The network adds value to each of these transactions since without it the individual parties must all become self-sufficient. But this added value is not always perceived as adequate compensation for the cost of grid access. This distortion will ultimately lead to an over-investment in distributed generation and storage to go with an existing over-investment in the grid.

Reaping the benefits of distributed generation and storage

I think two changes could foster more efficient co-development of network infrastructure and distributed generation and storage:

- developing a real-time communication and control protocol with customer loads and storage

- re-evaluating the worth of the network, basing value not on sunk cost but on utility.

Developing a real-time communication and control protocol

To enhance the synergies between distributed generation and storage and the wider network, real-time status and control of loads and storage must be available to whoever needs it. The mechanics of this are not difficult unless response must be rapid. The sooner a standard or an accepted architecture can be adopted, the more efficient the transition and the faster the realisation of benefits.

One of the great challenges of distributed generation and storage for network operators is that it fundamentally changes the assumptions that can be made about the predictability of system demand in the minute-by-minute operation of the grid.

Linking available generation more directly to that demand alleviates some of the risk associated with the increased volatility on the demand side. It turns a looming risk into a relatively benign outcome, perhaps even a beneficial one.

For instance, if the decision to store is based on price and there is a small variation in this price setpoint across the storage fleet, then the amount of variation within one dispatch interval could be quite high, requiring larger amounts of regulation reserve to be dispatched for a larger percentage of dispatch intervals.

For large-scale renewable generators, linking to loads and storage may provide a way to increase demand to better utilise high potential yields that would otherwise be constrained in the market. The simplest example of this is a wind farm in a region where the interconnector to a larger region is at its limit. The wind farm output will be constrained even if more wind is available, unless additional demand can be found on the same side of the constraint as the wind farm.

Re-evaluating the worth of the network

Distributed generation and storage decreases some customers’ reliance on the grid. Those customers may value the grid less, but still pay the same amount to access it. And those customers are now saying this doesn’t make sense.

We know the grid does offer value. In capability terms (reliability and security), the grid is very valuable to most customers, even if they don’t appreciate it. But the grid is over-built in capacity terms for a market awash in distributed generation and storage. For many consumers, it is no longer a choice of whether to invest in distributed generation and storage, but rather a choice of what rating of inverter or storage.

Network charges cannot continue to be based purely on the sunk cost of the development and provision of the network. This worked when there was little alternative. But now that distributed generation and storage is viable for many, it is up to the network to improve its perceived value to keep its customers.

If customers’ willingness to pay is capped by a credible alternative, there is an easy choice for the rational customer with distributed generation and storage, and there is a hard choice for the electricity industry – change your pricing and enhance your product, or lose your customers. This reality is better dealt with sooner than later.

The grid of the future must be developed by considering distributed generation and storage, and comparing the relative costs of network development against distributed generation and storage developments.

It is critical that we ensure the grid is right-sized for the future. This will lead to any number of on-grid, hybrid or fully off-grid arrangements. For an efficient outcome, the flexibility and agility of grid design and operation must complement rather than duplicate the capability provided by distributed generation and storage.

It’s not the fall that kills you …

The grid has a role to play in the future delivery and consumption of electricity. But unless clear and correct signals are given to customers, the network will not follow an efficient trajectory to a new and suitable steady state, a soft landing.

A number of changes will help us create a bridge between where we are now (a grid that is increasingly unappealing to customers with distributed generation and storage) and where we need to be (a market with a seamless grid efficiently linking generators and loads). These changes centre on standardising technology and being open to adaptive network pricing and planning.

Accommodating the growing competitiveness of distribution and storage is essential to the long-term wellbeing not only of the electricity industry but also the economies it has nurtured and that sustain us all.

If you would like to find out more about how Entura can help you adapt successfully to the rapidly changing market for electricity generation and energy services, contact Donald Vaughan on +61 3 6245 4279.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Breathing new life into ageing assets: asset management in practice in PNG

The remote Ok Menga hydropower station in the Western Province of Papua New Guinea is vital to the operation of the Ok Tedi mine (OTML). It offers an example of just how expensive it can be when ageing power stations deteriorate and become increasingly unreliable.

The Ok Menga hydropower station provides almost three-quarters of the power needed to operate the mine, with the remaining power generated using expensive diesel fuel. The local power network is isolated and not connected to any of the country’s electricity grids, so any failure of the Ok Menga power station is costly.

If one of Ok Menga’s two generating sets is out of action, replacing that amount of hydropower (about 30 MW) with diesel-generated power could cost around AUD$650 000 a day in fuel alone. Worse still, a full outage of the power station could cause the mine to shut down, losing copper, silver and gold production worth around AUD$4 million per day!

The Ok Tedi mine had been scheduled to close in 2015, so preventative maintenance had not been a high priority for its owners, and the Ok Menga power station had become run down. When the mine’s proposed closure was delayed to 2025, a new operational strategy was needed to wring at least another ten years of useful and reliable life out of the more-than-30-year-old Ok Menga power station.

OTML needed the help of skilled asset management experts to extend the life of the Ok Menga power station, so it engaged specialist power and water consulting firm Entura to conduct an extensive condition assessment and come up with a risk mitigation plan to get the best out of the station in a cost-effective way. This also included building the skills and knowledge of OTML staff who had not had any formal training for years.

Ok Menga’s unique challenges

Although Ok Menga had many of the same asset management issues as any other hydro plant, it also presented some unique challenges in terms of risks and maintenance strategies. Its isolation and association with a large mining operation challenged many of the conventional rules fundamental to asset management in larger power utilities.

Leigh Smith, specialist consultant in asset management at Entura, explained: “In our asset management approach, we needed to take into account how the particular characteristics and circumstances at Ok Menga created differences for aspects such as the design life, planning outages, access to the plant, the holdings of critical spare parts, and the consequences of faults. For example, because outages at Ok Menga incur such high costs, we needed to replace rather than refurbish machinery, because they couldn’t have the machines offline for long.”

Bringing risks under control

Entura applied its best-practice asset management approach at Ok Menga by thoroughly assessing the condition, performance and remaining useful life of all aspects of the station, and developing a risk mitigation plan including urgent actions to remedy serious risks, and ‘quick wins’ to improve the state of the station quickly, cheaply and effectively.

As Leigh explained, “We report the condition of the plant in terms of business risk, and the mitigation strategies we propose are all about reducing risk to a level that’s acceptable to the business in cost-effective and practical ways”.

Quick wins and priority actions

At Ok Menga, two ‘quick win’ projects were identified to mitigate critical risks. The main inlet valves were difficult to access and in poor condition with no critical spare parts on site, and the original analogue turbine governors installed in the 1980s needed replacing but no governor spare parts were available.

“A failure in either or both of these areas was seen as likely in the foreseeable future and would create serious consequences of a prolonged forced outage for one unit or even the complete station,” said Leigh.

Replacements for the main inlet valves would take more than 18 months to deliver, so an emergency repair kit containing critical spares was ordered immediately. Replacement of the governor controllers with newer digital technology was also rapidly initiated to quickly reverse declining reliability.

Leigh said, “Getting these ‘quick win’ projects going straightaway was imperative and immediately reduced very significant risks.”

As well, at Ok Menga, three priority asset risk mitigations were identified relating to the station’s rock trap, unit 1 turbine and the dewatering and drainage system. The rock trap was found to be full, and cleaning it out was initiated quickly. Ok Menga’s unit 1 turbine was worn so the unit 1 runner and cassette were replaced. The security of the dewatering and drainage system had been degraded and it was at risk of failure so Entura recommended that it be upgraded to a system with greater reliability and redundancy.

“Because these priority actions minimised damage to turbines, avoided possible turbine malfunction, and reduced the risk of the powerhouse being flooded, they made a big contribution to reducing the owner’s overall risk exposure,” said Leigh.

![]()

Building capacity

To fill skill gaps at the Ok Menga power station, Entura developed an Australian-accredited program to train new and existing hydro operators. Local staff were included in the asset management process and have now had first-hand exposure to best-practice techniques.

“The owner of this power station is very committed to a sustainable future, and this extends to its staff. The platform is now set for local staff to build on their newfound knowledge and continue to improve their understanding and skills in asset management,” explained Leigh.

Entura has developed its knowledge of asset management through our involvement over the past 100 years with the extensive power and water assets of Hydro Tasmania, Australia’s largest renewable energy producer. Our approach to asset management is recognised as best practice.

“We have spent considerable time learning and developing our systems and knowledge, and this enables us to deliver cutting-edge asset management techniques to our clients without the expense they’d incur if they started from first principles,” said Leigh.

Entura’s holistic best-practice asset management approach at the Ok Menga power station delivered a range of benefits including reducing immediate and longer term risks, and increasing the knowledge and skills of local staff – saving OTML the time and cost of developing its own in-house programs.

If you would like to discuss how Entura can assist you with assessing your hydropower plants or other power or water assets to minimise risk and maximise efficiency and useful life, please contact Leigh Smith on +61 419 884 318 or Shekhar Prince on +61 412 402 110.

MORE THOUGHT LEADERSHIP ARTICLES

Less risk, more benefit: managing assets for long-term gains

Hydropower stations, like all technology or infrastructure, won’t stay efficient, reliable or safe without regular and ongoing attention.

Outages and failures caused by ageing or deteriorating infrastructure can be extremely expensive and serious, and far outweigh the costs of a well-targeted asset management plan. The costs of unreliability are even more significant for hydropower stations in isolated locations or where the power is relied on to run industrial or commercial operations.

But asset management isn’t only about avoiding disasters … It’s also about getting the most out of asset life or ‘getting more bang for your buck’. Owners and operators stand to reap rewards from improved performance and greater reliability if they protect and extend the lives of their investments using best-practice asset management techniques.

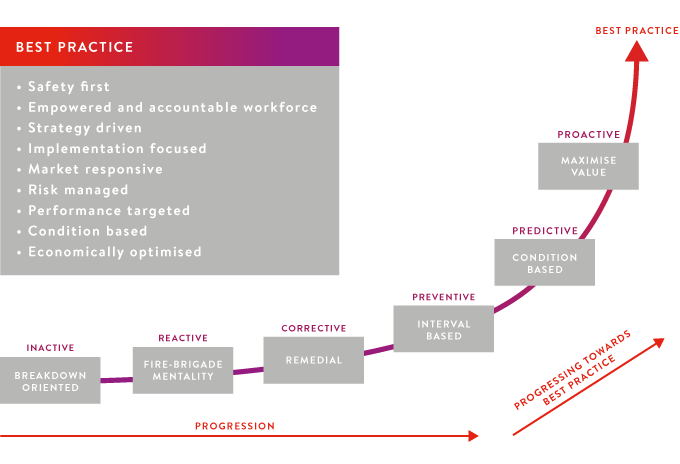

From basic to best practice

In today’s industry, significant amounts of time, energy and effort are invested in achieving desired plant performance at the lowest possible cost without exposing the business to unacceptable risk. Truly sustainable and successful businesses have found ways to balance these priorities, and have strategies in place to adjust the balance as needed when facing changing conditions.

Besides the large financial consequences of outages, failures of systems and equipment can also place the lives of workers at risk. Repairing and upgrading equipment and systems only after they fail is an extremely costly and dangerous way to manage assets. This kind of basic ‘breakdown-oriented’ or reactive asset management is likely to result in unreliable plant and increased human and financial risks.

As businesses mature in their approach to asset management, they progress from a breakdown-oriented approach, through reactive and corrective approaches, towards preventive, predictive and proactive approaches.

Best-practice asset management focuses on reducing risks and improving condition and performance to get the best results. It is driven by strategy and responds to the market, empowers the workforce and makes workers accountable, and always puts safety first. It also needs to be flexible enough to accommodate the individual characteristics of different hydropower stations.

Save time, save money, save lives

Specialist power and water consulting firm Entura thoroughly understands the complexities and benefits of asset refurbishment, upgrade, modernisation and extension of life. As part of Hydro Tasmania, Australia’s largest renewable energy producer and water manager, Entura has day-to-day experience of the challenges of maintaining and upgrading assets to get the best performance, reliability and economy over the long term, through dealing with 30 hydropower stations built and maintained over the past 100 years.

Entura’s asset management techniques are based on condition, performance and risk – designed to save companies time and money. This approach is underpinned by an optimised system that combines reliability-centred maintenance (RCM) and failure modes and effects analysis (FMEA) using generic failure mode databases that can be applied to various different assets with quick results.

Entura’s asset management approach has helped other asset owners across Australia, New Zealand, Papua New Guinea and Malaysia to reduce their costs, reverse declining reliability, obtain better returns through increased performance and improved technology, increase personnel safety, decrease fire and flooding risk and other hazards, increase skills of their staff, and ensure the long-term viability of their valuable infrastructure.

Three steps to best-practice asset management

Entura’s approach to best-practice asset management has three steps that fully consider your assets’ past, improve their present operation and risk profile, and position them for their best possible futures.

Step one: Assessing assets

To fully assess an asset, we undertake detailed inspections and consider the four parameters of:

- condition (observed and measured condition, and maintainability, which takes into account the availability of spare parts, technical ability, and industry compliance)

- performance (both capability and reliability)

- confidence (the level of detail or rigour of the assessment)

- remaining useful life (an estimate of the rate of deterioration of the asset, indicating where the particular asset is on its lifecycle curve, and whether a refurbishment or upgrade can improve its position on this curve, even effectively returning it to as-new condition).

We present a high-level ‘water-to-wire’ summary of the condition and performance assessment results that quickly and graphically displays the known asset condition and remaining useful life, and identifies components for which the condition is not adequately known.

Step two: Developing a risk and mitigation plan

Once an asset has been fully assessed, we develop a risk and mitigation plan.

First, we gather and review a comprehensive set of information on the operation, design and construction of the station and its assets. We explore both the asset history and generic databases to determine probable failure modes.

Once we’ve gathered this information and analysed it against the requirements of the power station, we report the known condition of the plant in terms of business risk and develop practical and cost-effective mitigation strategies to reduce risk to a level that is both achievable and acceptable for the business.

We identify and undertake mitigation actions including ‘quick wins’ (actions that can be undertaken quickly and easily to achieve major improvements) and immediate priority activities to reduce risks. We also detect assets or components that need further investigation.

Step three: Optimising future performance (tailoring the balance)

Best-practice asset management takes a broad view of the life and operation of an asset, not only reducing immediate risks, but also promoting long-term efficient performance and sustainability. Our approach optimises the capital and operational costs over the remaining life of the asset.

A valued part of Entura’s asset management approach is our ability to offer a review of likely efficiency and capacity gains, and other general suggestions for improving performance and systems.

An important step in our holistic approach to achieving long-term safety, reliability and efficiency is training local hydro operators to fill any identified skill gaps and better safeguard the maintenance of assets. We build the capacity of our clients through on-site or formalised training through our Entura clean energy and water institute.

If you would like to discuss how Entura can assist you with assessing your hydropower plants or other power or water assets to minimise risk and maximise efficiency and useful life, please contact Shekhar Prince on +61 412 402 110.

This article was written by Ambrose Canning, Entura’s Principal Consultant, Mechanical Engineering (retired 2025).

MORE THOUGHT LEADERSHIP ARTICLES

Dam safety: protecting lives and driving efficiencies

Humans have been damming rivers since 3000 BC for water retention and supply.

People can fish in the lakes formed by dams, sail on them, swim in them. They are important to life, providing water supply, irrigation for crops and power generation. But if a dam fails, causing devastating flooding downstream, the results can be catastrophic.

The worst dam failure in history occurred in China in 1975 when the Banqiao Reservoir Dam and other dams in Henan province failed, killing an estimated 171 000 people, with 11 million people losing their homes.

Safety is the key

Dam safety is a crucial aspect of modern dam building. Ensuring the safety of existing dams is a key concern of any dam owner, whether the dam is for generating power, protecting a nearby population from potential flooding or for the age-old reason of water supply.

Specialist power and water consulting firm Entura provides dam safety programs for Gordon Dam, the largest concrete arch dam in Australia, and other assets owned by Entura’s parent company, Hydro Tasmania, and for government and corporate clients around Australia, south-east Asia and southern Africa.

Hydro Tasmania is Australia’s largest water manager, so it needs to ensure that the risk of a failure across the portfolio is very, very small. With 55 large dams and many smaller ones, Hydro Tasmania needs to be able to identify the highest risk dams, so it is able to prioritise work on maintenance and refurbishment. This is achieved using a process undertaken by Entura called a portfolio risk assessment (PRA).

Hydro Tasmania is committed to the safety of its assets for the people of Tasmania and its PRA enables the business to prioritise where it focus its financial resources, management and dam safety efforts.

What’s the level of risk?

Energy and water asset owners are increasingly choosing to implement a dam safety program to quantify and manage operational risks, evaluate high risks and find solutions for identified risks or deficiencies. Entura believes that a risk-based framework like a PRA is the best way to achieve an efficient and effective dam safety program.

Older dams or dams located upstream from populated areas are often high risk. The inspection regime for high-risk dams is understandably more robust and rigid than for low risk dams. However, it’s not just ageing that creates risks for dams. In Australia, the methods used to predict and anticipate floods are equally important, as is the increased knowledge that we’ve gained of the various causes and mechanisms through which dams can fail.

Entura’s PRA reviews the consequences of failure of a dam by looking at the impact that it may have on downstream populations, and also looks at the chance of failure occurring by considering extreme events such as floods and earthquakes, taking into account the specific site conditions. It is the combination of the chance of failure with the resulting consequence that determines the level of risk.

A world-wide issue

A number of dam owners across the Asia-Pacific region are now looking at Entura’s PRA program, especially when they have a significant dam portfolio already developed. Our clients in the region are exploring how they can best use their resources and how to prioritise expenditure on their assets.

Having undertaken safety reviews and dam safety work in the Philippines, China, Indonesia, Malaysia, New Zealand, Papua New Guinea, Fiji and India, Entura understands the typical safety needs and drivers of dam owners across the world.

Australia has well-developed dam safety legislation in which Malaysia, for example, with its increasing number of dams, is very interested. Malaysia has experienced the tragic results of a dam safety incident, with the death of a number of people due to water releases through the spillway gates of Sultan Abu Bakar Dam.

On behalf of the Ministry of Public Utilities, Sarawak, Malaysia, Entura used its dam risk framework, similar to that used in a PRA, to assess whether the Bakun and Murum dams were ready to be impounded as construction reached conclusion. This dam risk framework looked at the potential scenarios that could lead to the sudden release of reservoir water, the likelihood of these scenarios occurring, and the corresponding consequences. Through this process the key dam safety risks were identified, and actions were determined to either eliminate or reduce the risks to an acceptable level. These actions needed to be addressed prior to impoundment.

Dam safety is an ongoing concern

The safety and risk-level of a dam can change with time. As dams or assets age, the way they are managed needs to change and they often need upgrading to ensure continued safe operation and desired life expectancy. But undertaking upgrades can potentially increase the risk of the dam during the construction phase – due to the removal of shoulder material from an embankment, or restricting the discharge capacity in a spillway chute. To contain the risks during the construction phase, operational practices might need modification, for example, operating a dam at a lower lake level during the period of construction to ensure the overall risk is not significantly increased. This is why it is so important to have a plan to manage the safety of the dam during its entire lifecycle.

Five steps to assess dam safety risks

Risks can be reduced in a range of ways and, in many cases, a number of risk treatment options are used together:

- reducing the likelihood of the risk occurring (e.g. strengthen a dam)

- reducing the consequences if the risk does occur (e.g. upgrade emergency planning)

- staging risk treatments (e.g. address most cost-effective risk mitigation works first)

- balancing the resources required to treat a risk with the benefits of reducing the risk (e.g. examine various levels of investment and their respective risk reductions).

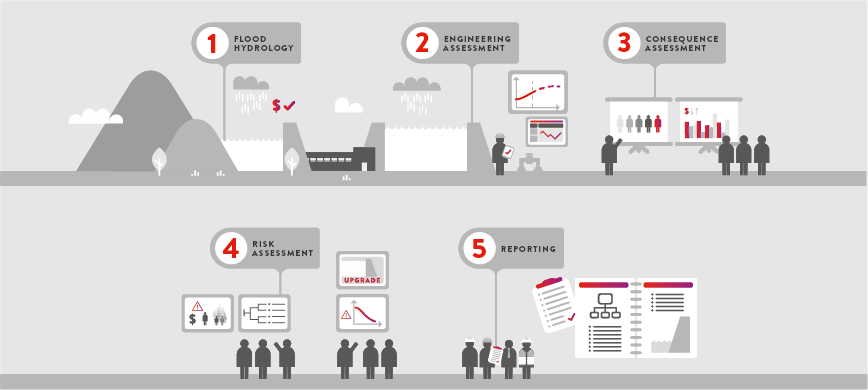

Entura’s portfolio risk assessment approach has five key steps:

| 1 – Flood hydrology | Flood hydrology is a key input as it is used in both the engineering and consequence assessments. Generally the hydrology is based on current best practice. For some low-hazard dams, an innovative regional flood hydrology approach has been developed that provides sufficiently robust answers at minimal cost. |

| 2 – Engineering assessment | The engineering assessment is a critical part of the process as it requires all potential failure modes to be identified and then the probability of failure to be estimated for each mode. The engineering assessment gathers all the information about the dam including design, construction, geology and operations that may assist in defining the potential failure modes. This is presented as response curves (i.e. conditional probability of failure). The level of detail varies with the hazard category of the dam (i.e. a high-hazard-category dam receives more intense scrutiny than a low-hazard dam). The engineering assessment also ensures an assessment of compliance with current engineering standards. |

| 3 – Consequence assessment | Key steps in the consequence assessment method include developing a dam break model; mapping the inundation zones; assessing the population at risk and probable loss of life; assessing the financial and economic losses; and qualitatively assessing the environmental, social and intangible consequences. |

| 4 – Risk assessment | The risk assessment uses event trees that evaluate societal and individual life risk and financial risks. Risks can be aggregated across a range of load conditions and failure modes to give a total risk position, retaining visibility of the scenarios that contribute to the total risk. Where the risks are unacceptable, upgrade concepts are developed and their impact on reducing risk is plotted. |

| 5 – Reporting | The results of the risk assessment are reported, summarising the potential failure modes, consequences and risk profile for each individual dam. Summary data across the portfolio is also presented, including information on the failure modes, and risk of all the dams against societal life risk and financial risk criteria in a simple but meaningful format. |

Resource levelling

All businesses need to share resources across many activities besides risk mitigation works. For a hydropower company, a significant reinvestment in generating plant is required to both manage risk and maintain asset capability. Resources are also needed for investment for growth and diversification.

Within the dam portfolio, it is important to ensure that resources, both human and financial, are not applied to risk mitigation projects at the expense of the fundamentally important surveillance and monitoring activities. A balance is needed between reducing risk and maintaining and enhancing surveillance and monitoring instrumentation.

An ongoing effort

Finally, it is important to realise that the capital works program for dam safety risk reduction is not a static program, locked in and then implemented without change. Rather, it is an active program that is reviewed regularly, actively managed and needs to remain responsive to new or changed risks, developing understanding of dams engineering, shifts in business priorities, delays to projects, and new developments in risk management processes.

The same process can be applied to other assets

The PRA process can also be used for other assets that have a low chance of failure but high consequences if failure were to occur. At Entura, we have successfully applied our PRA process to penstocks and pipelines, and to canal systems, identifying key risks and prioritising the actions needed in a way that most effectively manages resources.

If you would like to discuss how we can assist you with assessing your dam risks or developing a resource-effective and comprehensive dam safety program, or apply the same PRA process to other key assets, please contact Richard Herweynen on +61 3 6245 4130.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.