Renewables in remote mines – a litmus test for the wider renewables transition

Entura’s Greg Koppens has recently returned from the Energy and Mines Summit in Perth, where he led the ‘Think Tank’: a collaborative session addressing the challenge of powering process steam requirements from renewables-generated electricity. Here he shares his observations on the rise of renewables in the mining industry …

Australia’s mining industry is beginning the peak phase of its energy revolution. However, I find it unfortunate that this exciting fact is invisible to regular people. It is happening in remote areas on mining leases, inaccessible to the public. Each project alone is not sensational enough for media attention, but added together these projects are nothing short of a technology revolution. For remote mining sites to have a solar farm is now standard practice. In many cases this is backed up by battery storage and a handful of mines have onsite wind turbines.

The past: fossil-fuel driven mines

Australia is world-renowned for our mining industries, with mines of virtually every resource throughout our country. Up until about ten years ago, nearly all of Australia’s mines ran completely on diesel or gas. In most cases diesel was trucked in, or gas was brought in via pipeline. Most of these mines have energy expenses in the tens of millions of dollars per year. A small change in the oil price can drastically impact the mine’s bottom line.

If there’s one doubtless fact about mining, it’s that miners are practical people. They are problem solvers, and they know what works. With the boom-and-bust nature of resource markets and shareholder responsibilities, finances must be well managed.

The present: hybrid renewables power generation

At the Energy and Mines Summit, there was no discussion about whether it’s a good idea to consider renewables in the mix of power generation – it was simply a given. This is an industry in ‘early maturity’: it is no longer pioneers running a trial. Several systems are in the order of 100 MW capacity. Renewables are a tested and proven business decision. Everyone has crunched the numbers on their sites and, while each project has unique site-specific requirements, the conclusions are unanimous. The frontier is now getting access to skilled people, there is community engagement for siting of large assets and mutual benefits, and the industry is exploring emerging technologies such as electric fleet.

We now have all the technology needed to harness the power of the wind and the sun in an 80/20 mix with fossil fuels. Or a 50/50 mix when the system has solar power alone. And this is what is being implemented in practice all over Australia. We can do it in a way that achieves targets for price, reliability, service life, operability, maintainability and environmental impact. This greatly reduces the costs and risks of intermediate services such as refining and transportation as well as exposure to the global oil price. Mining companies are taking control of their energy supply by either owning the energy and storage assets or building well-defined low-risk partnerships.

The big project: transitioning the Pilbara to renewables

At the conference there was some focus on the Pilbara, which is a huge and complicated energy consumer, consuming 16 TWh (16 million MWh) of electricity per year, mostly coming from gas.

On the surface, it seems to be very low hanging fruit to quickly construct a few solar and wind assets to shift this picture. However, in the interests of the best long-term outcomes, the area needs planning, consultation and coordination. The Western Australian Government has developed a plan for ensuring that common-use infrastructure is used where possible, rather than risking having multiple redundant assets owned by different corporations. Aboriginal and community participation is recognised as crucial for the appropriate siting of wind, solar and transmission equipment.

The near future: electric fleet

Approximately half of a typical mine’s energy needs can be met by onsite electricity generation. The other half currently requires diesel fuel to run a fleet of light vehicles, monstrous ‘haul’ dump trucks such as the 250 tonne CAT 793, and every piece of mobile machinery in between. These mobile machines are the next target for reducing costs, carbon emissions and labour. Several trial projects are happening. For underground mines, where diesel has previously been used, huge ventilation fans will need far less power when there are no exhaust fumes to expel.

Machine manufacturers are developing a wide array of specialised battery electric products. In some applications, there is battery swap technology, as in modern power tools. In other applications, a fixed battery plugs in to recharge, like in an electric car. There are also trolley systems, akin to a tram or train. The best system for each job depends on the application.

Transitioning to a fully electric fleet will significantly increase a site’s electricity needs, with the biggest chargers running at 6 MW at full power. We are expecting to see sites’ electrical grids upgraded soon to integrate this high-power charging.

What is Entura doing?

At Entura, in addition to electrical generation and distribution design, we have specialised capabilities in control systems and power system studies for mining projects. Our microgrid control system (MCS) uses standard and reliable industrial Allen Bradley hardware to monitor and control the power station assets. We have a field-proven core algorithm for maintaining a priority of reliable power supply including backup/reserve supply, while making the greatest use of wind and solar where available. We’ve proven this process in our existing installations in the field and we lead the industry in methodology, practicality and voltage/frequency management.

We’ve seen the real benefits these systems bring to our clients and communities, both at mining sites and in other remote locations. Entura has a long history of design, formation and operation of microgrids throughout Australia (such as King Island, Flinders Island, Rottnest Island, and at mining sites such as the Agnew gold mine) and in the Pacific region (including the Cook Islands, the Federated States of Micronesia, Tonga, and the Solomon Islands, to name just a few).

Contact us if you’re interested in unlocking the full potential of microgrids for your operation or community, or if you’re interested in ways to increase your use of renewable energy.

[Image immediately above] Entura’s Patrick Pease, Greg Koppens and Mark Richardson at the 2025 Energy and Mines Summit

[Top of article] Greg Koppens (centre) onsite at Jabiru Power Station, Northern Territory

ABOUT THE AUTHOR

Greg Koppens is Entura’s Principal Control Engineer Hybrid Renewable Systems and previously led Entura’s secondary electrical engineering team. Greg’s experience spans power, oil and gas, and mining, including onsite roles. With over two decades of detailed design experience, Greg facilitates collaboration between engineering disciplines and other stakeholders to solve complex problems. He regularly shares his extensive expertise with the mining sector to advance their decarbonisation goals. Find out more about Greg in our podcast series here.

New technologies are important tools, but they need to be used properly

Entura’s Technical Director (Water), Richard Herweynen, recently attended the 2025 ICOLD Congress in Chengdu, China, themed ‘Common Challenges, Shared Future, Better Dams’. Here he shares his observations on the state of play in the international dams industry – and the opportunities emerging with artificial intelligence and automation.

My first ICOLD Congress was in Beijing, China in 2000. I was presenting some finite element analysis work that I had done on Gordon Dam, a 140m-high concrete arch dam in Tasmania. The analysis was being used to help predict and explain some cracks that had formed at the base of the downstream face of the concrete shell, roughly normal to the foundation, during first filling. In the 1980s, an attempt had been made to model the crack using finite element modelling, but with little success due to the coarseness of the mesh. However, by the late 1990s, computing power had increased and finite element programs had improved, providing the capability to construct more detailed finite element models, which were able to predict and explain the cracking that had occurred.

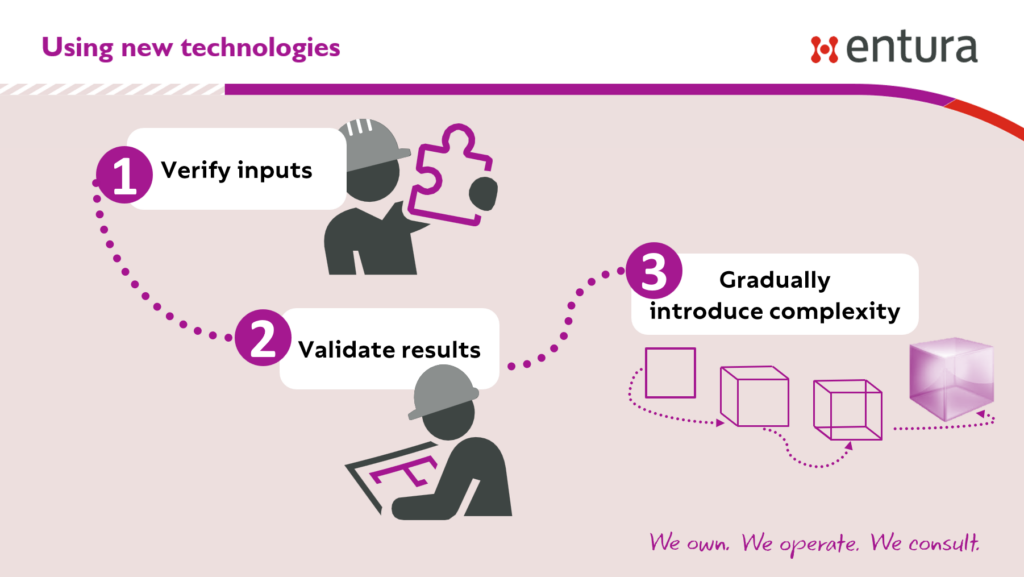

Dr Sergio Giudici, the designer of Gordon Dam, was my mentor on this finite element analysis, and he reinforced these principles:

- It is important to verify the input data to make sure the model represents, as well as possible, the actual dam parameters.

- Results should be validated using alternative techniques to give the engineer confidence in the results that the model is producing (i.e. structural hand calculations still have a place).

- Complexity should be built into these models only gradually, so that the engineer can see the impact of changes and determine whether they are reasonable.

These same principles are true for many complex engineering models and when setting up calculation spreadsheets or similar.

Now, 25 years on, I have had the privilege of attending the 2025 ICOLD Congress in Chengdu, China. At this Congress, there was much talk about the importance of dams in society for water security, the growing role dams and reservoirs play in providing resilience to climate change and the energy transition, the importance of balancing economic benefits and environmental needs, and – in all of this – the importance of ensuring that our dams are safe for communities downstream.

We have discussed many of these themes before – and they remain highly important; however, one thing I took away from ICOLD 2025 in particular was how China is embracing technology and advancing a ‘Smart Dam’ initiative.

New technologies and smarter dams

One could say that our industry has always been building smart dams, but China’s ‘Smart Dam’ concept is about using the full power of current technologies to construct, monitor and operate dams in smarter ways, and to use technologies to predict and adapt to changing conditions.

The CHINCOLD Workshop on Digital and Intelligent Technologies for Dam Construction, Operation and Maintenance, which occurred during ICOLD 2025, gave a glimpse of what may be possible.

Many projects utilise 3-dimensional digital models and building information modelling (BIM). However, the concept of having a digital twin of the dam, replicating every aspect of the physical dam in a digital form, opens the door to many possibilities, especially in light of the advent of artificial intelligence (AI).

Artificial intelligence and machine learning

Many organisations and nations have been cautious about AI, but China is increasingly adopting it to improve construction practices in dam engineering, improve monitoring and surveillance of dams, and to help adapt to extreme events as they occur.

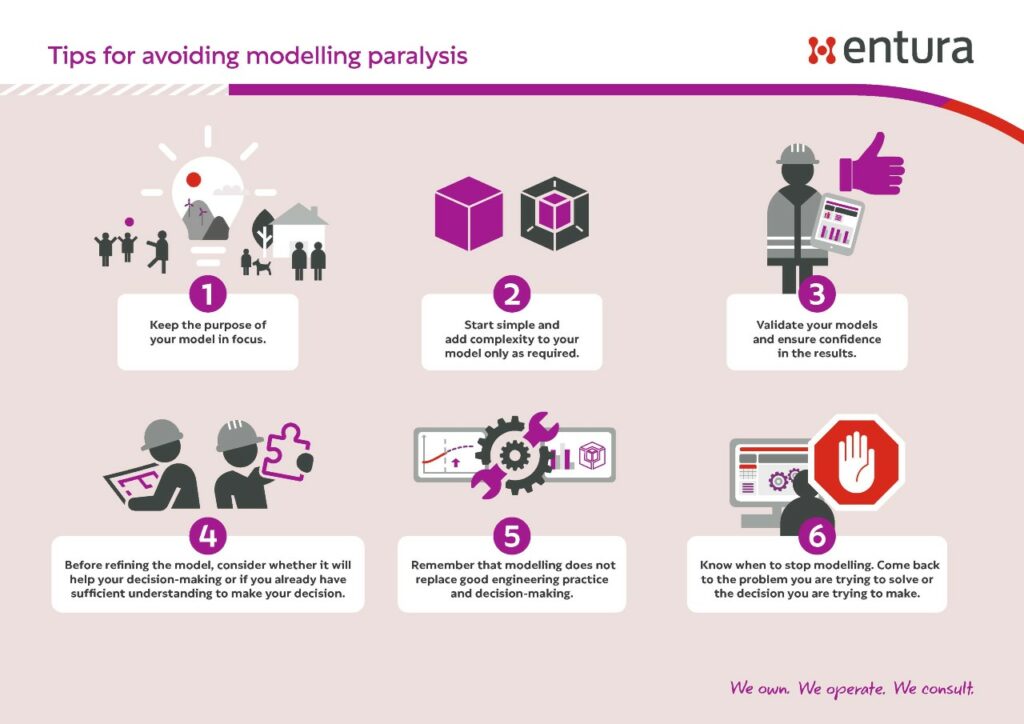

Machine learning (ML), an element of AI, enables computers to learn from data without being explicitly programmed. ML algorithms analyse data, identify patterns, and make predictions or decisions, improving their performance over time and with more data. There are no doubt many engineering applications where ML could be used to help improve predictive modelling or optimisation, and to make these more efficient. However, the same principles that were important when we were beginning to embrace larger, more refined finite element models with the advent of faster computing remain true here:

- We must verify the input data that machine learning is utilising to ensure we don’t get ‘garbage in equals garbage out’.

- Results need to be validated. AI needs to be trained correctly, and we need experts involved at this stage to ensure that the outputs from AI are correct.

- Complexity, or the full power of technology, should be added incrementally, to provide progressive confidence in the outcomes.

Engineering is the application of science, and therefore it is critical for every engineer to understand the fundamental principles and how to apply them. The complex computer programs used for a lot of engineering modelling can become ‘black boxes’, and practitioners risk diluting or losing their understanding of the fundamental principles behind the models, and hence their ability to validate the results.

Automation brings a step change in efficiency and accuracy

At the ICOLD Congress in 2000, I co-authored a paper for the international symposium on concrete-faced rockfill dams (CFRD) entitled ‘Hydro Tasmania experience in concrete-faced rockfill dams – past, present and future’. There is no doubt that Hydro Tasmania has a strong history in CFRD, with Cethana Dam playing an important role in the development of the modern, high CFRD.

In 2000, however, the future in CFRD that we envisaged did not include unmanned construction equipment with automatic quality control feedback loops. At the 2025 CHINCOLD Workshop on Digital and Intelligent Technologies for Dam Construction, Operation and Maintenance, a presentation was given by Wang Jiajun from Tianjin University on intelligent unmanned roller systems to compact rockfill dams. Unmanned rolling compaction (URC) systems involve three core technology modules: (1) intelligent perception, (2) autonomous planning and decision making, and (3) intelligent control. These systems use automated driving technology to control the rolling process on earth and rockfill dams, improving productivity and quality. They can accurately control compaction parameters such as passes, speed, vibration and lift thickness. URC systems also enable continuous monitoring and real-time feedback for quality control, reducing human error and improving overall project performance. This automated technology was used on the 295m-high, 1.57km-long Lianghekou hydropower dam in China, with a total fill volume of 43 million m3.

The changing face of dam engineering

With AI and automation, the scope for embracing new technology in dam engineering is growing fast. It is clear that there are significant benefits that could be realised for dam design, construction, operation, dam safety and emergency response – and there’s a role for these advanced technologies at all of the stages of the life cycle of a dam. A degree of caution is appropriate and necessary, but caution should not be a reason to refuse to engage with the new technologies available to our industry.

However, with more sophisticated models – such as digital twins – being created of our dams, it is important to ensure we maintain the guiding engineering principles of verifying input data, validating models for correctness, and building complexity gradually. By doing this, we can provide the necessary assurance and confidence in our increasingly sophisticated and evolving tools.

ABOUT THE AUTHOR

Richard Herweynen is Entura’s Technical Director – Water. He has more than three decades of experience in dam and hydropower engineering, working throughout the Indo-Pacific region on both dam and hydropower projects. His experience covers all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and was the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

When the lights go out

Major power outage events, like the one that affected Spain and Portugal this April, can be enormously disruptive and even deadly. Here Entura’s Technical Director Power, Donald Vaughan, considers the complex factors at play and their implications for grids everywhere ...

The recent power outage on the Iberian Peninsula provides a serious opportunity for reflection. Many articles have been published that try to explore the seconds and milliseconds after 12:32 PM on 28 April 2025 while only having access to the grainy frequency plots and approximate timelines that have been released (to date). This is not one of those articles. Nor is it an article that will lay blame on a particular technology or energy source. Instead, I will expand on the physics at play in this instance and reflect on whether current network security practices are adequately catering for changes to the power grid.

The physics

The power system is governed by the laws of physics, as is normal in the physical world. Quite a few of these laws tend to gang up on us during a power system event[1].

(i) conservation of energy

(ii) Ohm’s law

(iii) Newton’s laws of motion

and, of course,

(iv) Murphy’s law.

We’ll talk about the first three now and the last one later.

We learn very early that energy can neither be created nor destroyed (law i, above). This is at the heart of a power system event. The power system supplies loads by supporting voltage across the network that supplies millions of parallel loads. Each of these loads converts electrical energy into another form of energy based on the voltage it sees and its internal characteristics. This will continue as long as the voltage profile is maintained (law ii). So, demands take energy out of the power system regardless of what generation events occur.

We know that the main trouble in the recent Iberian event started when a large amount of generation stopped in southern Spain. This led to an imbalance between generation and demand in that region. That imbalance is immediately addressed through the inertial action of synchronous generation across Europe (law iii).

If interconnection were perfect, the burden of this inertial response would be shared perfectly across Europe and we probably wouldn’t be talking about this event quite as much as we are. Yet interconnection is rarely perfect (law ii). The frequency in Spain started to move away from frequency to the east and the AC interconnection to the east opened (which avoided the disturbance that stems from loss of synchronism). This should have been some help to the falling frequency in Spain given the eastward flows at the time. Under-frequency load shedding (UFLS) occurred around this time and should also have helped. It seems that the voltage disturbance that then occurred as a result of all these trips was the last straw.

Network security practices

It would be a gross over-simplification of network security practices to say that the power system should not lose customer load for the loss of one generation or network element (N-1 redundancy). The event on 28 April is way beyond that. Typically, for larger events, the grid should fail safely. We’ll look at that definition of ‘safely’ later. For now though, we can see that the grid did, in fact, try to fail gracefully:

- The AC interconnectors opened to avoid damaging loss of synchronism.

- The under-frequency load shedding operated to try to preserve supply to some customers and keep the grid up, so as to reduce the duration of the interruption.

- Other generating unit controls acted to either increase output or trip to avoid damage.

We see in the Iberian Peninsula outage, as we did in the major South Australian blackout in 2016, lots of independent protection operations slowly but surely weakening the grid to the extent that it is no longer viable. Each of these protection operations undergoes scrutiny after an event of this nature, and will likely lead to some changes in Spain and France as was the case in South Australia.

The 28 April event appears to be quite slow in comparison to some other network blackout events. Even so, the event lasted less than 20 seconds and had 2–3 stages within it. One of the bases of design of the AC network is that it can generally operate with minimal, fast coordination even under large events. Control relies on observation, computation and action. So, to manage an event, a control system must measure what it needs to reliably determine what control actions it must make, and then take those control actions (assuming it can control all the elements it might need to control) in time for them to have an effect. If we think about a need to deftly control the response of individual units (or control systems) in an unusual way in a short period of time, then we can quickly conclude that this may not be possible.

If we can’t manage these events in real time, we have three courses of action:

(i) Physical plant

We could design networks, network supports, and network and generator protection and control systems to be more robust in the face of large power system events, thus decreasing the likelihood of unnecessary cascading protection operation.

This would include better interconnection, more dynamic reactive support (separate from generating units and demand), system-level protection schemes, and a review of generating unit protection settings to ensure generator capability rather than network requirements setting operating limits

(ii) Dispatch rules

We could change dispatch to provide greater margin for real and reactive power control as determined by the security risk and the cost to mitigate it.

We could continue the traditional N-X approach to system supports or we could use a stochastic approach to determining system support requirements (weighting the probability of an event occurring against its impact). Either way, we’d have to pay an ‘insurance’ premium at each dispatch interval to make large-scale system outages less possible.

(iii) Restart planning and capability

We could make recovering from major blackout events easier and faster.

We think about these events in terms of how often they occur (which is what the first two course of action cover) and how long they last. System operators typically have generic plans for system restart that rely on starting synchronous plant and re-energising transmission systems and eventually customer demand. This can be made easier with interconnection. It can also be made easier with good visibility of voltages and voltage profiles across regions (and the tools to control them). Often, for big events like in South Australia in 2016, the network is left somewhat stricken from equipment damage. System restart efforts are often hampered in this scenario because plans need to be improvised to adapt. This depends on the skill, knowledge and experience of the operators. Some jurisdictions have simulated such events as part of training operators.

The fourth law

We know that ‘anything that can go wrong will go wrong’. Seemingly simple things can undermine the best laid plans and the best intentions. We often can’t plan for these things specifically, although HAZOPS, root-cause analyses, scenario simulations and reviews can help us understand where the problems may lie and give us a chance to close loop-holes before they become SNAFUs.

Major power outage events are serious. They often lead to loss of life or injury, and the recent Iberian Peninsula event was no exception. They also always have an economic impact, which is not always fairly distributed. As an industry we need to improve how we manage them. We also need to get better at talking about technical issues in a political environment. If there’s a risk of blackouts, we have a duty to not only mitigate that risk within the current rules but also advocate for rule changes if that mitigation is inadequate. To be most productive, this conversation should happen in a techno-economic environment. The automatic debate after power system events often focuses on the role of renewables, commercial interests and the like, which may sometimes be entertaining but inevitably affects the techno-economic outcomes in a negative way for everyone.

ABOUT THE AUTHOR

Donald Vaughan has over 20 years’ experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. He has worked for all areas of the electrical industry, including generators, equipment suppliers, customers, NSPs and market operators. Donald specialises in the performance of power systems. His experience in generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves.

Image: Basil James on Unsplash

[1] There are more laws, but these are the main and most accessible.

Decommissioning battery energy storage systems: It’s never too early to plan for retirement

All good things come to an end – even big battery energy storage systems (BESS). In Australia, the end of life for BESS may feel very distant, since we’re really only in the infancy of the booming BESS industry; however, the life expectancy of these big batteries is nothing like the design life of other renewable energy and storage technologies. With BESS currently only lasting for around 10 to 15 years of operation, developers and owners of BESS installations need to be thinking and planning now for what decommissioning will involve and what it will cost. In fact, planning for decommissioning is best done right from the start – long before the project is constructed.

Here, one of Entura’s BESS specialists, Dr Rahmat Khezri, answers some burning questions about the end stages of a BESS project.

- When does the life of a BESS project come to an end?

The need to decommission a BESS project could arise either from the conclusion of a contract or power purchase agreement – though this is unlikely – or from the expiration of the battery’s operational lifespan. This could be when the battery capacity has degraded to a point where it is no longer financially viable to operate in the market or when the battery’s internal chemistry has reached a point where it is unsafe to continue operating.

For nickel-manganese-cobalt (NMC) batteries, which held a significant share of batteries before lithium-iron-phosphate (LFP) batteries entered the market, this could be after 3,000 to 7,000 cycles at 80% depth of discharge (DoD) or around 10 to 15 years. For LFP batteries, which are gradually dominating the battery market for BESS, it’s around 4,000 to 10,000 cycles or 15 to 20 years. However, several factors can either reduce or extend the battery lifespan. Higher DoD shortens battery life, and frequent high-power cycling (e.g. for frequency control ancillary services, FCAS) can accelerate degradation. Avoiding prolonged high or low state-of-charge management (SoC) reduces degradation. Temperature is also an issue – so proper cooling and heating systems can support greater longevity.

- Is decommissioning the only option?

Full decommissioning of aging BESS assets is not always necessary at battery end of life, as some key components – such as inverters, transformers and balance of plant (PoP) – often retain residual service life. There may be opportunities for repowering or augmentation instead, which will require a much lower level of decommissioning activities. Repowering replaces old batteries with newer or upgraded technology to restore or enhance performance. Augmentation generally aims to increase capacity or power output by expanding the system with additional capacity, for example by adding extra battery racks to an existing setup.

- What does a full BESS decommissioning program involve?

A typical full BESS decommissioning program includes the following activities:

- developing the decommissioning plan including a risk assessment

- de-energising the BESS

- removing power conversion systems (inverter/transformer stations)

- removing integrated battery storage units (site dismantling and packaging may be required)

- shipping the packed battery storage units to recycling facilities

- removing electrical cables and conduits

- removing substation equipment

- shipping the power conversion systems and cables to recyclers of electronic waste

- transporting non-recyclable material removed from the site to disposal facilities

- restoring the site.

- How long could BESS decommissioning take?

Once a BESS project stops operating, the decommissioning process can begin (usually within 12 months) and can take around 6 to 9 months. Of course, this will depend on the scale of the BESS project, which will determine the amount of battery units and electrical infrastructure that will need to be removed from the site. If site restoration is required, this could extend the timeframe.

- What might BESS decommissioning cost?

Decommissioning costs are made up of labour, equipment, transport, materials, and recycling or disposal. These costs can be categorised across the stages of the project: removing the BESS facilities, restoring the site, packaging and transport, and the cost of recycling or disposal. If it is possible to achieve some value from salvage, this can be offset against the decommissioning costs. Currently the total recycling fee for high-powered batteries is around $10–15 per kg. Assuming approximately 6 kg for 1 kWh, the recycling cost would be $60–90 per kWh.

- Talking about recycling, what are the options for decommissioning BESS sustainably?

In Australia, we’re still in the early days of developing a lithium battery recycling industry – but we are seeing increasing recognition by owners, developers, regulators and the community of the need for the renewable energy industry to strengthen the circular economy and minimise landfill. Battery modules are recyclable – but salvage and reuse are likely to remain very dynamic and the future market for used lithium-ion modules remains uncertain. We recommend that every BESS developer/owner should aim to maximise recycling and develop as sustainable a waste management plan as possible. It is worth noting that recycling and reuse of inverters, transformers and BoP components are well established and available.

- What regulatory requirements are there in Australia for BESS decommissioning, and how do you envisage this changing?

In Australia, BESS projects must comply with relevant environmental regulations, which vary by state but generally align with the environmental protection guidelines set by each state’s Environment Protection Authority (EPA). At the federal level, the Product Stewardship Act 2011 promotes the responsible management of products at the end of their life cycle, including batteries. Decommissioned components from BESS projects, particularly lithium-ion batteries, are typically classified as prescribed industrial waste (PIW), requiring handling by licensed transporters and disposal at approved facilities.

At this stage the permitting process to build a BESS facility does not require a formal plan for decommissioning and disposal – but it is probably only a matter of time until we see more stringent requirements as part of the development application process. Despite a detailed plan not yet being required, it is definitely worthwhile doing, not least because the costs of decommissioning should be factored into the business case from the outset.

- What lessons have been learned from international examples of BESS decommissioning?

There haven’t been many examples of BESS decommissioning in our region yet, but the example of decommissioning the Tehachapi Energy Storage Project (TSP) project in South California in 2022 is an instructive real-life case study. This 8 MW / 32 MWh lithium-ion battery project was one of world’s first and largest BESS when it was commissioned in 2014. It had a footprint of 585 m2, with 604 battery racks and two 40-foot PCS containers. The decommissioning was completed in just over 4 months from the generation of the purchase order to the finish.

A key takeaway from this case study is the significant impact that logistical and site-specific constraints can have on project outcomes. Although the PCS containers were initially expected to be removed within a single day, unforeseen space limitations and permitting restrictions ruled out the use of cranes. As a result, the containers had to be dismantled and cut into sections on-site. This increased the schedule by 17% and the cost by 20%. The lesson here is clear: success lies in the details, particularly when it comes to transport and access logistics. Thorough, site-specific planning is essential to avoid unexpected delays and budget overruns.

- What should Australian BESS developers and owners be doing now about decommissioning?

Ideally, every player in the BESS industry in Australia should be thinking ahead, however far off BESS decommissioning, repowering or augmentation may seem right now. It is never too early to start investigating the potential options, costs, timing, emissions, challenges and solutions – and developing a plan that can continue to evolve as the industry matures. A robust decommissioning plan will also be a valuable input into the technical due diligence process for sale/purchase. Ultimately, solid, early planning is the key to minimising risk and maximising value – and achieving a more efficient, more cost-effective and more sustainable outcome for any BESS project.

At Entura, we’ve been involved with BESS since the very start of the sector in Australia, and we’re always learning from our experiences here and around the world. We’re actively developing our analyses of decommissioning costs, transport, timing and circularity opportunities so that we can support your BESS project holistically, from cradle to grave.

Regardless of the stage of your BESS project, Entura can help. Contact Patrick Pease to find out how.

About the author

Senior Renewable Energy and BESS Engineer Dr Rahmat Khezri has vast professional and technical experience with batteries. He has worked in the renewable energy and battery industry in project delivery from BESS design, business case and feasibility analysis to operation and construction. Rahmat has managed several utility-scale BESS projects during his time with Entura, overseeing successful delivery while ensuring compliance with industry standards, optimising performance, and managing key stakeholder relationships. Before joining Entura, he worked on projects supported by Sustainability Victoria for technical design and business case development of ‘second-life BESS’ using retired batteries of electric vehicles. In 2023 and 2024, he was recognised by Stanford University as being in the top 2% of scientists worldwide for two consecutive years.

Planning for the future – the challenges of dam inspection and maintenance

No dam is ‘maintenance free’. Without appropriate maintenance and refurbishment at the right times, a dam may not be able to fulfil its function safely for the full length of its design life (which could be more than a century).

This presents many challenges for asset owners. To keep the dam operating as the designer intended – and get the most out of the original investment over the long term – owners will need to develop and implement a suitable operations and maintenance manual aligned with the asset management plan and reflecting a ‘whole of life’ strategy. These plans will need to consider the unique characteristics of each dam and cover all the relevant issues. And there are many!

Dams consist of a number of different elements. There are the main civil engineering components including the wall that holds back the water and the spillway – but there could also be mechanical elements (pipework, valves and gates) and electrical elements (power supply to lights, valves, gate motors and control systems). Each of these elements will have its own operational and maintenance requirements and different lifecycle duration. Ideally, all this detail needs to be captured in the operation and maintenance manual (as recommended by ANCOLD guidelines) and in an asset management plan.

Civil components

The civil components of dams have the longest life span, typically more than 100 years if well constructed and maintained. Common maintenance items that need to be regularly addressed include:

- Vegetation management

Trees and bushes will readily grow in earthfill and rockfill embankments. Regular control (e.g. annually) is necessary to ensure that roots don’t grow through the fill and initiate leaks through the embankment. Mowing the grass on the downstream face of the earthfill embankment and downstream contact is necessary so that the condition of the face can be observed. Even concrete gravity and concrete arch dams will require vegetation control along the downstream face contact with the foundation so that the dam can be easily viewed in routine inspections.

- Surface water drainage

Dam construction typically affects natural drainage lines, which is why surface water drains are a common feature around and on dams – such as along the groins (where the dam wall intersects with natural ground), along berms in embankment dams, along benches, at the top of cuttings, and along access tracks. Drains will need regular inspection for both erosion and blockage due to sediment or vegetation.

- Foundation drain cleaning

Concrete gravity dams and concrete arch dams typically have drains drilled into the rock foundations to relieve uplift pressures and help maintain stability of the wall. Over time, silt or iron-rich slime can build up as a byproduct of bacterial growth in the drains, reducing effectiveness. These drains typically require 5-yearly high-pressure flushing. Cleaning will also be needed for drains underneath spillways founded on rock and cut slopes in rock.

- Protection of the dam safety monitoring system

Protecting the dam safety monitoring system requires a range of regular activities. These include cleaning and clearing vee-notch seepage monitoring weirs, checking survey monitoring pillars and targets, and checking the calibration of level monitoring and indication devices, such as reservoir-level sensors, piezometers, tiltmeters and inclinometers. Regular functional testing will also need to be carried out on the alarming and tripping devices that form the primary protection elements of the dam, including spillway gates and scour valves.

- Clearing of trash racks

Outlet works usually have trash racks to stop debris entering the pipework and causing blockages. It’s important to check that the build-up of debris is tolerable and that any hydraulic losses won’t affect operations. Assessing and removing the debris isn’t easy, as the trash racks are often accessible only by remotely operated vehicles (ROVs) or by divers. Before the inspection, the outlet will typically need to be closed and isolated.

Inspection-driven longer term maintenance will also be required for particular elements of the dam, ideally addressing repair items promptly to minimise damage and the cost of future repairs if left untreated. For example, concrete repairs may be needed to address erosion in stilling basins and spillway chutes, or spalling of concrete due to reinforcement corrosion or freeze/thaw damage.

While regular inspections should be undertaken to detect slow deterioration, special inspections following major events – such as floods or earthquakes – should also be part of the operations and maintenance plan. Given that the key areas for inspection are often difficult to access safely, use of UAVs (e.g. to inspect a spillway crest and chute) or ROVs (e.g. to undertake underwater inspections or scanning of stilling basins, plunge pools or riverbed scour) should be considered.

When special inspections identify the need for repairs, the time is right to consider whether the dam’s design or surveillance could be improved to increase resilience for a similar event in future. For example, a higher strength concrete overlay may treat erosion of a spillway chute and increase its resistance to future erosion.

Mechanical components

Mechanical items such as steel or cast-iron pipework can also often last up to 100 years if adequately protected from corrosion. Concrete and cement mortar are very effective for this purpose as the alkaline environment provided by the cement paste provides a very low corrosion environment. Key to the effectiveness of this protection is ensuring that the cement remains in intimate contact with the steel or iron. This will require regular inspections and timely repairs. Where concrete protection is not practical, paint systems can be very effective for up to about 20 years. A suitable inspection regime will be needed so that any areas where the paint has deteriorated can be detected and patched.

Mechanical items such as valves and gates typically have an effective life of around 50 years; however, they need to be exercised regularly to keep them able to work on demand. This is not an issue of the parts wearing out from use; rather, it’s the risk of them seizing due to lack of use. Regular lubrication of bearings, gearboxes and trunnions needs to be included as part of the maintenance of these items. This is particularly important in scour valves and spillway gates that may have a very low frequency of use during normal operations but are there for use in emergencies. The wire ropes commonly used to hoist spillway gates open will need even more frequent replacement, at approximately every 20 years.

Electrical components

Electric motors are commonly used to drive the winches hoisting spillway gates or driving the shafts to open valves. Associated with the motors will be switchboards and power supply systems, typically including grid power supply and backup diesel generators. The typical life of these components is around 25 years. As with the mechanical components, lack of operation can lead to premature failure, so a regular regime of exercise is necessary to ensure maximum reliability and life.

The programable logic controllers (PLC) that are used to automate operations, allow remote operations and generate alarms will have a typical life of only 10–12 years due to changes in programming languages and rapid evolution of the hardware.

Getting the most out of life

As we’ve seen, regular maintenance is fundamental for keeping all the components of a dam operating as intended and maximising their lifespan – whether that’s 10 years or 100. This maintenance, including the exercising of the mechanical and electrical components, needs to be clearly documented in the operations and maintenance manual and recorded in an asset management system. The asset management plan must allow for regular maintenance and also budget appropriately for replacement or refurbishment when any component of the dam is due for retirement.

At Entura, we believe in getting the most out of every piece of infrastructure because that’s good for our clients, communities and the planet. With a solid regime of inspection and maintenance, all the parts of your dam will be on the strongest path to a long, reliable and sustainable life.

If you’d like to talk with us about inspecting and maintaining your dam/s, contact Phil Ellerton, Paul Southcott, or Richard Herweynen.

About the author

Paul Southcott is Entura’s Senior Principal – Dams and Headworks. Paul has an outstanding depth of knowledge and skill developed over more than 3 decades in the fields of civil and dam engineering. He is a highly respected dams specialist and was recognised as Tasmania’s Professional Engineer of the Year in Engineers Australia’s 2021 Engineering Excellence Awards. Paul has contributed to many major dam and hydropower projects in Australia and abroad, including Tasmania’s ‘Battery of the Nation’, the Tarraleah hydropower scheme, Snowy Hydro, and numerous programs of work for water utilities including SeqWater, Sun Water and SAWater. His expertise is a crucial part of Entura’s ongoing support for upgrade and safety works for Hydro Tasmania’s and TasWater’s extensive dams portfolios. Paul is passionate about furthering the engineering profession through knowledge sharing, and has supported many young and emerging engineers through training and mentoring.

What have we learnt about renewable microgrids and remote area power systems?

With the evolution of modern inverter and renewable energy technologies, it’s become possible to build microgrids with very high renewable penetration. These renewable solutions are revolutionising electricity sustainability, reliability and access in many far-flung locations – such as Pacific islands, remote locations around Australia, and on mining sites.

High renewable penetration allows operators of off-grid microgrids to extract maximum value from their installed solar, wind or other renewable generation while minimising the use of fossil fuels, such as diesel. It’s a win-win for the financial bottom line and emissions-reduction goals. If the microgrid connects with a broader power system, the benefits of reducing reliance on externally sourced energy are significant too.

Establishing a relatively simple microgrid with modest fuel-saving targets doesn’t have to be particularly complex. It’s within the reach of current technology and practice to be able to optimise microgrids to all but eliminate the use of fossil fuel (with the related advantages of eliminating fuel handling, shipping, etc.). However, careful thought must be given to the distinct nature of the microgrid: its customers, energy sources and storage options.

To make a microgrid successful, some technical challenges will need to be managed. Resolving these challenges in a cost-effective way becomes more difficult as the renewable energy balance approaches 100% – but they’re not insurmountable. Let’s explore.

Challenge 1: Ensuring quality of supply and an acceptable customer experience

The small size of microgrids and the fact that they are usually dedicated to a single ‘customer’ makes engineering a microgrid a sensitive task. While larger grids can operate with tight voltage and frequency tolerances and multiple levels of redundancy, microgrids often cannot. This inevitably means negotiating acceptable system standards for islanded operation that are within the tolerance of customers’ equipment and expectations. Microgrids powered by fossil fuels typically have more difficulty maintaining tight frequency and voltage tolerances than renewables-based microgrids.

Understanding customer and stakeholder expectations relating to reliability and robustness (energy availability and the ability to ride-through faults) is key to the establishment of a successful microgrid. Where the microgrid exists with no possibility of interconnection to another power network (i.e. in an ‘island’), there is more flexibility and less operational complexity. Discerning acceptable standards and practices is still not easy but it can be a more productive discussion than when the microgrid must comply with less tailored standards due to interconnection.

When the microgrid is interconnected, many of the technical requirements for the microgrid will be specified and/or mandated by the network service provider, electricity code requirements, and some operational requirements for electrical safety. If additional communication and inter-tripping with network equipment remote to the microgrid are required, these can add further complexity.

Challenge 2: Managing different modes of operation requiring different controls

In the previous section, we discussed how complicated it is to determine system standards. A great deal of care is also needed when contemplating which standards and controls are most appropriate to the microgrid’s specific characteristics. This is where cookie-cutter solutions could under-deliver and a more insightful approach is required.

A microgrid must manage the voltage, frequency and quality of supply while it is islanded as well as during periods of interconnection. Islands can remain satisfactory for longer if there are energy sources, storage and load controls within the island. Each of these elements comes at a cost and, depending on the frequency and duration of islanded operation, must have a value outside of the islanded scenario.

Our experience with microgrids is that semi-autonomous operation of each of the power sources using standard power system control approaches (solar, BESS and other power sources on voltage and frequency droop control) leads to the simplest and most secure response to transients (load or generation trips, network or network faults). Slower controls can be put in place to balance generation and rates of battery charge or discharge. If the battery power rating is large enough relative to the largest disturbance, it can manage most frequency disturbances within acceptable limits. If the battery energy capacity is large enough, it can always maintain a state of charge that allows fast reaction to variations in customer demand or VRE. Alternatively, auxiliary plant such as switched resistors, synchronous condensers and customer-level load control can be used to minimise battery power, storage and other energy inputs.

Operating microgrids in different modes requires careful engineering of the controls and equipment. The solutions and approaches described above have proven successful across multiple projects, but the key is to always be open to new solutions as new problems arise or new technologies emerge.

Challenge 3: Understanding the marginal value of resistors, synchronous condensers and/or demand management

Auxiliary equipment can help to extend the range and effectiveness of a microgrid to rely solely on renewable energy. The challenge is to understand the actual value of extension in this context. Where it has a direct bearing on fossil fuel use, the benefits are clear. Where it might cause an incremental improvement in the robustness of the islanded operation only, it’s important to consider whether any operational benefits or security benefits gained from the additional capital investment are valuable enough to justify the cost.

If the robustness of islanded operation is to be increased by managing customer demand, customer storage and/or embedded generation (e.g. rooftop solar), the value of the extended island longevity should be weighed against the perceived cost (direct or indirect) to the customer. This requires careful consideration of the diversity within the community, their openness to energy management, and the relationship between true costs and benefits.

Microgrids that maximise local use of renewable resources represent a relatively cost-effective option for lowering carbon emissions and/or reducing energy costs. Isolated communities, remote industrial sites, unreliably connected rural communities and others could benefit greatly from considering microgrid opportunities.

Entura has a long history of design, formation and operation of microgrids throughout Australia (such as King Island, Flinders Island, Rottnest Island, and at mining sites such as the Agnew gold mine) and in the Pacific region (including the Cook Islands, the Federated States of Micronesia, Tonga, and the Solomon Islands, to name just a few). We’ve seen the real benefits these systems bring to our clients and communities.

Contact us if you’re interested in unlocking the full potential of microgrids for your operation or community, or if you’re interested in ways to increase your use of renewable energy.

ABOUT THE AUTHORS

Donald Vaughan has over 20 years’ experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. He has worked for all areas of the electrical industry, including generators, equipment suppliers, customers, NSPs and market operators. Donald specialises in the performance of power systems. His experience in generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves.

Greg Koppens is Entura’s Principal Control Engineer Hybrid Renewable Systems and has led Entura’s secondary electrical engineering team. Greg’s experience spans power, oil and gas, and mining, including onsite roles. With over a decade of detailed design experience, Greg facilitates collaboration between engineering disciplines and other stakeholders to solve complex problems. He regularly shares his extensive expertise with the mining sector to advance their decarbonisation goals. Find out more about Greg in our podcast series here.

We built this synchronicity … but what now?

The alternating current (AC) transmission age started in 1891 through collaboration and perseverance. This transmission method has transformed the world, led us to the brink (or over the brink) of a climate disaster, and provides the backbone for a future founded on abundant renewable resources (in Australia, at least). Collaboration and perseverance are now required to ensure the continued utility of the grid.

Synchronous machines have always been the driving force in the grid. These elegantly simple electrical machines sit in powerhouses around the globe using their century-old technology (nearly 150 years, in fact) to convert mechanical energy into electrical energy to power the computer that I’m using to type this.

There’s a romance to these machines. It’s more than nostalgia. They spin, as the name suggests, in synchronism. If one of them falters, all the rest pick up the slack. The only connection they need is the power lines. This robustness is central to the way our electricity grids have operated for over 130 years – but the influence of synchronous machines is slowly being eroded.

The most obvious erosion of the influence of synchronous machines is their displacement by inverter-based renewable (IBR) technologies as solar, wind and battery energy storage (BESS) installations proliferate. A less obvious erosion of their influence is the diminishing understanding and appreciation of synchronous technology within the industry. This lack of understanding by engineers, planners and regulators of the fundamental building blocks of the electricity grid is starting to show.

This might sound like the curmudgeonly ranting of yesterday’s engineer as technology passes them by. Maybe it is … but, rather than dwell on negatives, let’s look at what synchronous machines bring to the power system.

- System strength

The fundamental difference between synchronous machines and IBR is thermal inertia. Typical synchronous machine design can sustain high levels of over-current for a relatively long time (seconds) compared to IBR units (milliseconds). This difference allows synchronous machines to provide a strong ‘natural’ response to voltage variations in the power system without threat of overload and damage. Transmission protection systems – and therefore grid security and safety – rely on this characteristic.

There are alternatives. Overload capacity can be built into inverters, but this is expensive. Dedicated inverter-based devices such as static synchronous compensators (STATCOMs) can be used to provide fault response.

- Inertia

Synchronous machines spin. Their spinning bits (rotors) have mass, so they have mechanical inertia. This mechanical inertia doesn’t require a control system to provide an inertial response. The inertial response from a synchronous machine is a known, predictable quantity, regardless of voltage.

IBRs can provide synthetic inertia and, when voltage is healthy, can out-perform synchronous units. When voltage is not nominal, the same current limitations that affect the IBRs’ ability to deliver fault level can also restrict the effectiveness of synthetic inertia delivery.

- Robustness

The previous two characteristics – system strength and inertia – show the support that synchronous machines can provide to the power system during disturbances. The synchronous machine can deliver these supports across a wide range of power system disturbances to voltage and frequency.

IBRs typically rely on fast controls to manage their response to system disturbances. Under some extreme conditions these controls may not be fast enough or well enough tuned to manage. While tuning is important to synchronous machine performance, often it has a second-order effect or adds robustness over and above the natural response.

Displaced but not superseded

Understanding the inherent dynamics of synchronous machines gives power system engineers a better appreciation of these machines’ contribution to power system stability. Regulators should be mindful of the reduced risk (and mostly advantages) to system security that synchronous machines offer relative to IBRs. This is despite the uncontrollable nature of synchronous machines. That is, physics dictates the stabilising effects from synchronous machines whereas control algorithms determine whether an IBR can stabilise or destabilise. Controller model accuracy is therefore more important for IBRs than it is for synchronous machines where transient stability or electro-mechanical transient time frames are considered.

Better understanding of synchronous machines should lead to more appropriate rules relating to dynamic response to system events. Overly specific requirements for fault ride-through, power recovery post-fault, and maintenance of real and reactive power during voltage disturbances may all lead to needless protracted negotiations over access standards. This slows down the progress of the energy transition, frustrates otherwise helpful development, and diverts resources towards trivial considerations rather than focusing on issues of greater importance.

Synchronous machines will play a role in the energy grid of the future. Our industry needs to maintain expertise and regulatory frameworks that allow this technology to continue providing the grid with vital stabilisation and robustness.

ABOUT THE AUTHOR

Donald has over 20 years’ experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. He has worked for all areas of the electrical industry, including generators, equipment suppliers, customers, NSPs and market operators. Donald specialises in the performance of power systems. His experience in generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves.

Getting the answers you need: Technical due diligence for vendors, buyers, lenders or insurers of renewable energy projects

Technical due diligence (TDD) for a renewable energy project evaluates the risks and opportunities associated with the project to establish its technical and financial viability, compliance with regulations, and other factors influencing its value. TDD is fundamentally a well-understood risk assessment process, with practitioners typically having templates they can tailor to specific projects and client needs. However, different parties will have different objectives, different scope for TDD to cover, and different risk appetites.

Objectives

Vendor perspective: Do we have our house in order?

An owner (or vendor) is most likely to procure TDD to show the market and prospective buyers their project or portfolio of assets for sale. Engaging an ‘independent’ party to prepare a TDD report serves several purposes: it can facilitate a quicker sale process, enable the owner to anticipate a buyer’s questions, and allow the owner to take pre-emptive actions to mitigate perceived risks. This can give the owner greater control over the sale process or how the project is later structured. For example, in Australia, there is a trend of wind turbine suppliers (original equipment manufacturers, OEMs) getting involved early and developing the project around their specific wind turbine model, then selling the project while maintaining a strong interest as the OEM.

Buyer perspective: Is this project worth our investment?

A buyer conducts TDD to evaluate whether the project aligns with their investment goals, operational capabilities, and risk tolerance. They are interested in understanding the technical feasibility, potential challenges, and opportunities associated with the project. There is often a need for technical inputs to feed into a financial business case, such as CAPEX and OPEX estimates and estimates of energy yield.

Lender perspective: Will we get our money back?

Lenders, such as banks or funding agencies (e.g. Clean Energy Corporation, ARENA, World Bank, Asian Development Bank), conduct TDD to assess the project’s ‘bankability’. This involves evaluating whether the developer can fund the project and if the project can generate sufficient returns to repay loans. Lenders focus on mitigating financial risks and ensuring compliance with lending criteria and industry standards.

Insurer perspective: Is this project insurable, and at what cost?

A wide range of insurances may be in place during the construction and operation of a renewable energy project. Insurers will evaluate project risks and feasibility to determine insurability, the cost to insure, and how to manage potential claims effectively.

Scope

Vendor perspective: Help us prove to buyers that we’re transparent

A prudent vendor will try to anticipate everything buyers might want to know and present the project in the best possible light, ideally addressing information gaps and mitigating risks. The vendor will rely on the consultant’s independence for the TDD report to have value for potential buyers.

Buyer perspective: Tell us the risks – and if the project can be improved

A buyer may undertake TDD at any stage of the project life cycle, from conception to decommissioning, requiring a tailored scope of work. The buyer will focus on technical aspects impacting ownership and operational responsibilities, such as technology selection, construction feasibility, resource assessment, and operational performance expectations. Existing assets may also influence their priorities during TDD.

For example, a buyer who already operates a portfolio of wind farms will be much more comfortable with many of the typical risks of wind development in comparison to a buyer for whom the project is a first of its kind.

Owners will often employ a consulting business to undertake TDD alongside environmental, social and governance (ESG) due diligence, with legal and financial due diligence conducted by other specialist parties.

A good TDD for an owner will focus not only on risks, but also on opportunities for improving the project.

Lender perspective: Tell us everything!

Lenders sometimes directly engage a consultant for TDD; however, often the owner will manage the engagement of a ‘lender’s’ or ‘independent’ engineer for TDD, with the resulting TDD report provided to a bank or consortium of banks for their evaluation and questioning.

Lender’s TDD engagements typically have a broad scope, encompassing not only technical aspects but also financial, legal and regulatory considerations. They assess the project’s financial model, revenue projections, contractual agreements, insurance, permitting, and compliance with regulatory requirements. Lenders are interested in the capability and experience of key contractors, the robustness of contractual arrangements, and will look to TDD consultants for assurances that project schedules are achievable.

Lenders will have a particular interest in things like budget contingencies, and what contractual mechanisms offer assurances such as warranties and liquidated damages.

In practice, the TDD scope for a ‘shovel-ready’ project may be similar for a buyer and for a lender considering investment.

Insurer perspective: Is the technology mature, and what’s this we’ve heard about a flood zone?

Insurers assess risks, including vulnerabilities, operational disruptions, and compliance with industry standards. They are particularly interested in technology maturity and environmental risks that may lead to future insurance claims. For example, rapidly released new wind turbine models may increase the risk of failures, making insurers keenly interested in operational hours as a measure of a model’s proven reliability.

TDD is a core activity for insurance underwriters (those who evaluate and analyse the risk) and is not typically outsourced to consultants. But consultants can learn from the insurance industry, which deals in risk assessment every day.

Risk appetite

Vendor perspective: Help us show it’s a safe bet

Naturally, vendors will typically prefer to present risks as identified and under control. However, it is in their interest to present the project honestly. After all, many transactions have the vendor retaining a stake in the project.

Buyer perspective: Help us find a project with low risk and good returns

The buyer may be evaluating technical risks during project development, construction or long-term operation depending on the project status. In practice, the earlier in the project’s life cycle, the greater the risk, and, in theory, the greater potential financial return.

For example, a project claiming to be ‘shovel-ready’ should have all major planning permits in place, a confirmed grid connection, and technical studies completed (such as geotechnical investigations). The TDD assessment will review documentation to identify specific risks that might eventuate during construction and operation.

On the other hand, for a project in early development, the risks may be of a more generic nature and the buyer may need to accept that there are some unknowns. This is essentially greater risk but there is potential for greater rewards in the long run.

Lender perspective: We’re taking a lot of risk here, so has everyone done their homework?

A typical funding model is where a bank or syndicate of banks provides a loan to a project owner that is subsequently paid back via the revenue earned by the project. The loan is secured against the assets of the project, and the banks want to ensure they will be repaid. Lenders take on substantial risk; hence, during TDD they expect to see that projects are well-conceived and executed, and they will adopt relatively conservative views on issues such as expected energy yield.

Insurer perspective: What’s the right level/cost of cover?

Insurers have sophisticated risk modelling techniques and real-world experience of what is going wrong on projects and what it’s costing. Insurance is a global industry, and what happens overseas impacts the TDD that insurers do for Australian projects.

Decisions made by project owners can have a substantial impact on the cost of insurance, and in fact whether insurance is even obtainable. For example, if an owner selects a relatively new or untested wind turbine model, the cost of insurance may negate any intended savings.

In summary

While vendors, buyers, lenders and insurers conduct TDD to assess the feasibility and risks of a renewable energy project, their perspectives, objectives, scopes and decision-making criteria differ based on their roles and interests in the project. As technical consultants who conduct TDD, it’s our responsibility to understand these differences and tailor our TDD approach accordingly.

If you’d like to talk with our specialists about technical due diligence for a renewable energy project, contact Patrick Pease, Bunfu Yu or Shekhar Prince.

About the authors

Andrew Wright is Entura’s Senior Principal, Renewables and Energy Storage. He has more than 20 years of experience in the renewable energy sector spanning resource assessment, site identification, equipment selection (wind and solar), development of technical documentation and contractual agreements, operational assessments and owner’s/lender’s engineering services. Andrew has worked closely with Entura’s key clients and wind farm operators on operational projects, including analysing wind turbine performance data to identify reasons for wind farm underperformance and for estimates of long-term energy output. He has an in-depth understanding of the energy industry in Australia, while his international consulting experience includes New Zealand, China, India, Bhutan, Sri Lanka, the Philippines and Micronesia.

Brendon Bateman is a senior renewable energy engineer with more than 20 years of experience on renewable energy projects in Australia, New Zealand, Pacific islands, Philippines, China, India, Sri Lanka, North Korea and South Africa. Brendon is recognised as a technical expert for feasibility or due diligence of renewable energy projects with involvement in the assessment of over 10,000 MW of greenfield and operational projects, identifying key risks for developers, banks, equity funds and aid agencies looking to develop or invest in renewable energy projects. Brendon is highly experienced in the areas of resource assessment, energy estimates and their associated uncertainty, operational performance assessments, wind turbine due diligence and O&M practices.

Powering a greener mining future with hybrid renewables

This article reflects on a panel discussion chaired by Ray Massie at the Energy and Mines Australia Summit 2023, which you can read more about here.

The discussion about powering mines with renewable energy has moved a long way in a short time. As the imperative to go green has escalated, the mining sector has grown hungrier for viable, rapid and cost-effective strategies to decarbonise, build greater social licence and tap into the competitive market for products with a lower carbon footprint. Integrating cheap, abundant renewable energy into mining operations is the natural solution.

These are exciting times as the sector moves far beyond the ‘why’, ‘whether’ and ‘when’ of renewables – and digs much, much deeper into the nuances of ‘how’.

Early forays into small hybrid off-grid renewable energy systems have demonstrated and built confidence in the technology – so there is no longer any question in the mining industry of whether off-grid hybrid renewable systems will work. Off-grid hybrid projects aren’t small test beds anymore. They’re ground-breaking, large-scale, cutting-edge renewable power systems of the future, able to be deployed on a fully commercial basis with clearly understood risks and operational adjustments. In many ways, the mining sector is out ahead of the pack, and the deployment of renewables on off-grid mine sites is offering lessons for the wider power sector and the future of the grid.

With many of the early technical risks resolved, the driving focus now is how to take full advantage of what a hybrid system can offer. How can the system be optimised to maximise its benefits? What’s the required level of reliability? How much storage is enough – and in what form?

Of course, every mine site is different, so there are no one-size-fits-all answers. And today’s answer may not be the right fit for tomorrow, given the rapid and continuous transformation of the energy landscape – in terms of technology advances, policy shifts, price volatility and global trends. It’s a dynamic space.

Integrated control and storage change the game

Traditionally, the relationship between mining operations and power supply has been a relatively simple transaction requiring a given amount of power with a set level of reliability and availability. The modelling of the power system was based on simple load metrics and power quality dictated by the capabilities of thermal generation plant. This equated to a very simple, flat cost of energy with any variance at the macro scale driven by changes in the price of fuel.

As we all know, when we switch over to multiple intermittent and variable generators, things become more complex. One of the keys to unlocking the benefits of a hybrid renewable system is the integrated control approach. With the correct control philosophy in place, you have many more ‘levers’ that can bring each element into play for a given operational mode or system event. This enables achievement of the levels of power quality and reliability that are needed, rather than being limited to the levels that traditional thermal plant could supply.

With this sophistication of control, we can start to think differently about reliability across the whole mining operation. Does the mining plant process or works need the same reliability or availability across everything all the time? Perhaps, for example, power supply for pumping may not require as high a level of reliability as other more critical areas of the plant. A clear understanding of the true reliability needs will help derive the optimal design at minimal cost.

When storage comes into the mix, we can also start to think differently about how to best match energy supply, timing of energy-intensive activity, and storage of excess energy to get maximum value from the renewable resource and minimise both the cost of energy across the operation overall and the cost per tonne of the mine’s output. The economics of long-duration storage are improving all the time.

New horizons for energy storage

Although the technology and the sector have travelled a long way already, there are still issues to finesse. One area of uncertainty is the optimal and most cost-effective storage technology and duration.

Going back a decade, the economic storage duration was 10 to 20 minutes, using the battery primarily for its discharge capability. Now we are seeing economic storage durations approaching 4 hours, which lend themselves to energy-shifting roles in which the charging capability comes into play as well as the discharge mode. The economics of longer duration storage will continue to improve but the optimum arrangement will vary site by site.

Funding for advancing novel long-duration energy storage (LDES) technologies has increased by 36 times over the past 5 years[1]. While lithium-based batteries still dominate and are likely to continue to do so for the foreseeable future, many more types of storage are now possible, including metal-air, pumped hydro, compressed air, flow batteries, gravity, thermal and various novel chemistries. Some storage technologies require specific topography and geology, for example pumped hydro and large compressed air storage, and others are at varying stages of technical readiness. Flow batteries of various chemistries are experiencing a significant amount of support aimed at breaking through the long-term storage cost barrier, though this is yet to be achieved at scale, and more likely to be competitive at longer durations (>10 hr) and in larger sized systems (>100 MW).

It is clear, however, that finding the best LDES for a mine project is not just for the mining sector to solve alone. The entire global power industry is looking at storage – and the mining sector can take full advantage of this as LDES evolves. What the mining sector can do right now is to identify the energy use and demand side opportunities that various storage durations could unlock for their projects.

Another key learning we have found over years of hybrid system development is that not every bit of energy produced by renewables needs to be stored. Some can be spilt or, better still, adjustments can be made on the load side to better match the variability in generation. Once the system stability, reliability and demand-side opportunities have been addressed, the storage of ‘spill’ really comes down to economics, which will change over time as storage costs decrease.

Collaboration and risk management

With all these new approaches and possibilities – and the many factors that always come into play such as mine life, capital limits and risk – it’s possible to over-analyse. Not every new project needs to break barriers and set new records. There is definitely still a place for choosing the low-hanging fruit, as the primary case for renewable hybrids being cheaper than thermal-only is well established. You will never really be able to answer every question in a single project – or even predict every question that might arise.

This is where you simply don’t have to go it alone. The key to overcoming hesitation is collaboration. Getting the correct advice is always worth the investment, as is sharing learning at an industry-wide level. There are many players that specialise in one or more aspects of the future mix of technology, mining process, hybrid power operation, renewables knowhow, integration skills, commercial thinking and so on – and bringing these skills together is a must.. Collaboration is the key to solving problems, reducing risk and its appropriate allocation, and a successful project that will benefit all industry players more than competition and working in isolation.

We also believe in learning by doing, through delivery of a specific project. Forming a group of key parties to drive forward a tangible project makes it far more manageable. In innovative projects, ‘pushing risk through’ often just comes back as significantly increased cost. A better approach in these cases is a shared risk profile. The learning is a significant part of the return in early adoption.

Are the right people and the right materials available?

The industry is already experiencing a shortage of experienced hybrid system operators. This needs to be managed through increased training and backup. We believe that operational personnel should be engaged very early in the design of a hybrid power system so that they can have input into development of the system, gain familiarity with it, and consequently feel a level of ownership of the assets.

It is also important to have a close relationship between those involved in the mining process and those operating the power system. For the power system operators, this is a chance to better understand the criticality of various mine plant processes; for the mine operators, it’s a chance to get a better understanding of the mix of operation modes that can be used to meet the mine’s changing power needs.

In many ways, the people skills and resources needed across all the project delivery stages (design, deployment, operation, maintenance and support) are more important than the technology – and this needs to be considered carefully for hybrid projects to be successful.