Planning for the future – the challenges of dam inspection and maintenance

No dam is ‘maintenance free’. Without appropriate maintenance and refurbishment at the right times, a dam may not be able to fulfil its function safely for the full length of its design life (which could be more than a century).

This presents many challenges for asset owners. To keep the dam operating as the designer intended – and get the most out of the original investment over the long term – owners will need to develop and implement a suitable operations and maintenance manual aligned with the asset management plan and reflecting a ‘whole of life’ strategy. These plans will need to consider the unique characteristics of each dam and cover all the relevant issues. And there are many!

Dams consist of a number of different elements. There are the main civil engineering components including the wall that holds back the water and the spillway – but there could also be mechanical elements (pipework, valves and gates) and electrical elements (power supply to lights, valves, gate motors and control systems). Each of these elements will have its own operational and maintenance requirements and different lifecycle duration. Ideally, all this detail needs to be captured in the operation and maintenance manual (as recommended by ANCOLD guidelines) and in an asset management plan.

Civil components

The civil components of dams have the longest life span, typically more than 100 years if well constructed and maintained. Common maintenance items that need to be regularly addressed include:

- Vegetation management

Trees and bushes will readily grow in earthfill and rockfill embankments. Regular control (e.g. annually) is necessary to ensure that roots don’t grow through the fill and initiate leaks through the embankment. Mowing the grass on the downstream face of the earthfill embankment and downstream contact is necessary so that the condition of the face can be observed. Even concrete gravity and concrete arch dams will require vegetation control along the downstream face contact with the foundation so that the dam can be easily viewed in routine inspections.

- Surface water drainage

Dam construction typically affects natural drainage lines, which is why surface water drains are a common feature around and on dams – such as along the groins (where the dam wall intersects with natural ground), along berms in embankment dams, along benches, at the top of cuttings, and along access tracks. Drains will need regular inspection for both erosion and blockage due to sediment or vegetation.

- Foundation drain cleaning

Concrete gravity dams and concrete arch dams typically have drains drilled into the rock foundations to relieve uplift pressures and help maintain stability of the wall. Over time, silt or iron-rich slime can build up as a byproduct of bacterial growth in the drains, reducing effectiveness. These drains typically require 5-yearly high-pressure flushing. Cleaning will also be needed for drains underneath spillways founded on rock and cut slopes in rock.

- Protection of the dam safety monitoring system

Protecting the dam safety monitoring system requires a range of regular activities. These include cleaning and clearing vee-notch seepage monitoring weirs, checking survey monitoring pillars and targets, and checking the calibration of level monitoring and indication devices, such as reservoir-level sensors, piezometers, tiltmeters and inclinometers. Regular functional testing will also need to be carried out on the alarming and tripping devices that form the primary protection elements of the dam, including spillway gates and scour valves.

- Clearing of trash racks

Outlet works usually have trash racks to stop debris entering the pipework and causing blockages. It’s important to check that the build-up of debris is tolerable and that any hydraulic losses won’t affect operations. Assessing and removing the debris isn’t easy, as the trash racks are often accessible only by remotely operated vehicles (ROVs) or by divers. Before the inspection, the outlet will typically need to be closed and isolated.

Inspection-driven longer term maintenance will also be required for particular elements of the dam, ideally addressing repair items promptly to minimise damage and the cost of future repairs if left untreated. For example, concrete repairs may be needed to address erosion in stilling basins and spillway chutes, or spalling of concrete due to reinforcement corrosion or freeze/thaw damage.

While regular inspections should be undertaken to detect slow deterioration, special inspections following major events – such as floods or earthquakes – should also be part of the operations and maintenance plan. Given that the key areas for inspection are often difficult to access safely, use of UAVs (e.g. to inspect a spillway crest and chute) or ROVs (e.g. to undertake underwater inspections or scanning of stilling basins, plunge pools or riverbed scour) should be considered.

When special inspections identify the need for repairs, the time is right to consider whether the dam’s design or surveillance could be improved to increase resilience for a similar event in future. For example, a higher strength concrete overlay may treat erosion of a spillway chute and increase its resistance to future erosion.

Mechanical components

Mechanical items such as steel or cast-iron pipework can also often last up to 100 years if adequately protected from corrosion. Concrete and cement mortar are very effective for this purpose as the alkaline environment provided by the cement paste provides a very low corrosion environment. Key to the effectiveness of this protection is ensuring that the cement remains in intimate contact with the steel or iron. This will require regular inspections and timely repairs. Where concrete protection is not practical, paint systems can be very effective for up to about 20 years. A suitable inspection regime will be needed so that any areas where the paint has deteriorated can be detected and patched.

Mechanical items such as valves and gates typically have an effective life of around 50 years; however, they need to be exercised regularly to keep them able to work on demand. This is not an issue of the parts wearing out from use; rather, it’s the risk of them seizing due to lack of use. Regular lubrication of bearings, gearboxes and trunnions needs to be included as part of the maintenance of these items. This is particularly important in scour valves and spillway gates that may have a very low frequency of use during normal operations but are there for use in emergencies. The wire ropes commonly used to hoist spillway gates open will need even more frequent replacement, at approximately every 20 years.

Electrical components

Electric motors are commonly used to drive the winches hoisting spillway gates or driving the shafts to open valves. Associated with the motors will be switchboards and power supply systems, typically including grid power supply and backup diesel generators. The typical life of these components is around 25 years. As with the mechanical components, lack of operation can lead to premature failure, so a regular regime of exercise is necessary to ensure maximum reliability and life.

The programable logic controllers (PLC) that are used to automate operations, allow remote operations and generate alarms will have a typical life of only 10–12 years due to changes in programming languages and rapid evolution of the hardware.

Getting the most out of life

As we’ve seen, regular maintenance is fundamental for keeping all the components of a dam operating as intended and maximising their lifespan – whether that’s 10 years or 100. This maintenance, including the exercising of the mechanical and electrical components, needs to be clearly documented in the operations and maintenance manual and recorded in an asset management system. The asset management plan must allow for regular maintenance and also budget appropriately for replacement or refurbishment when any component of the dam is due for retirement.

At Entura, we believe in getting the most out of every piece of infrastructure because that’s good for our clients, communities and the planet. With a solid regime of inspection and maintenance, all the parts of your dam will be on the strongest path to a long, reliable and sustainable life.

If you’d like to talk with us about inspecting and maintaining your dam/s, contact Phil Ellerton, Paul Southcott, or Richard Herweynen.

About the author

Paul Southcott is Entura’s Senior Principal – Dams and Headworks. Paul has an outstanding depth of knowledge and skill developed over more than 3 decades in the fields of civil and dam engineering. He is a highly respected dams specialist and was recognised as Tasmania’s Professional Engineer of the Year in Engineers Australia’s 2021 Engineering Excellence Awards. Paul has contributed to many major dam and hydropower projects in Australia and abroad, including Tasmania’s ‘Battery of the Nation’, the Tarraleah hydropower scheme, Snowy Hydro, and numerous programs of work for water utilities including SeqWater, Sun Water and SAWater. His expertise is a crucial part of Entura’s ongoing support for upgrade and safety works for Hydro Tasmania’s and TasWater’s extensive dams portfolios. Paul is passionate about furthering the engineering profession through knowledge sharing, and has supported many young and emerging engineers through training and mentoring.

Breathing new life into Australia’s aging wind farms

The wind industry, well-established in Europe for decades, took baby steps onto Australian soil in the late 1980s and 1990s. By the early 2000s, Australia’s new wind industry was ready to take off. Given that wind farms usually have a design life of anywhere between 15 and 30 years, our earliest wind farms are now reaching retirement age. The industry therefore faces a new set of challenges. Can these older wind farms continue to serve their important role in Australia’s clean energy transition or are they at their end of life?

So far, few wind farms in Australia have been decommissioned, dismantled and removed from the land. With many of our older wind farms sited to capture the best wind resources, there’s every reason to try to continue using these sites to harness wind energy.

One option is to squeeze more years out of the wind farm through effective maintenance and supportive analysis to ensure it is safe to do so while accepting that there may be increasingly frequent outages and increased maintenance costs to keep the wind turbines in service. However, although operation beyond the nominal life of a wind turbine is theoretically feasible, old wind turbines can’t keep spinning forever and will need to be stopped at some stage.

Other options for aging wind farms are refurbishment of some parts of the turbines, or full ‘repowering’ with completely new machines. This could also include a full redesign to accommodate larger turbines or to incorporate solar or battery energy storage systems.

An example of rejuvenation

Small grids may be some of the first to need to consider what to do about old wind farms. As an example, Hydro Tasmania’s Huxley Hill Wind Farm on King Island has three 250 kW wind turbines that were installed in 1998, and two 850 kW wind turbines that were installed in 2003.

For Huxley Hill Wind Farm, the King Island electricity load has not changed much over time, and offsetting diesel using renewable energy continues to make perfect sense.

For this site, the owner opted for a like-for-like replacement of nacelles (generator, gearbox, yaw system) of the Nordex 3 x N29 250 kW and potentially for the 2 x Vestas V52 850 kW wind turbines. This decision was partly about the good economics and sustainability of reusing existing infrastructure, and also because wind turbines of this size continue to suit the project so well.

When the wind farm was constructed 20+ years ago, the installed wind turbines were considered modern, large wind turbines. These days, the same suppliers do not offer anything less than 2 MW in capacity, with rotor diameters greater than 110 m. The lack of availability of what are now considered smaller wind turbines (say 1 MW) poses challenges for some small projects. At the scale of less than 1 MW, there are now few proven wind turbine options. At an even smaller scale (<100 kW), solar PV now dominates.

When any existing infrastructure is to be retained to support life extension of old wind turbines, such as at Huxley Hill, it’s crucial to confirm that it is still suitable and safe. This can include various techniques and activities, including:

- physical inspection by technicians and engineers

- excavation of the foundation backfill cover to reveal the tower-foundation joint and inspect corrosion and remediation

- surveying the tower and blade condition using drones

- surveying the tower verticality

- surveying the thickness of tower sections

- ultrasonic testing of bolts

- eddy current testing of welds to detect any flaws

- reviewing data from the turbines to refresh understanding of the actual wind regime, reassess fatigue loads and estimate remaining life.

Another important consideration when rejuvenating older wind farms is to consider the potential for adding solar or battery energy storage. With solar now more viable than when Huxley Hill Wind Farm was conceived, a 1.5 MW solar farm has been added to augment the wind generation.

Starting over with full repowering

Because the Australian wind industry is still relatively young, there is not yet an established practice or precedents for full repowering. However, in Europe, hundreds of wind farms have been repowered, often massively increasing output by using fewer but much larger modern turbines.

Repowering at around 25 years seems the most likely timeframe for most Australian wind farms – but few have yet reached this age. Ultimately, market factors will determine when repowering provides the best financial return.

Even though we’re still just on the brink of Australia’s repowering journey, it’s never too early to start considering the complexities and implications and assessing all options.

Repowering won’t be simple or quick. The development process for repowering NEM-connected wind farms is likely to be just as challenging as developing a new wind farm on a greenfield site.

The concept of ‘repowering’ involves a range of options for replacing old wind turbines and associated footings and electrical balance of plant with new, but it’s unlikely that much of the existing infrastructure and balance of plant will be able to retained if larger, modern turbines are selected. The layout of the wind farm is also likely to need revision to accommodate longer blades.

Planning approvals need to start just as early, as should the process of renegotiating with hosts, neighbours and communities. People may be concerned about the impacts of much taller turbines and the logistical issues of getting them to the site, as well as arrangements for the dismantling, removal and disposal of the superseded technology and infrastructure.

Repowering with bigger and more powerful turbines is also likely to involve re-permitting and negotiating a new grid connection agreement – neither of which are certain, given the cumulative impacts that may have emerged over time and any changes to rules and regulations since the wind farm was first developed.

By planning early for repowering, developers can get ahead on these issues as well as on condition assessment of the assets, decommissioning plans for old turbines, new studies that might be needed (such as bird monitoring), and new wind measurements for taller, modern wind turbines, perhaps using modern wind measurement technology such as lidar.

While some repowered wind farms will very likely incorporate new battery energy storage systems (BESS), they are less likely to deploy large-scale solar as a default, given that many of the best original wind sites in Australia are coastal or hilly, particular those in the south of the country. Nevertheless, the potential for co-located renewable generation, storage and loads is worth exploring.

Don’t wait for trouble – start planning now

We suggest that wind farm owners take action now to deepen their understanding of the condition and present value of their assets, and explore the full range of short-term and long-term options available through a feasibility and options study. After all, in such a dynamic market and technology landscape, and with the potential for aging assets to deteriorate or fail, decisions about end of life may need to be made earlier than expected.

About the author

Andrew Wright is Entura’s Senior Principal, Renewables and Energy Storage. He has more than 20 years of experience in the renewable energy sector spanning resource assessment, site identification, equipment selection (wind and solar), development of technical documentation and contractual agreements, operational assessments and owner’s/lender’s engineering services. Andrew has worked closely with Entura’s key clients and wind farm operators on operational projects, including analysing wind turbine performance data to identify reasons for wind farm underperformance and for estimates of long-term energy output. He has an in-depth understanding of the energy industry in Australia, while his international consulting experience includes New Zealand, China, India, Bhutan, Sri Lanka, the Philippines and Micronesia.

MORE THOUGHT LEADERSHIP ARTICLES

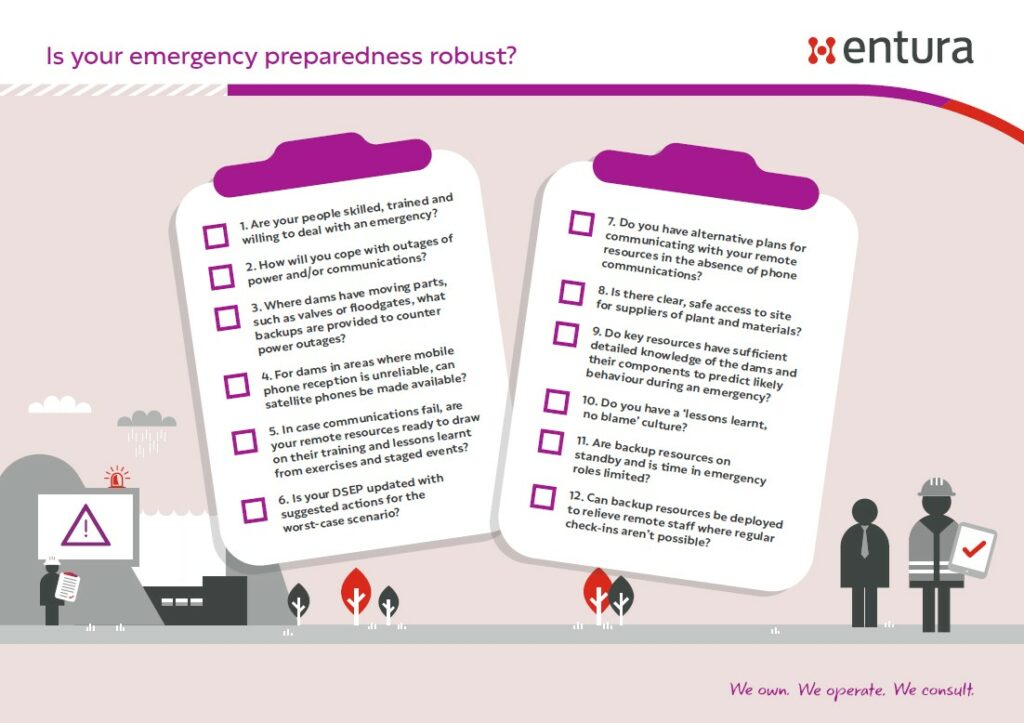

How robust is your emergency preparedness?

The old adage of ‘a company’s greatest assets are its people’ is never more true than in an emergency situation. The success of any emergency plan depends upon the skills, training and willingness of the people involved. It also relies on robust emergency preparation that takes as many scenarios as possible into account, and builds in a range of backups and alternatives for maximum agility and resilience.

All responsible dam owners have dam safety emergency plans (DSEP) which are carefully created and tailored to the needs of the company, its assets and its available resources.

If called upon in an extreme event, these plans will likely be pushed to their limit – but it’s vital that they perform as intended to reduce risk and consequences downstream.

The ultimate test of the emergency plan is how well it can cope with outages of power and/or communications. ‘Stress testing’ emergency plans for outage scenarios and implications is key to achieving a robust plan.

Power and communications outages

Where dams have moving parts, such as valves or floodgates, backups are needed to counter power outages. Are backup generators in place, or can a portable generator be brought to site at short notice? Is there a clear, safe access route to site during emergency conditions (e.g. not flooded or blocked by fallen trees)? Where this is not possible, can the valves or floodgates be operated by hand? A further question is whether these components are readily operable and exercised regularly.

Many dams are located in remote areas, and in some cases mobile phone reception is unreliable. In these situations, can satellite phones be made available? Landline phones may be available but depend on poles and lines remaining intact and operable during emergency conditions.

Communications are vital to ensuring the emergency plans are enacted under the direction of the incident controller. Where communications with remote resources are limited or not possible, those involved must fall back on their training and on lessons learnt from exercises and site-based, staged events involving scenarios of outages of power and communications. The DSEP can be updated with suggested actions for the on-site operators and emergency management team to follow in the worst-case scenario.

Alternative means of communication and access

In situations where check-in communications are required with those working remotely, alternative means must be considered in case of an outage of communications. In the absence of satellite phones, this could involve a messenger driving to site, but this relies on clear, safe access routes and careful consideration of the time required. In extreme cases, the only means of reaching a remote site may be by helicopter. This would require pre-arrangement with the closest helicopter providers regarding emergency availability.

The situation is similar with suppliers of plant and materials that may be required to assist with conditions at or downstream of the dam. How can they be contacted, and is there clear, safe access to site? Consider having emergency stockpiles at site or nearby and ready access to earthmoving plant.

Decision-making in a SCADA outage

If a power outage results in a localised SCADA outage, there will be no current instrumentation data available to guide critical decisions. In such circumstances, decisions must be based on likely behaviour during emergency conditions or on forecasts from before the emergency is declared. This would likely require detailed knowledge of the dams and their components, which highlights the importance of regular routine monitoring and detailed studies such as comprehensive surveillance reviews and dam safety reviews.

Company culture, teamwork and support

Where there is a ‘no blame’ company culture in which employees are encouraged to speak up, point out flaws in systems and processes and identify faults with assets, there is a greater likelihood that employees will participate successfully in staged exercises and events and provide useful information regarding how an incident response team will perform during an emergency.

Another important aspect of company culture is working together as a team. It is possible that a person may become fatigued but cannot convey this due to a communications outage. It is also conceivable that during an emergency a person may be unwilling to ‘leave their post’ until the job is done, becoming fatigued in the process.

It is important to have backup resources and to limit time in any role during the emergency to minimise the chance of mistakes being made. The emergency plan is only as strong as the weakest link in the chain of command.

For all resources, including external resources, provision of backups should take into account leave, prolonged illness and the need to ensure replacement when employees leave the company.

Where a company has a strong and positive safety culture and team ethos, detailed knowledge of its assets, regular inspection and exercising of valves and gates, and a commitment to team-based emergency training, employees are more likely to overcome the challenges posed by outages of power and communications during emergency conditions. They will find a way.

No one can predict and plan for every emergency scenario, but we believe that the tips we’ve shared here can help dam owners to develop and maintain robust emergency plans that have a higher likelihood of success when called into action.

If you would like support with your emergency planning, contact Richard Herweynen or Phillip Ellerton.

About the author

Jamie Cowan is a senior dams engineer at Entura with over 2 decades of civil engineering experience in the UK and Australia. His experience includes the management of investigation, design and construction projects in the civil, dams and water industries. He has worked across all stages of project delivery, from feasibility to the commissioning of assets. He has provided construction support roles during dam construction and upgrade projects, and conducted intermediate and comprehensive inspections of dams for water authorities in Victoria.

MORE THOUGHT LEADERSHIP ARTICLES

Engineering – by humans, for humans

When engineers think about the future, do we get so engrossed in the complex technical problems that we don’t attend enough to the human angle?

Engineers have a reputation, whether rightly or wrongly, for being poor communicators, working obsessively and in isolation, and focusing on the immediate goal rather than its impacts on communities. Often, clichés have a basis in truth. If we are going to shift perceptions, we need to start by thinking about the way we work and the leadership we show to the next generation of engineers.

There’s no way we can predict the major developments, challenges or solutions of the next five or six generations of engineering careers. What we should focus on is what we can do right now to lead change in our profession and our communities – and I think the keys are communication, collaboration and community.

Communication

I recently listened to a podcast in which two energy market experts talked with a power system engineer. They discussed all sorts of technical matters relating to frequency and voltage control. I love those topics, but this conversation was limited and uninspiring because the participants simply didn’t have a common language or understanding.

We need to learn to communicate in ways that a variety of people can understand. That will mean better conversations with the people who can help our work have greater impact, and it will help our communities to appreciate the importance of our work in their lives.

It’s too easy for us as a profession to sit at our desks or stand under our hard hats and luxuriate in how clever we are, and then bemoan how so many people have no idea what we do and don’t value our work.

When things that involve engineers go wrong, a flurry of opinions erupts. Failures such as the blackout in South Australia, or the cladding issues at the Grenfell Towers, or issues with airlines or bridges or dams all lead to our communities questioning and debating engineering practice. Engineers tend to try to stay out of this rough and tumble for fear of being misrepresented. Yet maybe it’s better that we do engage where we can, since being misrepresented on a small issue is better than allowing a groundswell of misguided public opinion due to a lack of understanding of engineering principles.

We need to try to better explain our work and find simple ways to convey the complexities of the decisions that we make.

Collaboration

The world is far more complex now than it was a century ago – but it is impossible to imagine what level and pace of change future generations will experience. If we want to transform our world or help build a better future, we can’t do it by ourselves.

Engineering no longer operates in isolation, if it ever did. We must collaborate across the engineering team and across other professional disciplines to achieve truly effective development for our communities. Sometimes we may need to focus a little less on technical delivery as a primary outcome, and increase our recognition of the value gained by engaging successfully with the communities on whom the project relies for success.

Collaboration makes our work more effective, and exposes us to a wider range of inputs and values that we can incorporate into our designs and processes. Engineering can be a leader but it can also be a facilitator for better outcomes when we draw on, listen to and learn from the other experts involved in other aspects of our projects.

Community

Engineering work almost always benefits more people than merely the one who pays the bill. Much of my work is in connecting wind farms and solar farms to the grid. Mostly my work is paid for by the owner of the farm, and while it delivers direct benefits to the owner through return on investment, it also affects everyone connected to the nearby network. It affects the network service provider and market operator, it pays salaries, and it supplies the clean energy that helps the country reduce emissions and meet its international targets. In other words, my work, which may seem intangible, has tangible effects in the real world.

If we agree that our labours produce real impacts, we need to take better care to fully consider the wider consequences of our work, which often has the potential to cause ‘collateral damage’. We can’t build a road or a wind farm without changing the landscape. When we build a machine, it uses energy and may emit pollutants; and it reduces reliance on manual labour, which may put someone out of a job. There may be a risk to lives, livelihoods or the environment if something goes wrong.

Do we always make decisions about these matters with the community front of mind, or do we place our clients on the higher pedestal? This is a tricky area and I’m not espousing a puritanical approach. However, if we knew in 1919 what we know now about lead poisoning, acid rain, greenhouse gases, scarcity and general sustainability principles, what different choices could have been made?

In a time of automation, we need to think about benefits and risks and how they affect our communities. On one occasion early in my career, I designed a controller to turn on and off a couple of compressors at a power station. I wrote some code to balance the run hours. A few months after the new system was commissioned, I asked one of the operators how the system was going, in terms of the run hours management, and he said ‘you’ve done me out of a job’. I hope he was joking. The task he’d been doing wasn’t particularly important, but there was value in having a person who was in tune with the equipment to take care of it, and there was also value in giving that person dignity through work.

My point is that we must keep our communities foremost in our minds as we go about our work. It’s not just about what we produce. It is the way we work and the people we choose to work with and for. Our influence on the development of the next generation of engineers perhaps has more impact on communities than our actual work outputs.

Through communication, collaboration and community, engineering can be both ‘more human’ and ‘for humans’.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Becoming the Battery of the Nation

This article appeared first on the International Hydropower Association blog.

How can a small island become a giant battery for a nation? We’re finding the answers in increasing interconnection, developing new pumped hydro and repurposing our existing hydropower assets.

Tasmania is a small island state, with excellent water and wind resources. We’re powered mostly by an extensive hydropower system developed over the last hundred years – supplemented with newer wind developments. We’re connected to Australia’s National Electricity Market by an interconnector running across Bass Strait to the mainland. This has allowed us to trade in the national market for some time now, but as thermal generation progressively retires and Australia embraces greater proportions of variable renewables, the future national market will be vastly different. It will be characterised by low-cost variable renewable energy sources firmed by dispatchable storage and generation.

With Tasmania’s fantastic natural resources, established hydropower system and expertise, we want to be the ‘Battery of the Nation’, offering the generation and the storage and system support needed to help Australia achieve a clean, reliable, affordable energy future. Our Battery of the Nation vision is shaping up to be one of the most credible, competitive and coordinated solutions, able to be built in stages, aligned to market drivers.

In a nutshell, the Battery of the Nation means generating more renewable energy from our hydropower and wind assets, developing more storage solutions in the form of pumped hydro and building more interconnection to the mainland so that we can get our product to the national market to quickly and reliably support variable generation.

With the support of funding from the Australian Renewable Energy Agency (ARENA), we’ve been making progress towards this vision on a number of fronts.

Connecting the battery

Batteries aren’t much use if they’re not connected, so we need more interconnection to mainland Australia to get the power to where it’s needed. The initial business case for a new, second interconnector between Tasmania and mainland Australia shows it stacks up, and federal funding has recently been secured to fast track this 1200 MW interconnection project, known as Marinus Link.

Priming the pump

Around the world, significant investment is being made in new technologies such as grid-scale batteries and solar thermal projects, yet pumped hydro remains the most viable technology for longer term storage (greater than eight hours). Our state has significant pumped hydro potential and our existing hydropower assets offer excellent potential to repurpose and create cost-effective pumped hydro. We’re filtering down the possible pumped hydro options to identify around 2500 MW of future potential. The three most promising sites offer between 12 and 31 hours of storage and would cost around AUD 1.5 million / MW to develop. Further feasibility investigations will identify which one of these three will be the preferred option that can be ready to take advantage of more interconnection.

Redeveloping existing assets

We are also focusing on how to get the most out of our existing hydropower assets by repurposing and futureproofing them for a transitioning electricity market. The Tarraleah scheme in Tasmania’s central highlands was commissioned in the 1930s and our studies have been considering whether the scheme should be progressively refurbished or redeveloped. Redevelopment would more than double the scheme’s capacity from 104 MW to up to 220 MW – contributing to Battery of the Nation targets. By converting the station to flexible and fully dispatchable operation, instead of just baseload, it could flexibly boost output at times of high market demand and provide the ancillary services likely to be increasingly valued in the market. It is also expected to have flow-on benefits for the entire cascade of power stations below it.

We are also continuing major refurbishment and upgrades of other existing hydropower assets so that we can get more generation, efficiency and longevity from these assets to support our plan to become the Battery of the Nation.

Benefits for our island and the nation

The Battery of the Nation vision offers economies of scale and diversity by combining flexible, reliable renewable energy resources with cost-competitive, large-scale storage that can be built in stages, aligned to market drivers.

Battery of the Nation is designed to serve and support our local and national communities. Across the nation it will contribute to achieving lower power prices, reliable and secure energy supply, and meeting sustainability targets. It will also offer specific benefits to Tasmania through energy security and economic stimulus.

Battery of the Nation is a bold and bright vision to unlock our potential to contribute to the nation. It’s an example of how to reimagine hydropower and storage for the new market paradigms of a shifting energy future.

Can the power grid weather the weather?

Even a single day of load shedding makes people doubt the national grid’s robustness. How will the grid cope if we experience extreme weather conditions more often?

Things get hot in Australia. They can get smoky, or wet, or cold. Australia’s beauty is in its ruggedness, its unpredictability and its diversity of natural environments. It’s what Dorothea Mackellar captured so well in the famous Australian poem ‘My Country’ – a ‘sunburnt’ land of ‘flood and fire and famine’, with ‘droughts and flooding rains’.

As dramatic weather patterns become more intense and more frequent, the electricity grid must be robust, or at least be managed to adapt to short-term challenges.

If we get the design standards right and if conditions fall within the expected extremes contemplated by the framers of the standard, then everything works. However, what happens when conditions are abnormal? In heatwaves, we see people hosing the rail network to stop expansion. We’ve seen hosing to cool distribution power transformers at peak times too. But there’s only so much water and so many hoses that we can deploy when the heat is on. It’s not a sustainable solution.

Can we manage?

Yes … but we must manage actively. Business as usual will not be enough. Consumers will not tolerate lower levels of reliability based on the weather. So something has to change.

There are a few mutually supporting paths we could take, including (1) considering extreme temperature ratings and improving the reach and spread of weather monitoring and weather-dependent grid management; (2) adjusting standards to contemplate higher temperatures; and (3) reducing our reliance on high flows to deliver peak demand.

1. Consider extreme temperature ratings

Incentives already exist for our network service providers (NSPs) to release hidden capacity in networks. The incentives remain a small percentage of the overall regulated income they receive. The contemplation and control of realistic ratings under unusual weather conditions could be made more attractive to our NSPs. The NSPs would then be more likely to make these opportunities for capacity benefits transparent to the regulator and the public.

Generators are now being required to stipulate capacity at higher temperatures, but this is not being applied universally across existing plant. As we saw in Victoria this summer, the market is very reactive to the unplanned withdrawal of power from large thermal units – as much, if not more, than it is to variations in wind and solar power. Thermal machines have shown themselves to be sensitive and not always robust in prolonged hot spells.

2. Change the standards

If maximum temperatures continue to climb, our standards or ratings may need to be adjusted to suit. In a global market, we have to be careful about being too ‘special’ or we’ll end up paying for specifications that cost more than the benefits they deliver. A half-way position may be for generators to estimate their capacity in relation to temperature conditions and require tuning of these estimates over time. This would at least give us an idea of the temperature effects on production across the fleet. The results of this might then inform the need for changes to standards or at least build quality to relieve unmanageable reductions.

3. Reduce reliance on high flows

We’ve seen the effect that emergency events such as storms and fire have on the grid. Storms are managed through localised declarations of special constraint sets. They’re also generally short-lived. As we saw with the Tasmanian bushfires this summer, smoke and fire can affect a transmission corridor for weeks at a time. Because intense storms and fires tend to be rare, the market can take some time to adapt. Some planning or scenario work by AEMO might help prepare the market and reduce the impact on supply.

Reducing our reliance on high flows to regulate price or maintain supply may also be valuable. This suggests a need for storage/s at opposite ends of tie lines and interconnectors so that short periods of constrained flow can be compensated partially or fully by the far-end storage.

We may also need some flow-path diversity on critical corridors or on corridors that link dispatchable generation sources with loads.

There’s little doubt that Australia will experience more frequent and intense floods, fires and heatwaves. In our ‘sunburnt country’ we need to keep our eyes firmly on the future of our climate, and we must build resilience into our generators, grid and market systems.

If you would like to find out more about how Entura can help you navigate your challenges in the electricity market, please contact Donald Vaughan on +61 3 6245 4279.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Should you upgrade or replace your SCADA system – which option is best?

New functionality, increased visibility of plant, greater security … SCADA systems are rapidly advancing. So, should you stick with what you have, upgrade some components, or embrace a complete replacement?

This is an important and complex question for power and water owners, operators and utilities to consider. As SCADA systems become obsolete, outdated or unsupported, a range of risks come into play – so you need to carefully weigh up your options in terms of benefits and costs. Choosing the wrong system could affect your business operations or your future upgrade options.

The first step in your decision making must be to explore and understand the available SCADA options in the context of your business strategy. SCADA systems are too great an investment and too important for ad hoc or hasty decisions. This is the time for a clear-headed view of your business goals over the long term, and how your choice of action will support achieving the outcomes you seek.

In the context of this strategic view, you now need to objectively assess the value and relevance of your existing SCADA system and identify if the entire system needs to be replaced or whether some devices or software can be reused. Let’s look at ten key considerations in the decision:

1 System architecture: When you introduce new equipment or systems, your system architecture is likely to be affected. Changes to system architecture can affect the reliability or operation of your plant. A partial upgrade may or may not significantly affect the system architecture – it really depends on the changes made. The system architecture following a total system replacement may be dictated by the vendor you select, so keep this in mind when selecting vendors. Does this system suit your business or the vendor supplying it? Also make sure that your system architecture is thoroughly and accurately detailed, and keep your SCADA strategy in your back pocket for reference throughout your journey.

2 Reliability: If parts of your existing SCADA system are reused, will this impact the reliability of the new system? Depending on the age and condition, there may be a greater risk of unreliability with the reuse or partial upgrade of components vs a complete replacement. The key here is to ensure the right people can evaluate the system and components with the knowledge of how to overcome these challenges. To minimise the likelihood of equipment failures and achieve the best outcome in terms of reliability, sometimes the best option is to carry out a full replacement.

3 Costs: A complete SCADA replacement is a costly exercise but at some point you can’t keep delaying a major outlay by only fixing the immediate concerns. Just like the increasing costs of servicing and replacing parts on an ageing car, at some point the ongoing incremental costs may no longer be worth it, and you may have to consider a total replacement. Regardless of the option you choose, having the expertise to make this call and carefully planning/estimating the work will reduce the risks of unexpected costs. The key decision-makers in your business will need to explore how to balance the initial outlay against the potential cost savings to be achieved through limiting the duration of system outages and attaining a longer whole-of-system life.

4 Functionality: The range of SCADA devices is extensive. A simple device may be cheap but it may not have been designed and built to meet high performance and reliability requirements, and it may not have the management functionality or redundancy capability you need. Your choice of functionality is partly a matter of initial cost, but you also need to carefully consider how much you need the extra functionality, what savings that functionality can offer over the longer term, your tolerance for failure, and the cost of failure to your business.

5 Compatibility and standardisation: When devices and software are upgraded or replaced, compatibility challenges and limitations may arise when interfacing with existing system components. Carefully assess your existing system and verify that the specifications and functionality of the proposed equipment are sufficient. Also consider the benefits of standardisation of system components. Standardising equipment throughout your site or sites can greatly speed up fault diagnosis, reduce design costs, minimise the need for more training, and lower your spares requirements.

6 Human interface: When your SCADA system upgrade includes the Human Machine Interface (HMI), identify which parts of your HMI screens work well and which don’t, and consider the option of designing your screens from the ground up. Avoid cluttered interfaces and consider dashboards for a single, easily interpreted overview of parts of your plant or station. If you’re changing your screen navigation and displays, you will need to allow for additional training to ensure your people are confident and capable of operating and monitoring the new system. Upgrading your HMI with a newer version of the software may be the best way forward depending on your requirements. This may require less financial outlay in terms of licensing, engineering and training costs and may be less intrusive on your system. If your system assessment warrants a complete replacement, you should carefully evaluate alternative HMI solutions to achieve the right functionality, product roadmap and financial outlay.

7 Security: How will upgrading parts of your SCADA system affect overall system security? SCADA security has evolved dramatically in recent years. Managing today’s SCADA systems can be a challenge without the right security precautions in place. Because SCADA system attacks exploit both cyber and physical vulnerabilities, it is critical to align cybersecurity measures accordingly. System security challenges of partial upgrades may not be able to be overcome depending on the age and type of equipment. So implementing a new system with the latest security technology is becoming the best option for limiting your exposure to attack.

8 Future-proofing: Just as you need to plan your pathway to implementation, you also need to keep your eyes on the future. If you’re upgrading old components, factor in the end-of-life date for support. If a device becomes obsolete, you’ll need a changeover plan to limit the impact on the system. Even if your upgrades give you the functionality you need now, what will you need in the future? Transitioning to a new SCADA system will introduce new functionality that is likely to increase the effectiveness of your operations and maintenance, and give you the opportunity to embrace the potential of big data, machine learning and artificial intelligence.

9 Pathway to implementation: Whatever the journey you’re on, you need to think about the path ahead so that you don’t encounter unexpected obstacles such as hidden costs or schedule blow-outs. Identify what upgrading may mean for your existing system and what limitations your system may have. Will your historical data need to be migrated to your new system, and, if so, how will this need to be handled? Upgrading to a new version of your SCADA system may be the easiest solution, but if you decide you need a new system, you’ll need to carefully handle your historical data and massage the data into the correct format for your new system.

10 Testing and commissioning: During the design process, contemplate how your system will be implemented and commissioned. Commissioning new equipment instead of reusing old technology may reduce the risk of incompatibilities and unusual operations. It may also reduce the time required for testing due to thorough system factory acceptance tests. Retesting of old equipment may have considerable impacts on your plant or station operations. The testing process and sequence is another key item that can make or break your system implementation. Assess how your system will behave during the cutover process and how the correct sequence or test process could reduce or eliminate your plant or station downtime.

Deciding whether to upgrade or completely replace your SCADA system is very much a case-by-case situation – but you’ll find the right solution if you consider all the key issues carefully and have your decision assessed by the right people and carried out objectively.

If you would like to discuss your SCADA challenges and opportunities, contact James Devine on +61 417 389 713, Patrick Pease or Shekhar Prince on +61 412 402 110.

About the author

James Devine is Entura’s Specialist SCADA Engineer and has over sixteen years’ experience in SCADA and automation design, implementation, commissioning and project management. James has worked with clients both within Australia and overseas on a diverse range of systems including solar and wind farm SCADA systems, substation SCADA and automation systems, hydro and gas generation SCADA systems, water and wastewater SCADA systems, and wide-area SCADA and telemetry systems. James has considerable experience reviewing many clients’ existing systems and proposed designs, as well as providing specialist technical advice for single-site SCADA and automation systems through to wide-area SCADA systems and master stations.

MORE THOUGHT LEADERSHIP ARTICLES

Are you an asset manager or an ‘asset guesser’?

In the hydropower sector, we’re all trying to do more with less. And as hydropower assets age, there’s always more to be done.

Gut feelings and guesswork won’t be enough if you want to make the best use of your asset management budget and keep your assets safe, reliable and profitable.

Today, ‘asset management’ is a much more sophisticated practice than twenty to thirty years ago. Back then, we’d refurbish or replace components at fixed time intervals (whether the work was needed or not), hoping that this would prevent or reduce breakdowns and forced outages. In most cases, this sort of scheduled maintenance was based on original equipment manufacturers (OEM) recommendations, best guesses or a mixture of both with very little evidence of root causes of actual or potential failures identified.

This maintenance attitude led to repeated failures. It also resulted in short-term planning. And, because of a lack of good evidence that current maintenance approaches were achieving direct positive business returns either in plant or financial performance, it increased the pressure to reduce maintenance budgets.

Asset management today

Hydropower assets are increasing globally, both in number and in size. So too, our knowledge of hydro assets continues to strengthen. We have much better understanding and insights now into how and why these assets wear out, how they behave, why they fail, and the ways in which they respond to various operating conditions and environments.

Operating conditions are constantly changing due to variables in the energy market, power purchase agreements, increasing expectations of customers, changing technologies and regulatory requirements, and more. So asset management needs to be flexible and to respond to the evolving context.

Today, ‘asset management’ is a trendy term – but there’s a very broad spectrum of practice across the hydropower industry, and it is a long path from basic approaches through to achievement of superior methods and strategies.

To achieve the lowest lifecycle costs for assets, as well as to minimise forced outages and breakdowns, power and water businesses need to see asset management as a crucial component of risk management and business strategy. It also needs to be viewed as an incremental journey of improvement, supported by processes and structures based on standards.

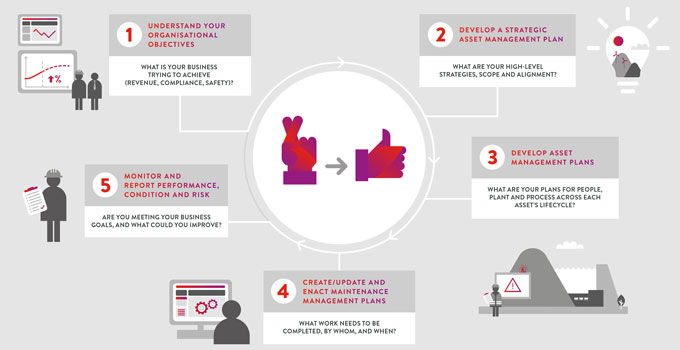

Ideally, your asset management policy, strategy, plans and activities should be based on the ISO/AS 55000 series of standards. The ISO 55000 standard series encourages aligning asset management with your broader organisational objectives, context and plans – and recommends that you regularly revisit this to be sure that alignment is maintained. This can now filter through your asset management policy and strategic asset management plan (SAMP), and be embedded in the reality of implementing your asset management plans.

In other words, your asset management policy provides direction which is aligned to your organisational context; your SAMP translates this; and your asset management plans act as the catalyst to create and sustain change in leadership, culture and asset management practice.

People, plant and process

Alignment with the principles of the ISO/AS 55000 standard series are fundamental to achieving the lowest lifecycle costs for hydropower assets. For success in your business you need to consider not only the physical asset but the entire delivery process, you need to understand what is required in each of three ‘P’s – people, plant and process – and you need an implementation plan to get you there.

Without people, we don’t have plant. Having the right people involved, right from conception, can make the difference between successful projects with years of profitability and projects that face years of increased expenditure and issues to manage. Ensuring that the right people have the right skills, training and competencies to carry out the right maintenance at the right time is paramount to achieving the plant performance you desire.

When it comes to plant, we recognise that, ultimately, all assets have a finite life – but our increasing knowledge of asset behaviour can help us to design components better for longer life and for greater cost-effectiveness and efficiency. By developing and implementing the right asset management techniques, you will increase the likelihood of your assets being profitable, reliable, available and safely operated – and staying that way. A strategic investment in asset management will more than pay for itself through increased benefits and decreased risks.

Turning to the ‘process’ element, we should recognise the importance of assessing, organising, planning, budgeting and reporting on the work effort – but there’s a need to ‘keep the processes real’. In other words, don’t implement processes for the sake of it, nor to try to address or mask problems in other areas that would be better to rectify than to over-manage. Processes should support the integration of the broader organisational context into operations and maintenance and then help to assess and report on effectiveness and performance.

By bringing people, plant and process together, and aligning asset management with your business vision and decision-making, you are far more likely to be able to get the best out of your valuable assets. And you’ll achieve a culture of continuous improvement and proactive, prioritised action – leaving no more room for reactivity and guesswork.

If you would like to discuss how Entura can assist you with assessing and managing your hydropower plants or other power or water assets to minimise risk and maximise efficiency and useful life, please contact Leigh Smith on +61 419 884 318.

About the author

Leigh Smith is a specialist consultant with extensive experience and proven ability in asset management, condition assessment, risk management and project management in the power sector, particularly hydropower. He has over three decades of practical experience with hydropower assets and has successfully delivered and project managed many major projects in Australia and internationally. Leigh has produced numerous asset management plans to support financial modelling and feasibility of major hydropower projects, as well as detailed 30-year asset management and maintenance plans that have been critical to the progression of projects around the world.

MORE THOUGHT LEADERSHIP ARTICLES

Asset management trends for profitable wind farms

How can a wind farm realise its full lifetime potential in an increasingly cost-sensitive market?

Until now, improving the wind industry’s profitability equation has been driven by increasing the size and efficiency of wind turbines, resulting in more energy produced for every dollar of capital expenditure. However, there’s only so far we can go with this approach.

To keep driving costs down and maintaining your wind farm performance, we now need to turn our focus to another aspect of the equation: a wind farm’s significant ongoing operational and maintenance (O&M) costs, which are set to increase as wind assets age. Achieving maximum yield at minimum risk and cost across a wind farm’s full operational life is a major asset management challenge, and much is yet to be learned.

In 2018, at the Wind O&M EU conference in Germany, I observed some international trends and perspectives on O&M that can offer useful insights for the wind industry in Australia. Although some aspects of the topic generated a deal of consensus, other areas are far less certain with many questions and possibilities yet to be fully explored.

Learn from other industries

Across the wind industry, there’s strong agreement that commercial returns for wind farms are not as high or as easy to obtain as they once were, and that reducing O&M costs on wind farms is critical when profit margins are being squeezed.

This may seem obvious, but the fact that we still need to articulate this point demonstrates that the wind industry has a significantly less sophisticated O&M approach than more mature industries such as oil, gas, other energy and heavy industries, and the IT and telecommunications sectors.

The wind sector should, and no doubt will, look to these more mature industries in the coming years for innovations that can be applied successfully to streamline our O&M and asset management strategies.

Plan for a longer life

Another implication of the relative youth of commercial wind farm development is that the industry has little practical experience with ageing wind farms – yet wind farms are set to get even older. Where it was previously the norm for a wind farm’s business case to be based on a 20–25 year life, it is becoming increasingly common for business case scenarios and asset management strategies to consider lifetimes up to and potentially beyond 30 years.

We need to be developing thorough and sophisticated asset management strategies that fully embrace the later stages of a wind farm’s life – not only the earlier stages in which O&M may have been conducted under contract with risks managed very effectively.

When we think about ageing wind farms, we weigh up the choices of continuing operations, decommissioning, or repowering with new turbines. From our understanding, it seems that wind farm repowering is only happening in locations with very friendly tariffs (such as a few areas in Germany), or where the existing project is fundamentally unsound from a technical and commercial perspective.

In Australia, full repowering with new wind turbines is not currently a commercially attractive proposition, and may not be widely considered for at least another decade. So, a wind farm’s extension of life will need to be achieved through effective O&M and refurbishment. I observed that some wind turbine owners and suppliers are beginning to think in more sophisticated ways about whole-of-life asset management strategies that maximise project value for the longer term, but it is still early days across the sector.

I also noted a range of diverging opinions about whether it is preferable for an owner to manage O&M through long-term comprehensive O&M contracts or whether risk is better mitigated by owners taking on the management of O&M themselves. Approaches vary depending on portfolio size, experience, capability and the general philosophy of the business. Clearly, this is not an area in which one solution will work for all.

Share information to build knowledge

Given the relative newness of the large-scale wind industry, and the need to squeeze every last drop from existing infrastructure, there is much to be gained from learning from and with each other.

Many industry players at the conference expressed a desire to see increased cooperation and sharing of information between different owners, operators and manufacturers.

The industry as a whole will benefit if SCADA system data is the property of the wind farm owner and shared more openly across the industry. Greater openness and availability of data will allow better benchmarking across turbine models scattered across the globe, enabling operators to better predict future costs and performance and incorporate reliability-centred maintenance.

Better benchmarking may offer insights into the extent of the performance improvements that could be gained on existing projects by adopting some available upgrade options. Many service providers are offering control system upgrades, aerodynamic improvements, yaw alignment systems, and advanced condition monitoring systems for increased availability – yet the industry is still learning how to translate this dizzying variety of rapidly developing technologies and options into a robust business case.

It can be difficult for owners to justify expenditure when the gains are uncertain, difficult to measure, and sometimes accompanied by drawbacks that are hard to quantify directly. For example, do you take increased generation at the risk of a reduced lifetime or increased maintenance costs?

If performance improvements of wind projects were more easily measured, we could more realistically quantify their impact on profit.

From these trends, observations and uncertainties, it’s clear that in any wind farm project – whether developing a new project or changing ownership of an existing project – we need to look very carefully at ongoing O&M costs, particularly as the increasing costs of end-of-life loom large. Thorough due diligence and realistic assumptions in this area will be vital for developing viable business cases across an increasing range of possible lifespans.

If you would like to find out more about how Entura can help you optimise your wind farm, develop an asset management strategy, or support you with due diligence services for proposed or operational projects, contact Patrick Pease or Silke Schwartz on +61 407 886 872.

About the author

Andrew Wright is a Senior Renewable Energy Engineer at Entura. He has more than 15 years of experience in the renewable energy sector spanning resource assessment, site identification, equipment selection (wind and solar), development of technical documentation and contractual agreements, operational assessments and owner’s/lender’s engineering services. Andrew has worked closely with Entura’s key clients and wind farm operators on operational projects, including analysing wind turbine performance data to identify reasons for wind farm underperformance and for estimates of long-term energy output. He has an in-depth understanding of the energy industry in Australia, while his international consulting experience includes New Zealand, China, India, Bhutan, Sri Lanka, the Philippines and Micronesia.

MORE THOUGHT LEADERSHIP ARTICLES

Early action is the best approach for operational environmental management

Building, maintaining and operating power and water assets involves a level of environmental risk. If you can identify and manage these risks early, your projects or operations are far less likely to run into trouble down the track.

Power and water utilities can incur major penalties when natural values are insufficiently understood and poorly managed. Not only could the environment be damaged, but there could also be penalties for a compliance breach, increased costs and conditions for construction and operation, significant remediation costs, project disruption and delays, and delivery overruns.

On top of all of this, there’s no doubt that poor environmental management will damage your corporate reputation and reduce your level of acceptance by and engagement with the community and stakeholders, both at and potentially far beyond the local area.

Power and water asset owners and developers manage or have influence over large areas of natural assets. These environments often include flora and fauna on land and in waterways that are listed as threatened under state and national environmental legislation and/or international agreements.

A land manager or owner with a strong environmental management system will know and proactively manage these values. However, in many areas there is a lack of knowledge of natural values, which are consequently not included in an environmental management framework. These values are therefore at risk of adverse effects from operational decisions.

So what can you do to make sure you have a handle on your environmental risks?

Find out what you’ve got

A thorough review of available information will help you better understand the values you need to manage.

This means using existing data-sets and reports to understand the current knowledge base and identify any gaps. In other words, create an inventory of natural values for all your land and water assets. You will need to identify the flora, fauna and ecological community values on your land and in your waterways and lakes, and record their condition and their status.

To understand the social values associated with your assets, you may also need to engage with other stakeholders and local communities to understand how they value and use your natural assets (e.g. fisheries, recreational users, water supply, transportation), as this will also influence management.

Incorporating the data into a spatial database accessible to everyone in the business will allow easy searching for flora and fauna values that may be affected by maintenance activities or new projects and ensure that relevant information about your natural assets is readily available for managers and field staff. However, this phase only identifies issues, and the degree of impact of a proposed management action on flora and fauna values is likely to require further interpretation by an ecologist.

If gaps are detected in the data or there is doubt about accuracy, field surveys can identify and verify natural values and record their condition. For example, vegetation and /or habitats have often been mapped from aerial photos and not verified in the field, so errors can arise in the attribution of a vegetation community or habitat type.

Understand your compliance requirements

Once you know what’s on your land or in your water, you can identify the potential regulatory and compliance issues.

Are there threatened species or communities listed under state or national legislation or international agreements? Are there weed or pest species or communities that have legislative requirements? Does analysis of existing water quality data highlight any trends that may affect values within the water-body or downstream (e.g. increased nutrient loading)?

If you already know what natural values you have on your land or water, you’ll be in a much better position to respond effectively to any legislative changes. You may even be ahead of the game!

Identify potential risks and their significance

Identifying and understanding risks to natural values under current and future operational scenarios is critical to successful and proactive environmental management. This requires some ‘big picture’ thinking in which the whole landscape, both terrestrial and aquatic, is considered.

A big-picture approach focuses on risks to ecological communities or functional ecosystems (e.g. wetland, lake or river) rather than extrapolating from localised information that may not reflect the broader risks. For example, to manage species at a habitat level rather than at site level, you need to identify and map habitat for threatened species across your natural assets as well as assess habitat quality.

In another example, a big-picture approach to water quality would involve having an understanding of the natural range of parameters at the local catchment scale, which may be different to recommendations in national water quality guidelines due to natural local conditions (such as the relatively low pH of tannic water bodies in peatland landscapes).

Many project risks can be mitigated if they are properly anticipated early and managed throughout the life of the project, minimising corporate, technical, environmental and social impacts and their associated costs. Having a comprehensive inventory of your natural assets will allow any threatened species or important ecological communities to be identified early in the planning phase for upgrades of existing assets or new projects. This will make the difference in understanding the effort required to avoid or minimise impacts.

The planning process is likely to be expedited because you will already know what your potential environmental impacts are and will have accounted for them in your project design, planning approval documentation and operational management plan.

This informed management approach also applies to maintenance programs, particularly weed and vegetation management, on easements and around assets. If you know where your high-value natural assets are, they can be accounted for in the maintenance program so that they will be protected.

Develop management approaches

Knowing which natural values require active management and which values may be best left alone is another key factor for successful environmental management.

Some natural values may be protected by default because they are associated with assets that are not accessible to the public (e.g. remote assets or those closed to the public because of safety risks). These natural values, particularly in intact remote wild areas, may be best managed by being left alone without any management intervention because they are not under pressure from human activities.

Other natural values may need active management and protection because they are under threat from human activities, introduced species or diseases. In this case, you need to consider the potential issues and consequences, plus the likelihood of them occurring, to evaluate the potential risk and significance of the issue.

Where the risk level is considered to be high, identify how the risk can be mitigated (e.g. restricting public access to a sensitive area while directing access to another less-sensitive area). Potential mitigation measures are generally best identified in consultation with other stakeholders, including user groups and the local community, to ensure that the measures are supported and endorsed by the community for greater success.

For example, an important conservation site such as a lake that supports threatened fish as well as recreational fish species will require a management approach supported by the angling community. That might mean developing hardened access points (e.g. tracks and boat ramps) in less-sensitive areas supported by anglers. Otherwise anglers will continue to develop their own access points, degrading lakeside habitats and potentially affecting important breeding or foraging habitat for threatened species.

Identify opportunities

If you proactively identify and manage the environmental values for which you are responsible, you may even stand to reap a range of extra benefits. You may identify natural values with potential economic and environmental value beyond the obvious.

For example, native vegetation in good condition on your land could be used to offset the loss of native vegetation associated with other projects you undertake. Or, possibly, land in good condition could be made available to other proponents for purchase as offsets for their projects. These hidden opportunities could be very valuable and make a major difference to project viability.

If you can make structured and systematic efforts to manage environmental issues proactively, you are far more likely to achieve environmental sustainability, as well as pave the way for project success, social licence and a positive reputation. For power and water asset developers and utilities, a genuine commitment and responsible approach to achieving greater operational sustainability is increasingly recognised as a key marker of success and corporate reputation.

Don’t wait. Act now to understand and manage your environmental risks.

If you would like to discuss how Entura can assist you with minimising risks and increasing sustainability, please contact Ray Brereton on +61 417 336 407.

About the author

Dr Eleni Taylor-Wood is Entura’s Principal Consultant, Environmental and Social Science. Eleni has 20 years’ experience successfully managing large-scale, complex projects, as well as providing expert advice and independent review for a range of infrastructure and planning projects. She has worked on projects around the world including in Australia, Mozambique, South Africa, Iceland, Colombia, India, Malaysia, China, Solomon Islands, Fiji and Papua New Guinea. Her experience includes environmental and social impact assessment and management, strategic management of wetlands and waterways, feasibility and approvals for new hydropower projects, environmental flow determination and assessment, and sustainability assessments. Eleni is currently one of eleven accredited assessors worldwide under the Hydropower Sustainability Assessment Protocol.

Raymond Brereton is a senior ecologist with 30 years’ experience in the field of fauna and flora survey and management. He has been involved in assessing the impacts of development on flora and fauna and their habitats, as well as providing advice on the development and implementation of policy and prescriptions for fauna and flora management across south-eastern Australia (Queensland, New South Wales, Victoria, South Australia and Tasmania). Raymond has a high level of technical expertise in the assessment and the management of threatened species and communities in both terrestrial and aquatic ecosystems in compliance with regulatory requirements

MORE THOUGHT LEADERSHIP ARTICLES

Six sink-or-swim questions for the modern dam engineer

Technology and expectations are constantly evolving for the dam engineer but the ultimate goal remains the same: safe, lasting dams. Are you fully equipped to make that target a reality?

All industries and jobs change over time, but for dam engineers there has been very significant change on many fronts over the last few decades. Improvements and new developments in technology and construction methods are constantly emerging. Expectations of the role continue to broaden beyond technical skills. And, since the 1970s and 1980s, dam engineers have needed to keep abreast of the surge in legislation, regulations and procedures for modern dam safety programs which emerged in the wake of major dam failures.

Of course, generational change is also always occurring. For organisations that have experienced bubbles and dips in the age distribution of their workforce, this is particularly challenging, and gaps may emerge in particular experience brackets. As older engineers move towards retirement, they take with them the knowledge of the generation who designed and constructed older dams that may still retain original technology.

The modern dam engineer therefore faces a dual challenge: not only to stay up to date with the latest technology and requirements, but also to maintain an understanding of older equipment and instruments.

For dam owners and managers, success in your business strategy will depend on ensuring that your dam engineers have the right skills and competencies. Investing in workforce planning and training for your people will help you manage risk, deliver your key functions, and move toward your long-term business goals.

To me, the following key factors are essential for the modern dam engineer to keep on top of our fast-changing profession.

1 – Are you keeping up with changing technology for dam engineering and monitoring?

Dam engineering and monitoring technology keeps improving, and the pace of change gets faster all the time. Defensive measures to ensure the safety of dams have improved greatly over recent decades, such as filters for internal erosion protection, and corrosion protection in ground anchors.

Methods for analysing dams have also become more sophisticated with increased computing power and more advanced analysis software, in particular for extreme floods and non-linear analysis for seismic loading. The modern dam engineer also has access to contemporary geotechnical and structural monitoring instruments, which are useful for interpreting the behaviour of a dam.

It is no longer acceptable for a dam safety engineer to rely only on visual inspection and monitoring data. Modern dam engineers need to understand the underlying design philosophy and keep up with the latest construction practices and their impacts on dam behaviour. We also need to maintain an enhanced understanding of the performance of dam structures and appurtenance structures under various load conditions.

In recent years, advanced instruments and automated data acquisition systems have enabled real-time monitoring of dams and near-continuous time history records for the dam engineer to evaluate.