How the BESS general arrangement drives safety, certainty, speed and value

Despite the deceptively simple appearance of plug-and-play modularity, there’s a lot of crucial detail involved in achieving an efficient, safe and resilient BESS layout.

The layout or ‘general arrangement’ design will cover the BESS equipment (DC battery units/enclosures, PCS/inverters, medium-voltage transformers, switchgear, control and communications systems), the balance of plant (fire water tanks, buildings, laydowns, cable trenches, noise barriers, etc.) and the BESS substation.

Experience across the global BESS market shows that the devil is in the detail. In the push to accelerate renewable integration, there’s a danger that design decisions could be rushed, with too many details inadequately thought through or resolved. With a well-considered layout, a project is likely to move more quickly through approvals, construction and commissioning. A poorly designed project arrangement can embed inefficiencies, risks, delays and constraints that may be difficult to remedy.

Many developers have discovered that the layout of a BESS is a lever for risk, cost, speed and safety – with major implications for permitting, fire risk, insurability, environmental performance, lifecycle operating costs, augmentation and decommissioning complexity and, increasingly, community acceptance.

The BESS GA supports every phase of development

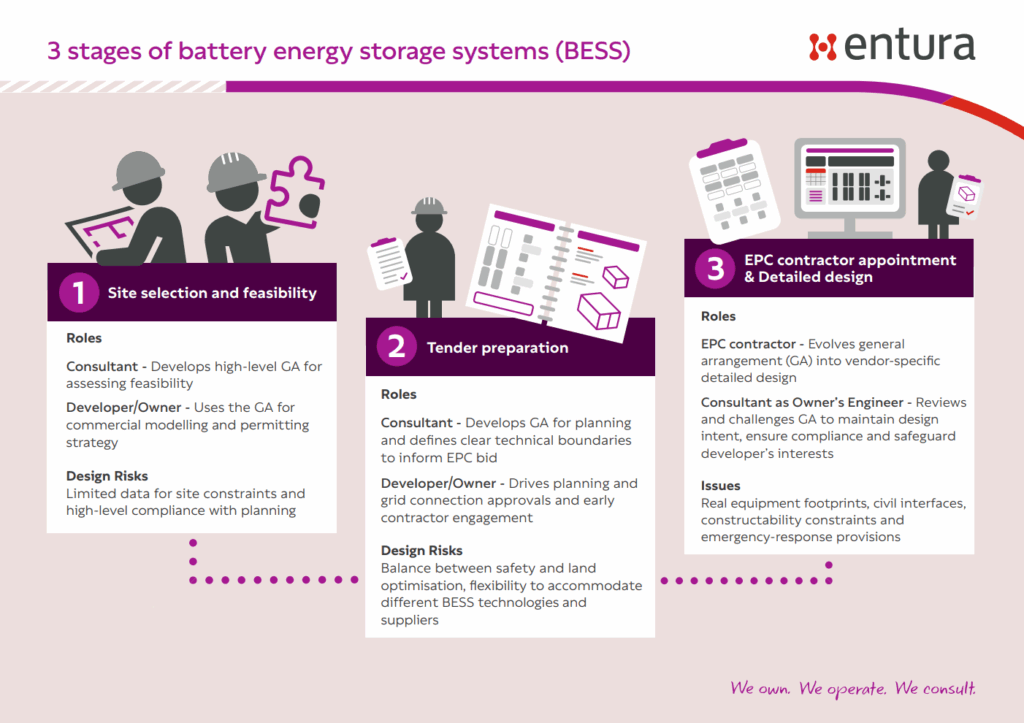

The responsibility for developing the BESS general arrangement (GA) shifts across the life of a project, and each iteration responds to the client’s evolving drivers, constraints and uncertainties. Early in development, the GA is typically prepared by the developer – or a consultant working under tight budgets – to support site selection, feasibility assessments and initial commercial decisions, often when project viability is not yet assured. As the project progresses into tender preparation, consultants refine the GA to define clear technical boundaries, ensuring EPC bids are accurate, comparable and compliant with planning requirements, fire safety and electrical standards.

Once an EPC contractor is appointed, the GA evolves into a vendor-specific detailed design, incorporating real equipment footprints, civil interfaces, constructability constraints and emergency-response provisions. The consultant – now acting as Owner’s Engineer – continues to review and challenge the GA to maintain design intent, ensure compliance and safeguard the developer’s interests throughout delivery.

Across all phases, a capable consultant adds value by anticipating the requirements of the utility and regulators, maintaining continuity through uncertainty, and designing with an appreciation of the developer’s realities – limited budgets, required studies, iterative decision cycles, and the constant question of whether the project will ultimately proceed – to ensure the final layout is safe, compliant and truly buildable.

Here we explore why GA decisions matter so much, and the key considerations shaping best-practice BESS arrangement today.

Navigating easements in BESS design

A workable GA begins with an accurate appreciation of the site’s constraints. Easements and land-use limits are not peripheral issues: they define the true buildable envelope and shape the BESS solution. Treat easements as primary design parameters rather than later checks.

Early identification and mapping of utility and service easements, gas pipelines, and other buried assets helps avoid design rework and ensures that access obligations and no-build zones are incorporated into the layout from day one, thereby reducing the risk of project delays. Hydrology deserves equal weight. Natural drainage paths and any stormwater easements identified through hydrological studies can restrict equipment placement, influence grading, and affect the location of roads and trenches. Flood mapping, too, should inform early decisions about elevating sensitive equipment or siting infrastructure on less exposed ground.

In many Australian settings, bushfire clearance requirements can dictate a reduced density and more generous separation between battery enclosures and vegetation. Where environmental or conservation easements exist, they may remove sizeable portions of land from consideration and require careful alignment with approval strategies.

Gather all easement, hydrology, flood and environmental information as early as possible, integrate it into spatial modelling, and shape the first iteration of the GA around these constraints. This will avoid the pitfall of attempting to impose an idealised arrangement on land that can’t support it and will create a stronger pathway to feasibility.

Addressing fire risk and emergency response

Given the nature of modern lithium battery technologies, fire risk must be front of mind. The spatial relationships between containers and the provision of firebreaks and passive barriers influence not only the likelihood of thermal events, but also whether a fire will spread beyond a single enclosure. Industry standards and guidelines as well as local fire codes provide structured approaches for managing separation distances, ventilation and fire-mitigation measures. The frameworks are increasingly referenced by regulators and insurers to verify that system layouts limit multi-unit fire spread.

Fire authorities in Australia now often expect evidence of large-scale fire testing which goes one step further by assuming the entire container is alight and evaluating whether the layout could allow fire to spread to adjacent units. Importantly, compliance is not limited to holding a certificate: the installed system must be constructed and configured in the same manner as the tested system, typically in accordance with the OEM’s certified design, internal spacing, materials and fire-mitigation features. Any deviation may invalidate the test assumptions and compromise fire-propagation performance.

Importantly, BESS technologies and safety standards continue to mature, with new insights regularly emerging from operational experience, incident investigations and evolving test methodologies. As a result, GAs must be developed with adaptability in mind, recognising that future updates to best practice or regulatory expectations may influence separation requirements, access provisions or fire-mitigation design.

Asset protection zones (APZs) are defined through a bushfire study. Requirements can vary even across a single site, reflecting changes in vegetation density or type, but recent projects have needed at least 10 m of separation on all sides.

The GA should support effective emergency response by providing clear access routes, equipment isolation points and adequate separation for firefighting operations – ensuring that the layout not only minimises the likelihood of fire spread but also enables authorities to intervene safely and efficiently. It’s crucial that the firefighting response is supported by engineered containment so that runoff remains within controlled zones. Grading, bunding and drainage design are therefore integral components of the overall GA, rather than secondary civil features.

Hybrid sites demand particular care, as the original renewable facility may not have been designed with BESS-specific hazards in mind. Shared roads, substations, cable routes and drainage systems must be adapted so that the BESS retains its own safety envelope.

Designing for construction, operation, maintenance and evolution

Construction is a real test for the GA. If adequate allowance isn’t made in the GA for heavy vehicle movements, crane access, delivery sequencing and temporary staging, projects are likely to run into significant costs and delays.

The size of the construction compound, laydown area and temporary storage will depend on the project scale, the number of trucks and size of workforce engaged, and the delivery and installation schedule. Critically, the expected size and reach of cranes, as well as the dimensions and handling requirements of major components such as transformers, need to be identified early in development so that access routes, turning circles, lifting zones and hardstand areas can be properly incorporated into the layout from the outset.

While a number of critical considerations should be defined during the concept design phase, it is inevitable that certain elements – such as final medium-voltage cable routing, auxiliary systems, drainage and other balance-of-plant details – will only be resolved as the design matures. To mitigate the risk of future spatial constraints leading to reduced capacity or alterations that could adversely affect the business case or grid-connection obligations, the initial GA should be intentionally developed with flexibility to accommodate later design requirements without compromising the ultimate capability of the facility.

Over the operational life of the BESS, the GA will continue to influence efficiency and cost. Reliable access for technicians, sufficient working clearances around major equipment and logical circulation routes are fundamental to safe and effective maintenance. Designs that overlook these requirements may appear economical on day one but can impose persistent operational inefficiencies over decades.

Energy storage assets built today must remain adaptable to tomorrow’s operating environment. As batteries degrade, room will be needed for augmentation or expansion – through reserved space, scalable electrical infrastructure and clear routing for future cabling. The increase in land area or civil cost is likely to be outweighed by the long-term benefit of being able to let the BESS evolve without major disruption.

No project is an island

BESS projects, like any other major infrastructure developments, will be subject to significant public scrutiny on issues such as fire risk, noise exposure, visual impacts, traffic movements and ecological impacts. Landowners, communities, stakeholders and regulators will want to know what impacts can be expected and how these will be managed. Many of these factors can be moderated to some extent by strategic placement and screening.

A clear and well-engineered GA needs to capture these considerations. It will demonstrate to regulators, stakeholders and the local community that project risks and impacts have been appropriately investigated, understood and managed – which will help build social and environment licence. A thoughtful GA is one of the most effective ways to build confidence in a project.

Make your GA a strategic advantage

As we’ve explored, the BESS GA is not just a technical document. It’s a set of strategic decisions where safety, social and environmental licence, operability, optionality and commercial performance intersect. Civil, electrical, mechanical, control, environmental and safety factors all influence – and are influenced by – the site arrangement, which makes it essential to bring an array of different perspectives and disciplines together early to avoid unforeseen flow-on implications and clashes among disciplines. At Entura, we integrate these streams to fully stress-test our designs and advice from all angles.

Now is the time to treat your BESS’s GA as one of the clearest opportunities to manage risk and materially improve your project outcomes.

To talk with us about your BESS project, contact Patrick Pease (Business Development Manager – Power & Renewables) or Donald Vaughan (Technical Director Power).

ABOUT THE AUTHORS

Senior Renewable Energy and BESS Engineer Dr Rahmat Khezri has vast professional and technical experience with batteries. He has worked in the renewable energy and battery industry in project delivery from design, business case and feasibility analysis to operation and construction. Rahmat has managed several utility-scale BESS projects during his time with Entura, overseeing successful delivery while ensuring compliance with industry standards, optimising performance and managing key stakeholder relationships. Before joining Entura, he worked on projects supported by Sustainability Victoria for technical design and business case development of ‘second-life BESS’ using retired batteries of electric vehicles. In 2023–25, he was recognised by Stanford University as being in the top 2% of scientists worldwide for 3 consecutive years.

Dr Chris Blanksby is a Principal Engineer who uses his expertise in solar and battery technologies to provide strong leadership in delivering a range of services to the industry. Chris is Entura’s lead battery specialist and has been technical lead on several key projects in the Australian battery industry over the past years. Chris leads multidisciplinary teams in feasibility, design and construction supervision for utility-scale solar, battery, and hybrid integration projects. Projects Chris has led include Owner’s Engineer and independent engineer, feasibility studies, construction supervision, tariff reform and power purchase agreements, resource and energy yield analysis, project technical specification and principal’s project requirements, technical due diligence, model and control system development and network integration.

Reflections from MYCOLD 2025: Innovation, resilient dams and the evolving role of hydropower

Earlier this month, I had the privilege of joining colleagues from across Malaysia and the region at the 3rd International Conference on Dam Safety Management and Engineering (ICDSME2025), organised by the Malaysia Commission on Large Dams (MYCOLD), held in Kuching, Sarawak. There’s a particular energy that comes with a MYCOLD conference – part reunion, part technical deep-dive, part regional conversation about water, resilience and community safety.

I returned energised and inspired – not only by the technical excellence on display, but also by the sense of shared purpose across our industry and the tangible people-to-people exchanges and collaborations. With energy systems transforming rapidly, climate change accelerating and dam safety expectations strengthening, it has never been more important for dam and hydropower professionals to share openly and learn from one another. ICDSME2025 offered that in abundance.

Here are just a few reflections on some of what I heard …

Reimagining hydropower in changing markets and climates

In the ‘Advancing sustainable hydropower’ session, I shared perspectives from Tasmania’s long hydropower journey and Entura’s experience supporting the state’s major renewable energy initiatives.

My message was clear: the feasibility of pumped hydro or of reimagining conventional hydropower isn’t simply a technical question of ‘can we build it?’ but ‘what is the long-term value it creates?’ Smart choices depend on a holistic understanding of context – i.e. the markets, energy mix, climate, environmental impacts and benefits, and community perspectives and impacts. Pumped hydro is never ‘impact-free’, and it is not inherently more sustainable than conventional hydropower. What matters is how we think about the future of the energy transition, understanding what role pumped hydro can play in that context, how well we select sites, how carefully we consider environmental and social impacts, and how thoughtfully we design (and extend) assets for long-term economic and social value.

With wind and solar dominating new energy investment in Australia, hydropower’s baseload role can shift to respond to evolving market dynamics. Hydropower’s deep storage, flexibility and system stability are becoming increasingly important. We’re seeing these opportunities in Tasmania, where both conventional hydropower and pumped hydro could – with more interconnection to the mainland – help balance a renewables-rich National Electricity Market while returning extra revenue to Tasmania and increasing the reliability of supply across Australia’s south-east.

Climate change adds further complexity to feasibility considerations. Changing rainfall patterns, more variable inflows and more frequent extremes – as well as with the increasingly variable generation mix and how energy sources interact – all influence when hydropower can generate or store.

Ultimately, I believe there are not only opportunities with extending operating life, refurbishing or redeveloping dam assets; there are also obligations upon us as an industry to do our best for the sustainability of these assets. We need to focus constantly on how to optimise outcomes from the base impacts of hydropower or dam developments and seek ways to reduce impacts into the future. We also need to think about how to deliver great outcomes and value that extends across a long asset life, beyond the limited commercial timeframes considered in final investment decisions.

Technology, people and the future of dam safety

I had the honour of chairing a keynote session featuring Yang Berbahagia Prof. Datin Ir. Dr. Lariyah binti Mohd Sidek and Dr Martin Wieland.

Dr Wieland’s insights into the seismic performance of dams reminded us that strong engineering fundamentals remain as crucial as ever, even as digital tools advance. Prof. Lariyah explored how digital platforms, artificial intelligence and risk-based frameworks are shaping the next generation of dam safety practice. She emphasised the importance of the human layer: building institutional readiness, strengthening safety culture, fostering stakeholder trust, and ensuring effective engagement with communities.

Together, their perspectives reinforced that the future of dam safety will depend on both technological innovation and human-centred capability and how effectively these dimensions interact. That’s something Entura is focused on as we continue to bring deep expertise and experience, while exploring and testing the possibilities of new technology to support design and analysis.

Learning from incidents to strengthen global knowledge

Another highlight for me was chairing a session on dam surveillance, monitoring and evaluation. Seven presentations, while different in context and purpose, in combination emphasised the power of data and the importance of learning from experience.

A standout paper examined the 2022 landslide incident at Kenyir Dam, an event that occurred quite soon after Entura’s dam safety inspector training program used the dam as a site visit capstone. Despite extreme rainfall and slope instability, and some damage to appurtenant structures and spillway, instrumentation data confirmed that the dam behaved as designed. What was also clear was that, largely, the instrumentation in place and the data that was able to be collected was a positive demonstration of the importance of robust dam design and monitoring systems.

Another paper explored machine-learning approaches to forecasting short-term reservoir levels at Batang Ai Hydroelectric Project – a scheme with which Entura has long been associated. The results were impressive and point to a future where AI-supported forecasting strengthens real-time operations, especially under increasing climate variability.

These are exactly the kinds of insights our industry must continue to share openly and widely. We can never ‘design out’ all risk, but we can reduce it through good data and continual reflection and learning from real-world events.

Strengthening long-term capability in Malaysia

ICDSME2025 also highlighted the importance of building capability – something I am passionate about. It was encouraging to see Malaysia’s Certified Dam Safety Inspector program, developed with input from Entura’s training arm ECEWI, growing into a sustained and locally led pathway, launched during the conference. Strengthening dam safety ultimately depends on skilled people and strong institutions, making investment in training an investment in long-term sustainability of dam safety governance – and ultimately greater national resilience. We hope to continue to work with MYCOLD to determine how our specialised expertise can further enhance capability uplift beyond surveillance, extending to dam safety risk decision making and dam safety engineering.

A shared commitment to the future

Conferences like ICDSME2025 are timely reminders of our collective responsibility and the shared purpose we need to bring to the challenges ahead. We’re all navigating the same landscape, and when we come together – sharing data, stories and lessons – we accelerate progress for everyone.

I am grateful to MYCOLD for the invitation to contribute and for the generous knowledge-sharing throughout the event. I left Sarawak optimistic: the connection, commitment and collaboration across our sector have never been stronger as we work toward our common goal: safer, more sustainable dams and hydropower systems that support resilient futures.

How hydropower history and innovation can continue to power progress

Having been named as the Planning Institute of Australia’s Young Planner of the Year for 2024 and awarded a bursary, Entura’s Bunfu Yu travelled through Switzerland and France to study hydropower and energy innovation. Her reflections from the study tour highlight how history-rich hydropower assets can continue to evolve and add value in a changing world …

Switzerland’s Ritom hydropower project – which is in the late stages of a major redevelopment and anticipated to be operational later in 2025 – is a technical marvel of the past and the present. It is also a lesson in how energy infrastructure can evolve while still respecting its historical roots.

The original Ritom power station was commissioned in 1920 as part of a traditional hydropower scheme using water from Lake Ritom to generate electricity. It holds a special place in Swiss energy history as the first plant to supply electricity to the Gotthard railway, which is a vital north–south transit corridor through the Alps. This early integration of hydropower with transport infrastructure helped shape the modern Swiss energy landscape.

However, after more than a century of faithful service, Ritom’s aging infrastructure and the region’s changing energy needs prompted a major rethink.

Modernising with purpose

Ritom is undergoing a major transformation to meet 21st century demands. The redevelopment project involves replacing the historic hydropower plant with modern facilities and converting it from a conventional hydropower scheme to include a pumped hydropower component. By using two existing lakes (Lake Ritom and Lago di Cadagno) as the upper and lower reservoirs, energy can be stored by pumping water uphill during periods of low demand and releasing it to generate electricity when demand peaks. This is critical for maintaining reliability and stability in today’s dynamic grid. The lakes are also popular with walkers, and this recreational value will continue alongside the repurposed scheme.

The revamped facility will increase capacity to 120 MW, improving energy resilience for both the local Ticino region and the Swiss Federal Railways. The upgrade enhances energy security and does so with a strong emphasis on environmental and community values.

Balancing environment, engineering and community

Like all major infrastructure projects, Ritom has complexities. A key concern is managing downstream water flow to protect river ecosystems. To address this, the project incorporates a demodulation basin – an engineered feature that moderates flow variations, preserving the ecological health of the river below.

Minimising disruption for the local community during construction has also been a priority. This has taken careful management, as the project is nestled between the alpine villages of Piotta and Piora. The project team constructed a dedicated cableway to move heavy materials – such as massive steel penstocks – away from narrow local roads. This solution reduced construction traffic and helped preserve the peace and safety of surrounding communities.

Ritom is an inspiring example of how infrastructure can evolve when regulators, engineers and communities work together. Innovative thinking coupled with flexibility in permitting has enabled tailored solutions that are practical and environmentally sound – an approach that is replicable worldwide.

Technical excellence delivering long-term social value

Ritom reminds us that great infrastructure is more than engineering and functionality – it can inspire and be enjoyed.

Each year, the region celebrates the connection between nature, people and infrastructure through the ‘Stairways to Heaven’ race – a brutal yet iconic event that ascends 4,261 steps alongside the original penstocks of the Ritom scheme. With an average 89% incline over 1.2 km, it is Europe’s steepest race, attracting elite athletes as well as daring locals. The climb is physically punishing, but those who reach the summit are rewarded with breathtaking panoramic views of the Swiss Alps and the glistening Ritom reservoir.

This race is more than a sporting challenge. It is a symbol of how infrastructure can become deeply woven into the identity of a community, engendering enduring pride and delivering long-term social value well beyond its technical purpose.

The Ritom project is a powerful reminder that the future of energy lies in more than technology alone, but in how we carefully and intentionally navigate the intersections and synergies of history, environment and communities.

Planning for progress

Redeveloping or repurposing long-standing hydropower assets demands more than engineering expertise – it requires sensitivity to contemporary expectations. Since many of these projects were first built, the regulatory environment has shifted dramatically, with much greater emphasis on biodiversity protection (terrestrial and aquatic), climate resilience, the voices of local communities, and the cultural and heritage values of the Country on which these projects have been developed. The best projects don’t treat these as hurdles, but as opportunities to build broader value into the asset’s future.

Making good decisions at the earliest stages of refurbishment, repurposing or redevelopment is critical. To ensure lasting benefits, projects will need clear strategies grounded in sound technical evidence and shaped by a strong understanding of regulatory requirements and community expectations. Long-term success is more likely when projects are not only viewed through the technical lens of extending asset life, but are reimagined with community and environment at their core. Hydropower projects such as these can be catalysts for long-term energy security, greater ecological stewardship, strengthened social outcomes, and even become a source of community pride and inspiration.

In Australia, Entura is working with Hydro Tasmania to apply these principles through our work on the redevelopment of the Tarraleah hydropower scheme, parts of which are more than 80 years old. The redevelopment aims to increase capacity and flexibility so that Tarraleah can better serve the needs of the changing energy market – and future generations. It’s a project that echoes Ritom’s lesson: that heritage and innovation can coexist to create modern, sustainable infrastructure with value that endures for generations. By striking the right balance, hydropower can continue to do what it has always done best – power progress – while also meeting the needs and values of communities and environments today and long into the future.

Bunfu (above left) thanks Lombardi Engineering Switzerland for organising a comprehensive on-site tour of the Ritom hydropower project.

ABOUT THE AUTHOR

Bunfu Yu is a dynamic young leader in renewable energy planning, approvals, and business development. Bunfu played a pivotal role in Entura’s Environment and Planning Team’s success in achieving the Planning Institute of Australia’s National Award for Stakeholder Engagement in 2024. In 2023, Bunfu was named the National Young Planner of the Year by the Planning Institute of Australia. This honour recognised not only her passion for the planning and delivery of renewable infrastructure but also her active contribution to the profession through mentoring, public engagement, and knowledge sharing. She is currently a Senior Environmental Planner and a Business Development Manager at Entura, having joined the business as a Graduate Planner in 2018.

Renewables in remote mines – a litmus test for the wider renewables transition

Entura’s Greg Koppens has recently returned from the Energy and Mines Summit in Perth, where he led the ‘Think Tank’: a collaborative session addressing the challenge of powering process steam requirements from renewables-generated electricity. Here he shares his observations on the rise of renewables in the mining industry …

Australia’s mining industry is beginning the peak phase of its energy revolution. However, I find it unfortunate that this exciting fact is invisible to regular people. It is happening in remote areas on mining leases, inaccessible to the public. Each project alone is not sensational enough for media attention, but added together these projects are nothing short of a technology revolution. For remote mining sites to have a solar farm is now standard practice. In many cases this is backed up by battery storage and a handful of mines have onsite wind turbines.

The past: fossil-fuel driven mines

Australia is world-renowned for our mining industries, with mines of virtually every resource throughout our country. Up until about ten years ago, nearly all of Australia’s mines ran completely on diesel or gas. In most cases diesel was trucked in, or gas was brought in via pipeline. Most of these mines have energy expenses in the tens of millions of dollars per year. A small change in the oil price can drastically impact the mine’s bottom line.

If there’s one doubtless fact about mining, it’s that miners are practical people. They are problem solvers, and they know what works. With the boom-and-bust nature of resource markets and shareholder responsibilities, finances must be well managed.

The present: hybrid renewables power generation

At the Energy and Mines Summit, there was no discussion about whether it’s a good idea to consider renewables in the mix of power generation – it was simply a given. This is an industry in ‘early maturity’: it is no longer pioneers running a trial. Several systems are in the order of 100 MW capacity. Renewables are a tested and proven business decision. Everyone has crunched the numbers on their sites and, while each project has unique site-specific requirements, the conclusions are unanimous. The frontier is now getting access to skilled people, there is community engagement for siting of large assets and mutual benefits, and the industry is exploring emerging technologies such as electric fleet.

We now have all the technology needed to harness the power of the wind and the sun in an 80/20 mix with fossil fuels. Or a 50/50 mix when the system has solar power alone. And this is what is being implemented in practice all over Australia. We can do it in a way that achieves targets for price, reliability, service life, operability, maintainability and environmental impact. This greatly reduces the costs and risks of intermediate services such as refining and transportation as well as exposure to the global oil price. Mining companies are taking control of their energy supply by either owning the energy and storage assets or building well-defined low-risk partnerships.

The big project: transitioning the Pilbara to renewables

At the conference there was some focus on the Pilbara, which is a huge and complicated energy consumer, consuming 16 TWh (16 million MWh) of electricity per year, mostly coming from gas.

On the surface, it seems to be very low hanging fruit to quickly construct a few solar and wind assets to shift this picture. However, in the interests of the best long-term outcomes, the area needs planning, consultation and coordination. The Western Australian Government has developed a plan for ensuring that common-use infrastructure is used where possible, rather than risking having multiple redundant assets owned by different corporations. Aboriginal and community participation is recognised as crucial for the appropriate siting of wind, solar and transmission equipment.

The near future: electric fleet

Approximately half of a typical mine’s energy needs can be met by onsite electricity generation. The other half currently requires diesel fuel to run a fleet of light vehicles, monstrous ‘haul’ dump trucks such as the 250 tonne CAT 793, and every piece of mobile machinery in between. These mobile machines are the next target for reducing costs, carbon emissions and labour. Several trial projects are happening. For underground mines, where diesel has previously been used, huge ventilation fans will need far less power when there are no exhaust fumes to expel.

Machine manufacturers are developing a wide array of specialised battery electric products. In some applications, there is battery swap technology, as in modern power tools. In other applications, a fixed battery plugs in to recharge, like in an electric car. There are also trolley systems, akin to a tram or train. The best system for each job depends on the application.

Transitioning to a fully electric fleet will significantly increase a site’s electricity needs, with the biggest chargers running at 6 MW at full power. We are expecting to see sites’ electrical grids upgraded soon to integrate this high-power charging.

What is Entura doing?

At Entura, in addition to electrical generation and distribution design, we have specialised capabilities in control systems and power system studies for mining projects. Our microgrid control system (MCS) uses standard and reliable industrial Allen Bradley hardware to monitor and control the power station assets. We have a field-proven core algorithm for maintaining a priority of reliable power supply including backup/reserve supply, while making the greatest use of wind and solar where available. We’ve proven this process in our existing installations in the field and we lead the industry in methodology, practicality and voltage/frequency management.

We’ve seen the real benefits these systems bring to our clients and communities, both at mining sites and in other remote locations. Entura has a long history of design, formation and operation of microgrids throughout Australia (such as King Island, Flinders Island, Rottnest Island, and at mining sites such as the Agnew gold mine) and in the Pacific region (including the Cook Islands, the Federated States of Micronesia, Tonga, and the Solomon Islands, to name just a few).

Contact us if you’re interested in unlocking the full potential of microgrids for your operation or community, or if you’re interested in ways to increase your use of renewable energy.

[Image immediately above] Entura’s Patrick Pease, Greg Koppens and Mark Richardson at the 2025 Energy and Mines Summit

[Top of article] Greg Koppens (centre) onsite at Jabiru Power Station, Northern Territory

ABOUT THE AUTHOR

Greg Koppens is Entura’s Principal Control Engineer Hybrid Renewable Systems and previously led Entura’s secondary electrical engineering team. Greg’s experience spans power, oil and gas, and mining, including onsite roles. With over two decades of detailed design experience, Greg facilitates collaboration between engineering disciplines and other stakeholders to solve complex problems. He regularly shares his extensive expertise with the mining sector to advance their decarbonisation goals. Find out more about Greg in our podcast series here.

New technologies are important tools, but they need to be used properly

Entura’s Technical Director (Water), Richard Herweynen, recently attended the 2025 ICOLD Congress in Chengdu, China, themed ‘Common Challenges, Shared Future, Better Dams’. Here he shares his observations on the state of play in the international dams industry – and the opportunities emerging with artificial intelligence and automation.

My first ICOLD Congress was in Beijing, China in 2000. I was presenting some finite element analysis work that I had done on Gordon Dam, a 140m-high concrete arch dam in Tasmania. The analysis was being used to help predict and explain some cracks that had formed at the base of the downstream face of the concrete shell, roughly normal to the foundation, during first filling. In the 1980s, an attempt had been made to model the crack using finite element modelling, but with little success due to the coarseness of the mesh. However, by the late 1990s, computing power had increased and finite element programs had improved, providing the capability to construct more detailed finite element models, which were able to predict and explain the cracking that had occurred.

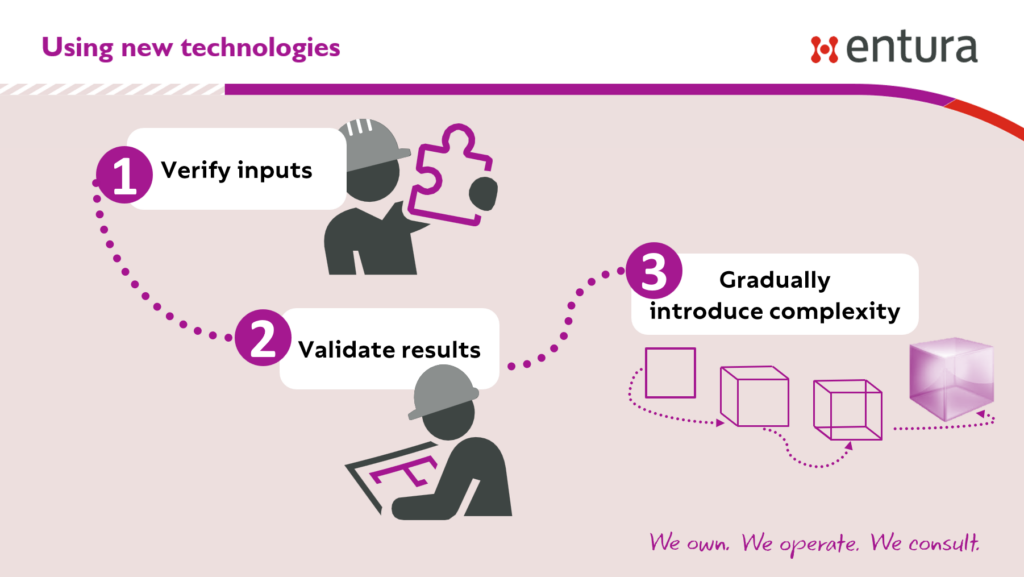

Dr Sergio Giudici, the designer of Gordon Dam, was my mentor on this finite element analysis, and he reinforced these principles:

- It is important to verify the input data to make sure the model represents, as well as possible, the actual dam parameters.

- Results should be validated using alternative techniques to give the engineer confidence in the results that the model is producing (i.e. structural hand calculations still have a place).

- Complexity should be built into these models only gradually, so that the engineer can see the impact of changes and determine whether they are reasonable.

These same principles are true for many complex engineering models and when setting up calculation spreadsheets or similar.

Now, 25 years on, I have had the privilege of attending the 2025 ICOLD Congress in Chengdu, China. At this Congress, there was much talk about the importance of dams in society for water security, the growing role dams and reservoirs play in providing resilience to climate change and the energy transition, the importance of balancing economic benefits and environmental needs, and – in all of this – the importance of ensuring that our dams are safe for communities downstream.

We have discussed many of these themes before – and they remain highly important; however, one thing I took away from ICOLD 2025 in particular was how China is embracing technology and advancing a ‘Smart Dam’ initiative.

New technologies and smarter dams

One could say that our industry has always been building smart dams, but China’s ‘Smart Dam’ concept is about using the full power of current technologies to construct, monitor and operate dams in smarter ways, and to use technologies to predict and adapt to changing conditions.

The CHINCOLD Workshop on Digital and Intelligent Technologies for Dam Construction, Operation and Maintenance, which occurred during ICOLD 2025, gave a glimpse of what may be possible.

Many projects utilise 3-dimensional digital models and building information modelling (BIM). However, the concept of having a digital twin of the dam, replicating every aspect of the physical dam in a digital form, opens the door to many possibilities, especially in light of the advent of artificial intelligence (AI).

Artificial intelligence and machine learning

Many organisations and nations have been cautious about AI, but China is increasingly adopting it to improve construction practices in dam engineering, improve monitoring and surveillance of dams, and to help adapt to extreme events as they occur.

Machine learning (ML), an element of AI, enables computers to learn from data without being explicitly programmed. ML algorithms analyse data, identify patterns, and make predictions or decisions, improving their performance over time and with more data. There are no doubt many engineering applications where ML could be used to help improve predictive modelling or optimisation, and to make these more efficient. However, the same principles that were important when we were beginning to embrace larger, more refined finite element models with the advent of faster computing remain true here:

- We must verify the input data that machine learning is utilising to ensure we don’t get ‘garbage in equals garbage out’.

- Results need to be validated. AI needs to be trained correctly, and we need experts involved at this stage to ensure that the outputs from AI are correct.

- Complexity, or the full power of technology, should be added incrementally, to provide progressive confidence in the outcomes.

Engineering is the application of science, and therefore it is critical for every engineer to understand the fundamental principles and how to apply them. The complex computer programs used for a lot of engineering modelling can become ‘black boxes’, and practitioners risk diluting or losing their understanding of the fundamental principles behind the models, and hence their ability to validate the results.

Automation brings a step change in efficiency and accuracy

At the ICOLD Congress in 2000, I co-authored a paper for the international symposium on concrete-faced rockfill dams (CFRD) entitled ‘Hydro Tasmania experience in concrete-faced rockfill dams – past, present and future’. There is no doubt that Hydro Tasmania has a strong history in CFRD, with Cethana Dam playing an important role in the development of the modern, high CFRD.

In 2000, however, the future in CFRD that we envisaged did not include unmanned construction equipment with automatic quality control feedback loops. At the 2025 CHINCOLD Workshop on Digital and Intelligent Technologies for Dam Construction, Operation and Maintenance, a presentation was given by Wang Jiajun from Tianjin University on intelligent unmanned roller systems to compact rockfill dams. Unmanned rolling compaction (URC) systems involve three core technology modules: (1) intelligent perception, (2) autonomous planning and decision making, and (3) intelligent control. These systems use automated driving technology to control the rolling process on earth and rockfill dams, improving productivity and quality. They can accurately control compaction parameters such as passes, speed, vibration and lift thickness. URC systems also enable continuous monitoring and real-time feedback for quality control, reducing human error and improving overall project performance. This automated technology was used on the 295m-high, 1.57km-long Lianghekou hydropower dam in China, with a total fill volume of 43 million m3.

The changing face of dam engineering

With AI and automation, the scope for embracing new technology in dam engineering is growing fast. It is clear that there are significant benefits that could be realised for dam design, construction, operation, dam safety and emergency response – and there’s a role for these advanced technologies at all of the stages of the life cycle of a dam. A degree of caution is appropriate and necessary, but caution should not be a reason to refuse to engage with the new technologies available to our industry.

However, with more sophisticated models – such as digital twins – being created of our dams, it is important to ensure we maintain the guiding engineering principles of verifying input data, validating models for correctness, and building complexity gradually. By doing this, we can provide the necessary assurance and confidence in our increasingly sophisticated and evolving tools.

ABOUT THE AUTHOR

Richard Herweynen is Entura’s Technical Director – Water. He has more than three decades of experience in dam and hydropower engineering, working throughout the Indo-Pacific region on both dam and hydropower projects. His experience covers all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and was the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

Decommissioning battery energy storage systems: It’s never too early to plan for retirement

All good things come to an end – even big battery energy storage systems (BESS). In Australia, the end of life for BESS may feel very distant, since we’re really only in the infancy of the booming BESS industry; however, the life expectancy of these big batteries is nothing like the design life of other renewable energy and storage technologies. With BESS currently only lasting for around 10 to 15 years of operation, developers and owners of BESS installations need to be thinking and planning now for what decommissioning will involve and what it will cost. In fact, planning for decommissioning is best done right from the start – long before the project is constructed.

Here, one of Entura’s BESS specialists, Dr Rahmat Khezri, answers some burning questions about the end stages of a BESS project.

- When does the life of a BESS project come to an end?

The need to decommission a BESS project could arise either from the conclusion of a contract or power purchase agreement – though this is unlikely – or from the expiration of the battery’s operational lifespan. This could be when the battery capacity has degraded to a point where it is no longer financially viable to operate in the market or when the battery’s internal chemistry has reached a point where it is unsafe to continue operating.

For nickel-manganese-cobalt (NMC) batteries, which held a significant share of batteries before lithium-iron-phosphate (LFP) batteries entered the market, this could be after 3,000 to 7,000 cycles at 80% depth of discharge (DoD) or around 10 to 15 years. For LFP batteries, which are gradually dominating the battery market for BESS, it’s around 4,000 to 10,000 cycles or 15 to 20 years. However, several factors can either reduce or extend the battery lifespan. Higher DoD shortens battery life, and frequent high-power cycling (e.g. for frequency control ancillary services, FCAS) can accelerate degradation. Avoiding prolonged high or low state-of-charge management (SoC) reduces degradation. Temperature is also an issue – so proper cooling and heating systems can support greater longevity.

- Is decommissioning the only option?

Full decommissioning of aging BESS assets is not always necessary at battery end of life, as some key components – such as inverters, transformers and balance of plant (PoP) – often retain residual service life. There may be opportunities for repowering or augmentation instead, which will require a much lower level of decommissioning activities. Repowering replaces old batteries with newer or upgraded technology to restore or enhance performance. Augmentation generally aims to increase capacity or power output by expanding the system with additional capacity, for example by adding extra battery racks to an existing setup.

- What does a full BESS decommissioning program involve?

A typical full BESS decommissioning program includes the following activities:

- developing the decommissioning plan including a risk assessment

- de-energising the BESS

- removing power conversion systems (inverter/transformer stations)

- removing integrated battery storage units (site dismantling and packaging may be required)

- shipping the packed battery storage units to recycling facilities

- removing electrical cables and conduits

- removing substation equipment

- shipping the power conversion systems and cables to recyclers of electronic waste

- transporting non-recyclable material removed from the site to disposal facilities

- restoring the site.

- How long could BESS decommissioning take?

Once a BESS project stops operating, the decommissioning process can begin (usually within 12 months) and can take around 6 to 9 months. Of course, this will depend on the scale of the BESS project, which will determine the amount of battery units and electrical infrastructure that will need to be removed from the site. If site restoration is required, this could extend the timeframe.

- What might BESS decommissioning cost?

Decommissioning costs are made up of labour, equipment, transport, materials, and recycling or disposal. These costs can be categorised across the stages of the project: removing the BESS facilities, restoring the site, packaging and transport, and the cost of recycling or disposal. If it is possible to achieve some value from salvage, this can be offset against the decommissioning costs. Currently the total recycling fee for high-powered batteries is around $10–15 per kg. Assuming approximately 6 kg for 1 kWh, the recycling cost would be $60–90 per kWh.

- Talking about recycling, what are the options for decommissioning BESS sustainably?

In Australia, we’re still in the early days of developing a lithium battery recycling industry – but we are seeing increasing recognition by owners, developers, regulators and the community of the need for the renewable energy industry to strengthen the circular economy and minimise landfill. Battery modules are recyclable – but salvage and reuse are likely to remain very dynamic and the future market for used lithium-ion modules remains uncertain. We recommend that every BESS developer/owner should aim to maximise recycling and develop as sustainable a waste management plan as possible. It is worth noting that recycling and reuse of inverters, transformers and BoP components are well established and available.

- What regulatory requirements are there in Australia for BESS decommissioning, and how do you envisage this changing?

In Australia, BESS projects must comply with relevant environmental regulations, which vary by state but generally align with the environmental protection guidelines set by each state’s Environment Protection Authority (EPA). At the federal level, the Product Stewardship Act 2011 promotes the responsible management of products at the end of their life cycle, including batteries. Decommissioned components from BESS projects, particularly lithium-ion batteries, are typically classified as prescribed industrial waste (PIW), requiring handling by licensed transporters and disposal at approved facilities.

At this stage the permitting process to build a BESS facility does not require a formal plan for decommissioning and disposal – but it is probably only a matter of time until we see more stringent requirements as part of the development application process. Despite a detailed plan not yet being required, it is definitely worthwhile doing, not least because the costs of decommissioning should be factored into the business case from the outset.

- What lessons have been learned from international examples of BESS decommissioning?

There haven’t been many examples of BESS decommissioning in our region yet, but the example of decommissioning the Tehachapi Energy Storage Project (TSP) project in South California in 2022 is an instructive real-life case study. This 8 MW / 32 MWh lithium-ion battery project was one of world’s first and largest BESS when it was commissioned in 2014. It had a footprint of 585 m2, with 604 battery racks and two 40-foot PCS containers. The decommissioning was completed in just over 4 months from the generation of the purchase order to the finish.

A key takeaway from this case study is the significant impact that logistical and site-specific constraints can have on project outcomes. Although the PCS containers were initially expected to be removed within a single day, unforeseen space limitations and permitting restrictions ruled out the use of cranes. As a result, the containers had to be dismantled and cut into sections on-site. This increased the schedule by 17% and the cost by 20%. The lesson here is clear: success lies in the details, particularly when it comes to transport and access logistics. Thorough, site-specific planning is essential to avoid unexpected delays and budget overruns.

- What should Australian BESS developers and owners be doing now about decommissioning?

Ideally, every player in the BESS industry in Australia should be thinking ahead, however far off BESS decommissioning, repowering or augmentation may seem right now. It is never too early to start investigating the potential options, costs, timing, emissions, challenges and solutions – and developing a plan that can continue to evolve as the industry matures. A robust decommissioning plan will also be a valuable input into the technical due diligence process for sale/purchase. Ultimately, solid, early planning is the key to minimising risk and maximising value – and achieving a more efficient, more cost-effective and more sustainable outcome for any BESS project.

At Entura, we’ve been involved with BESS since the very start of the sector in Australia, and we’re always learning from our experiences here and around the world. We’re actively developing our analyses of decommissioning costs, transport, timing and circularity opportunities so that we can support your BESS project holistically, from cradle to grave.

Regardless of the stage of your BESS project, Entura can help. Contact Patrick Pease to find out how.

About the author

Senior Renewable Energy and BESS Engineer Dr Rahmat Khezri has vast professional and technical experience with batteries. He has worked in the renewable energy and battery industry in project delivery from BESS design, business case and feasibility analysis to operation and construction. Rahmat has managed several utility-scale BESS projects during his time with Entura, overseeing successful delivery while ensuring compliance with industry standards, optimising performance, and managing key stakeholder relationships. Before joining Entura, he worked on projects supported by Sustainability Victoria for technical design and business case development of ‘second-life BESS’ using retired batteries of electric vehicles. In 2023 and 2024, he was recognised by Stanford University as being in the top 2% of scientists worldwide for two consecutive years.

What have we learnt about renewable microgrids and remote area power systems?

With the evolution of modern inverter and renewable energy technologies, it’s become possible to build microgrids with very high renewable penetration. These renewable solutions are revolutionising electricity sustainability, reliability and access in many far-flung locations – such as Pacific islands, remote locations around Australia, and on mining sites.

High renewable penetration allows operators of off-grid microgrids to extract maximum value from their installed solar, wind or other renewable generation while minimising the use of fossil fuels, such as diesel. It’s a win-win for the financial bottom line and emissions-reduction goals. If the microgrid connects with a broader power system, the benefits of reducing reliance on externally sourced energy are significant too.

Establishing a relatively simple microgrid with modest fuel-saving targets doesn’t have to be particularly complex. It’s within the reach of current technology and practice to be able to optimise microgrids to all but eliminate the use of fossil fuel (with the related advantages of eliminating fuel handling, shipping, etc.). However, careful thought must be given to the distinct nature of the microgrid: its customers, energy sources and storage options.

To make a microgrid successful, some technical challenges will need to be managed. Resolving these challenges in a cost-effective way becomes more difficult as the renewable energy balance approaches 100% – but they’re not insurmountable. Let’s explore.

Challenge 1: Ensuring quality of supply and an acceptable customer experience

The small size of microgrids and the fact that they are usually dedicated to a single ‘customer’ makes engineering a microgrid a sensitive task. While larger grids can operate with tight voltage and frequency tolerances and multiple levels of redundancy, microgrids often cannot. This inevitably means negotiating acceptable system standards for islanded operation that are within the tolerance of customers’ equipment and expectations. Microgrids powered by fossil fuels typically have more difficulty maintaining tight frequency and voltage tolerances than renewables-based microgrids.

Understanding customer and stakeholder expectations relating to reliability and robustness (energy availability and the ability to ride-through faults) is key to the establishment of a successful microgrid. Where the microgrid exists with no possibility of interconnection to another power network (i.e. in an ‘island’), there is more flexibility and less operational complexity. Discerning acceptable standards and practices is still not easy but it can be a more productive discussion than when the microgrid must comply with less tailored standards due to interconnection.

When the microgrid is interconnected, many of the technical requirements for the microgrid will be specified and/or mandated by the network service provider, electricity code requirements, and some operational requirements for electrical safety. If additional communication and inter-tripping with network equipment remote to the microgrid are required, these can add further complexity.

Challenge 2: Managing different modes of operation requiring different controls

In the previous section, we discussed how complicated it is to determine system standards. A great deal of care is also needed when contemplating which standards and controls are most appropriate to the microgrid’s specific characteristics. This is where cookie-cutter solutions could under-deliver and a more insightful approach is required.

A microgrid must manage the voltage, frequency and quality of supply while it is islanded as well as during periods of interconnection. Islands can remain satisfactory for longer if there are energy sources, storage and load controls within the island. Each of these elements comes at a cost and, depending on the frequency and duration of islanded operation, must have a value outside of the islanded scenario.

Our experience with microgrids is that semi-autonomous operation of each of the power sources using standard power system control approaches (solar, BESS and other power sources on voltage and frequency droop control) leads to the simplest and most secure response to transients (load or generation trips, network or network faults). Slower controls can be put in place to balance generation and rates of battery charge or discharge. If the battery power rating is large enough relative to the largest disturbance, it can manage most frequency disturbances within acceptable limits. If the battery energy capacity is large enough, it can always maintain a state of charge that allows fast reaction to variations in customer demand or VRE. Alternatively, auxiliary plant such as switched resistors, synchronous condensers and customer-level load control can be used to minimise battery power, storage and other energy inputs.

Operating microgrids in different modes requires careful engineering of the controls and equipment. The solutions and approaches described above have proven successful across multiple projects, but the key is to always be open to new solutions as new problems arise or new technologies emerge.

Challenge 3: Understanding the marginal value of resistors, synchronous condensers and/or demand management

Auxiliary equipment can help to extend the range and effectiveness of a microgrid to rely solely on renewable energy. The challenge is to understand the actual value of extension in this context. Where it has a direct bearing on fossil fuel use, the benefits are clear. Where it might cause an incremental improvement in the robustness of the islanded operation only, it’s important to consider whether any operational benefits or security benefits gained from the additional capital investment are valuable enough to justify the cost.

If the robustness of islanded operation is to be increased by managing customer demand, customer storage and/or embedded generation (e.g. rooftop solar), the value of the extended island longevity should be weighed against the perceived cost (direct or indirect) to the customer. This requires careful consideration of the diversity within the community, their openness to energy management, and the relationship between true costs and benefits.

Microgrids that maximise local use of renewable resources represent a relatively cost-effective option for lowering carbon emissions and/or reducing energy costs. Isolated communities, remote industrial sites, unreliably connected rural communities and others could benefit greatly from considering microgrid opportunities.

Entura has a long history of design, formation and operation of microgrids throughout Australia (such as King Island, Flinders Island, Rottnest Island, and at mining sites such as the Agnew gold mine) and in the Pacific region (including the Cook Islands, the Federated States of Micronesia, Tonga, and the Solomon Islands, to name just a few). We’ve seen the real benefits these systems bring to our clients and communities.

Contact us if you’re interested in unlocking the full potential of microgrids for your operation or community, or if you’re interested in ways to increase your use of renewable energy.

ABOUT THE AUTHORS

Donald Vaughan has over 20 years’ experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. He has worked for all areas of the electrical industry, including generators, equipment suppliers, customers, NSPs and market operators. Donald specialises in the performance of power systems. His experience in generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves.

Greg Koppens is Entura’s Principal Control Engineer Hybrid Renewable Systems and has led Entura’s secondary electrical engineering team. Greg’s experience spans power, oil and gas, and mining, including onsite roles. With over a decade of detailed design experience, Greg facilitates collaboration between engineering disciplines and other stakeholders to solve complex problems. He regularly shares his extensive expertise with the mining sector to advance their decarbonisation goals. Find out more about Greg in our podcast series here.

We built this synchronicity … but what now?

The alternating current (AC) transmission age started in 1891 through collaboration and perseverance. This transmission method has transformed the world, led us to the brink (or over the brink) of a climate disaster, and provides the backbone for a future founded on abundant renewable resources (in Australia, at least). Collaboration and perseverance are now required to ensure the continued utility of the grid.

Synchronous machines have always been the driving force in the grid. These elegantly simple electrical machines sit in powerhouses around the globe using their century-old technology (nearly 150 years, in fact) to convert mechanical energy into electrical energy to power the computer that I’m using to type this.

There’s a romance to these machines. It’s more than nostalgia. They spin, as the name suggests, in synchronism. If one of them falters, all the rest pick up the slack. The only connection they need is the power lines. This robustness is central to the way our electricity grids have operated for over 130 years – but the influence of synchronous machines is slowly being eroded.

The most obvious erosion of the influence of synchronous machines is their displacement by inverter-based renewable (IBR) technologies as solar, wind and battery energy storage (BESS) installations proliferate. A less obvious erosion of their influence is the diminishing understanding and appreciation of synchronous technology within the industry. This lack of understanding by engineers, planners and regulators of the fundamental building blocks of the electricity grid is starting to show.

This might sound like the curmudgeonly ranting of yesterday’s engineer as technology passes them by. Maybe it is … but, rather than dwell on negatives, let’s look at what synchronous machines bring to the power system.

- System strength

The fundamental difference between synchronous machines and IBR is thermal inertia. Typical synchronous machine design can sustain high levels of over-current for a relatively long time (seconds) compared to IBR units (milliseconds). This difference allows synchronous machines to provide a strong ‘natural’ response to voltage variations in the power system without threat of overload and damage. Transmission protection systems – and therefore grid security and safety – rely on this characteristic.

There are alternatives. Overload capacity can be built into inverters, but this is expensive. Dedicated inverter-based devices such as static synchronous compensators (STATCOMs) can be used to provide fault response.

- Inertia

Synchronous machines spin. Their spinning bits (rotors) have mass, so they have mechanical inertia. This mechanical inertia doesn’t require a control system to provide an inertial response. The inertial response from a synchronous machine is a known, predictable quantity, regardless of voltage.

IBRs can provide synthetic inertia and, when voltage is healthy, can out-perform synchronous units. When voltage is not nominal, the same current limitations that affect the IBRs’ ability to deliver fault level can also restrict the effectiveness of synthetic inertia delivery.

- Robustness

The previous two characteristics – system strength and inertia – show the support that synchronous machines can provide to the power system during disturbances. The synchronous machine can deliver these supports across a wide range of power system disturbances to voltage and frequency.

IBRs typically rely on fast controls to manage their response to system disturbances. Under some extreme conditions these controls may not be fast enough or well enough tuned to manage. While tuning is important to synchronous machine performance, often it has a second-order effect or adds robustness over and above the natural response.

Displaced but not superseded

Understanding the inherent dynamics of synchronous machines gives power system engineers a better appreciation of these machines’ contribution to power system stability. Regulators should be mindful of the reduced risk (and mostly advantages) to system security that synchronous machines offer relative to IBRs. This is despite the uncontrollable nature of synchronous machines. That is, physics dictates the stabilising effects from synchronous machines whereas control algorithms determine whether an IBR can stabilise or destabilise. Controller model accuracy is therefore more important for IBRs than it is for synchronous machines where transient stability or electro-mechanical transient time frames are considered.

Better understanding of synchronous machines should lead to more appropriate rules relating to dynamic response to system events. Overly specific requirements for fault ride-through, power recovery post-fault, and maintenance of real and reactive power during voltage disturbances may all lead to needless protracted negotiations over access standards. This slows down the progress of the energy transition, frustrates otherwise helpful development, and diverts resources towards trivial considerations rather than focusing on issues of greater importance.

Synchronous machines will play a role in the energy grid of the future. Our industry needs to maintain expertise and regulatory frameworks that allow this technology to continue providing the grid with vital stabilisation and robustness.

ABOUT THE AUTHOR

Donald has over 20 years’ experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. He has worked for all areas of the electrical industry, including generators, equipment suppliers, customers, NSPs and market operators. Donald specialises in the performance of power systems. His experience in generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves.

Understanding the business risks of small dams and weirs

Small dams may pose significant business risks that are often under-appreciated, even if these dams don’t pose a safety risk to the community. Managing risk is a key part of running any sustainable business and understanding how to mitigate risks requires that they are properly identified, analysed and evaluated.

The Guidelines on Risk Assessment prepared by ANCOLD (Australian National Committee on Large Dams) provides a detailed process for quantitative analysis of dam safety risks for large high-consequence dams, but adopting this process for small dams and weirs can be costly and may not be clearly justifiable.

For owners of small dams, ANCOLD has a number of other guidelines that can be useful for managing these dams, including Guidelines on the Consequence Categories for Dams and Guidelines on Dam Safety Management. Assigning a consequence category for a small dam can be a useful first step in understanding the risks – and will consider the impacts on community safety, on the environment, on the dam owner’s business, and on other social factors including impacts on health, community and business dislocation, loss of employment and damage to recreational facilities and heritage.

The consequence categories are graded from ‘Low’ to ‘Extreme’. These categories are used for a number of purposes including:

- regulatory requirements (depending on which state the dam is in)

- recommended surveillance and monitoring activities

- maintenance and operational requirements

- spillway flood capacity

- dam design standards.

The focus of ANCOLD’s consequence category guidelines is on wider community safety and impacts, but not on the dam owner’s business. This potentially leaves the dam owner exposed to significant unidentified business risks. Ideally, these should be managed consistently alongside all the other business risks.

A structured approach to assessing the business risks of small dams

ANCOLD’s Guidelines on Risk Assessment is a useful starting point for undertaking a business-focused risk assessment of small dam assets. As with all risk assessments, it is useful to follow a structured approach, including the following steps:

- identify the hazards

- brainstorm the failure modes

- estimate the likelihood of the failure

- estimate the consequences of failure

- evaluate the risks

- develop risk mitigation measures.

Such a risk assessment approach is ideally completed with a dam engineer working closely with the business owner to capture both the dam engineering and the business-specific knowledge.

1. Hazards

Dams need to be properly designed, constructed and maintained to continue to perform their function safely. It is essential to avoid becoming complacent. Floods are a significant hazard to all dams and cause around 50% of all failures in large, well-engineered embankment dams. Small dams are often constructed with no or minimal engineering input into the design or construction and as a result may have inherent defects that may not manifest themselves until years later.

Dams in general do not require a lot of maintenance; however, a lack of suitable maintenance can lead to failures. A key maintenance activity is management of vegetation so that trees do not establish themselves in the embankment. Tree roots can create leakage paths that could lead to piping or internal erosion, and ultimately to a failure.

2. Failure modes

A key part of the expertise of a dams engineer is understanding how different types of dams can fail, which is crucial for identifying potential failure modes. The ANCOLD guidelines on risk assessment recommend completing a site inspection of the dam to help identify the key ways in which the dam could fail. The inspection should be conducted with the dam owner to look for evidence of failure modes, such as:

- deformation or cracking, which may indicate issues with the stability of the dam

- wet areas or flows through the dam, which may indicate a piping failure

- spillways where the original crest is filled in or raised to increase storage in the reservoir, which can often be an area of concern

- erosion close to the dam from operation of the spillway, which could lead to undermining and instability of the dam wall.

Typically, failure modes are identified in a workshop setting and then prioritised by criticality. The full list of failure modes is then reduced to a shortlist of those that are most critical.

3. Likelihood of failure

ANCOLD’s Guidelines on Risk Assessment provides an approach that can be used for detailed quantitative risk assessments; however, such approaches require significant effort to apply and can be costly. For small dams, it can be more appropriate to use a risk matrix approach, similar to that outlined in the Australian standard AS ISO 31000 Risk Management.

Typically, most businesses have a standard risk assessment procedure that can be adapted to give a qualitative or semi-qualitative assessment of likelihood. An experienced dams engineer will be able to assign a likelihood for each of the credible failure modes based on engineering judgement and some simple calculations (e.g. using regional flood estimates and estimates of the spillway discharge capacity). Failure modes for dams that are well designed and constructed will often have a likelihood rating of ‘Rare’ or ‘Unlikely’. The likelihood may be higher for dams in poor condition or with identified deficiencies.

4. Consequences of failure

A business risk assessment focuses on the consequences to the business, rather than the wider community, if the small dam were to fail. This will be unique to each business and will need input from the owner. It can be assessed by working through a series of questions about the need for the dam and its purpose – for example:

- What is the water in the dam used for? Can the business function without the water or the storage space in the dam?

- Are there alternative sources for the water that can be quickly accessed, and will these be sufficient for normal operations or would it be necessary to reduce operation?

- Is there business infrastructure downstream of the dam, and could a failure of the dam cause failure of these assets (e.g. pumping stations, water treatment plants or other dams) that would impact business operations? Can the business operate without these assets?

- How will customers be affected and what are the reputational consequences of not being able to supply or only partially supply?

- What are the financial implications for the business, and is there insurance that would cover the cost of the event, including consequential losses?

- How long would it take to replace the dam (including refilling) and the other assets?

5. Evaluation of risks

Using the business’s standard risk assessment tool enables comparison of the small dam risks against other business risks on a consistent basis (e.g. safety risks to employees). The level of risk will indicate the urgency of addressing the risk. This process allows a clearly articulated justification to be presented to the business for putting in place any required mitigations. It also enables the owner to focus on the key business risks rather than become distracted by issues with lower risk.

6. Risk mitigation

Mitigations can address either likelihood or consequences and will need to be tailored to the specific risks and the business needs. Addressing the risks by reducing the likelihood will typically involve physical works to the dam – for example, increasing the size of the spillway to reduce the likelihood of an overtopping failure, or managing vegetation to reduce the likelihood of a piping failure.

Where reducing the likelihood is not practical or not sufficient, addressing the consequences may be an effective approach. Addressing the consequences may involve options such as securing alternative water supplies, contingency planning to reduce impacts on customers, or insurance to cover the financial losses.

Bringing it all together for better business insights

Entura has undertaken qualitative and semi-qualitative small dam risk assessments for a number of clients in a cooperative environment to bring together our dams engineering expertise with the owner’s knowledge of their business. This is a cost-effective approach that has provided clarity on the specific business risks related to small dams, allowing targeted risk mitigation measures to be put in place. The process has provided important insights enabling owners to justify business decisions and reduce their overall business risk exposure.

If you have small dams and would like to talk with us about assessing your business risks, contact Phillip Ellerton or Richard Herweynen.

About the author

Paul Southcott is Entura’s Senior Principal – Dams and Headworks. Paul has an outstanding depth of knowledge and skill developed over more than 3 decades in the fields of civil and dam engineering. He is a highly respected dams specialist and was recognised as Tasmania’s Professional Engineer of the Year in Engineers Australia’s 2021 Engineering Excellence Awards. Paul has contributed to many major dam and hydropower projects in Australia and abroad, including Tasmania’s ‘Battery of the Nation’, the Tarraleah hydropower scheme, Snowy Hydro, and numerous programs of work for water utilities including SeqWater, Sun Water and SAWater. His expertise is a crucial part of Entura’s ongoing support for upgrade and safety works for Hydro Tasmania’s and TasWater’s extensive dams portfolios. Paul is passionate about furthering the engineering profession through knowledge sharing, and has supported many young and emerging engineers through training and mentoring.

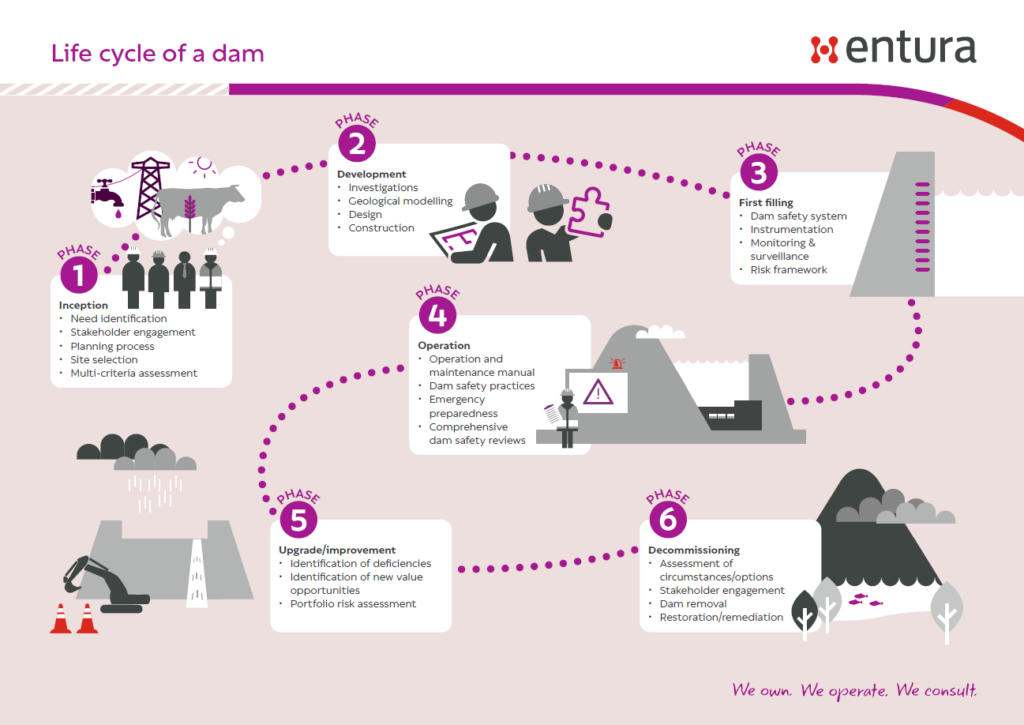

The life cycle of a dam – Bringing it all together